Bending properties of graphene/Al layered beams under transverse and longitudinal loads

-

摘要: 采用分子动力学(MD)方法模拟了石墨烯(GNs)/Al层状梁在横向荷载和纵向压缩下的弯曲变形,探究了层状梁弯曲特性的影响因素。从横向荷载下的弯曲结果可见,由于层间作用的影响,层状梁的弯曲刚度随着GNs层数的增加而不断降低。GNs/Al层状梁的弯曲机制并非由GNs和Al组分特性的简单相加,这使经典连续力学难以适用于高各向异性的层状材料中。在单轴纵向压缩中,GNs使细长的层状梁在塑性变形前更易发生屈曲行为。发生屈曲的临界应力σcr和临界应变εcr主要受层状梁中重复层厚度的影响,尤其在重复层厚度不足2 nm时,σcr和εcr急剧降低。屈曲后的弯曲变形中,位错形核的拉-压不对称性使原子缺陷仅从受压缩的地方产生。随着GNs层数的增加,重复层间距离降低,层状梁的柔韧性随之增加。Abstract: Molecular dynamics (MD) method was used to simulate the bending deformation of graphene (GNs)/Al layered beams under transverse load and longitudinal compression, and the influencing factors of the bending characteristics of the laminated beams were investigated. It can be seen from the bending results under transverse load that the bending stiffness of the layered beam decreases with the increase of the number of GNs layers due to the effect of interlayer action. The bending mechanism of GNs/Al layered beams is not simply the addition of GNs and Al component properties, which makes it difficult to apply classical continuum mechanics to high anisotropy layered materials. In uniaxial longitudinal compression, GNs makes the slender beam more prone to buckling before plastic deformation. The critical stress (σcr) and critical strain (εcr) of buckling are mainly affected by the thickness of the repeating layer in the layered beam, especially when the thickness of the repeating layer is less than 2 nm, the σcr and εcr decrease sharply. In flexural deformation after buckling, the tension-pressure asymmetry of dislocation nucleation causes atomic defects to occur only from the compressed place. As the number of GNs increases and the distance between repeated layers decreases, the flexibility of the layered beam increases.

-

Key words:

- graphene/Al layered beam /

- molecular dynamics /

- bending deformation /

- bending stiffness /

- buckling

-

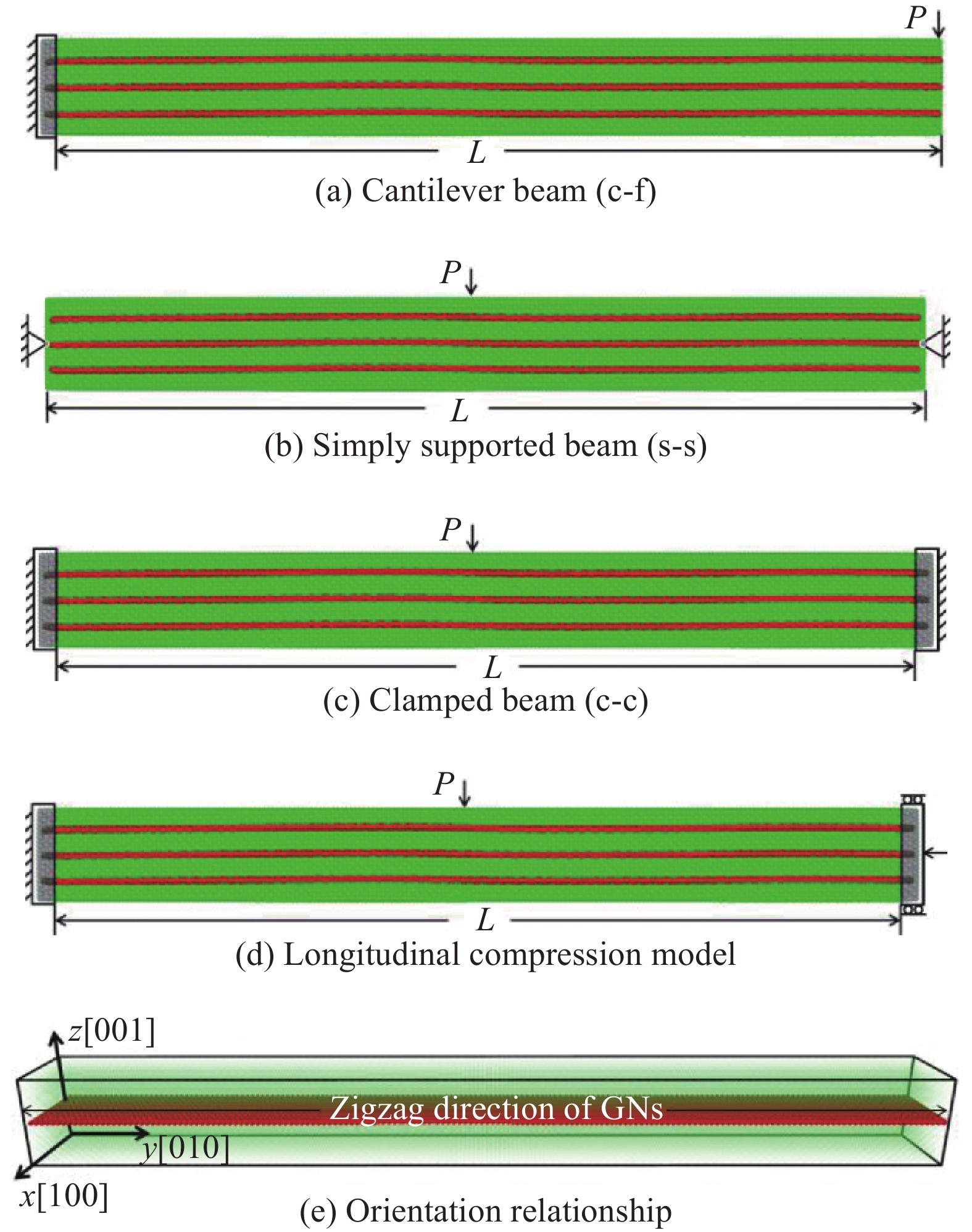

图 4 悬臂梁的计算模型

Figure 4. Calculation model of cantilever beam

Nx , Ny and Nz—Number of atomic layers in x, y and z direction; d0—Distance between adjacent atomic layers; a0—Lattice constant of single crystal Al; q—Uniform distributed load; b—Width of GNs/Al layered beam; h—Height of GNs/Al layered beam ; η—Length ratio of the no-load area

表 1 纯Al梁的横截面尺寸与相应的弯曲刚度

Table 1. Cross-section size and corresponding bending stiffness of pure Al beam

Nx=Ny 9 11 13 15 17 19 21 γ

/%L1 45.30 37.21 31.61 27.51 24.37 21.89 19.88 L2 45.18 37.09 31.49 27.38 24.25 21.77 19.76 L3 45.09 37.01 31.40 27.30 24.16 21.68 19.67 L4 45.02 36.93 31.33 27.23 24.09 21.61 19.61 w

/nmL1 0.318 0.237 0.183 0.146 0.119 0.098 0.083 L2 0.337 0.251 0.194 0.154 0.126 0.104 0.087 L3 0.354 0.264 0.204 0.162 0.132 0.109 0.092 L4 0.370 0.275 0.213 0.169 0.137 0.114 0.095 EB

/10−23 N·m2L1 3.245 4.354 5.625 7.065 8.677 10.468 12.447 L2 4.918 6.599 8.529 10.718 13.239 15.910 18.935 L3 7.043 9.453 12.223 15.370 18.909 22.856 27.225 L4 9.662 12.972 16.784 21.119 26.007 31.454 37.511 Notes: γ—Ratio of the number of atoms on the outermost surface of the model to the total number of atoms in the model; w—Deflection; EB—Bending stiffness. -

[1] ERINGEN A C. Nonlocal polar elastic continua[J]. International Journal of Engineering Science,1972,10(1):1-16. doi: 10.1016/0020-7225(72)90070-5 [2] ERINGEN A C. On differential equations of nonlocal elasticity and solutions of screw dislocation and surface waves[J]. Journal of Applied Physics,1983,54(9):4703-4710. doi: 10.1063/1.332803 [3] WU M, YUAN Q, LI H, et al. Effect of curvature-dependent surface elasticity on the flexural properties of nanowire[J]. Advances in Civil Engineering,2021,2021:1-5. [4] MILLER R E, SHENOY V B. Size-dependent elastic properties of nanosized structural elements[J]. Nanotechnology,2000,11(3):139-147. doi: 10.1088/0957-4484/11/3/301 [5] WU H A. Molecular dynamics simulation of loading rate and surface effects on the elastic bending behavior of metal nanorod[J]. Computational Materials Science,2004,31(3):287-291. doi: 10.1016/j.commatsci.2004.03.017 [6] QIN H S, YAN Y B, LIU H C, et al. Modified Timoshenko beam model for bending behaviors of layered materials and structures[J]. Extreme Mechanics Letters,2020,39:1-12. [7] PAN F, WANG G R, LIU L Q, et al. Bending induced interlayer shearing, rippling and kink buckling of multilayered graphene sheets[J]. Journal of the Mechanics and Physics of Solids,2019,122:340-363. doi: 10.1016/j.jmps.2018.09.019 [8] NOROUZZADEH A, ANSARI R, DARVIZEH M. From nonlinear micromorphic to nonlinear micropolar shell theory[J]. Applied Mathematical Modelling,2021,100:689-727. doi: 10.1016/j.apm.2021.07.041 [9] AMBARTSUMIAN S A. Micropolar theory of shells and plates[M]. Berlin: Springer, 2021. [10] TRAN T T, TRAN V K, PHAM Q H, et al. Extended four-unknown higher-order shear deformation nonlocal theory for bending, buckling and free vibration of functionally graded porous nanoshell resting on elastic foundation[J]. Composite Structures,2021,264:113737. doi: 10.1016/j.compstruct.2021.113737 [11] SAYYAD A S, GHUGAL Y M. Bending, buckling and free vibration analysis of size-dependent nanoscale FG beams using refined models and Eringen’s nonlocal theory[J]. International Journal of Applied Mechanics,2020,12(1):2050007. doi: 10.1142/S1758825120500076 [12] FUSCHI P, PISANO A A, POLIZZOTTO C. Size effects of small-scale beams in bending addressed with a strain-difference based nonlocal elasticity theory[J]. International Journal of Mechanical Sciences,2019,151:661-671. doi: 10.1016/j.ijmecsci.2018.12.024 [13] ELTAHER M A, KHATER M E, EMAM S A. A review on nonlocal elastic models for bending, buckling, vibrations, and wave propagation of nanoscale beams[J]. Applied Mathematical Modelling,2016,40(5-6):4109-4128. doi: 10.1016/j.apm.2015.11.026 [14] REDDY J N. Nonlocal theories for bending, buckling and vibration of beams[J]. International Journal of Engineering Science,2007,45(2):288-307. doi: 10.1016/j.ijengsci.2007.04.004 [15] ARASH B, WANG Q. A review on the application of nonlocal elastic models in modeling of carbon nanotubes and graphenes[J]. Computational Materials Science,2012,51(1):303-313. [16] CIVALEK Ö, DEMIR Ç. Bending analysis of microtubules using nonlocal Euler-Bernoulli beam theory[J]. Applied Mathematical Modelling,2011,35(5):2053-2067. doi: 10.1016/j.apm.2010.11.004 [17] SEIFOORI S, ABBASPOUR F, ZAMANI E. Molecular dynamics simulation of impact behavior in multi-walled carbon nanotubes[J]. Superlattices and Microstructures,2020,140:1-15. [18] LIU P, XIE J P, WANG A Q, et al. First-principles prediction of enhancing graphene/Al interface bonding strength by graphene doping strategy[J]. Applied Surface Science,2020,517:146040. doi: 10.1016/j.apsusc.2020.146040 [19] FANG B C, SPRINGBORG M, ZHAO N Q, et al. Interfacial chemical bonding between carbon nanotube and aluminum substrate modulated by alloying elements[J]. Diamond and Related Materials,2015,59:1-6. doi: 10.1016/j.diamond.2015.08.011 [20] HASEGAWA M, NISHIDATE K. Transfer doping of a metallic carbon nanotube and graphene on metal surfaces[J]. Physical Review B,2011,83(15):1-11. [21] GONG C, LEE G, SHAN B, et al. First-principles study of metal-graphene interfaces[J]. Journal of Applied Physics,2010,108(12):1-8. [22] VANIN M, MORTENSEN J J, KELKKANEN A K, et al. Graphene on metals: A van der Waals density functional study[J]. Physical Review B,2010,81(8):1-8. [23] MISHIN Y, FARKAS D, MEHL M J, et al. Interatomic potentials for monoatomic metals from experimental data and ab initio calculations[J]. Physical Review B,1999,59(5):3393-3407. doi: 10.1103/PhysRevB.59.3393 [24] LEE W, JANG S, KIM M J, et al. Interfacial interactions and dispersion relations in carbon-aluminium nanocomposite systems[J]. Nanotechnology,2008,19(28):1-13. [25] SHEN Y K, WU H A. Interlayer shear effect on multilayer graphene subjected to bending[J]. Applied Physics Letters,2012,100(10):101909. [26] ZHAO Y X, LIU X Y, ZHU J, et al. Unusually high flexibility of graphene-Cu nanolayered composites under bending[J]. Physical Chemistry Chemical Physics,2019,21(31):17393-17399. doi: 10.1039/C9CP02980J [27] BARTOLUCCI S F, PARAS J, RAFIEE M A, et al. Graphene–aluminum nanocomposites[J]. Materials Science and Engi-neering: A,2011,528(27):7933-7937. doi: 10.1016/j.msea.2011.07.043 [28] SU Y S, LI Z, YU Y, et al. Composite structural modeling and tensile mechanical behavior of graphene reinforced metal matrix composites[J]. Science China Materials,2018,61(1):112-124. doi: 10.1007/s40843-017-9142-2 [29] WANG J Y, LI Z Q, FAN G L, et al. Reinforcement with graphene nanosheets in aluminum matrix composites[J]. Scripta Materialia,2012,66(8):594-597. doi: 10.1016/j.scriptamat.2012.01.012 [30] YANG W S, ZHAO Q Q, XIN L, et al. Microstructure and mechanical properties of graphene nanoplates reinforced pure Al matrix composites prepared by pressure infiltration method[J]. Journal of Alloys and Compounds,2018,732:748-758. doi: 10.1016/j.jallcom.2017.10.283 [31] ZHAO L, GUO Q A, LI Z, et al. Grain boundary-assisted deformation in graphene-Al nanolaminated composite micro-pillars[J]. Materials Research Letters,2018,6(1):41-48. doi: 10.1080/21663831.2017.1386241 [32] ZHANG H P, XU C, XIAO W L, et al. Enhanced mechanical properties of Al5083 alloy with graphene nanoplates prepared by ball milling and hot extrusion[J]. Materials Science and Engineering: A,2016,658:8-15. doi: 10.1016/j.msea.2016.01.076 [33] ZHU J Q, LIU X, YANG Q S. Dislocation-blocking mechanism for the strengthening and toughening of laminated graphene/Al composites[J]. Computational Materials Science,2019,160:72-81. doi: 10.1016/j.commatsci.2018.12.061 [34] WANG X, XIAO W, WANG L G, et al. Investigation on mechanical behavior of multilayer graphene reinforced aluminum composites[J]. Physica E: Low-dimensional Systems and Nanostructures,2020,123:114172. doi: 10.1016/j.physe.2020.114172 [35] 颜建伟, 程超, 金超奇, 等. 石墨烯增强层对石墨烯/Al复合材料不同压缩阶段的强化影响[J]. 复合材料学报, 2023, 40(6):3662-3672.YAN Jianwei, CHENG Chao, JIN Chaoqi, et al. Effect of graphene reinforcement layer on strengthening of grapheme/Al composites at different compression stages[J]. Acta Materiae Compositae Sinica,2023,40(6):3662-3672(in Chinese). [36] TJONG S C. Recent progress in the development and pro-perties of novel metal matrix nanocomposites reinforced with carbon nanotubes and graphene nanosheets[J]. Materials Science and Engineering: R: Reports,2013,74(10):281-350. doi: 10.1016/j.mser.2013.08.001 [37] 吴恒安, 倪向贵, 王宇, 等. 金属纳米棒弯曲力学行为的分子动力学模拟[J]. 物理学报, 2002, 51(7):1412-1415. doi: 10.3321/j.issn:1000-3290.2002.07.002WU Heng'an, NI Xianggui, WANG Yu, et al. Molecular dynamics simulation on bending behaviour of metal nanorod[J]. Acta Physica Sinica,2002,51(7):1412-1415(in Chinese). doi: 10.3321/j.issn:1000-3290.2002.07.002 [38] 李煜冬, 傅卓佳, 汤卓超. 功能梯度碳纳米管增强复合材料板弯曲和模态的广义有限差分法[J]. 力学学报, 2022, 54(2):414-424. doi: 10.6052/0459-1879-21-439LI Yudong, FU Zhuojia, TANG Zhuochao. Generalized finite difference method for bending and modal analysis of functionally graded carbon nanotube-reinforced compo-site plates[J]. Chinese Journal of Theoretical and Applied Mechanics,2022,54(2):414-424(in Chinese). doi: 10.6052/0459-1879-21-439 [39] 文诗琦, 李克智, 宋强. 碳纤维上原位生长碳纳米管对C/C复合材料弯曲性能的影响[J]. 复合材料学报, 2013, 30(6):7-13. doi: 10.3969/j.issn.1000-3851.2013.06.002WEN Shiqi, LI Kezhi, SONG Qiang. Influence of in situ grown carbon nanotubes on carbon fiber on the flexural properties of C/C composites[J]. Acta Materiae Compositae Sinica,2013,30(6):7-13(in Chinese). doi: 10.3969/j.issn.1000-3851.2013.06.002 [40] NI W B, ZHAO J W, LIU Y H, et al. Atomic simulation of the bending deformation of a single-crystal simply supported nano-beam[J]. Advanced Materials Research, 2009, 79(1): 1185-1188. [41] PLIMPTON S. Fast parallel algorithms for short-range molecular dynamics[J]. Journal of Computational Physics,1995,117(1):1-19. doi: 10.1006/jcph.1995.1039 [42] DAI Z H, HOU Y A, SANCHEZ D A, et al. Interface-governed deformation of nanobubbles and nanotents formed by two-dimensional materials[J]. Physical Review Letters,2018,121(26):266101. doi: 10.1103/PhysRevLett.121.266101 [43] SILVESTRE N, FARIA B, CANONGIA LOPES J N. Compressive behavior of CNT-reinforced aluminum composites using molecular dynamics[J]. Composites Science and Technology,2014,90(10):3842-3844. [44] WU Q, MIAO W S, ZHANG Y D, et al. Mechanical properties of nanomaterials: A review[J]. Nanotechnology Reviews,2020,9(1):259-273. doi: 10.1515/ntrev-2020-0021 [45] SHAHABODINI A, AHMADI B. On the buckling and bending analysis of FG straight-sided quadrilateral nanoplates using a continuum mechanics-based surface elastic model[J]. Proceedings of the Institution of Mechanical Engi-neers, Part N: Journal of Nanomaterials, Nanoengineering and Nanosystems, 2022, 236(3-4): 69-86. [46] HASHEMIAN M, FOROUTAN S, TOGHRAIE D. Comprehensive beam models for buckling and bending behavior of simple nanobeam based on nonlocal strain gradient theory and surface effects[J]. Mechanics of Materials,2019,139:103209. doi: 10.1016/j.mechmat.2019.103209 [47] OLSSON P A T, MELIN S, PERSSON C. Atomistic simulations of tensile and bending properties of single-crystal BCC iron nanobeams[J]. Physical Review B,2007,76(22):1-15. [48] WEN Y H, WANG Q, LIEW K M, et al. Compressive mechanical behavior of Au nanowires[J]. Physics Letters A,2010,374(29):2949-2952. doi: 10.1016/j.physleta.2010.05.015 [49] ZHANG J Y, ZHANG X, LIU G, et al. Scaling of the ductility with yield strength in nanostructured Cu/Cr multilayer films[J]. Scripta Materialia,2010,63(1):101-104. doi: 10.1016/j.scriptamat.2010.03.024 [50] ZHU Y X, LI Z H, HUANG M S, et al. Strengthening mechanisms of the nanolayered polycrystalline metallic multilayers assisted by twins[J]. International Journal of Plasticity,2015,72:168-184. doi: 10.1016/j.ijplas.2015.05.014 [51] PENG W X, SUN K. Effects of Cu/graphene interface on the mechanical properties of multilayer Cu/graphene compo-sites[J]. Mechanics of Materials,2020,141:103270. doi: 10.1016/j.mechmat.2019.103270 [52] ARMSTRONG R W, RODRIGUEZ P. Flow stress/strain rate/grain size coupling for fcc nanopolycrystals[J]. Philosophical Magazine,2006,86(36):5787-5796. doi: 10.1080/14786430600764872 [53] LIU X Y, WANG F C, WANG W Q, et al. Interfacial strengthening and self-healing effect in graphene-copper nanolayered composites under shear deformation[J]. Carbon,2016,107:680-688. doi: 10.1016/j.carbon.2016.06.071 [54] LIU X, CAI J, LUO S N. Interfacial anti-fatigue effect in graphene-copper nanolayered composites under cyclic shear loading[J]. Physical Chemistry Chemical Physics,2018,20(11):7875-7884. doi: 10.1039/C8CP00127H [55] TIAN Y, DING J, HUANG X, et al. Plastic deformation mechanisms of tension-compression asymmetry of nano-polycrystalline tial: Twin boundary spacing and tempera-ture effect[J]. Computational Materials Science,2020,171:109218. doi: 10.1016/j.commatsci.2019.109218 [56] XIE G, GAO Z, YU X, et al. Tension/compression asymmetry of quasi-Static and dynamic mechanical properties in a face centered cubic Ni-W-Co ternary alloy[J]. Journal of Materials Research and Technology,2022,18:2797-2807. doi: 10.1016/j.jmrt.2022.03.127 [57] KATIN K P, PRUDKOVSKIY V S, MASLOV M M. Molecular dynamics simulation of nickel-coated graphene bending[J]. Micro & Nano Letters,2018,13(2):160-164. -

下载:

下载: