Research progress of nano yolk-shell structured silicon/carbon anode materials for lithium-ion batteries

-

摘要: 由于硅的大体积变化和电导率差等问题,这种容量高达4200 mA·h·g−1的负极材料难以实现商业化。蛋黄核壳结构的硅碳负极是目前锂离子电池硅碳负极材料研究的热点,该结构可以很好地缓解硅负极在充放电过程中因体积膨胀而引发的一系列问题,从而获得优越的储锂性能。本文对蛋黄核壳结构硅碳负极的碳源、结构类型和制备工艺等进行了分类和总结,并对一些重要的结构参数进行了阐述,展望了未来蛋黄核壳结构硅碳负极的发展方向。Abstract: Due to the large volume variation of silicon and the poor conductivity, it is difficult to commercialize this anode material with a capacity of up to 4200 mA·h·g−1. The silicon/carbon anode of the yolk-shell structure is currently a hot spot in the research of silicon/carbon anode materials for lithium-ion batteries, which can well alleviate a series of problems caused by volume expansion of silicon anode during the charging and discharging process, so as to obtain superior lithium storage performance. In this paper, the carbon source, structure type and preparation process of the silicon/carbon anode of the yolk-shell structure are classified and summarized, and some important structural parameters are elaborated, and the development direction of the silicon/carbon anode of the yolk-shell structure is prospected in the future.

-

Key words:

- lithium-ion batteries /

- composites /

- yolk-shell structure /

- Si/C anode /

- solid electrolyte interface

-

图 16 基于Si纳米粒子表面改性和自组装得到的2D-Si@石墨碳(gC)的合成流程图[44]

OA—Oleic acid; PE—Polyethylene; 2D-Si@gC—Two-dimensional (2D) assemblies of interconnected Si@graphitic carbon yolk-shell nanoparticles

Figure 16. Flow chart of 2D-Si@graphitic carbon (gC) synthesis based on surface modification and self-assembly of Si nanoparticles[44]

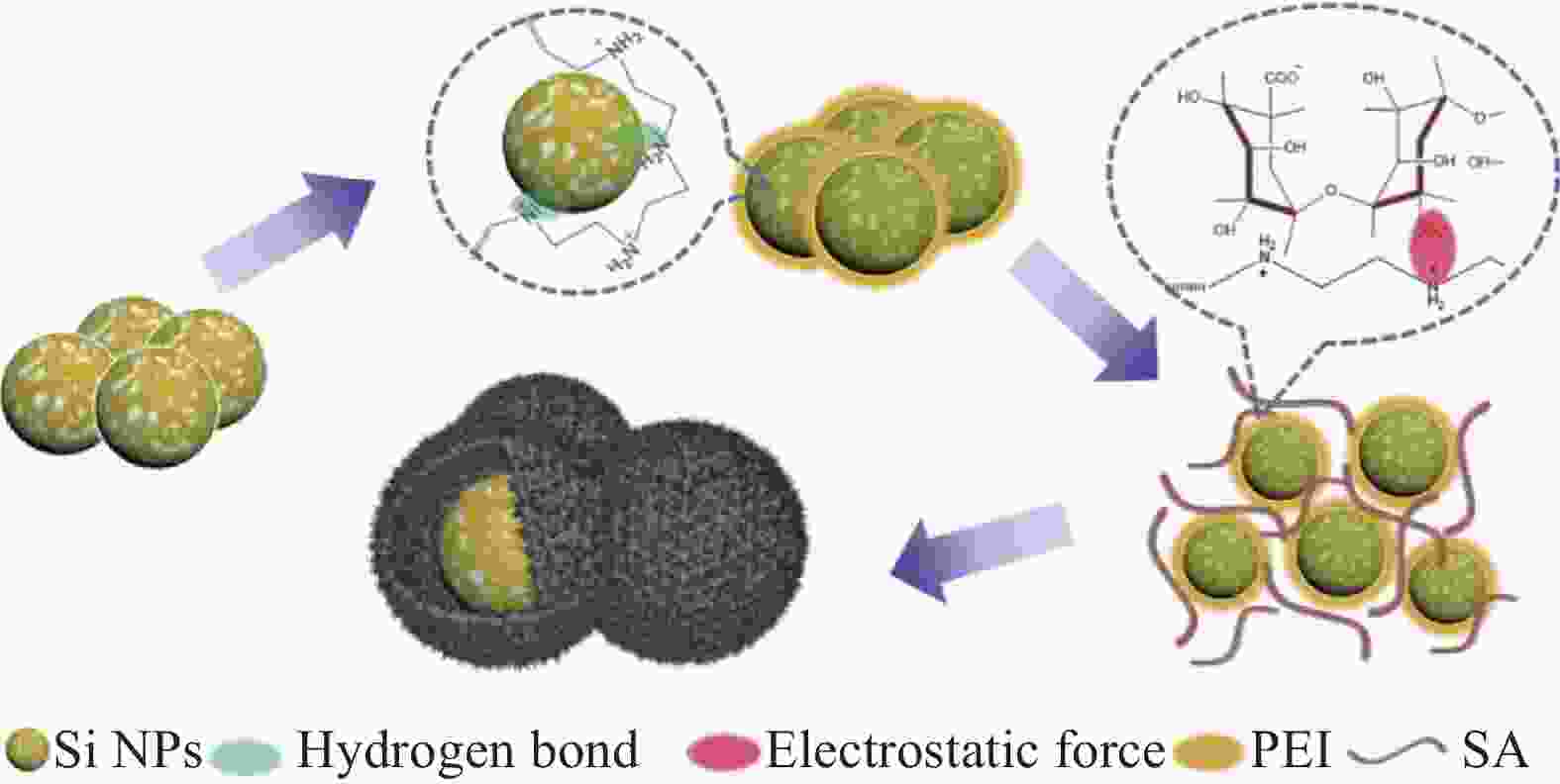

图 19 覆盆子状蛋黄壳结构硅碳微纳米球复合材料结构示意图[47]

NP—Nanocomposite; NMP—Nitromethyl-pyrrolidone; HTT—Heat treatment; P-SD—Collected Si@SiO2 powder obtained by spray drying; R-YS—Raspberry-like yolk-shell structured

Figure 19. Schematic diagram of raspberry-shaped yolk-shell structure silicon-carbon micro-nanosphere composite[47]

图 22

${\rm{Si@C}} \subseteq {\rm{Ni}} $ 蛋黄核壳结构纳米材料制备流程图 [50]DA—Dopamine; NNH—Nickel nitrate hydroxide; ${\rm{Si@C}} \subseteq {\rm{NiY}} $−S—Si@C nanoparticles firmly trappe in a durable and ultrathin Ni matrix

Figure 22. Flow chart of preparation of nanomaterials with yolk-shell structure of

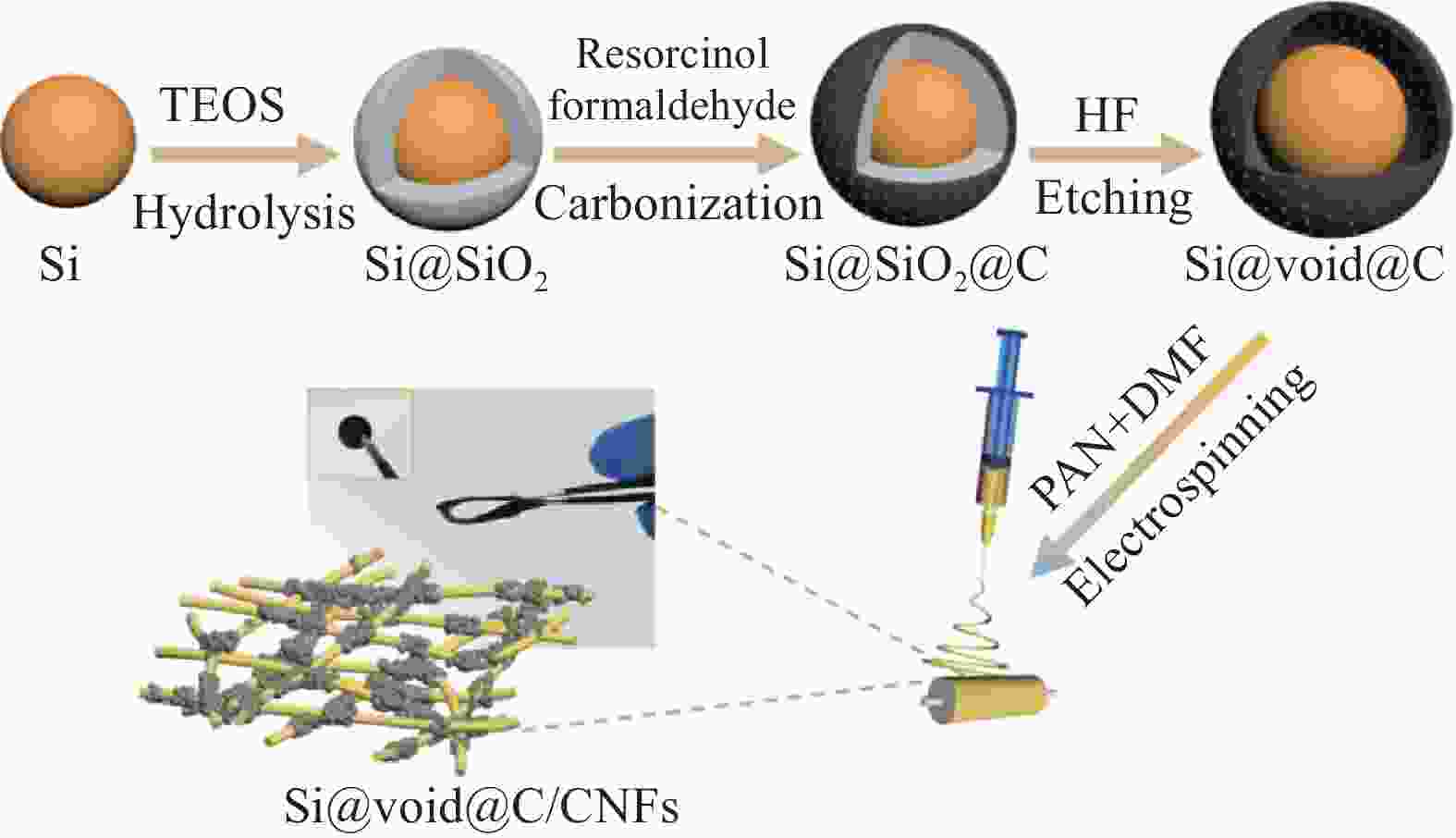

${\rm{Si@C}} \subseteq {\rm{Ni}} $ yolk-shell structure[50]图 41 GF为前驱体制备的自支撑电极制造工艺图[85]

Figure 41. Manufacturing process diagram of free-standing electrode prepared by GF for precursor[85]

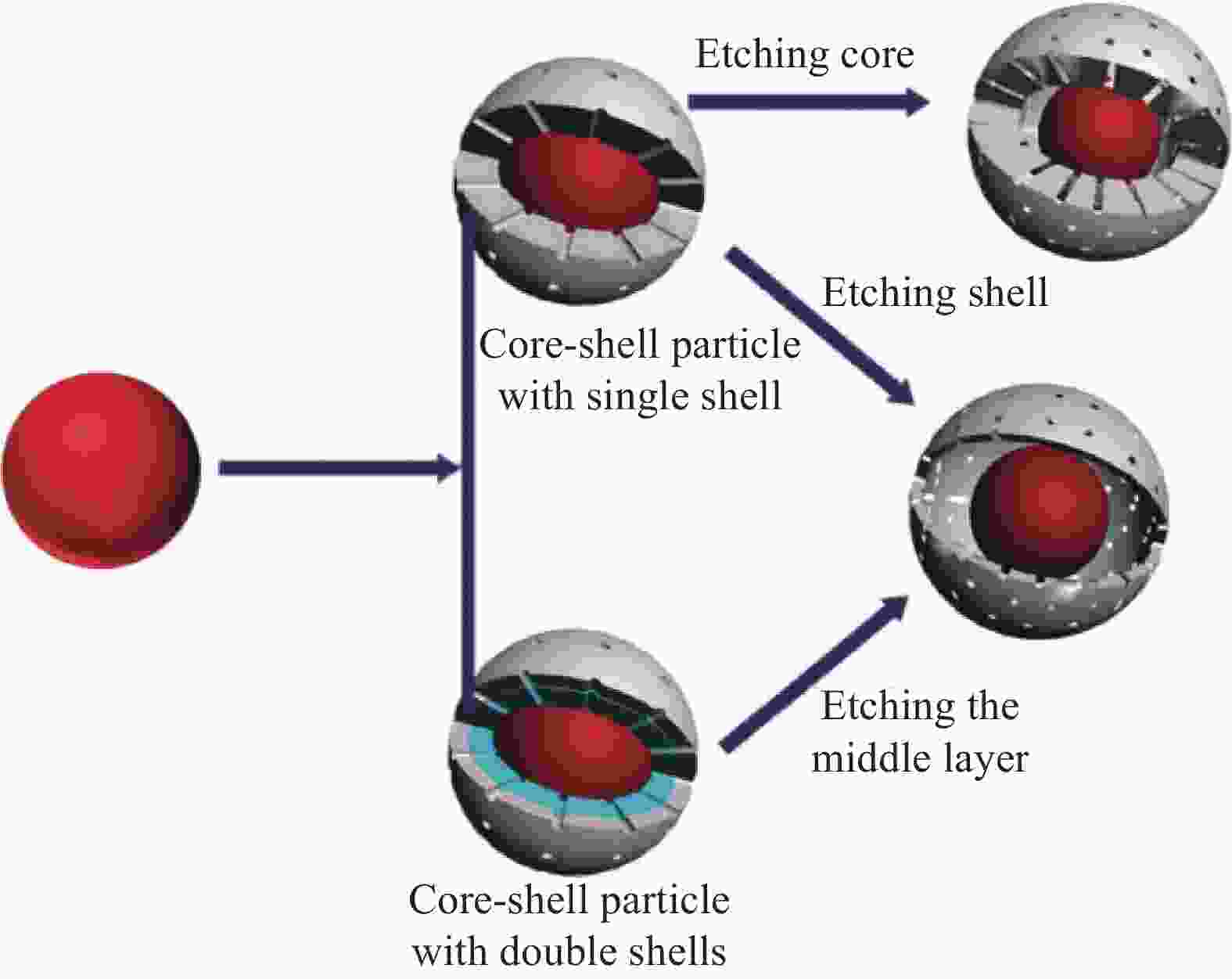

GF—Waste glass microfiber filters; MgR—Magnesiothermic reduction; GF-dMGR—GFs after deep magnesiothermic reduction; GF-oxi—GFs after oxidation; GF-C30/Si—GF-derived Si/carbon composite electrode (carbon coating time in 30 minutes)

图 42 (a) 在不同空隙尺寸停止锂化和碳壳断裂的情况;(b) 碳壳层内部体积/原始硅的体积(Vc/Vp)= 1.5;(c) Vc/Vp = 3;(d) Vc/Vp = 3.6[86]

SOC—State of charge; Rou/Rin—A carbon shell with initial inner radius Rin and outer radius Rou

Figure 42. (a) Cases where lithiation and carbon shell fracture are stopped at different void sizes; (b) Internal volume of the carbon shell/volume of the original silicon (Vc/Vp)= 1.5; (c) Vc/Vp=3; (d) Vc/Vp=3.6[86]

-

[1] ZHANG T, FU L, GAO J, et al. Core-shell Si/C nanocompo-site as anode material for lithium ion batteries[J]. Pure and Applied Chemistry,2006,78(10):1889-1896. doi: 10.1351/pac200678101889 [2] FENG Z Y, PENG W J, WANG Z X, et al. Review of silicon-based alloys for lithium-ion battery anodes[J]. International Journal of Minerals Metallurgy and Materials,2021,28(10):1549-1564. doi: 10.1007/s12613-021-2335-x [3] HSIEH C C, LIU W R. Carbon-coated Si particles binding with few-layered graphene via a liquid exfoliation process as potential anode materials for lithium-ion batteries[J]. Surface & Coatings Technology,2020,387:7-14. [4] BENZAIT Z, YUCA N. Synergistic effect of carbon nanomaterials on a cost-effective coral-like Si/rGO composite for lithium-ion battery application[J]. Electrochimica Acta,2020,339:12-24. [5] RAHMAN M A, SONG G S, BHATT A I, et al. Nanostructured silicon anodes for high-performance lithium-ion batteries[J]. Advanced Functional Materials,2016,26(5):647-678. doi: 10.1002/adfm.201502959 [6] ZHAO H, WEI Y, WANG C, et al. Mussel-inspired conductive polymer binder for Si-alloy anode in lithium-ion batteries[J]. ACS Applied Materials & Interfaces,2018,10(6):5440-5446. [7] GU M, LI Y, LI X L, et al. In situ TEM study of lithiation behavior of silicon nanoparticles attached to and embedded in a carbon matrix[J]. ACS Nano,2012,6(9):8439-8447. doi: 10.1021/nn303312m [8] ZUO X X, ZHU J, MULLER-BUSCHBAUM P, et al. Silicon based lithium-ion battery anodes: A chronicle perspective review[J]. Nano Energy,2017,31:113-143. doi: 10.1016/j.nanoen.2016.11.013 [9] LIN L S, SONG J B, YANG H H, et al. Yolk-shell nanostructures: Design, synthesis, and biomedical applications[J]. Advanced Materials,2018,30(6):30−60. [10] MA X, GAO Y, CHEN M, et al. Synthesis of robust silicon nanoparticles@void@graphitic carbon spheres for high-performance lithium-ion-battery anodes[J]. Chemelectrochem,2017,4(6):1463-1469. doi: 10.1002/celc.201700173 [11] LIU N, WU H, MCDOWELL M T, et al. A yolk-shell design for stabilized and scalable Li-ion battery alloy anodes[J]. Nano Letters,2012,12(6):3315-3321. doi: 10.1021/nl3014814 [12] LIU J, QIAO S Z, CHEN J S, et al. Yolk/shell nanoparticles: New platforms for nanoreactors, drug delivery and lithium-ion batteries[J]. Chemical Communications,2011,47(47):12578-12591. doi: 10.1039/c1cc13658e [13] YANG J, WANG Y X, CHOU S L, et al. Yolk-shell silicon-mesoporous carbon anode with compact solid electrolyte interphase film for superior lithium-ion batteries[J]. Nano Energy,2015,18:133-142. doi: 10.1016/j.nanoen.2015.09.016 [14] GONG X H, ZHENG Y B, ZHENG J, et al. Yolk-shell silicon/carbon composites prepared from aluminum-silicon alloy as anode materials for lithium-ion batteries[J]. Ionics,2021,27(5):1939-1948. doi: 10.1007/s11581-021-03967-5 [15] LIN M H, HY S, CHEN C Y, et al. Resilient yolk-shell silicon-reduced graphene oxide/amorphous carbon anode material from a synergistic dual-coating process for lithium-ion batteries[J]. Chemelectrochem,2016,3(9):1446-1454. doi: 10.1002/celc.201600254 [16] SHAO J, YANG Y, ZHANG X Y, et al. 3D yolk-shell structured Si/void/rGO free-standing electrode for lithium-ion battery[J]. Materials,2021,14(11):13-26. [17] ZHANG L, HUANG Q W, LIAO X Z, et al. Scalable and controllable fabrication of CNTs improved yolk-shelled Si anodes with advanced in operando mechanical quantification[J]. Energy & Environmental Science,2021,14(6):3502-3509. [18] GAO Y, QIU X T, WANG X L, et al. Facile preparation of nitrogen-doped yolk-shell Si@void@C/CNTs microspheres as high-performance anode in lithium-ion batteries[J]. Materials Today Communications,2020,25:9-15. [19] HAN N, LI J J, WANG X C, et al. Flexible carbon nanotubes confined yolk-shelled silicon-based anode with superior conductivity for lithium storage[J]. Nanomaterials,2021,11(3):11-22. [20] XIE X, XIAO P, PANG L, et al. Facile synthesis of yolk-shell Si@void@C nanoparticles with 3D conducting networks as free-standing anodes in lithium-ion batteries[J]. Journal of Alloys and Compounds,2023,931:167473. doi: 10.1016/j.jallcom.2022.167473 [21] HE Y L, HAN F, WANG F, et al. Optimal microstructural design of pitch-derived soft carbon shell in yolk-shell silicon/carbon composite for superior lithium storage[J]. Electrochimica Acta,2021,373:11−22. [22] WU P, GUO C, HAN J, et al. Fabrication of double core-shell Si-based anode materials with nanostructure for lithium-ion battery[J]. RSC Advances,2018,8(17):9094-9102. doi: 10.1039/C7RA13606D [23] LIN N, XU T J, LI T Q, et al. Controllable self-assembly of micro-nanostructured Si-embedded graphite/graphene composite anode for high-performance Li-ion batteries[J]. ACS Applied Materials & Interfaces,2017,9(45):39318-39325. [24] SEHRAWAT P, SHABIR A, ABI D, et al. Recent trends in silicon/graphene nanocomposite anodes for lithium-ion batteries[J]. Journal of Power Sources,2021,501:33 − 66. [25] PENG J, LI W W, WU Z Y, et al. Si/C composite embedded nano-Si in 3D porous carbon matrix and enwound by conductive CNTs as anode of lithium-ion batteries[J]. Sustainable Materials and Technologies,2022,32:e00410. doi: 10.1016/j.susmat.2022.e00410 [26] HU L, LUO B, WU C H, et al. Yolk-shell Si/C composites with multiple Si nanoparticles encapsulated into double carbon shells as lithium-ion battery anodes[J]. Journal of Energy Chemistry,2019,32:124-130. doi: 10.1016/j.jechem.2018.07.008 [27] SU L, XIE J, XU Y, et al. Preparation and lithium storage performance of yolk-shell Si@void@C nanocomposites[J]. Physical Chemistry Chemical Physics,2015,17(27):17562-17565. doi: 10.1039/C5CP01954K [28] HUANG X, SUI X, YANG H, et al. Hf-free synthesis of Si/C yolk/shell anodes for lithium-ion batteries[J]. Journal of Materials Chemistry A,2018,6(6):2593-2599. doi: 10.1039/C7TA08283E [29] SHAO D, SMOLIANOVA I, TANG D, et al. Novel core-shell structured Si/S-doped-carbon composite with buffering voids as high performance anode for Li-ion batteries[J]. RSC Advances,2017,7(5):2407-2414. doi: 10.1039/C6RA26247C [30] ZHANG Y Y, HU G W, YU Q, et al. Polydopamine sacrificial layer mediated SiOx/C@C yolk@shell structure for durable lithium storage[J]. Materials Chemistry Frontiers,2020,4(6):1656-1663. doi: 10.1039/D0QM00120A [31] WANG H Q, QUE X Q, LIU Y N, et al. Facile synthesis of yolk-shell structured SiOx/C@void@C nanospheres as anode for lithium-ion batteries[J]. Journal of Alloys and Compounds,2021,874:7-14. [32] MIN K, KIM K, AN H, et al. Yolk-shell-structured SiO2@N, P co-doped carbon spheres as highly stable anode materials for lithium ion batteries[J]. Journal of Power Sources,2022,543:12-22. [33] YANG L Y, LI H Z, LIU J, et al. Dual yolk-shell structure of carbon and silica-coated silicon for high-performance lithium-ion batteries[J]. Scientific Reports, 2015: 5-14. [34] LIU Z H, ZHAO Y L, HE R H, et al. Yolk@shell SiOx/C microspheres with semi-graphitic carbon coating on the exterior and interior surfaces for durable lithium storage[J]. Energy Storage Materials,2019,19:299-305. doi: 10.1016/j.ensm.2018.10.011 [35] GUO S C, HU X, HOU Y, et al. Tunable synthesis of yolk-shell porous silicon@carbon for optimizing Si/C-based anode of lithium-ion batteries[J]. ACS Applied Materials & Interfaces,2017,9(48):42084-42092. [36] PARK S W, SHIM H W, KIM J C, et al. Uniform Si nanoparticle-embedded nitrogen-doped carbon nanofiber electrodes for lithium ion batteries[J]. Journal of Alloys and Compounds,2017,728:490-496. doi: 10.1016/j.jallcom.2017.09.023 [37] LEI C, HAN F, LI D, et al. Dopamine as the coating agent and carbon precursor for the fabrication of N-doped carbon coated Fe3O4 composites as superior lithium ion anodes[J]. Nanoscale,2013,5(3):1168-1175. doi: 10.1039/c2nr33043a [38] WEI Y B, HUANG Y D, ZENG Y F, et al. Designed formation of yolk-shell-like N-doped carbon-coated Si nanoparticles by a facile method for lithium-ion battery anodes[J]. ACS Applied Energy Materials,2022,5(2):1471-1477. doi: 10.1021/acsaem.1c02785 [39] SHIN W H, JEONG H M, KIM B G, et al. Nitrogen-doped multiwall carbon nanotubes for lithium storage with extremely high capacity[J]. Nano Letters,2012,12(5):2283-2288. doi: 10.1021/nl3000908 [40] GAO C H, ZHAO H L, LV P P, et al. Superior cycling performance of SiOx/C composite with arrayed mesoporous architecture as anode material for lithium-ion batteries[J]. Journal of the Electrochemical Society,2014,161(14):A2216-A2221. doi: 10.1149/2.0911414jes [41] JUNG H J, KIM Y J, LEE D H, et al. Pore structure characterization of poly(vinylidene chloride)-derived nanoporous carbons[J]. Carbon Letters,2012,13(4):236-242. doi: 10.5714/CL.2012.13.4.236 [42] MI H W, YANG X D, LI Y L, et al. A self-sacrifice template strategy to fabricate yolk-shell structured silicon@void@carbon composites for high-performance lithium-ion batteries[J]. Chemical Engineering Journal,2018,351:103-109. doi: 10.1016/j.cej.2018.06.065 [43] XIE J, TONG L, SU L, et al. Core-shell yolk-shell Si@C@void@C nanohybrids as advanced lithium ion battery anodes with good electronic conductivity and corrosion resistance[J]. Journal of Power Sources,2017,342:529-536. doi: 10.1016/j.jpowsour.2016.12.094 [44] CHEN X, CHEN C, ZHANG Y, et al. Exploiting oleic acid to prepare two-dimensional assembly of Si@graphitic carbon yolk-shell nanoparticles for lithium-ion battery anodes[J]. Nano Research,2019,12(3):631-636. doi: 10.1007/s12274-018-2270-y [45] LU Y, CHANG P, WANG L B, et al. Yolk-shell Si/SiOx@void@C composites as anode materials for lithium-ion batteries[J]. Functional Materials Letters,2019,12(1):6-13. [46] CHEN M, ZHOU Q N, ZAI J T, et al. High power and stable P-doped yolk-shell structured Si@C anode simultaneously enhancing conductivity and Li+ diffusion kinetics[J]. Nano Research,2021,14(4):1004-1011. doi: 10.1007/s12274-020-3142-9 [47] MA C L, WANG Z R, ZHAO Y, et al. A novel raspberry-like yolk-shell structured Si/C micro/nano-spheres as high-performance anode materials for lithium-ion batteries[J]. Journal of Alloys and Compounds,2020,844:13-52. [48] LIU N T, LIU J, JIA D Z, et al. Multi-core yolk-shell like mesoporous double carbon-coated silicon nanoparticles as anode materials for lithium-ion batteries[J]. Energy Storage Materials,2019,18:165-173. doi: 10.1016/j.ensm.2018.09.019 [49] ZHANG L, RAJAGOPALAN R, GUO H, et al. A green and facile way to prepare granadilla-like silicon-based anode materials for Li-ion batteries[J]. Advanced Functional Materials,2016,26(3):440-446. doi: 10.1002/adfm.201503777 [50] JIANG J, ZHANG H, ZHU J H, et al. Putting nanoarmors on yolk-shell Si@C nanoparticles: A reliable engineering way to build better Si-based anodes for Li-ion batteries[J]. ACS Applied Materials & Interfaces,2018,10(28):24157-24163. [51] ZHOU Z W, PAN L, LIU Y T, et al. From sand to fast and stable silicon anode: Synthesis of hollow Si@void@C yolk-shell microspheres by aluminothermic reduction for lithium storage[J]. Chinese Chemical Letters,2019,30(3):610-617. doi: 10.1016/j.cclet.2018.08.018 [52] ZHANG L, WANG C R, DOU Y H, et al. A yolk-shell structured silicon anode with superior conductivity and high tap density for full lithium-ion batteries[J]. Angewandte Chemie-International Edition,2019,58(26):8824-8828. doi: 10.1002/anie.201903709 [53] JIAO Z, GAO Y, LIU S, et al. Controlled scalable synthesis of yolk-shell structured large-size industrial silicon with interconnected carbon network for lithium storage[J]. Electrochimica Acta,2018,283:1702-1711. doi: 10.1016/j.electacta.2018.07.143 [54] CHEN W Y, KUANG S J, WEI H S, et al. Dual carbon and void space confined SiOx/C@void@Si/C yolk-shell nanospheres with high-rate performances and outstanding cyclability for lithium-ion batteries anodes[J]. Journal of Colloid and Interface Science,2022,610:583-591. doi: 10.1016/j.jcis.2021.11.099 [55] PAN L, WANG H, GAO D, et al. Facile synthesis of yolk-shell structured Si-C nanocomposites as anodes for lithium-ion batteries[J]. Chemical Communications,2014,50(44):5878-5880. doi: 10.1039/C4CC01728E [56] XIAO Z L, XIA N, SONG L B, et al. Synthesis of yolk-shell-structured Si@C nanocomposite anode material for lithium-ion battery[J]. Journal of Electronic Materials,2018,47(10):6311-6318. doi: 10.1007/s11664-018-6513-1 [57] CHEN Y F, ZHANG J Q, CHEN X Q, et al. Facile preparation of hollow Si/SiC/C yolk-shell anode by one-step magnesiothermic reduction[J]. Ceramics International,2019,45(14):17040-17047. doi: 10.1016/j.ceramint.2019.05.255 [58] RU Y, EVANS D G, ZHU H, et al. Facile fabrication of yolk-shell structured porous Si-C microspheres as effective anode materials for Li-ion batteries[J]. RSC Advances,2014,4(1):71-75. doi: 10.1039/C3RA44752A [59] LI X Q, XING Y F, XU J, et al. Uniform yolk-shell structured Si-C nanoparticles as a high performance anode material for the Li-ion battery[J]. Chemical Communications,2020,56(3):364-367. doi: 10.1039/C9CC07997A [60] SHAO T, LIU J, GAN L H, et al. Yolk-shell Si@void@C composite with chito-oligosaccharide as a C-N precursor for high capacity anode in lithium-ion batteries[J]. Journal of Physics and Chemistry of Solids,2021,152:9-18. [61] ZHANG W, LI J J, GUAN P, et al. One-pot sol-gel synthesis of Si/C yolk-shell anodes for high performance lithium-ion batteries[J]. Journal of Alloys and Compounds,2020,835:7-14. [62] ZHANG Y Z, QIN X, LIU Y, et al. Synthetic strategy of Si@void@C nanoparticles for high-performance lithium-ion battery anodes[J]. ACS Applied Energy Materials, 2022, 5(11): 14476-14486. [63] MA Y H, TANG H Q, ZHANG Y, et al. Facile synthesis of Si-C nanocomposites with yolk-shell structure as an anode for lithium-ion batteries[J]. Journal of Alloys and Compounds,2017,704:599-606. doi: 10.1016/j.jallcom.2017.02.083 [64] PARK J B, HAM J S, SHIN M S, et al. Synthesis and electrochemical characterization of anode material with titanium-silicon alloy solid core/nanoporous silicon shell structures for lithium rechargeable batteries[J]. Journal of Power Sources,2015,299:537-543. doi: 10.1016/j.jpowsour.2015.09.019 [65] SU J, ZHANG C, CHEN X, et al. Carbon-shell-constrained silicon cluster derived from Al-Si alloy as long-cycling life lithium ion batteries anode[J]. Journal of Power Sources,2018,381:66-71. doi: 10.1016/j.jpowsour.2018.02.010 [66] LEE J S, SHIN M S, LEE S M. Electrochemical properties of polydopamine coated Ti-Si alloy anodes for Li-ion batteries[J]. Electrochimica Acta,2016,222:1200-1209. doi: 10.1016/j.electacta.2016.11.094 [67] WU Z Q, YANG F, LI X M, et al. Solid and hollow nanoparticles templated using non-ionic surfactant-based reverse micelles and vesicles[J]. Colloids and Surfaces A-Physicochemical and Engineering Aspects,2022,634:7 −14. [68] LI Y Y, KRUK M. Single-micelle-templated synthesis of hollow silica nanospheres with tunable pore structures[J]. RSC Advances,2015,5(85):69870-69877. doi: 10.1039/C5RA13492G [69] KWON H J, HWANG J Y, SHIN H J, et al. Nano/microstructured silicon-carbon hybrid composite particles fabricated with corn starch biowaste as anode materials for Li-ion batteries[J]. Nano Letters,2020,20(1):625-635. doi: 10.1021/acs.nanolett.9b04395 [70] LI H H, WANG J W, WU X L, et al. A novel approach to prepare Si/C nanocomposites with yolk-shell structures for lithium ion batteries[J]. RSC Advances,2014,4(68):36218-36225. doi: 10.1039/C4RA07043G [71] MA J Y, TAN H, LIU H, et al. Facile and scalable synthesis of Si@void@C embedded in interconnected 3D porous carbon architecture for high performance lithium-ion batteries[J]. Particle & Particle Systems Characterization, 2021, 38(3): 288-301. [72] SU H P, BARRAGAN A A, GENG L X, et al. Colloidal synthesis of silicon-carbon composite material for lithium-ion batteries[J]. Angewandte Chemie-International Edition,2017,56(36):10780-10785. doi: 10.1002/anie.201705200 [73] ZHANG L, BLOM D A, WANG H. Au-Cu2O core-shell nanoparticles: A hybrid metal-semiconductor heteronanostructure with geometrically tunable optical properties[J]. Chemistry of Materials,2011,23(20):4587-4598. doi: 10.1021/cm202078t [74] ZHOU Z W, LIU Y T, XIE X M, et al. Aluminothermic reduction enabled synthesis of silicon hollow microspheres from commercialized silica nanoparticles for superior lithium storage[J]. Chemical Communications,2016,52(54):8401-8404. doi: 10.1039/C6CC03766F [75] HUANG H B, CHEN R P, YANG S Y, et al. High-performance Si flexible anode with rGO substrate and Ca2+ crosslinked sodium alginate binder for lithium ion battery[J]. Synthetic Metals,2019,247:212-218. doi: 10.1016/j.synthmet.2018.12.011 [76] MUKHERJEE R, THOMAS A V, KRISHNAMURTHY A, et al. Photothermally reduced graphene as high-power anodes for lithium-ion batteries[J]. ACS Nano,2012,6(9):7867-7878. doi: 10.1021/nn303145j [77] JIANG H, ZHOU X, LIU G G, et al. Free-standing Si/graphene paper using Si nanoparticles synthesized by acid-etching Al-Si alloy powder for high-stability Li-ion battery anodes[J]. Electrochimica Acta,2016,188:777-784. doi: 10.1016/j.electacta.2015.12.023 [78] DENG N, LI Y, LI Q, et al. Multi-functional yolk-shell structured materials and their applications for high-performance lithium ion battery and lithium sulfur battery[J]. Energy Storage Materials,2022,53:684-691. doi: 10.1016/j.ensm.2022.08.003 [79] LUO Z P, XIAO Q Z, LEI G T, et al. Si nanoparticles/graphene composite membrane for high performance silicon anode in lithium ion batteries[J]. Carbon,2016,98:373-380. doi: 10.1016/j.carbon.2015.11.031 [80] ZHANG H X, JING S L, HU Y J, et al. A flexible free standing Si/rGO hybrid film anode for stable Li-ion batteries[J]. Journal of Power Sources,2016,307:214-219. doi: 10.1016/j.jpowsour.2015.12.107 [81] ZHU Y A, HU J M, QIN C X, et al. Synthesis of free-standing N-doping Si/SiC/C composite nanofiber film as superior lithium-ion batteries anode[J]. Materials Letters,2022,306:130895. doi: 10.1016/j.matlet.2021.130895 [82] TOCOGLU U, ALAF M, AKBULUT H. Towards high cycle stability yolk-shell structured silicon/rGO/MWCNT hybrid composites for Li-ion battery negative electrodes[J]. Materials Chemistry and Physics,2020,240:10-20. [83] ZHAO H, YANG F, LI C, et al. Progress and perspectives on two-dimensional silicon anodes for lithium-ion batteries[J]. ChemPhysMater,2023,2(1):1-19. doi: 10.1016/j.chphma.2022.03.005 [84] CHOI S, KIM M C, MOON S H, et al. 3D yolk-shell Si@void@CNF nanostructured electrodes with improved electrochemical performance for lithium-ion batteries[J]. Journal of Industrial and Engineering Chemistry,2018,64:344-351. doi: 10.1016/j.jiec.2018.03.035 [85] KANG W, KIM J C, KIM D W. Waste glass microfiber filter-derived fabrication of fibrous yolk-shell structured silicon/carbon composite freestanding electrodes for lithium-ion battery anodes[J]. Journal of Power Sources,2020,468:7-14. [86] JIA Z, LIU W K. Analytical model on stress-regulated lithiation kinetics and fracture of Si-C yolk-shell anodes for lithium-ion batteries[J]. Journal of the Electrochemical Society,2016,163(6):A940-A946. doi: 10.1149/2.0601606jes [87] LIU B, LUO M, WANG Z, et al. On the specific capacity and cycle stability of Si@void@C anodes: Effects of particle size and charge/discharge protocol[J]. Batteries-Basel,2022,8(10):154-168. doi: 10.3390/batteries8100154-168 [88] LIU Z, LUO Y W, ZHOU M J, et al. Enhanced performance of yolk-shell structured Si-PPy composite as an anode for lithium ion batteries[J]. Electrochemistry,2015,83(12):1067-1070. doi: 10.5796/electrochemistry.83.1067 -

下载:

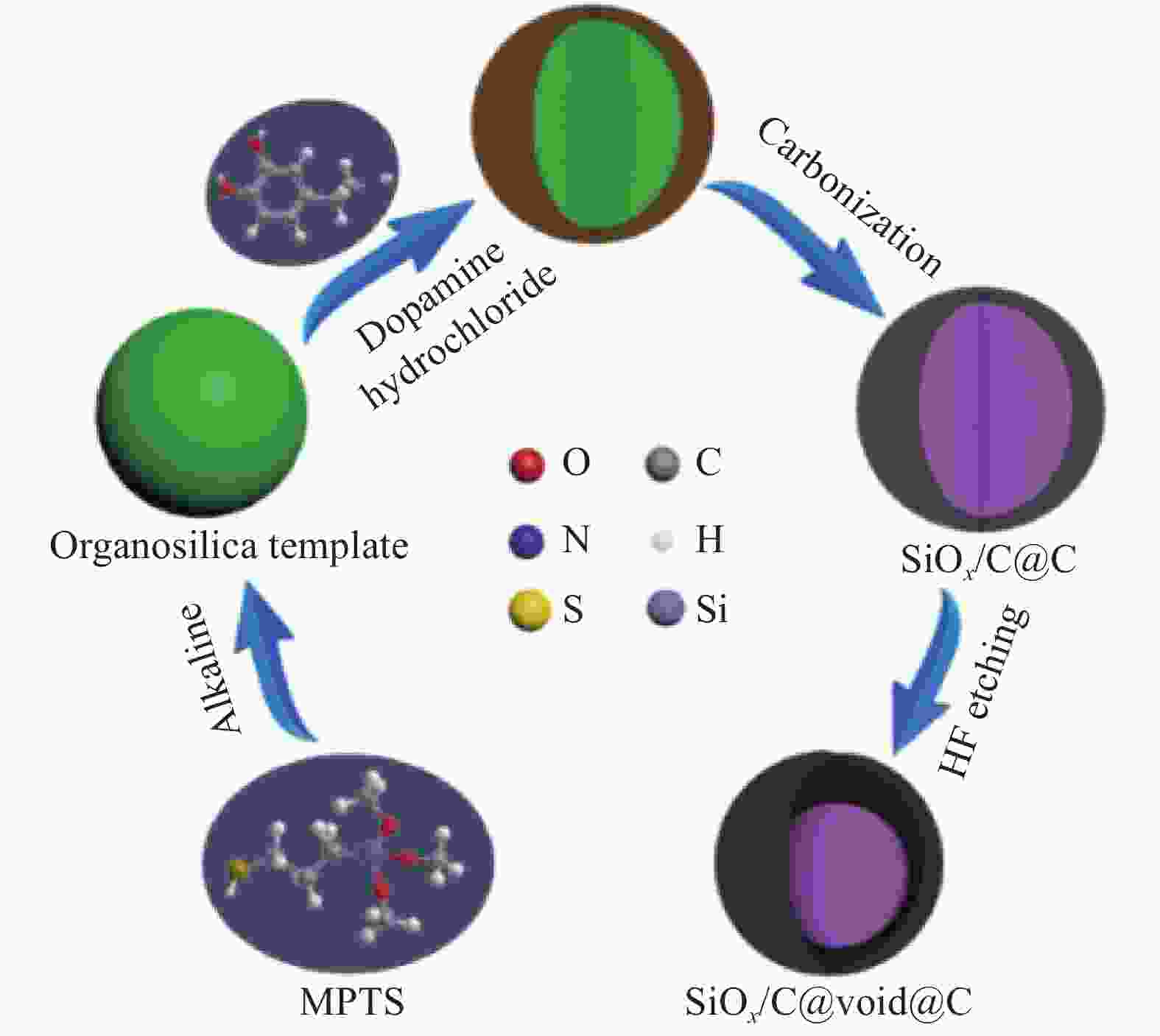

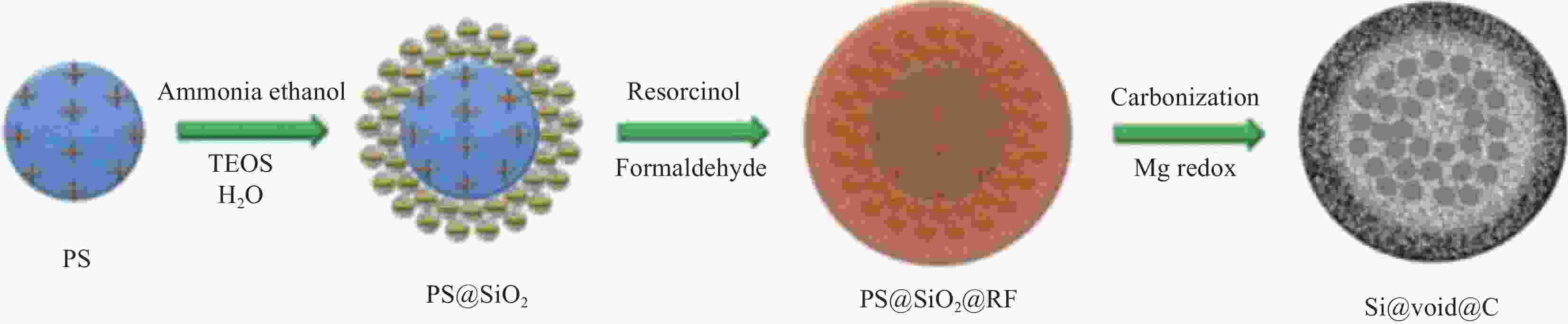

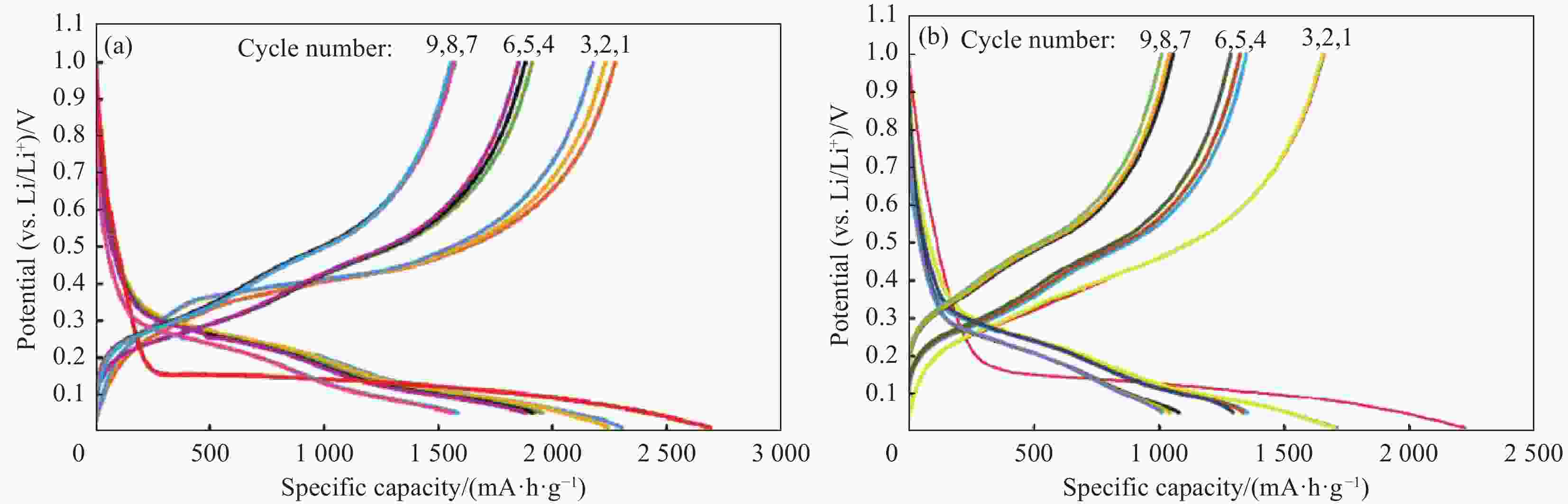

下载: