Trapezoidal tearing propagation mechanisms of biaxial-warp-knitted fabric composites and tensile-shear coupling behaviors involved

-

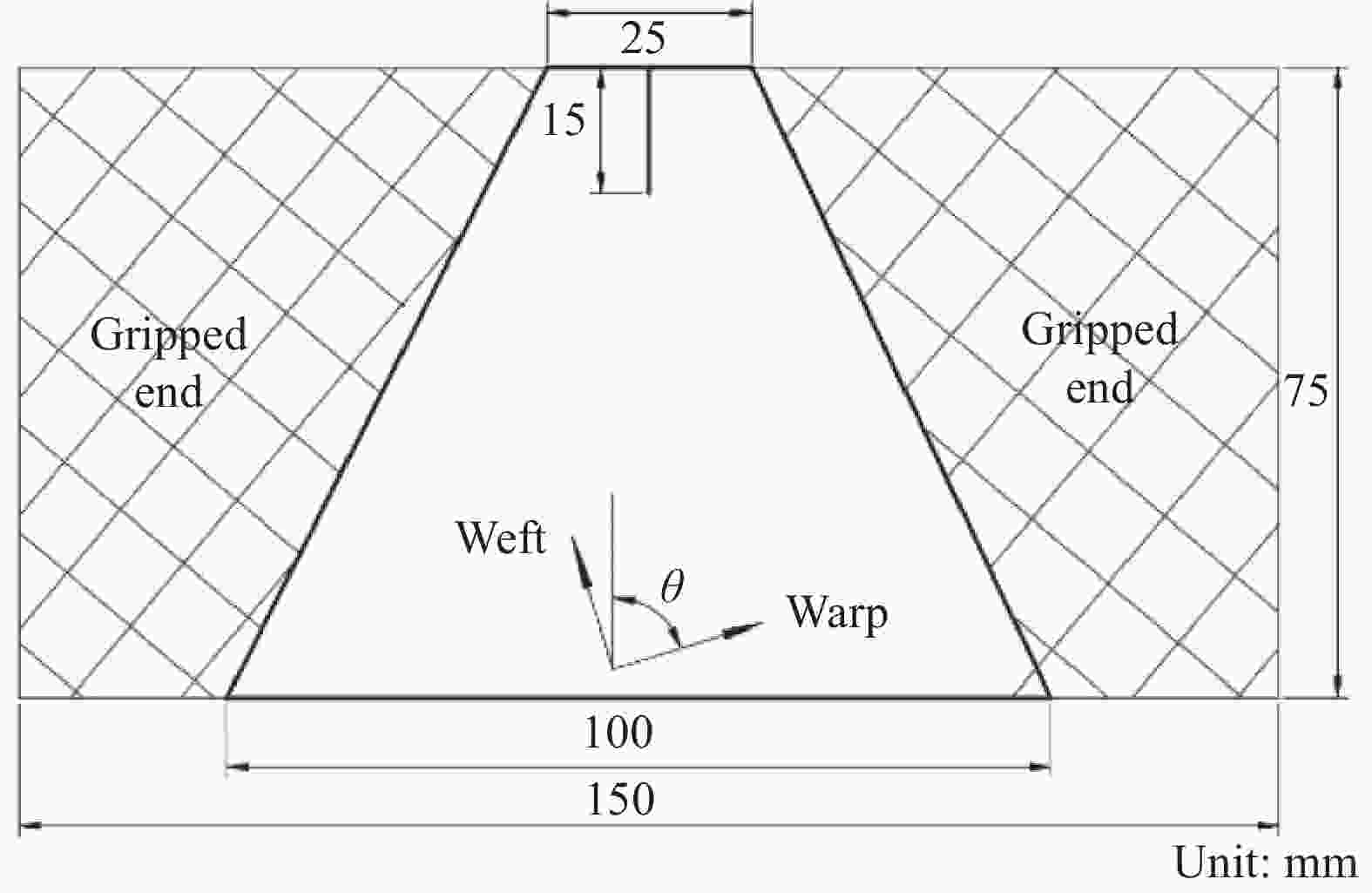

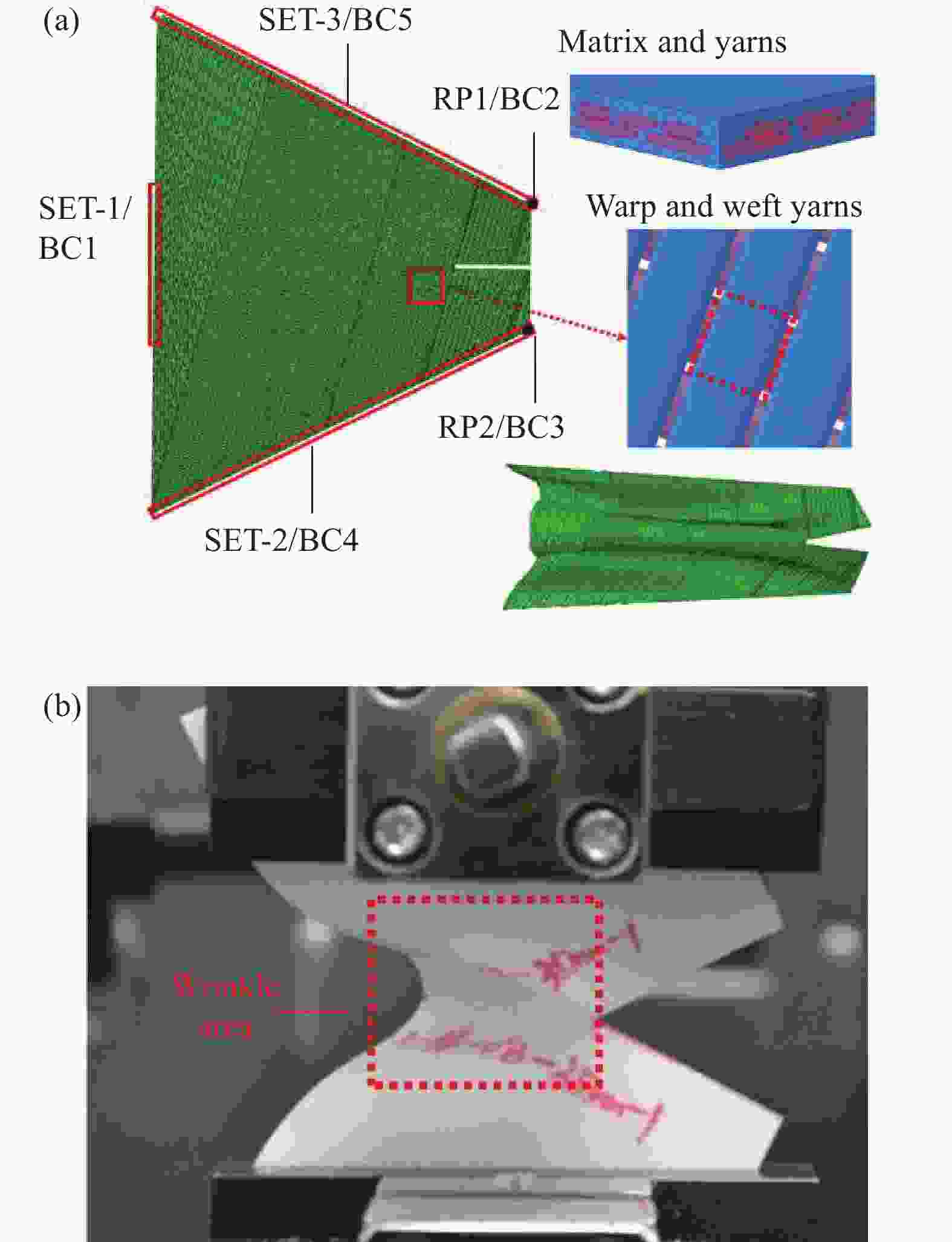

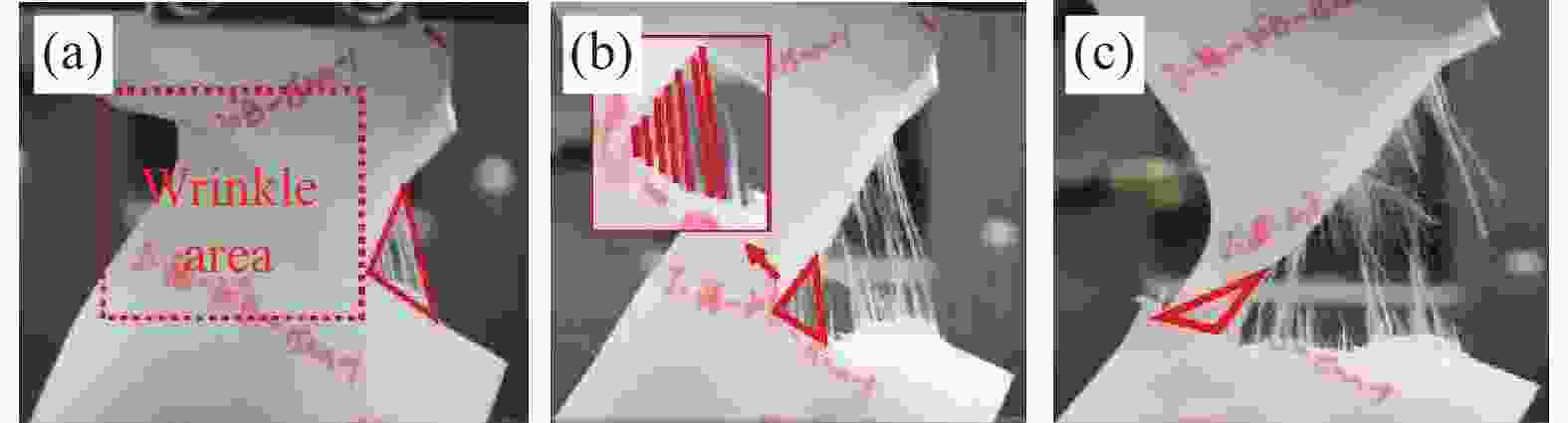

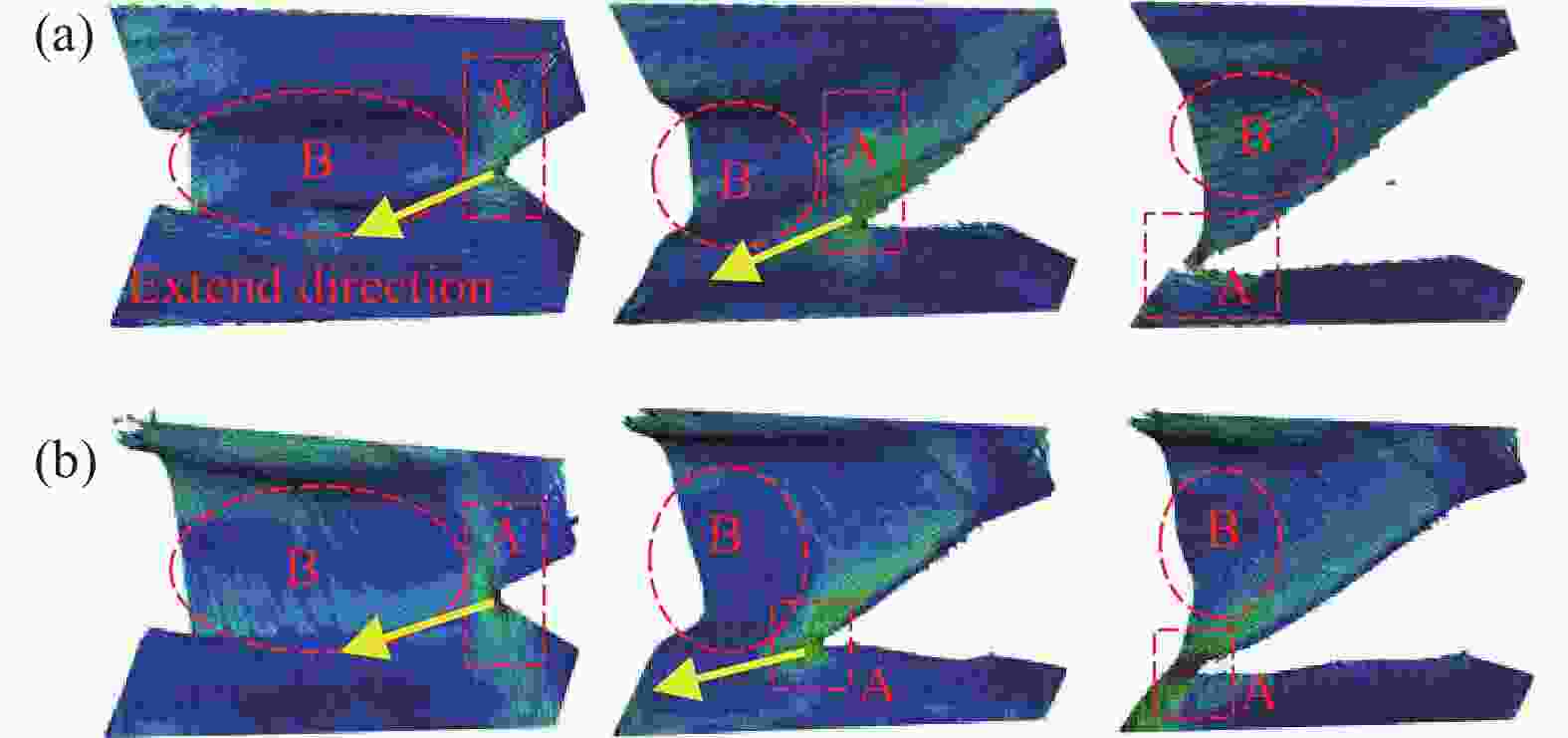

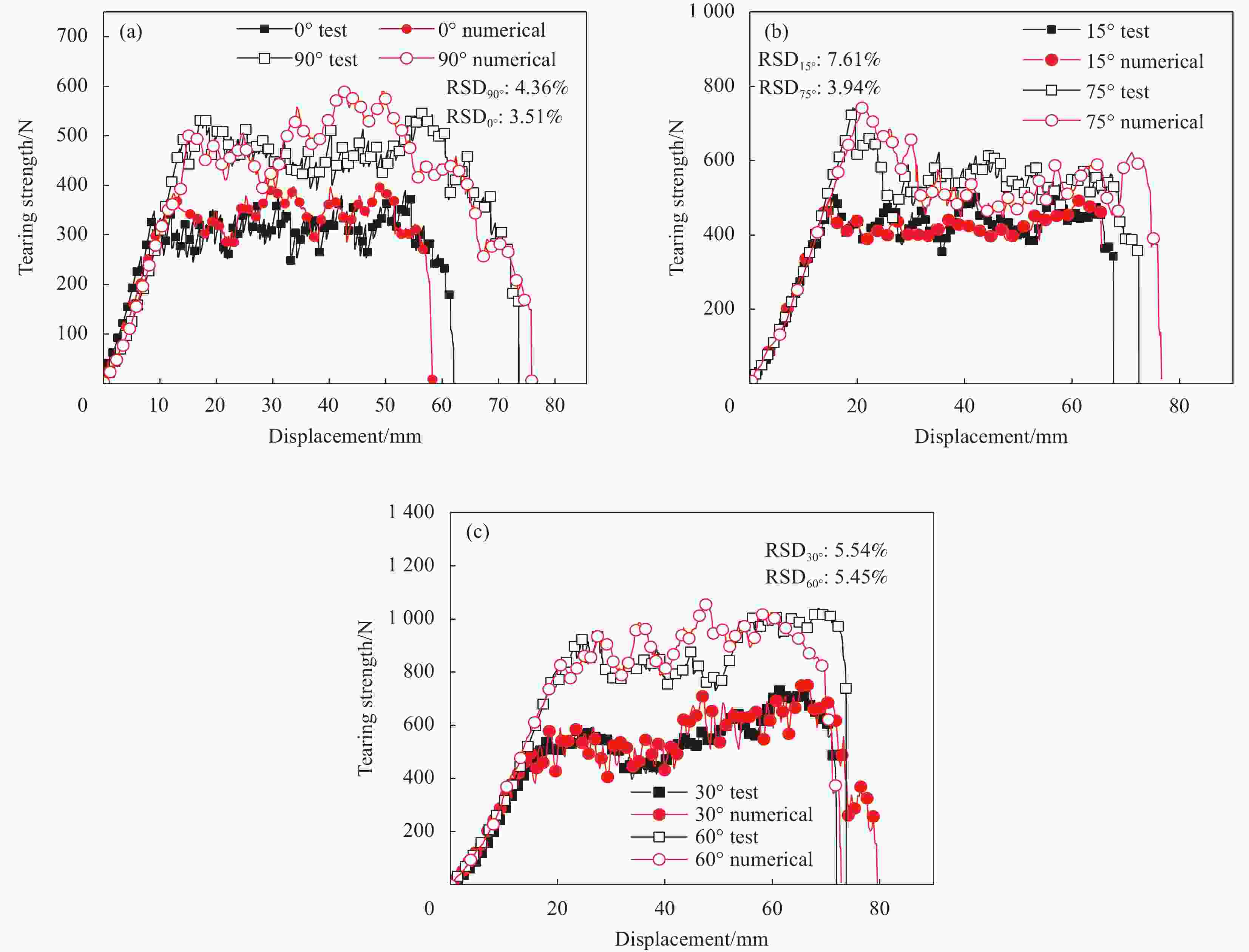

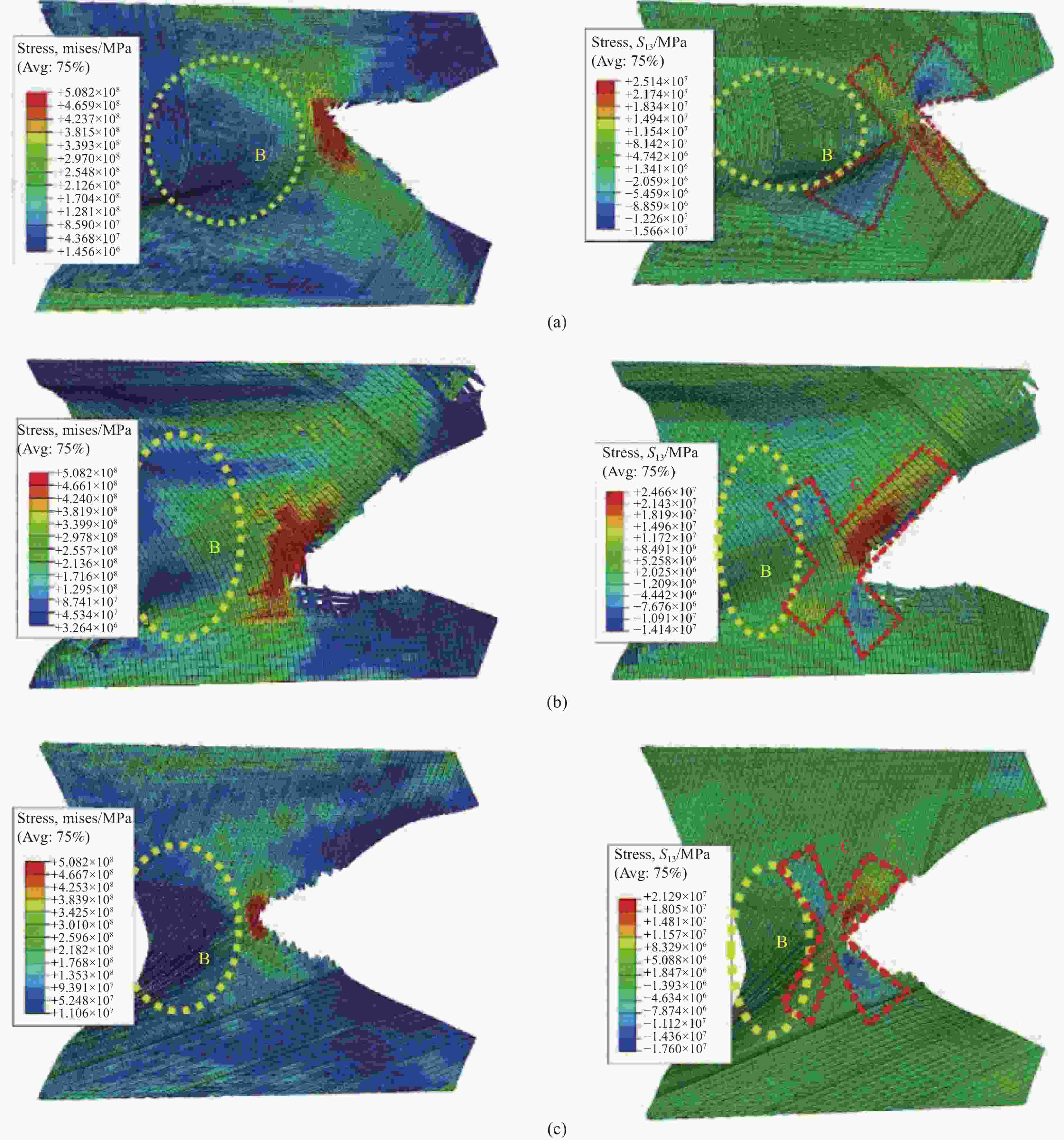

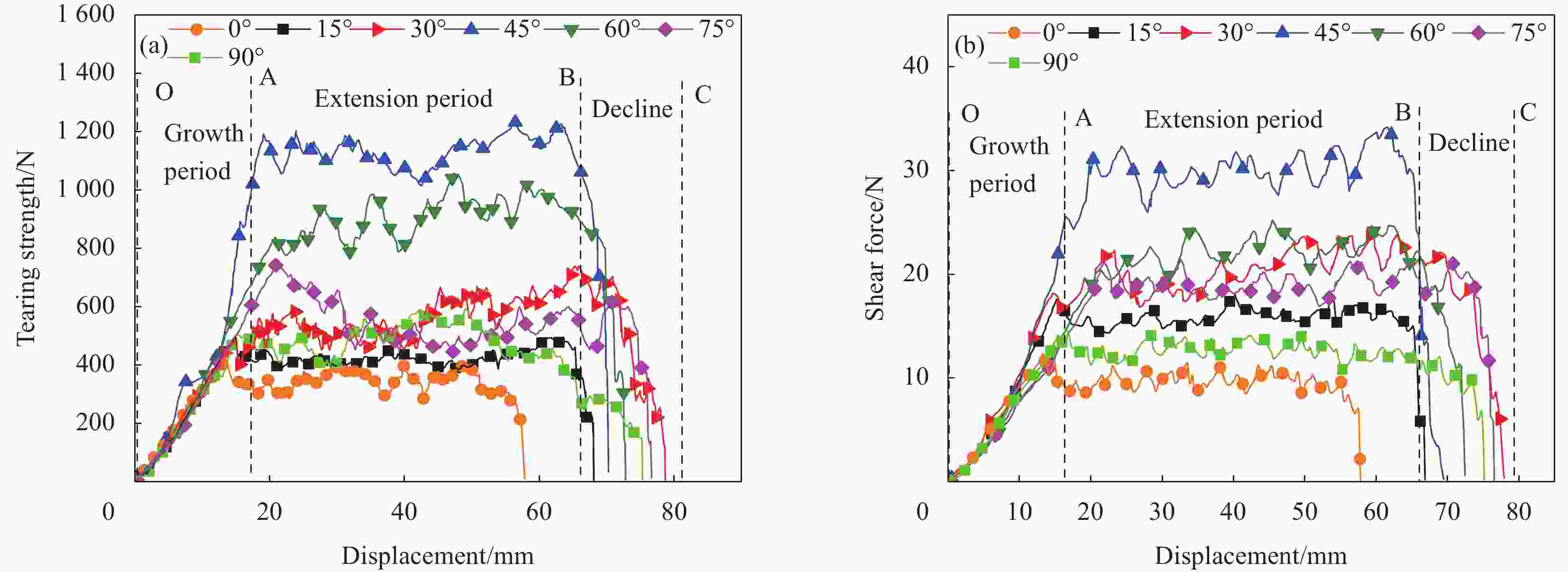

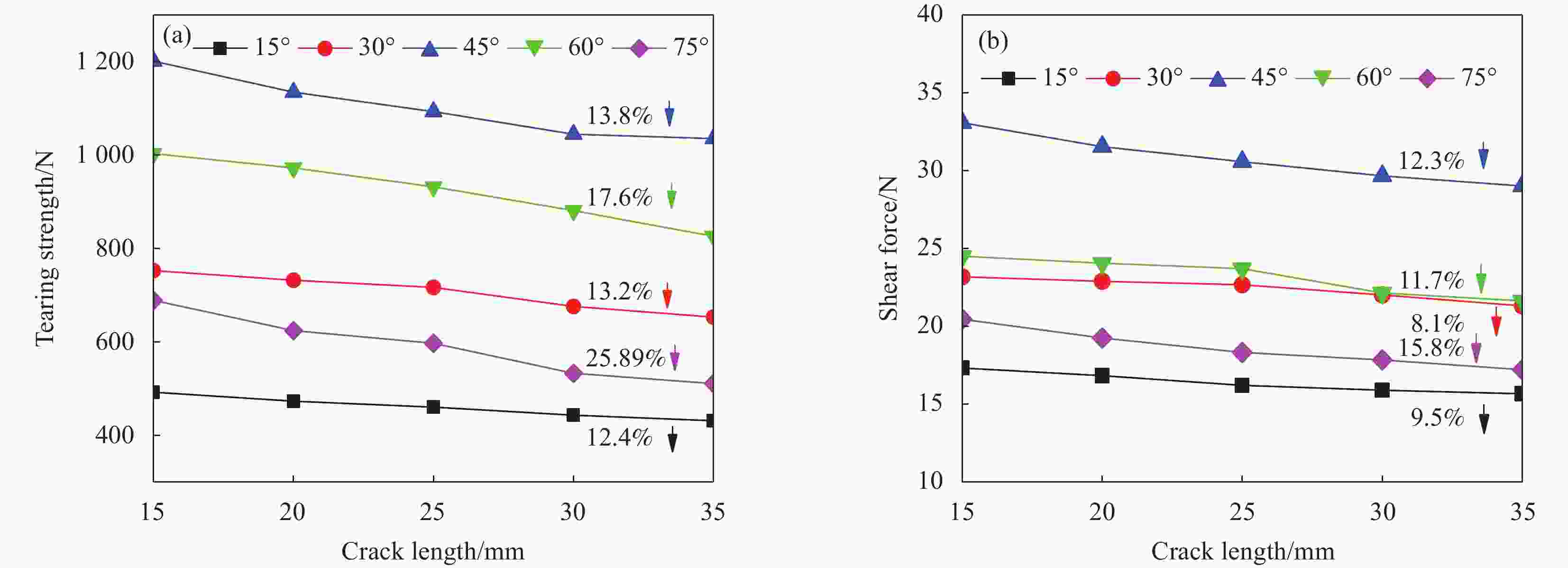

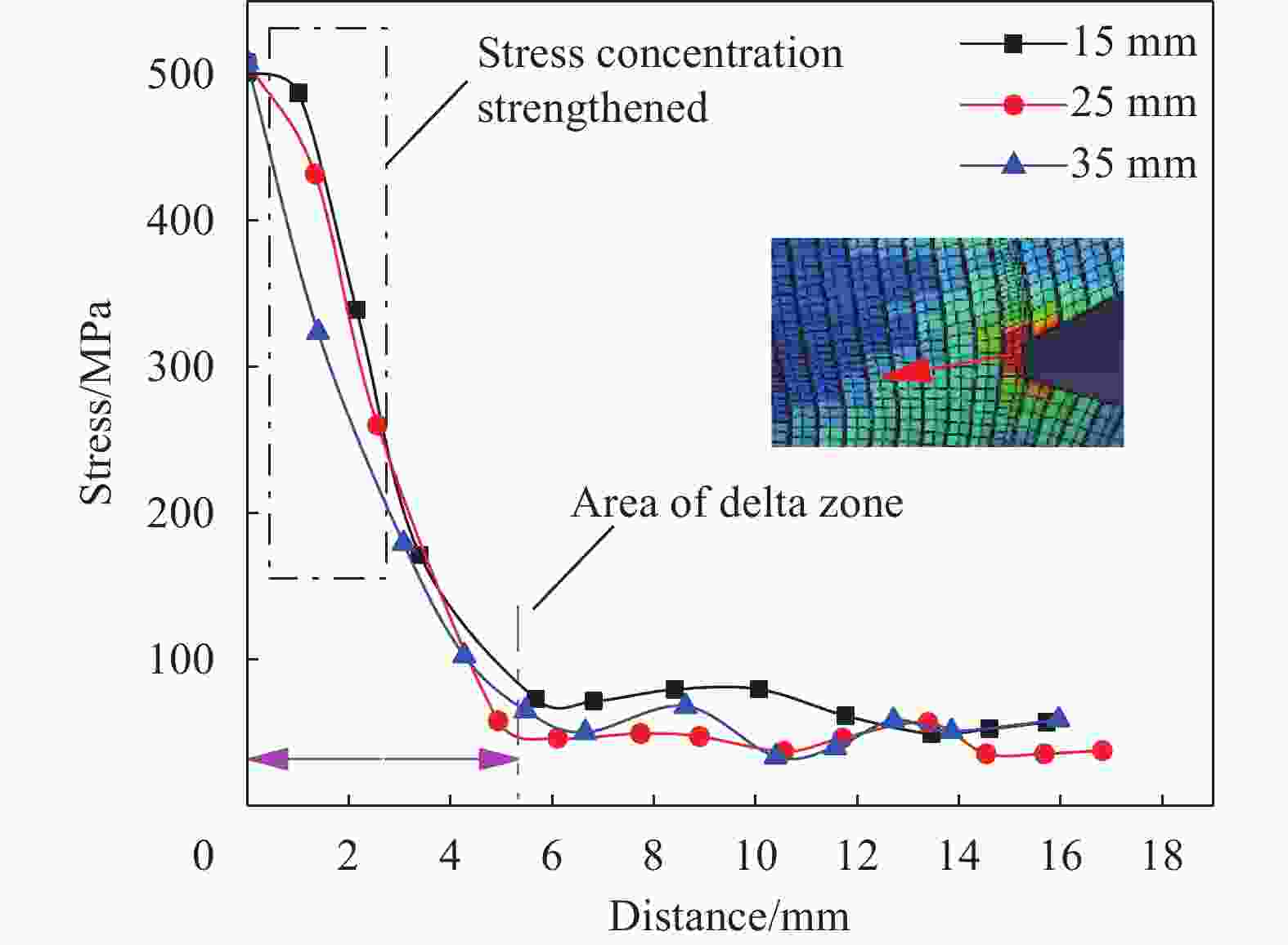

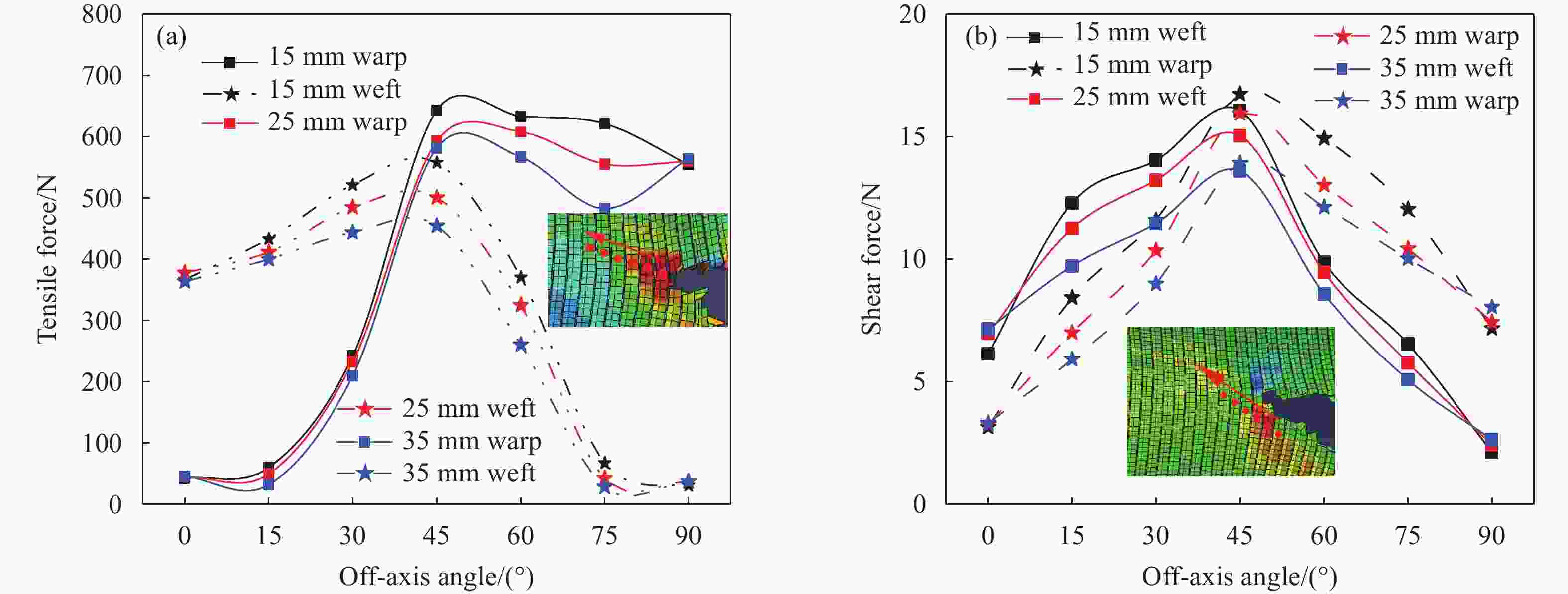

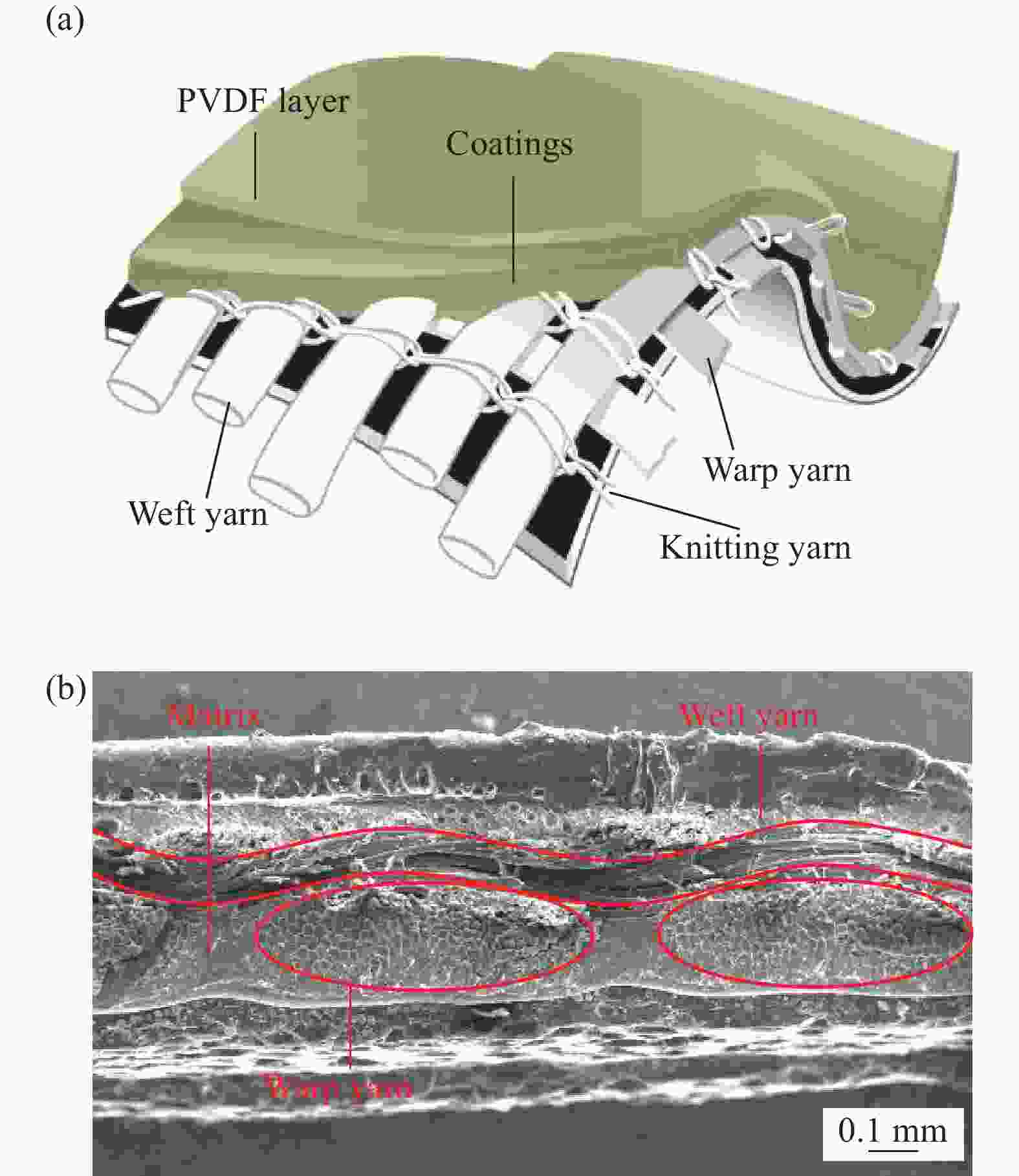

摘要: 针对经编织物类膜材,考虑纱线方向性及其细观力学结构,进行了系列纱线偏转(梯度15°)及裂缝参数下梯形撕裂试验及数值研究,探讨了撕裂强度及力学行为受参数影响规律,论证了裂纹扩展机制及其涉及的拉剪耦合行为特征。结果表明:裂缝扩展与主纱应力三角区及X形剪应力区的衍变存在显著关联,并据此可界定撕裂历程中各典型阶段。经纬纱间的协同变形及材料的拉剪耦合作用是材料撕裂性能表现出纱线方向依赖性的主要诱因,且随偏角趋于45°两因素均呈现出规律性变化,进而造成裂纹两向杂糅延展及撕裂抗力的“山脊”式变化规律的呈现。所得结论可为相关织物膜材的损伤分析及膜结构安全性评估提供有益参考。Abstract: Considering the yarn orientation and microscopic structure of the biaxial-warp-knitted fabric, a series of experimental and numerical studies on trapezoidal tearing under off-axis and crack parameters were conducted at first. Then, the influences of parameters on the tearing strength and mechanical properties were investigated. Finally, the crack propagation mechanisms and the characteristics of tensile-shear coupling behavior involved were demonstrated. Results show that there is a significant correlation between crack propagation and the evolution of the main yarn delta zone as well as the X-shaped shear stress region, and the typical stages in the tearing history can be defined. Also, the tensile-shear coupling of the material and the cooperative deformation between warp and weft yarns are the main factors that cause tearing properties to show a dependence on yarn orientation. In addition, both factors vary regularly as the off-axis angle tends to 45° and cause mixed propagation of cracks in both directions and the "ridge" pattern of tearing strength. The conclusions obtained can provide references for damage analysis of related fabric composites and safety assessment of membrane structures.

-

表 1 PVDF膜材纱线力学参数

Table 1. Mechanical parameters for yarns in PVDF fabric

Yarn Strain/% Modulus/MPa εI εII εIII EI EII EIII Warp 0.02 9.00 18.00 4909.32 971.20 3196.41 Weft 3.00 15.50 27.00 3246.33 851.52 2477.14 Notes: εI, εII, εIII—Strain for three characteristic stages; EI, EII, EIII—Elastic modulus for three characteristic stages. 表 2 模型边界参数

Table 2. Boundary parameters of model

Step Model boundary Settings of displacement boundary Region Step-1 BC-1 U2=30 mm; U1=UR2=U3=UR1=UR3=0 SET-1 BC-2 UR2=0.523; U1=U2=U3=UR1=UR3=0 RP-1 BC-3 UR2=−0.523; U1=U2=U3=UR1=UR3=0 RP-2 Step-2 BC-4 ENCASTRE SET-2 BC-5 U3=100 mm; U1=UR2=U3=UR1=UR3=0 SET-3 Note: U, UR—Boundary displacement parameters. -

[1] AMBROZIAK A, KŁOSOWSKI P. Mechanical properties for preliminary design of structures made from PVC coated fabric[J]. Construction and Building Materials,2014,50:74-81. doi: 10.1016/j.conbuildmat.2013.08.060 [2] QING Q, SHEN S S, GONG J H. Deflation behavior and related safety assessment of an air-supported membrane structure[J]. Thin-Walled Structures,2018,129:225-236. doi: 10.1016/j.tws.2018.01.037 [3] KANDEL A, SUN X Y, WU Y. Wind-induced responses and equivalent static design method of oval-shaped arch-supported membrane structure[J]. Journal of Wind Engineering and Industrial Aerodynamics,2021,213:104620. doi: 10.1016/j.jweia.2021.104620 [4] CHEN J W, CHEN W J, ZHAO B, et al. Mechanical responses and damage morphology of laminated fabrics with a central slit under uniaxial tension: A comparison between analytical and experimental results[J]. Construction and Building Materials,2015,101:488-502. doi: 10.1016/j.conbuildmat.2015.10.134 [5] 陈建稳, 陈务军, 侯红青, 等. 织物类蒙皮材料中心切缝撕裂破坏强度分析[J]. 复合材料学报, 2016, 33(3):666-674.CHEN Jianwen, CHEN Wujun, HOU Hongqing, et al. Analysis on tearing strength of envelope fabric materials under central crack tearing[J]. Acta Materiae Compositae Sinica,2016,33(3):666-674(in Chinese). [6] 张营营, 张其林, 周传志. PTFE膜材的单向拉伸性能[J]. 建筑材料学报, 2010, 13(4):535-539. doi: 10.3969/j.issn.1007-9629.2010.04.024ZHANG Yingying, ZHANG Qilin, ZHOU Chuanzhi. Uniaxial tensile properties of PTFE membrane material[J]. Jour-nal of Building Materials,2010,13(4):535-539(in Chinese). doi: 10.3969/j.issn.1007-9629.2010.04.024 [7] 矫卫红, 陈南梁. 经编双轴向织物用作涂层基布的性能优势[J]. 东华大学学报(自然科学版), 2004, 30(6):91-95.JIAO Weihong, CHEN Nanliang. Performance advantages of warp knitting biaxial fabrics used as coating substrates[J]. Journal of Donghua University (Natural Science),2004,30(6):91-95(in Chinese). [8] 宋寅搏, 陈务军, 高成军, 等. 飞艇用织物膜材单轴拉伸蠕变强度试验与模型[J]. 复合材料学报, 2022, 39(10):5041-5048.SONG Yinbo, CHEN Wujun, GAO Chengjun, et al. Uniaxial tensile creep experiment and creep model of fabric for airship structures[J]. Acta Materiae Compositae Sinica,2022,39(10):5041-5048(in Chinese). [9] 李龙, 段跃新, 李超, 等. 双轴向经编织物T700/BMI6421复合材料力学性能[J]. 复合材料学报, 2011, 28(6):92-97.LI Long, DUAN Yuexin, LI Chao, et al. Mechanical properties of bi-axial warp-knitted fabric T700/BMI6421 compo-sites[J]. Acta Materiae Compositae Sinica,2011,28(6):92-97(in Chinese). [10] 谈亚飞. 经编复合材料的市场现状与发展趋势[J]. 针织工业, 2010, 38(2):17-20. doi: 10.3969/j.issn.1000-4033.2010.02.009TAN Yafei. The present market situation and developing trend of the warp knitted composites fabric[J]. Knitting Industries,2010, 38(2):17-20(in Chinese). doi: 10.3969/j.issn.1000-4033.2010.02.009 [11] 王思明, 谭惠丰, 罗锡林, 等. Nylon-230 T/TPU织物蒙皮撕裂性能的数值模拟和试验研究[J]. 复合材料学报, 2018, 35(7):1869-1877.WANG Siming, TAN Huifeng, LUO Xilin, et al. Numerical simulation and experimental study on fabric skin tearing properties of Nylon-230 T/TPU[J]. Acta Materiae Compo-sitae Sinica,2018,35(7):1869-1877(in Chinese). [12] 包晗, 张旭波, 吴明儿. PVC涂层聚酯纤维膜材撕裂性能试验研究[J]. 建筑材料学报, 2020, 23(3):631-641.BAO Han, ZHANG Xubo, WU Minger. Experimental study on tearing behavior of PVC coated polyester fiber membrane[J]. Journal of Building Materials,2020,23(3):631-641(in Chinese). [13] ZHANG Y Y, SONG X G, ZHANG Q L, et al. Fracture failure analysis and strength criterion for PTFE coated woven fabrics[J]. Journal of Composite Materials,2015,49(12):1409-1421. [14] SHI T B, CHEN W J, GAO C J, et al. Biaxial constitutive relationship and strength criterion of composite fabric for airship structures[J]. Composite Structures,2019,214(28):379-389. [15] ZHANG X, WU M B, BAO H E. Tearing behaviors of polytetrafluoroethylene coated fabric under uniaxial in-plane tearing tests[J]. Textile Research Journal,2022,92(5):929-953. [16] LI X C, ZHANG Y Y, XU J H, et al. Central tearing behavior of PVDF coated fabrics with multiple initial notches[J]. Polymer Composites,2021,42(2):1049-1058. doi: 10.1002/pc.25885 [17] HE R J, SUN X Y, WU Y, et al. Biaxial tearing properties of woven coated fabrics using digital image correlation[J]. Composite Structures,2021,272:114206. doi: 10.1016/j.compstruct.2021.114206 [18] 张营营, 赵玉帅, 徐俊豪, 等. PVC涂层织物撕裂破坏机理分析与强度预测模型[J]. 建筑结构学报, 2018, 39(S2):336-343.ZHANG Yingying, ZHAO Yushuai, XU Junhao, et al. Analysis of tearing failure mechanism and strength predictive model of PVC coated fabrics[J]. Journal of Building Structures,2018,39(S2):336-343(in Chinese). [19] ZHANG X B, WU M E. Modified stress field model for critical tearing strength of architectural coated fabrics[J]. Jour-nal of Industrial Textiles,2022,51(4):5560-5591. [20] 刘龙斌, 吕明云, 肖厚地. 含初始裂纹的平流层飞艇用蒙皮薄膜撕裂行为[J]. 复合材料学报, 2015, 32(2):508-514. doi: 10.13801/j.cnki.fhclxb.20140603.001LIU Longbin, LYU Mingyun, XIAO Houdi. Tearing behaviors of envelope thin films used in stratospheric airships with initial cracks[J]. Acta Materiae Compositae Sinica,2015,32(2):508-514(in Chinese). doi: 10.13801/j.cnki.fhclxb.20140603.001 [21] 张旭波, 吴明儿, 包晗. 涂层织物类膜材的偏轴梯形撕裂行为[J]. 建筑材料学报, 2021, 24(1):121-130. doi: 10.3969/j.issn.1007-9629.2021.01.017ZHANG Xubo, WU Minger, BAO Han. Off-axial trapezoid tearing behaviors of coated fabrics[J]. Journal of Building Materials,2021,24(1):121-130(in Chinese). doi: 10.3969/j.issn.1007-9629.2021.01.017 [22] WANG P, SUN B Z, GU B H. Comparisons of trapezoid tearing behaviors of uncoated and coated woven fabrics from experimental and finite element analysis[J]. International Journal of Damage Mechanics,2013,22(4):464-489. doi: 10.1177/1056789512450524 [23] FORSTER B, MOLLAERT M. European design guide for tensile surface structure[M]. Brussels: Tensinet Association, 2004. [24] Membrane Structures Association of Japan. Testing method for inplane shear properties of membrane materials: MSAJ/M-01[S]. Tokyo: Membrane Structures Association of Japan, 1993. [25] Membrane Structures Association of Japan. Testing method for elastic constants of membrane materials: MSAJ/M-02[S]. Tokyo: Membrane Structures Association of Japan, 1995. [26] NATALIE S, JORG U. Prospect for European guidance for the structural design of tensile membrane structures[M]. Brussels: European Commission, 2016. [27] 张若男, 陈建稳. 经编织物膜材偏轴中心撕裂行为及破坏机理[J]. 复合材料科学与工程, 2022, 10 (5):28-36. doi: 10.19936/j.cnki.2096-8000.20220528.004ZHANG Ruonan, CHEN Jianwen. Off-axis central tearing behaviors and damage mechanisms of warp-knitted fabric membranes[J]. Composites Science and Engineering,2022,10 (5):28-36(in Chinese). doi: 10.19936/j.cnki.2096-8000.20220528.004 [28] 陈建稳, 关晓宇, 张若男, 等. 拉剪耦合应力对经编织物类膜材双轴撕裂破坏影响机制[J]. 华南理工大学学报(自然科学版), 2021, 49(10):78-86.CHEN Jianwen, GUAN Xiaoyu, ZHANG Ruonan, et al. Biaxial tearing behaviors and mechanisms of warp-knitted fabric membranes under combined shear and tensile stresses[J]. Journal of South China University of Technology (Natural Science Edition),2021,49(10):78-86(in Chinese). -

下载:

下载: