Effect of high temperature on mechanical properties of CFRP plate-steel plate lapping interface based on developed adhesive

-

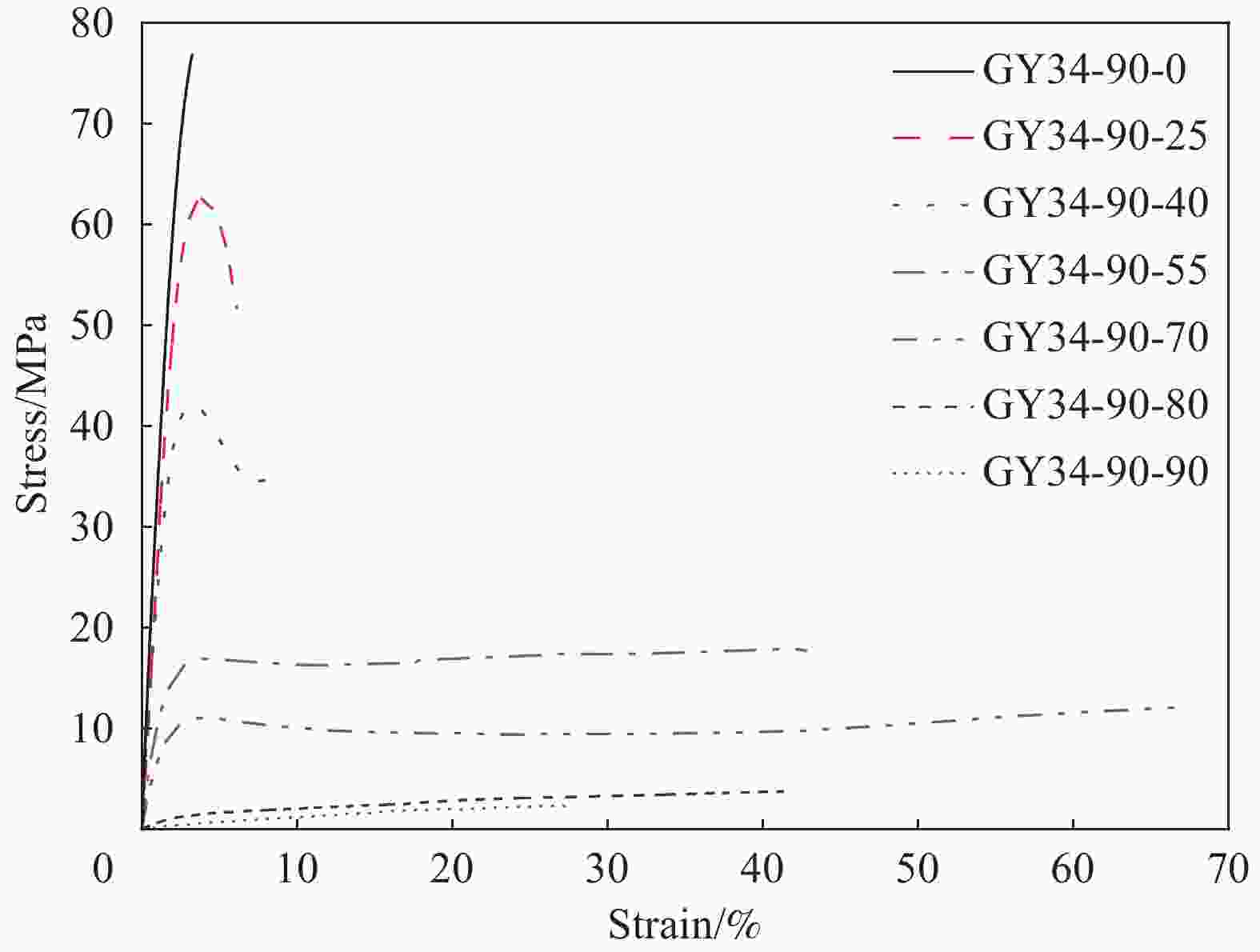

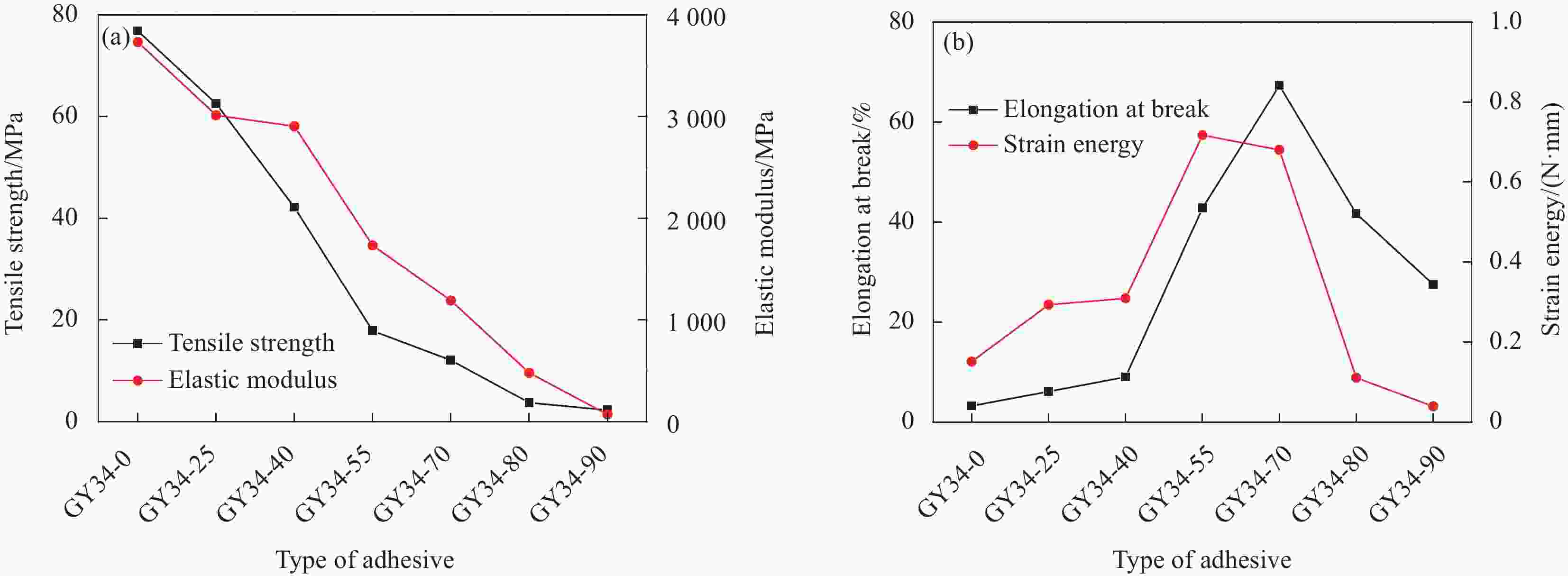

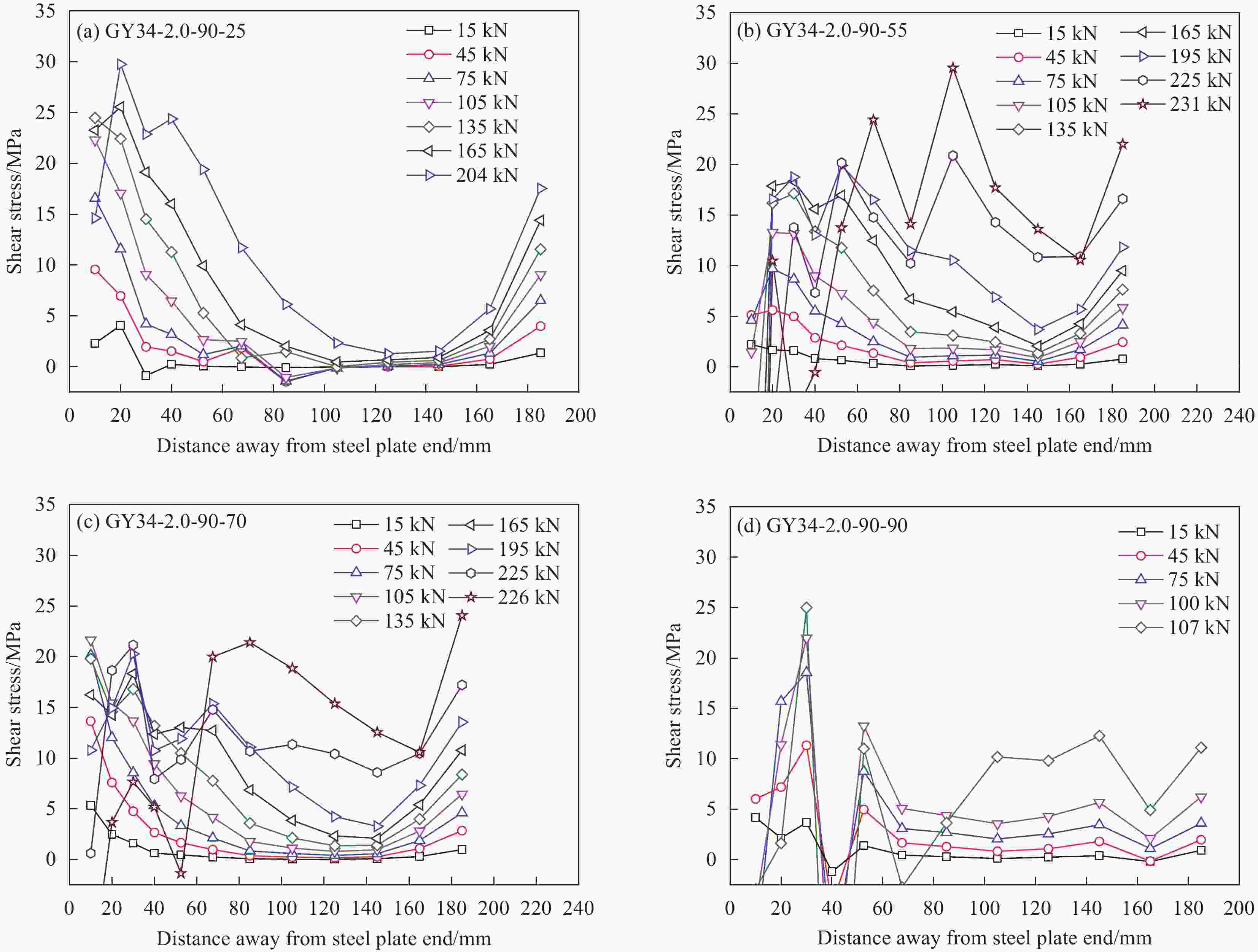

摘要: 针对夏季钢桥面温度高达60℃左右,而温度对碳纤维增强复合材料(CFRP)加固钢结构黏结界面力学性能影响显著的现象。基于研制的高性能胶黏剂GY34,制作了21个胶黏剂拉伸试件、15个CFRP板-钢板双搭接试件,进行了不同温度下的准静态拉伸试验、剪切拉伸试验,揭示了高温(≤90℃)对胶黏剂力学性能及CFRP板-钢板搭接界面力学性能的影响规律,建立了考虑温度影响的搭接界面极限承载力预测模型,得到了黏结-滑移关系模型随温度的变化趋势。研究结果表明:随温度的升高,胶黏剂GY34拉伸强度及弹性模量逐渐降低;断裂伸长率及应变能先增大后减小,在温度接近胶黏剂的玻璃化转变温度Tg,S时达到峰值。随温度升高,基于研制胶黏剂的CFRP-钢搭接试件的极限承载力先增大后减小,破坏模式由CFRP板层离逐渐过渡为钢-胶层界面破坏。小于胶黏剂玻璃化转变温度Tg,S的高温下,荷载-位移曲线具有明显的延性发展阶段。随温度升高搭接试件的应变分布更加均匀,剪应力传递范围及有效黏结长度显著增加。基于研制胶黏剂的搭接试件的黏结-滑移关系的形状在不同温度下均为三线性梯形。高温环境不会改变黏结-滑移关系模型的形状,会导致界面剪应力峰值及刚度逐渐降低,相对滑移与界面断裂能先增加后减小。

-

关键词:

- 纳米SiO2环氧胶黏剂 /

- CFRP-钢搭接接头 /

- 破坏模式 /

- 黏结-滑移关系 /

- 抗剪承载力

Abstract: According to the phenomenon that the temperature of the steel bridge deck reached about 60℃ in summer, and significantly affect the mechanical properties of the bonding interface of carbon fiber reinforced composite (CFRP)-reinforced steel structure, a total of 21 adhesive tensile test pieces and 15 CFRP plate-steel double-lap joints were fabricated, and quasi-static tensile tests and shear tests at different ambient temperatures were performed, based on developed high-performance adhesive GY34. The influence of high temperature (≤90℃) on the mechanical properties of adhesive and the mechanical properties of bonded CFRP plate-steel lap joints was obtained. A prediction model for the bearing capacity of the lap joint interface considering the effect of tempera-ture was established, and the trend of the bond-slip relationship model with the increasing of the temperature was obtained. The results show that the tensile strength and elastic modulus of the adhesive GY34 gradually decreases, and the elongation at break and the strain energy first increase and then decrease with the increasing of tempera-ture, and reaching a peak when the temperature is close to the glass transition temperature Tg,S of the adhesive. With the increase of temperature, the bearing capacity of CFRP-steel lap joints based on the developed adhesive first increases and then decreases, and the failure mode gradually transits from CFRP plate delamination to steel adhesive interface failure. The load-displacement curve has a significant ductile development stage at high tempera-ture below the Tg,S of the adhesive. With the increase of temperature, the strain distribution of lap joints becomes more uniform, and the shear stress transfer range and the effective bonding length increase significantly. The shapes of bond-slip relationship model of lap joints based on the developed adhesives are trilinear trapezoids at different temperatures. The shape of the bond-slip relationship model remains constant at high temperature, but the maximum shear stress and stiffness gradually decrease, and the relative slip and interface fracture energy first increase and then decrease with the increasing of temperature.-

Key words:

- nano-SiO2 epoxy adhesive /

- CFRP-steel lap joint /

- failure mode /

- bond-slip relationship /

- shear capacity

-

表 1 研制胶黏剂的配方

Table 1. Formulas for developing adhesives

Name Type and amount of curing agent/g Epoxy resin/g Nano-SiO2/g GY34 Amine 105(11.67)+

D230(23.33)120 0.6 表 2 碳纤维增强复合材料(CFRP)板及钢板材料参数

Table 2. Material properties of carbon fiber reinforced composite (CFRP) plate and steel plate

Parameter of material CFRP 2.0 laminate Steel plate Thickness/mm 2.0 12 Width/mm 50 50 Tensile strength/MPa 2433 514 Elasticity modulus/GPa 162.8 206 Elongation at break/% 1.62 – 表 3 CFRP-钢双搭接接头拉伸试验结果

Table 3. Tensile test results of CFRP-steel double lap joints

Number of specimen Limit displacement/mm Ultimate load/kN Average bond strength/MPa Failure mode $ {D}_{\mathrm{m}\mathrm{a}\mathrm{x}} $ Average $ {P}_{\mathrm{m}\mathrm{a}\mathrm{x}} $ Average $ {\stackrel{-}{p}}_{\mathrm{m}\mathrm{a}\mathrm{x}} $ Average GY34-2.0-90-25-1 4.42 204.20 10.21 d GY34-2.0-90-25-2 4.69 4.01 208.99 205.10 10.45 10.26 d GY34-2.0-90-25-3 4.11 202.11 10.11 d GY34-2.0-90-55-1 7.62 231.51 11.58 d GY34-2.0-90-55-2 7.65 7.61 226.80 228.48 11.81 11.63 d GY34-2.0-90-55-3 7.55 227.13 11.51 d GY34-2.0-90-70-1 6.71 225.40 11.27 d/b GY34-2.0-90-70-2 7.46 7.06 232.59 229.15 11.63 11.46 d/b GY34-2.0-90-70-3 7.02 229.46 11.47 d/b GY34-2.0-90-80-1 5.20 199.48 9.97 b/a GY34-2.0-90-80-2 5.24 5.18 202.15 199.14 10.11 9.96 b/a GY34-2.0-90-80-3 5.11 195.79 9.79 b GY34-2.0-90-90-1 2.86 110.27 5.51 b GY34-2.0-90-90-2 2.56 2.70 100.31 106.37 5.02 5.32 b GY34-2.0-90-90-3 2.67 108.54 5.43 b Notes: Specimen number GY34-2.0-90-25-1: GY34 stands for the type of adhesive, “2.0” indicates the thickness of CFRP plate, “90” indicates the curing temperature of specimen, “25” indicates the service temperature of the specimen, “1” indicates the serial number of specimens in each group; Dmax—Limit displacement. It represents variation of the distance between A1 and B1 points when specimens failed, as shown in Fig.3; Pmax—Ultimate load; $ {\stackrel{-}{p}}_{\mathrm{m}\mathrm{a}\mathrm{x}} $—Average bond strength; Failure mode: a—CFRP and adhesive debonding failure; b—Steel and adhesive debonding failure; d—CFRP delamination. 表 4 CFRP-钢界面黏结-滑移简化模型相关参数

Table 4. Relevant parameters of bond-slip simplified model of CFRP-steel interface

Name $ {\tau }_{\mathrm{f}} $/MPa $ {\delta }_{1} $/mm $ {\delta }_{2} $/mm $ {\delta }_{\mathrm{f}} $/mm $ {K}_{\mathrm{E}} $/(MPa·mm−1) $ {K}_{\mathrm{S}} $/(MPa·mm−1) $ {G}_{\mathrm{f}} $/(MPa·mm) GY34-2.0-90-25 24.58 0.211 0.401 0.518 116.49 210.09 8.701 GY34-2.0-90-55 19.06 0.202 0.549 0.641 94.36 207.17 9.416 GY34-2.0-90-70 16.36 0.178 0.621 0.758 91.91 119.42 9.824 GY34-2.0-90-80 12.16 0.141 0.507 0.613 86.24 114.72 5.952 GY34-2.0-90-90 3.63 0.086 0.185 0.230 42.21 80.67 0.597 Notes: τf—Peak of shear stress; $ {\delta }_{1} $−Maximum elastic slip; $ {\delta }_{2} $−Maximum plastic slip; δf—Limit of slip; KE—Slope of ascending section; Ks—Slope of descent section; Gf—Interface fracture energy. -

[1] 李传习, 李游, 陈卓异, 等. 钢箱梁横隔板疲劳开裂原因及补强细节研究[J]. 中国公路学报, 2017, 30(3):121-131. doi: 10.3969/j.issn.1001-7372.2017.03.013LI Chuanxi, LI You, CHEN Zhuoyi, et al. Fatigue cracking reason and detail dimension of reinforcement about transverse diaphragm of steel box girder[J]. China Journal of Highway and Transport,2017,30(3):121-131(in Chinese). doi: 10.3969/j.issn.1001-7372.2017.03.013 [2] 李游, 李传习, 陈卓异, 等. 基于监测数据的钢箱梁U肋细节疲劳可靠性分析[J]. 工程力学, 2020, 37(2): 111-123.LI You, LI Chuanxi, CHEN Zhuoyi, et al. Fatigue reliability analysis of U-rib detail of steel box girder based on monitoring data[J]. Engineering Mechanics, 2020, 37(2): 111-123. [3] 谢桂华, 孙悦, 严鹏, 等. 湿/热条件下的CFRP筋粘结型锚具性能研究[J]. 材料导报, 2020, 34(22):22178-22184. doi: 10.11896/cldb.19100008XIE Guihua, SUN Yue, YAN Peng, et al. Performance of bonded anchorage for CFRP tendons affected by tempera-ture or moisture[J]. Materials Reports,2020,34(22):22178-22184(in Chinese). doi: 10.11896/cldb.19100008 [4] LI Y, MA X W, LI H Y, et al. Effect of moisture-heat coupling on mechanical behavior of nano-SiO2 adhesives and CFRP-steel lap joints[J]. Thin-Walled Structures,2023,183:110391. doi: 10.1016/j.tws.2022.110391 [5] 秦国锋, 糜沛纹, 那景新. 胶粘剂和CFRP吸湿对复合材料粘接接头失效的影响[J]. 交通运输工程学报, 2021, 21(5):149-160.QIN Guofeng, MI Peiwen, NA Jingxin. Effect of moisture absorption of adhesive and CFRP on the failure of compo-site material adhesive joints[J]. Journal of Traffic and Transportation Engineering,2021,21(5):149-160(in Chinese). [6] 刘思琴, 李传习, 李涛, 等. 基于概率分析的钢箱梁竖向温度梯度模式[J]. 交通科学与工程, 2018, 34(2):45-51. doi: 10.3969/j.issn.1674-599X.2018.02.009LIU Siqin, LI Chuanxi, LI Tao, et al. Study on temperature gradient of steel box girder without pavement based on probability analysis[J]. Journal of Transport Science and Engineering,2018,34(2):45-51(in Chinese). doi: 10.3969/j.issn.1674-599X.2018.02.009 [7] 李传习, 曹先慧, 柯璐, 等. 高温对结构加固用环氧黏结剂力学性能的影响[J]. 建筑材料学报, 2020, 23(3):642-649.LI Chuanxi, CAO Xianhui, KE Lu, et al. Effects of high temperatures on mechanical properties of epoxy adhesives for structural strengthening[J]. Journal of Building Materials,2020,23(3):642-649(in Chinese). [8] 李游, 李传习, 郑辉, 等. 固化剂混掺对高温下CFRP板-钢板界面黏结性能的影响[J]. 复合材料学报, 2021, 38(12):4073-4089. doi: 10.13801/j.cnki.fhclxb.20210311.005LI You, LI Chuanxi, ZHENG Hui, et al. Effect of curing agent mixing on interfacial bond behavior of glued CFRP plate-steel plate at elevated temperature[J]. Acta Materiae Compositae Sinica,2021,38(12):4073-4089(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210311.005 [9] LI S, ZHU T, LU Y Y, et al. Effect of temperature variation on bond characteristics between CFRP and steel plate[J]. International Journal of Polymer Science,2016,2016:1-8. [10] DAI J G, GAO W Y, TENG J G. Bond-slip model for FRP laminates externally bonded to concrete at elevated temperature[J]. Journal of Composites for Construction,2013,17(2):217-228. [11] BISCAIA H C, CHASTRE C, BORBA I S, et al. Experimental evaluation of bonding between CFRP laminates and different structural materials[J]. Journal of Composites for Construction,2016,20(3):04015070. [12] XIA S, TENG J G. Behaviour of FRP-to-steel bonded joints[C]//Proceedings of the International Symposium on Bond Behaviour of FRP in Structures (BBFS 2005). 2005: 419-426. [13] WANG H T, WU G. Bond-slip models for CFRP plates externally bonded to steel substrates[J]. Composite Structures,2018,184:1204-1214. doi: 10.1016/j.compstruct.2017.10.033 [14] FERNANDO D, YU T, TENG J G. Behavior of CFRP lami-nates bonded to a steel substrate using a ductile adhesive[J]. Journal of Composites for Construction,2014,18(2):04013040. [15] YANG Y M, BISCAIA H, CHASTRE C, et al. Bond characteristics of CFRP-to-steel joints[J]. Journal of Constructional Steel Research,2017,138:401-419. doi: 10.1016/j.jcsr.2017.08.001 [16] DEHGHANI E, DANESHJOO F, AGHAKOUCHAK A A, et al. A new bond-slip model for adhesive in CFRP-steel compo-site systems[J]. Engineering Structures,2012,34:447-454. doi: 10.1016/j.engstruct.2011.08.037 [17] NGUYEN T C, BAI Y, ZHAO X L, et al. Mechanical characterization of steel/CFRP double strap joints at elevated temperatures[J]. Composite Structures,2011,93(6):1604-1612. doi: 10.1016/j.compstruct.2011.01.010 [18] YAO M X, ZHU D J, YAO Y M, et al. Experimental study on basalt FRP/steel single-lap joints under different loading rates and temperatures[J]. Composite Structures,2016,145:68-79. doi: 10.1016/j.compstruct.2016.02.061 [19] AL-SHAWAF A, AL-MAHAIDI R, ZHAO X L, et al. Effect of elevated temperature on bond behaviour of high modulus CFRP/steel double-strap joints[J]. Australian Journal of Structural Engineering,2009,10(1):63-74. doi: 10.1080/13287982.2009.11465033 [20] LIU H B, ZHAO X L, BAI Y, et al. The effect of elevated temperature on the bond between high modulus carbon fibre-reinforced polymer sheet and steel[J]. Australian Journal of Structural Engineering,2014,15(4):355-366. [21] KORAYEM A H, CHEN S J, ZHANG Q H, et al. Failure of CFRP-to-steel double strap joint bonded using carbon nanotubes modified epoxy adhesive at moderately elevated temperatures[J]. Composites Part B: Engineering,2016,94:95-101. doi: 10.1016/j.compositesb.2016.03.042 [22] ZHOU H, URGEL J M, EMBERLEY R, et al. Behaviour of the FRP-to-steel bonded joints under elevated temperature[C]//APFIS2017-6th Asia-Pacific Conference on FRP in Structures. 2017:1-6. [23] LI Y, LI C X, HE J, et al. Effect of functionalized nano-SiO2 addition on bond behavior of adhesively bonded CFRP-steel double-lap joint[J]. Construction and Building Materials,2020,244:118400. doi: 10.1016/j.conbuildmat.2020.118400 [24] 李传习, 李游, 贺君, 等. 固化剂对室温胶黏CFRP板/钢板界面性能的影响[J]. 建筑材料学报, 2021, 24(2):339-347. doi: 10.3969/j.issn.1007-9629.2021.02.016LI Chuanxi, LI You, HE Jun, et al. Effect of curing agent on interfacial performance of adhesively bonded CFRP lami-nate/steel plate cured at room temperature[J]. Journal of Building Materials,2021,24(2):339-347(in Chinese). doi: 10.3969/j.issn.1007-9629.2021.02.016 [25] American Society for Testing and Materials. Standard test method for tensile properties for plastics: ASTM D638−10[S]. West Conshohocken: ASTM International, 2010. [26] American Society for Testing and Materials. Standard test method for strength properties of double lap shear adhesive joints by tension loading: ASTM D3528−96[S]. West Conshohocken: ASTM, 2008. [27] SOUSA J M, CORREIA J R, CABRAL-FONSECAS. Durability of an epoxy adhesive used in civil structural applications[J]. Construction and Building Materials, 2018, 161: 618-633. [28] E. ISO. Plastics—Determination of dynamic mechanical properties. Part 1: General principles: 6721-1-2019[S]. Switzerland: ISO, 2019. [29] ASTM. Standard test method for assignment of the glass transition temperature by dynamic mechanical analysis: E1640[S]. West Conshohocken: ASTM, 2013. [30] NAKABA K, KANAKUBO T, FURUTA T, et al. Bond behavior between fiber-reinforced polymer laminates and concrete[J]. Structural Journal,2001,98(3):359-367. [31] HASSEIN ABED G. Effects of temperature on the adhesive bonding in steel beams reinforced with CFRP composites[D]. Southampton: University of Southampton, 2012. -

下载:

下载: