Investigation on the influence of winding tension on residual stress and spring-in deformation of dry wound composite structure

-

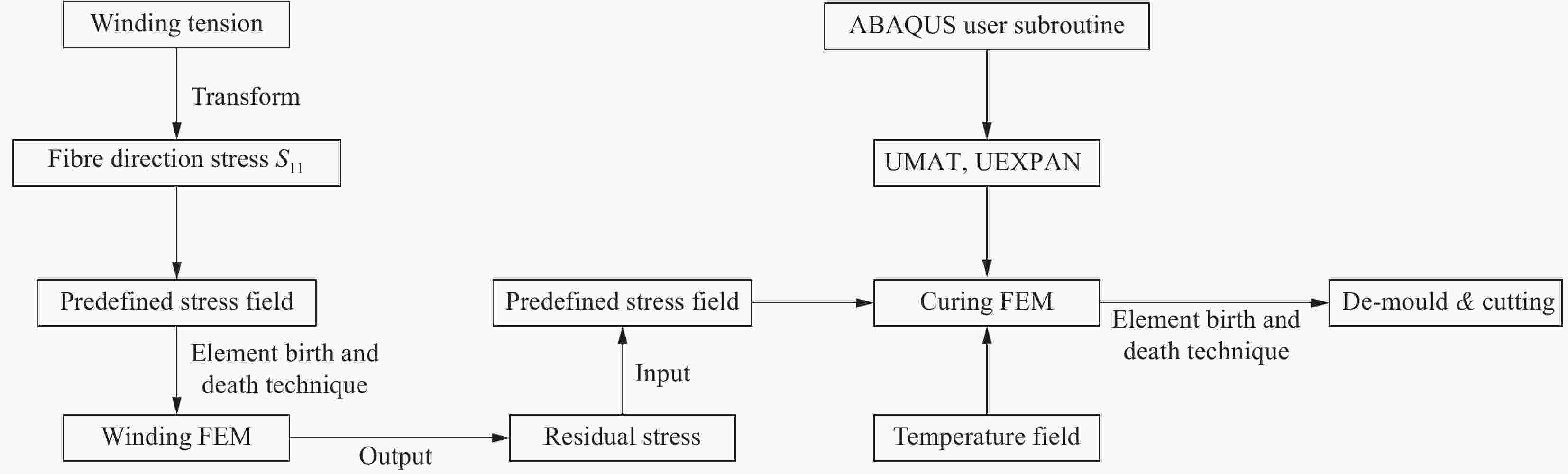

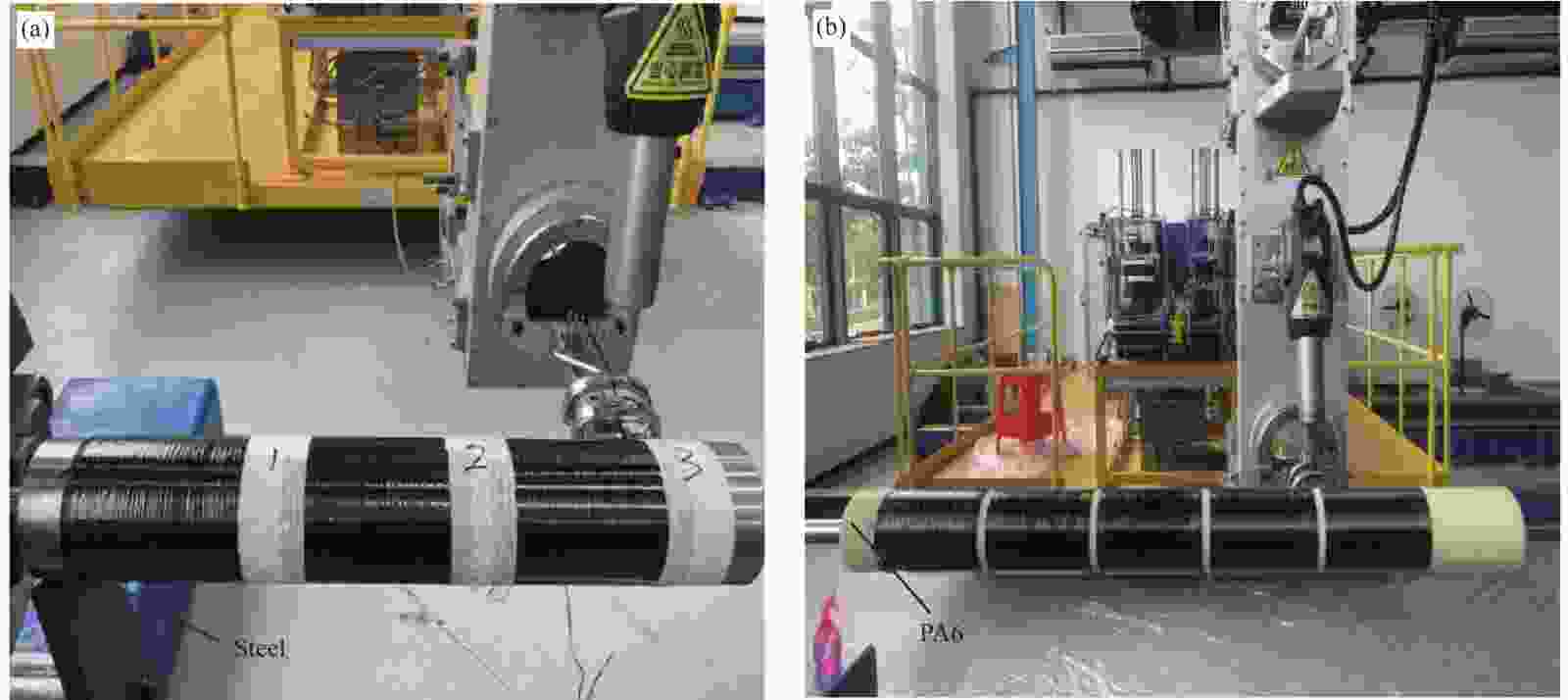

摘要: 开展纤维缠绕结构缠绕与固化后残余应力评估是开展缠绕工艺优化设计、实现服役前预应力设计的重要前提。本文采用干法缠绕工艺,基于钢芯模和尼龙6(PA6)芯模分别制备了恒定张力(40 N)、内松外紧(20 N-40 N-60 N)和内紧外松(60 N-40 N-20 N)3种不同张力制度的复合材料缠绕圆筒,通过测试切割过程应变释放量与回弹变形对内部残余应力进行对比分析。借助生死单元法,建立了复合材料圆筒的逐层缠绕过程分析模型,模拟缠绕后残余应力分布;并基于CHILE(Tg)本构模型,开展了复合材料圆筒固化过程模拟,预测固化后残余应力及切割后回弹变形。研究表明:固化应力与缠绕张力均对总残余应力产生贡献,但由于固化过程剩余缠绕张力进一步放松,固化后总残余应力水平低于缠绕残余应力与固化应力之和。固化过程不会改变缠绕张力对最终残余应力分布的影响;缠绕张力对总残余应力的影响程度与芯模材质相关,芯模热变形越大,缠绕张力的影响越弱。当采用相同芯模时,内松外紧(20 N-40 N-60 N)张力制度产生的切割回弹角最小,内紧外松(60 N-40 N-20 N)张力制度产生的回弹角最大;当采用相同张力制度时,PA6芯模制备的缠绕圆筒试样切割后回弹角远大于钢芯模制备试样。Abstract: The evaluation of residual stress after winding and curing process is the basement for the optimization design of winding process scheme and the achievement of pre-service stressing design. In this paper, three kinds of winding tension strategies, e.g. constant tension (40 N), loose inside and tight outside tension (20 N-40 N-60 N), and tight inside and loose outside tension (60 N-40 N-20 N), were used to prepare the composite winding cylinders on the steel mould and polyamide 6 (PA6) mould by the dry winding process, respectively. The internal residual stresses were analyzed by measuring the released strain and spring-in angle during cutting process. With the aid of element birth and death technique, numerical model of the layer-by-layer winding process were created and the distributions of residual stress during winding were calculated. Subsquently, the curing process was simulated based on the constitutive model of CHILE (Tg). The after-curing residual stress and after-cutting spring-in deformation were predicted. It is shown that both the curing stress and the winding tension stress contribute to the total residual stresses. However, due to the further releasing of winding residual tension during the curing process, the total residual stresses are lower than the sum of the winding residual stresses and curing residual stresses. The impact of the winding tension strategies on total residual stresses is not affected by curing operation. The contribution of winding tension to the total residual stress is affected by the mould material used. The larger thermal deformation of the mould, the weaker the influence of winding tension strategy. For the situations with same mould, the winding cylinder with loose inside and tight outside (20 N-40 N-60 N) tension strategy shows the smallest after-cutting spring-in angle and the one with tight inside and loose outside (60 N-40 N-20 N) tension strategy shows the largest after-cutting spring-in angle. For the cases with same tension strategy, the winding cylinders made on PA6 mould give much larger after-cutting spring-in angle than that made on steel mould.

-

Key words:

- dry winding /

- winding tension strategy /

- residual stress /

- spring-in deformation /

- numerical model

-

图 4 半径法计算回弹角示意图

Figure 4. Schematic diagram of the spring-in angle calculated by the radius method

θ—Central angle; Δθ—Spring-in angle; O—Center point of the molding surface before cutting; O’—Center point of specimen forming surface after cutting; r—Radius of the molding surface before cutting; r'—Radius of specimen forming surface after cutting

表 1 不同张力制度的缠绕圆筒每层的缠绕张力

Table 1. Winding tension of each layer of the winding cylinder with different tension strategies

Layers S1/N S2/N S3/N 1-3 40 20 60 4-6 40 40 40 7-9 40 60 20 Note: S1, S2 and S3—40 N constant tension, the variable tension from 20 N to 60 N and the variable tension from 60 N to 20 N. 表 2 钢芯模和PA6芯模制备的不同张力制度缠绕圆筒内外表面应变变化

Table 2. Changes of inner and outer surface strain of the cylinder wound with different tension strategies on steel mould and PA6 mould

Winding tension Mould Router/10−6 Rinner/10−6 S1 Steel 272±8 −276±4 PA6 1367±7 −1332±9 S2 Steel 127±5 −123±2 PA6 1178±10 −1225±9 S3 Steel 451±4 −440±5 PA6 1452±9 −1481±6 Notes: Router—Average value of the strain for strain gauges R1, R2 and R3; Rinner—Average value for strain gauges R4, R5 and R6. 表 3 钢芯模和PA6芯模制备的不同张力制度缠绕圆筒回弹角

Table 3. Spring-in angle of the cylinders wound with different tension strategies on steel mould and PA6 mould

Winding tension Mould Spring-in angle/(°) S1 Steel 6.23±0.1 PA6 25.45±0.2 S2 Steel 2.43±0.1 PA6 22.65±0.2 S3 Steel 8.58±0.2 PA6 28.39±0.2 表 4 SS58#-12 KHF30 F预浸纱热膨胀系数和参数

Table 4. Thermal expansion coefficients and parameters of SS58#-12 KHF30 F prepreg yarn

Parameter Value T1/℃ −30 T2/℃ −25 $ \alpha _{{\text{EXP1}}}^{\text{T}} $/℃−1 26.91×10−6 $ \alpha _{{\text{EXP2}}}^{\text{T}} $/℃−1 72.01×10−6 $ \alpha _{{\text{EXP1}}}^{\text{L}} $/℃−1 −0.8×10−6 $ \alpha _{{\text{EXP2}}}^{\text{L}} $/℃−1 −0.33×10−6 Notes: T1 and T2—Fitting parameters of temperature; $ \alpha _{{\text{EXP1}}}^{\text{T}} $and$ \alpha _{{\text{EXP2}}}^{\text{T}} $—Transverse coefficients of thermal expansion on glassy state and rubbery state; $ \alpha _{{\text{EXP1}}}^{\text{L}} $ and $ \alpha _{{\text{EXP2}}}^{\text{L}} $—Longitudinal coefficients of thermal expansion on glassy state and rubbery state. 表 5 不同缠绕张力对应的纤维方向等效应力

Table 5. Equivalent longitudional stress of different winding tensions

b/mm h/mm F/N S11/MPa 4.5 0.16 20 27.78 40 55.55 60 83.33 Notes: b —Bandwidth of prepreg yarn; h—Thickness of prepreg yarn; F—Winding tension in prepreg yarn; S11—Stress in the fiber direction. 表 6 SS58#-12KHF30F预浸纱用T700级碳纤维的力学性能参数

Table 6. Mechanical properties of T700 grade carbon fiber for SS58#-12KHF30F prepreg yarn

Parameter Value E1f /GPa 232 E2f =E3f /GPa 15 v12f =v13f 0.28 v23f 0.49 G12f =G13f /GPa 24 G23f/GPa 5.03 Notes: Subscrips of 1,2,3 are three directions of material coordinate; E—Elastic modulus; v—Poisson's ratio; G—Shear modulus. 表 7 芯模材料参数

Table 7. Material parameters of mandrels

Parameter Steel PA6 E/MPa 210000 2320 v 0.33 0.34 αEXP/10−6 K−1(20℃-60℃) 12 90.41 αEXP/10−6 K−1(60℃-120℃) 12 156.7 Note: αEXP—Coefficient of thermal expansion. 表 8 不同缠绕圆筒在切割过程内、外表面应变变化的实验值与仿真值

Table 8. Experimental and simulated values of the cutting-released strains on the inner and outer surfaces of the different winding cylinders

Tension strategy Mould Router Rinner Experimental

value/10−6Simulated

value/10−6Error/% Experimental

value/10−6Simulated

value/10−6Error/% S1 Steel 272 245 −9.93 −276 −259 −6.16 PA6 1367 1210 −11.49 −1332 −1218 −8.56 S2 Steel 127 116 −8.67 −123 −119 −3.25 PA6 1178 1070 −9.17 −1225 −1075 −12.24 S3 Steel 451 405 −10.20 −440 −411 −6.59 PA6 1452 1327 −8.60 −1481 −1335 −9.86 -

[1] 张红卫, 韦健, 黄胜德, 等. 碳纤维缠绕复合材料成型工艺浅析[J]. 石油化工技术与经济, 2021, 37(3):30-34. doi: 10.3969/j.issn.1674-1099.2021.03.009ZHANG Hongwei, WEI Jian, HUANG Shengde, et al. Analysis of forming process of carbon fiber winding composite[J]. Technology & Economics in Petrochemicals,2021,37(3):30-34(in Chinese). doi: 10.3969/j.issn.1674-1099.2021.03.009 [2] AZEEM M, YA H H, ALAM M A, et al. Application of filament winding technology in composite pressure vessels and challenges: A review[J]. Journal of Energy Storage, 2022, 49: 103468. [3] 黄家康, 岳红军, 董永琪. 复合材料成型技术[M]. 北京: 化学工业出版社, 1999.HUANG Jiakang, YUE Hongjun, DONG Yongqi. Composite forming technology[M]. Beijing: Chemical Industry Press, 1999(in Chinese). [4] 阳泽濠, 陶雷, 戚亮亮, 等. 干法缠绕用碳纤维增强环氧树脂预浸纱线的设计及其性能研究[J]. 复合材料科学与工程, 2022(3):87-95. doi: 10.19936/j.cnki.2096-8000.20220328.013YANG Zehao, TAO Lei, QI Liangliang, et al. Design and performance research of carbon fiber reinforced epoxy resin prepreg towfor dry filament winding[J]. Composites Science and Engineering,2022(3):87-95(in Chinese). doi: 10.19936/j.cnki.2096-8000.20220328.013 [5] 王鑫, 张骞, 费阳, 等. 基于干法缠绕的固体火箭发动机壳体补强工艺研究[J]. 复合材料科学与工程, 2021(11):31-38,115. doi: 10.19936/j.cnki.2096-8000.20211128.005WANG Xin, ZHANG Qian, FEI Yang, et al. Research on reinforcement scheme of solid rocket motor case based on prepreg winding[J]. Composites Science and Engineering,2021(11):31-38,115(in Chinese). doi: 10.19936/j.cnki.2096-8000.20211128.005 [6] WEISBERG A, ACEVES S M. The potential of dry winding for rapid, inexpensive manufacture of composite overwrapped pressure vessels[J]. International Journal of Hydrogen Energy,2015,40(11):4207-4211. doi: 10.1016/j.ijhydene.2015.01.130 [7] 余木火, 王昊, 余许多, 等. 干法缠绕用预浸纱制备工艺优化及其性能[J]. 复合材料学报, 2022, 39(12): 5688-5698.YU Muhuo, WANG Hao, YU Xuduo, et al. Preparation process optimization and properties of prepreg yarn for dry winding[J]. Acta Materiae Composite Sinica, 2022, 39(12): 5688-5698(in Chinese). [8] VARGAS-ROJAS E. Prescriptive comprehensive approach for the engineering of products made with composites centered on the manufacturing process and structured design methods: Review study performed on filament winding[J]. Composites Part B: Engineering,2022,243:110093. doi: 10.1016/j.compositesb.2022.110093 [9] 陈亮, 陆晓峰, 朱晓磊, 等. 纤维缠绕张力对玻璃纤维缠绕筒体性能的影响[J]. 化工新型材料, 2021, 49(S1):181-185. doi: 10.19817/j.cnki.issn1006-3536.2021.S.037CHEN Liang, LU Xaiofeng, ZHU Xiaolei, et al. Influence of filament winding tension on property of glass filament winding tube[J]. New Chemical Materials,2021,49(S1):181-185(in Chinese). doi: 10.19817/j.cnki.issn1006-3536.2021.S.037 [10] 康超, 史耀耀, 何晓东, 等. 具有厚壁内衬圆筒的缠绕张力算法[J]. 工程力学, 2016, 33(2):200-208. doi: 10.6052/j.issn.1000-4750.2014.07.0611KANG Chao, SHI Yaoyao, HE Xiaodong, et al. Algorithm of winding tension for cylinder with thick-walledliner[J]. Engineering Mechanics,2016,33(2):200-208(in Chinese). doi: 10.6052/j.issn.1000-4750.2014.07.0611 [11] 苏维国, 张贤彪, 魏锟, 等. 复合材料纤维张力缠绕预应力场动态特性[J]. 复合材料学报, 2019, 36(5):1143-1150. doi: 10.13801/j.cnki.fhclxb.20180821.003SU Weiguo, ZHANG Xianbiao, WEI Kun, et al. Pre-stress dynamic performance during filament winding with tension[J]. Acta Materiae Compositae Sinica,2019,36(5):1143-1150(in Chinese). doi: 10.13801/j.cnki.fhclxb.20180821.003 [12] 郭凯特, 文立华, 校金友, 等. 多角度纤维缠绕复合材料圆筒张力设计[J]. 固体火箭技术, 2020, 43(4):458-467.GUO Kaite, WEN Lihua, XIAO Jinyou, et al. Tension design for composite cylinder with multi-anglelayers[J]. Journal of Solid Rocket Technology,2020,43(4):458-467(in Chinese). [13] ZU L, XU H, ZHANG Q, et al. Investigation on mechanical behavior of composite electromagnetic gun barrel based on the high tension winding[J]. Composite Structures,2020,248:112521. doi: 10.1016/j.compstruct.2020.112521 [14] YIN D M, LI B M, XIAO H C. Analysis for the residual prestress of composite barrel for railgun with tension winding[J]. Defence Technology,2020,16(4):893-899. doi: 10.1016/j.dt.2019.11.008 [15] BŁACHUT A, WOLLMANN T, PANEK M, et al. Influence of fiber tension during filament winding on the mechanical properties of composite pressure vessels[J]. Composite Structures,2023,304(1):116337. [16] ZU L, XU H, ZHANG B, et al. Filament-wound composite sleeves of permanent magnet motor rotors with ultra-high fiber tension[J]. Composite Structures,2018,204:525-535. doi: 10.1016/j.compstruct.2018.07.119 [17] ERSOY N, POTTER K, WISNOMM R, et al. Development of spring-in angle during cure of a thermosetting composite[J]. Composites Part A: Applied Science & Manufacturing,2005,36(12):1700-1706. [18] BOGETTI T A, GILLESPIE J W. Process-induced stress and deformation in thick-section thermoset composite laminates[J]. Journal of Composite Materials,1992,26(5):626-660. doi: 10.1177/002199839202600502 [19] KHOUN L, CENTEA T, HUBERT P. Characterization methodology of thermoset resins for the processing of composite materials—Case study: CYCOM 890 RTM epoxy resin[J]. Journal of Composite Materials,2010,44(11):1397-1415. doi: 10.1177/0021998309353960 [20] HU H X, CAO D F, PAVIER M, et al. Investigation of non-uniform gelation effects on residual stresses of thick laminates based on tailed FBG sensor[J]. Composite Structures,2018,202:1361-1372. doi: 10.1016/j.compstruct.2018.06.074 [21] 雷伟华, 胡海晓, 曹东风, 等. 考虑界面应变传递机制的内埋FBGs环氧树脂固化过程模拟[J]. 复合材料学报, 2023, 40(3): 1807-1817.LEI Weihua, HU Haixiao, CAO Dongfeng, et al. Simulation of curing process of epoxy resin with embedded FBGs considering interfacial strain transfer mechanism[J]. Acta Materiae Compositae Sinica, 2023, 40(3): 1807-1817(in Chinese). -

下载:

下载: