Effect of polysiloxane modified epoxy on high temperature residual strength of glass fiber/phenolic composites

-

摘要: ASTM 3059-18标准将高温残余力学性能纳入树脂基复合材料阻燃指标,突破了复合材料传统化学阻燃概念,标志着结构阻燃概念得到了设计方的重视。本文将自制的聚硅氧烷改性环氧树脂(EP-Si)与酚醛树脂(PF)共混,并辅以无机粉料和玻璃纤维增强体,通过力学性能、热失重(TGA)、锥形量热(CCT)和扫描电镜(SEM)等测试方法,研究了EP-Si和无机粉料对玻璃纤维/酚醛复合材料高温残余强度的影响。实验结果表明:当EP-Si用量为40wt%,复合材料的常温及高温残余弯曲强度分别为384.4 MPa、53.3 MPa,相比PF复合材料提高了78.7%、85.1%;辅以适当比例无机粉料,高温残余弯曲强度最高可达85.1 MPa,相比PF复合材料提升了195.5%。高温处理后含硅PF复合材料厚度膨胀而PF复合材料厚度收缩;含硅PF复合材料的热解残留率更高,表层氧化降解更快,但内层生成CO含量低于PF复合材料;含硅树脂基体的无机热解产物保护了内层树脂和纤维,原位热解无机产物分布更均匀、与无机粉料相容性好及可能存在的共烧结作用进一步隔离了氧气侵入,提高了结构完整性和高温残余强度。

-

关键词:

- 酚醛树脂 /

- 聚硅氧烷改性环氧树脂 /

- 高温残余强度 /

- 氧化降解 /

- 复合材料

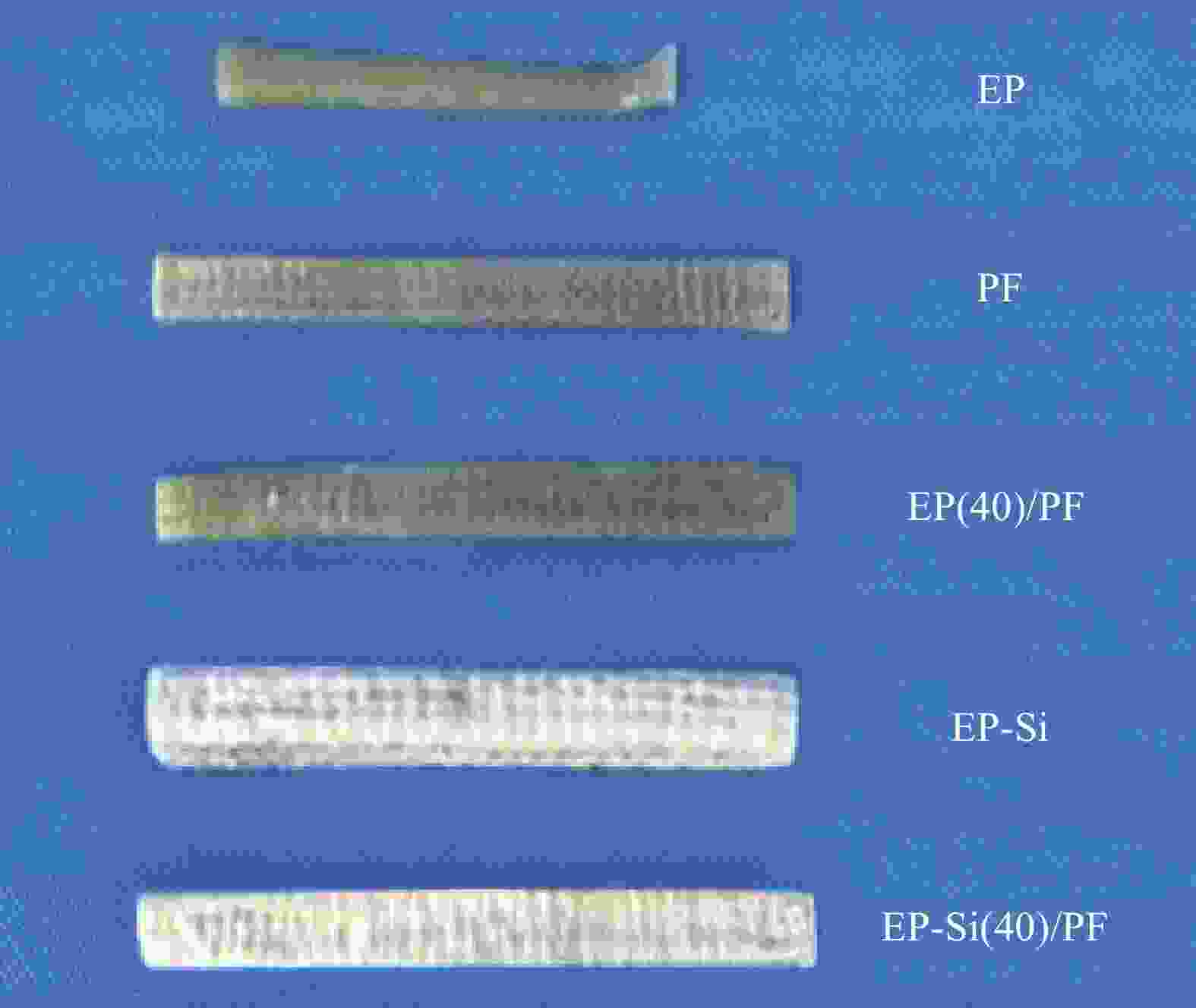

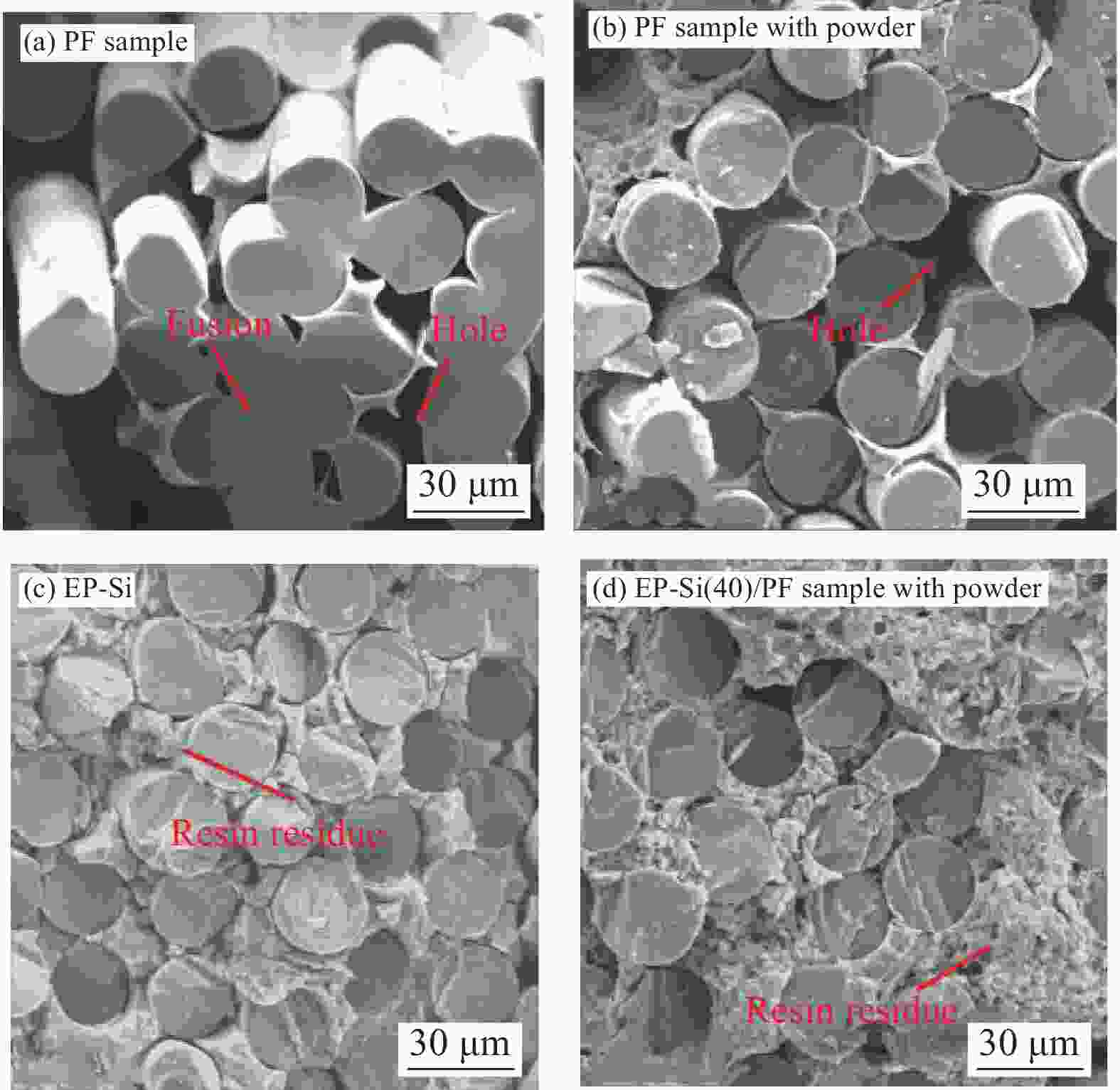

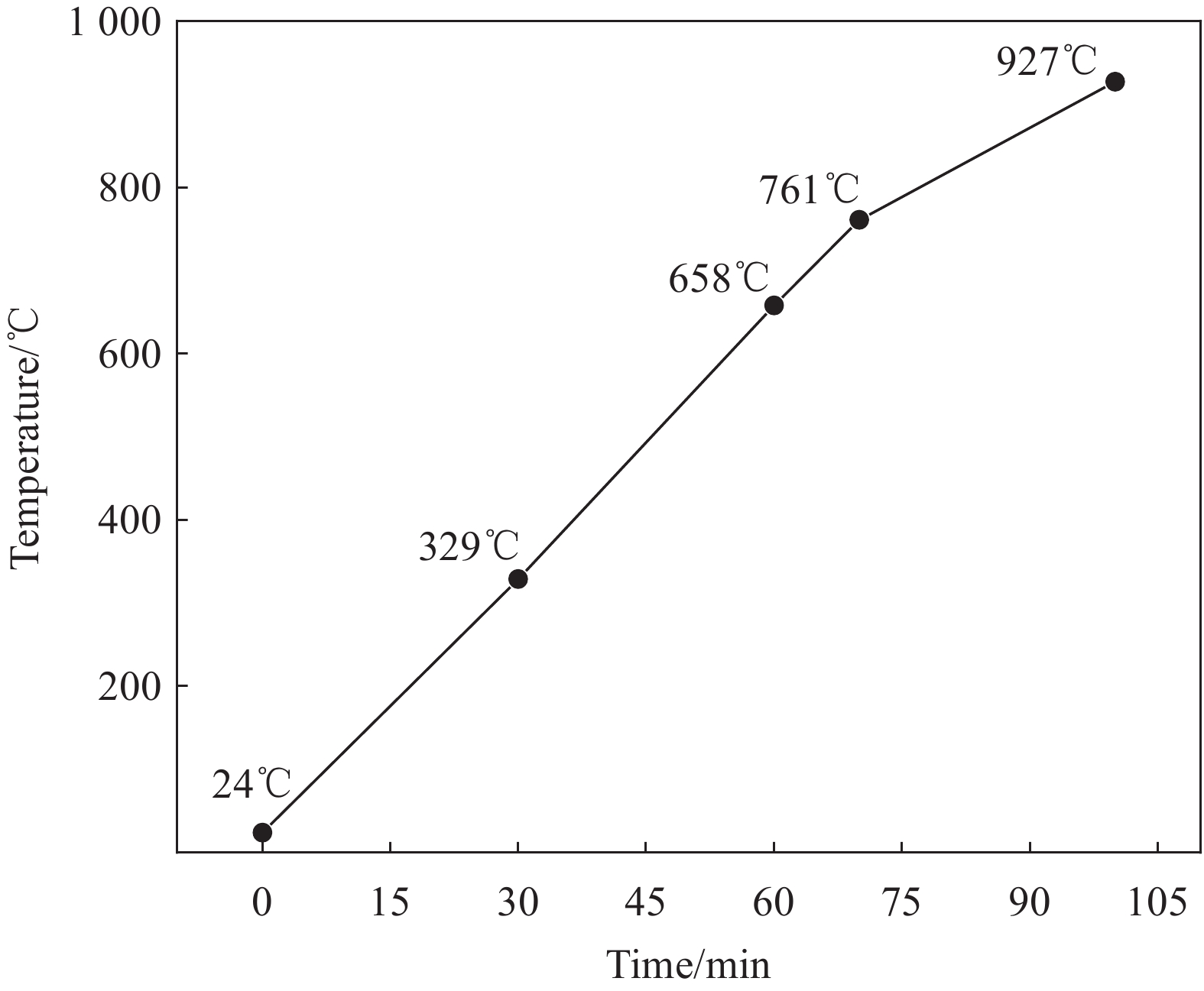

Abstract: The ASTM 3059-18 standard incorporated high temperature residual mechanical properties into the flame retardant index of resin matrix composites, which broke through the traditional chemical flame retardant concept of composites, and marked that the concept of structural flame-retardant has been valued by the designer. In this work, the self-made polysiloxane modified epoxy resin (EP-Si) was blended with phenolic resin (PF), supplemented with inorganic powder and glass fiber reinforcement. The effects of polysiloxane modified epoxy resin and inorganic powder on the high temperature residual strength of glass fiber/phenolic composites were studied by means of mechanical properties, thermogravimetric analysis (TGA), cone calorimeter (CCT) and scanning electron microscope (SEM). The experimental results show that when the amount of EP-Si is 40wt%, the flexural strength and high temperature residual flexural strength of the composite is 384.4 MPa and 53.3 MPa, respectively, which is 78.7% and 85.1% higher than PF composite. With appropriate proportion of inorganic powder, the maximum residual flexural strength can reach 85.1 MPa, which is 195.5% higher than PF composite. After heat-treated, PF composite containing silicon expands along thickness, while PF composite shrinks along thickness. The pyrolysis residual rate of the PF composite containing silicon is higher and oxidative degradation of the surface layer is faster, but the content of CO generated in the inner layer is lower than that of PF composite. The inorganic pyrolysis product of resin matrix containing silicon protects inner layer resin and fibers. The distribution of the in-situ pyrolysis inorganic product is more uniform, the good compatibility with inorganic powder and possible co-sintering effect further isolates the oxygen intrusion, improves structural integrity and high temperature residual strength. -

表 1 EP(40)/PF和EP-Si(x)/PF的命名

Table 1. Naming of EP(40)/PF and EP-Si(x)/PF

Sample Mass ratio of EP

(Total mass of resin

matrix is 100)Mass ratio of EP-Si

(Total mass of resin

matrix is 100)EP(40)/PF 40 — EP-Si(10)/PF — 10 EP-Si(20)/PF — 20 EP-Si(30)/PF — 30 EP-Si(40)/PF — 40 EP-Si(50)/PF — 50 表 2 粉料成分及含量对复合材料弯曲强度的影响

Table 2. Effect of powder composition and content on flexural strength of composite

Kaolin/wt% Flyash

/wt%Silica

/wt%EP-Si

/wt%PF

/wt%Resin residual rate/% Residual flexural

strength/MPaFlexural

strength

/MPa0 0 0 0 100 21.8 28.8 215.1 10 20 0 0 100 30.8 34.4 177.3 10 20 1 0 100 31.5 37.1 150.0 10 20 5 0 100 29.7 36.3 120.8 0 0 0 40 60 23.6 53.3 384.4 10 20 0 40 60 33.0 74.7 340.3 10 20 1 40 60 37.0 85.1 330.8 10 20 5 40 60 36.6 80.6 310.3 表 3 PF、EP(40)/PF和EP-Si(40)/PF树脂热重分析数据

Table 3. Thermogravimetric analysis data of PF, EP(40)/PF and EP-Si(40)/PF resin

Atmosphere Sample T−5%/℃ Tmax1/℃ Tmax2/℃ R800/% Air PF 297.5 — 623.0 1.5 EP(40)/PF 244.8 410.7 591.0 1.4 EP-Si(40)/PF 277.5 412.5 633.5 8.2 Notes: T−5%—Thermal degradation temperature at 5wt% mass loss; Tmax1 and Tmax2—Maximum thermal degradation temperature in the first and second stage; R800—Pyrolysis residue rate at 800℃. 表 4 EP-Si(40)/PF试样断面热解残留物表面元素原子分数

Table 4. Surface element atomic percentages of pyrolysis residue of EP-Si(40)/PF sample cross section

Sample C/at% O/at% Si/at% 1 81.06 18.75 0.19 2 72.69 26.10 1.21 Notes: Sample 1—EP-Si(40)/PF composite at room temperature; Sample 2—EP-Si(40)/PF composite after heat treatment. -

[1] 杨晓光, 贾旭宏, 徐松涛, 等. 酚醛树脂/玻璃纤维型飞机货舱衬板复合材料火灾危险性评价[J]. 消防科学与技术, 2022, 41(3):367-370. doi: 10.3969/j.issn.1009-0029.2022.03.018YANG Xiaoguang, JIA Xuhong, XU Songtao, et al. Fire hazard evaluation of phenolic resin/glass fiber aircraft cargo lining composite material[J]. Fire Science and Technology,2022,41(3):367-370(in Chinese). doi: 10.3969/j.issn.1009-0029.2022.03.018 [2] REN X W, ZHU Y P, WANG F, et al. Flame-retardant properties of polyester fabrics reinforced phenolic resin modified with silazanes composites[J]. Advanced Materials Research,2015,1120-1121(1):519-522. [3] AVILA M B, DEMBSEY N A, DORE C. Effect of resin type and glass content on the reaction to fire characteristics of typical FRP composites[J]. Composites Part A: Applied Science and Manufacturing, 2008, 39(9): 1503-1511. [4] ASTM Committee. Standard spec-ification for fiber-reinforced polymer (FRP) gratings used in marine construction and shipbuilding: ASTM F3059-18[S]. West Conshehoken: ASTM, 2018. [5] 华幼卿, 金日光. 高分子物理[M]. 北京: 化学工业出版社, 2013.HUA Youqing, JIN Riguang. Polymer physics[M]. Beijing: Chemical Industry Press, 2013(in Chinese). [6] ZHANG X P, ZHANG L X, ZHANG D X, et al. Mechanism of the temperature-responsive material regulating porous morphology on epoxy phenolic novolac resin microcapsule surface[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2020,593:124581. [7] KNOP A, PILATO L A. Phenolic resins: Chemistry, applications and performance[M]. Berlin: Springer Science & Business Media, 2013: 139-147. [8] 严侃, 黄朋. 复合材料在海洋工程中的应用[J]. 玻璃钢/复合材料, 2017(12):99-104. doi: 10.3969/j.issn.1003-0999.2017.12.018YAN Kan, HUANG Peng. Application of composite materials in marine engineering[J]. Fiber Reinforced Plastics/Composites,2017(12):99-104(in Chinese). doi: 10.3969/j.issn.1003-0999.2017.12.018 [9] SUTHERLAND L S. A review of impact testing on marine composite materials: Part I-Marine impacts on marine composites[J]. Composite Structures,2018,188:197-208. doi: 10.1016/j.compstruct.2017.12.073 [10] 石锦坤, 刘辉, 张西伟, 等. 复合材料水下防护结构在海洋油气开发的应用[J]. 复合材料科学与工程, 2021(12):78-81,128. doi: 10.19936/j.cnki.2096-8000.20211228.012SHI Jinkun, LIU Hui, ZHANG Xiwei, et al. Application of composite materials protector in the subsea of offshore oil[J]. Composites Science and Engineering,2021(12):78-81,128(in Chinese). doi: 10.19936/j.cnki.2096-8000.20211228.012 [11] GU P, ASARO R J. Structural buckling of polymer matrix composites due to reduced stiffness from fire damage[J]. Composite Structures,2005,69(1):65-75. [12] MOURITZ A P, MATHYS Z. Post-fire mechanical properties of marine polymer composites[J]. Composite Structures,1999,47(1):643-653. [13] GARDINER C P, MATHYS Z, MOURITZ A P. Post-fire structural properties of burnt GRP plates[J]. Marine Structures,2004,17(1):53-73. doi: 10.1016/j.marstruc.2004.03.003 [14] SHI S B, LIANG J, GU L X, et al. Degradation in compres-sive strength of silica/phenolic composites subjected to thermal and mechanical loading[J]. Journal of Reinforced Plastics and Composites,2016,35(7):579-588. doi: 10.1177/0731684415624769 [15] GIBSON A G, HUMPHREY J K, DI-MODICA P, et al. Post-fire integrity of composite gratings for offshore platforms[J]. Journal of Reinforced Plastics and Compo-sites,2014,33(6):543-555. doi: 10.1177/0731684413495933 [16] MOURITZ A P, MATHYS Z. Mechanical properties of fire-damaged glass-reinforced phenolic composites[J]. Fire and Materials,2000,24(2):67-75. doi: 10.1002/1099-1018(200003/04)24:2<67::AID-FAM720>3.0.CO;2-0 [17] RALLINI M, TORRE L, KENNY J M, et al. Effect of boron carbide nanoparticles on the thermal stability of carbon/phenolic composites[J]. Polymer Composites,2017,38(9):1819-1827. doi: 10.1002/pc.23752 [18] RALLINI M, WU H, NATALI M, et al. Nanostructured phenolic matrices: Effect of different nanofillers on the thermal degradation properties and reaction to fire of a resol[J]. Fire and Materials,2017,41(7):817-825. doi: 10.1002/fam.2425 [19] NAJAFABADIE P, KHANEGHAHI M H, AMIRI H A, et al. Experimental investigation and probabilistic models for residual mechanical properties of GFRP pultruded profiles exposed to elevated temperatures[J]. Composite Structures,2019,211:610-629. doi: 10.1016/j.compstruct.2018.12.032 [20] KATSOULIS C, KANDOLA B K, MYLER P, et al. Post-fire flexural performance of epoxy-nanocomposite matrix glass fibre composites containing conventional flame retardants[J]. Composites Part A: Applied Science and Manufacturing,2012,43(8):1389-1399. [21] DING J, HUANG Z, LUO H, et al. Preparation and thermal stability of boron-containing phenolic resin/microcrystalline muscovite composites[J]. Materials Research Innovations,2015,19(S8):440-444. [22] 刘强, 赵玉, 张兴刚, 等. 船舶与海洋工程用高耐火复合材料格栅研究[J]. 材料开发与应用, 2022, 37(3):45-51.LIU Qiang, ZHAO Yu, ZHANG Xinggang, et al. Development of high fire resistant composites grating for ship and ocean engineering[J]. Development and Application of Materials,2022,37(3):45-51(in Chinese). [23] 徐博, 丁杰, 王兵, 等. AlB2对高硅氧纤维/可瓷化酚醛树脂复合材料及其裂解产物力学性能的影响[J]. 复合材料学报, 2021, 38(1):129-136.XU Bo, DING Jie, WANG Bing, et al. Effects of AlB2 on mechanical properties of high silica fiber/ceramicizable phenolic resin composites and their pyrolysis products[J]. Acta Materiae Compositae Sinica,2021,38(1):129-136(in Chinese). [24] 李志强, 江艳艳, 冀运东, 等. 聚硅氧烷改性环氧树脂及其热解残留物研究[J]. 热固性树脂, 2022, 37(4):1-8. doi: 10.13650/j.cnki.rgxsz.2022.04.006LI Zhiqiang, JIANG Yanyan, JI Yundong, et al. Study on polysiloxane modified epoxy resin and its pyrolysis residue[J]. Thermosetting Resin,2022,37(4):1-8(in Chinese). doi: 10.13650/j.cnki.rgxsz.2022.04.006 [25] 文钦, 刘博伟, 冀运东. 端羟基聚二甲基硅氧烷改性环氧树脂研究[J]. 热固性树脂, 2020, 35(1):25-28. doi: 10.13650/j.cnki.rgxsz.2020.01.005WEN Qin, LIU Bowei, JI Yundong. Study on the hydroxylterminated polydimethylsiloxane modified epoxy resins[J]. Thermosetting Resin,2020,35(1):25-28(in Chinese). doi: 10.13650/j.cnki.rgxsz.2020.01.005 [26] 冀运东, 江艳艳, 曹东风, 等. 聚硅氧烷改性环氧/酚醛共混物热氧降解残留物的结构及组分演变[J]. 高分子材料科学与工程, 2022, 38(10):90-97.JI Yundong, JIANG Yanyan, CAO Dongfeng, et al. Structure and composition evolution of polysiloxane modified epoxy/phenolic blends under the condition of hot oxygen[J]. Polymer Materials Science and Engineering,2022,38(10):90-97(in Chinese). [27] 中国国家标准化管理委员会. 玻璃纤维增强塑料树脂含量试验方法: GB/T 2577—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People's Republic of China. Test method for resin content of glass fiber reinforced plastics: GB/T 2577—2005[S]. Beijing: China Standards Press, 2005(in Chinese). [28] 中国国家标准化管理委员会. 纤维增强塑料弯曲性能试验方法: GB/T 1449—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People's Republic of China. Fiber-reinforced plastic composites—Determination of flexural properties: GB/T 1449—2005[S]. Beijing: China Standards Press, 2005(in Chinese). [29] International Organization for Standarization. Reaction-to-fire tests-Heat release, smoke production and mass loss rate-Part 1: Heat release rate (cone calorimeter method) and smoke production rate (dynamic measurement) ISO 5660-1: 2015[S]. Geneva: International Organization for Standarization, 2015. [30] PENG Y L, ZENG L. Study on the phenolic-epoxy resin system[J]. Advanced Materials Research,2015,1088:439-443. doi: 10.4028/www.scientific.net/AMR.1088.439 [31] VORONKOV M G, YUZHELEVSKII Y A, MILESHKEVICH V P. The siloxane bond and its influence on the structure and physical properties of organosilicon compounds[J]. Russian Chemical Reviews,1975,44(4):355-372. doi: 10.1070/RC1975v044n04ABEH002273 [32] NATALI M, KENNY J M, TORRE L. Science and technology of polymeric ablative materials for thermal protection systems and propulsion devices: A review[J]. Progress in Materials Science,2016,84:192-275. doi: 10.1016/j.pmatsci.2016.08.003 [33] LI S, HAN Y, CHEN F H, et al. The effect of structure on thermal stability and anti-oxidation mechanism of silicone modified phenolic resin[J]. Polymer Degradation and Stability,2016,124:68-76. doi: 10.1016/j.polymdegradstab.2015.12.010 [34] TRICK K A, SALIBA T E. Mechanisms of the pyrolysis of phenolic resin in a carbon/phenolic composite[J]. Carbon,1995,33(11):1509-1515. doi: 10.1016/0008-6223(95)00092-R [35] QIAN X D, SONG L, HU Y, et al. Thermal degradation and flammability of novel organic/inorganic epoxy hybrids containing organophosphorus-modified oligosiloxane[J]. Thermochimica Acta,2013,552:87-97. doi: 10.1016/j.tca.2012.11.010 [36] JIA P, LIU H C, LIU Q, et al. Thermal degradation mechanism and flame retardancy of MQ silicone/epoxy resin composites[J]. Polymer Degradation and Stability,2016,134:144-150. doi: 10.1016/j.polymdegradstab.2016.09.029 [37] MCKEON T. Ablative degradation of a silicone foam[J]. Journal of Macromolecular Science: Part A-Chemistry,1969,3(4):585-612. doi: 10.1080/10601326908053831 [38] WU C S, LIU Y L, CHIU Y S. Epoxy resins possessing flame retardant elements from silicon incorporated epoxy compounds cured with phosphorus or nitrogen containing curing agents[J]. Polymer,2002,43(15):4277-4284. doi: 10.1016/S0032-3861(02)00234-3 -

下载:

下载: