| [1] |

HABOUB A, BALE H A, NASIATKA J R, et al. Tensile testing of materials at high temperatures above 1700℃ with in situ synchrotron X-ray micro-tomography[J]. Review of Scientific Instruments,2014,85(8):1-13.

|

| [2] |

PADTURE N P. Advanced structural ceramics in aerospace propulsion[J]. Nature Materials,2016,15(8):804-809. doi: 10.1038/nmat4687

|

| [3] |

DHANASEKAR S, GANESAN A T, RANI T L, et al. A comprehensive study of ceramic matrix composites for space applications[J]. Advances in Materials Science and Engineering,2022,2022(4):6160591.

|

| [4] |

陈代荣, 韩伟健, 李思维, 等. 连续陶瓷纤维的制备、结构、性能和应用: 研究现状及发展方向[J]. 现代技术陶瓷, 2018, 39(3):151-222.CHEN Dairong, HAN Weijian, LI Siwei, et al. Fabrication, microstructure, properties and applications of continuous ceramic fibers: A review of present status and further directions[J]. Advanced Ceramics,2018,39(3):151-222(in Chinese).

|

| [5] |

FAN D, HUANG J, ZHAO X, et al. Joining of Cf/SiC composite to Ti6Al4V with (Ti-Zr-Cu-Ni) +Ti filler based on in-situ alloying concept[J]. Ceramics International,2017,43(5):4151-4158. doi: 10.1016/j.ceramint.2016.12.030

|

| [6] |

KIM W J, KIM D, PARK J Y. Fabrication and material issues for the application of SiC composition to LWR fuel cladding[J]. Nuclear Engineering and Technology,2013,45(4):565-572. doi: 10.5516/NET.07.2012.084

|

| [7] |

SALEH M N, WANG Y, YUDHANTO A, et al. Investigating the potential of using off-axis 3D woven composites in composite joints' applications[J]. Applied Composite Materials,2017,24(2):377-396. doi: 10.1007/s10443-016-9529-9

|

| [8] |

CHAN K F, ZAID M H M, MAMAT M S, et al. Recent developments in carbon nanotubes-reinforced ceramic matrix composites: A review on dispersion and densification techniques[J]. Crystals,2021,11(5):457. doi: 10.3390/cryst11050457

|

| [9] |

ŽIVIĆ F, BUSARAC N, MILENKOVIC S, et al. General overview and applications of ceramic matrix composites (CMCs)[J]. Encyclopedia of Materials: Composites,2021,2:3-19.

|

| [10] |

BANSAL N P, LAMON J. Ceramic matrix composites: Materials, modeling and technology[R]. Washington: NASA, 2014: 465-519.

|

| [11] |

DOGIGLI M, SABATH D, KEMPER J P. CMC components for future RLVs[C]//The 4th European Workshop on Hot Structures and Thermal Protection Systems for Space Vehicles. Palermo, 2003, 521: 91-97.

|

| [12] |

AMUNDSEN R, LEONARD C, BRUCE W. Hyper-X hot structures comparison of thermal analysis and flight data[R]. Italy: Academic Press Inc, 2004.

|

| [13] |

BÖHRK H, BEYERMANN U. Secure tightening of a CMC fastener for the heat shield of re-entry vehicles[J]. Composite Structures,2010,92(1):107-112. doi: 10.1016/j.compstruct.2009.07.002

|

| [14] |

DOGIGLI M. CMC components for reusable space vehicles-improvement of lifetime and reliability[C]//International Astronautical Congress of the International Astronautical Federation. Bremen, 2003.

|

| [15] |

DOGIGLI M, HANDRICK K, BICKEL M, et al. CMC key technologies-background, status, present and future applications[C]//The 4th European Workshop on Hot Structures and Thermal Protection Systems for Space Vehicles. Palermo, 2003, 521: 79-90.

|

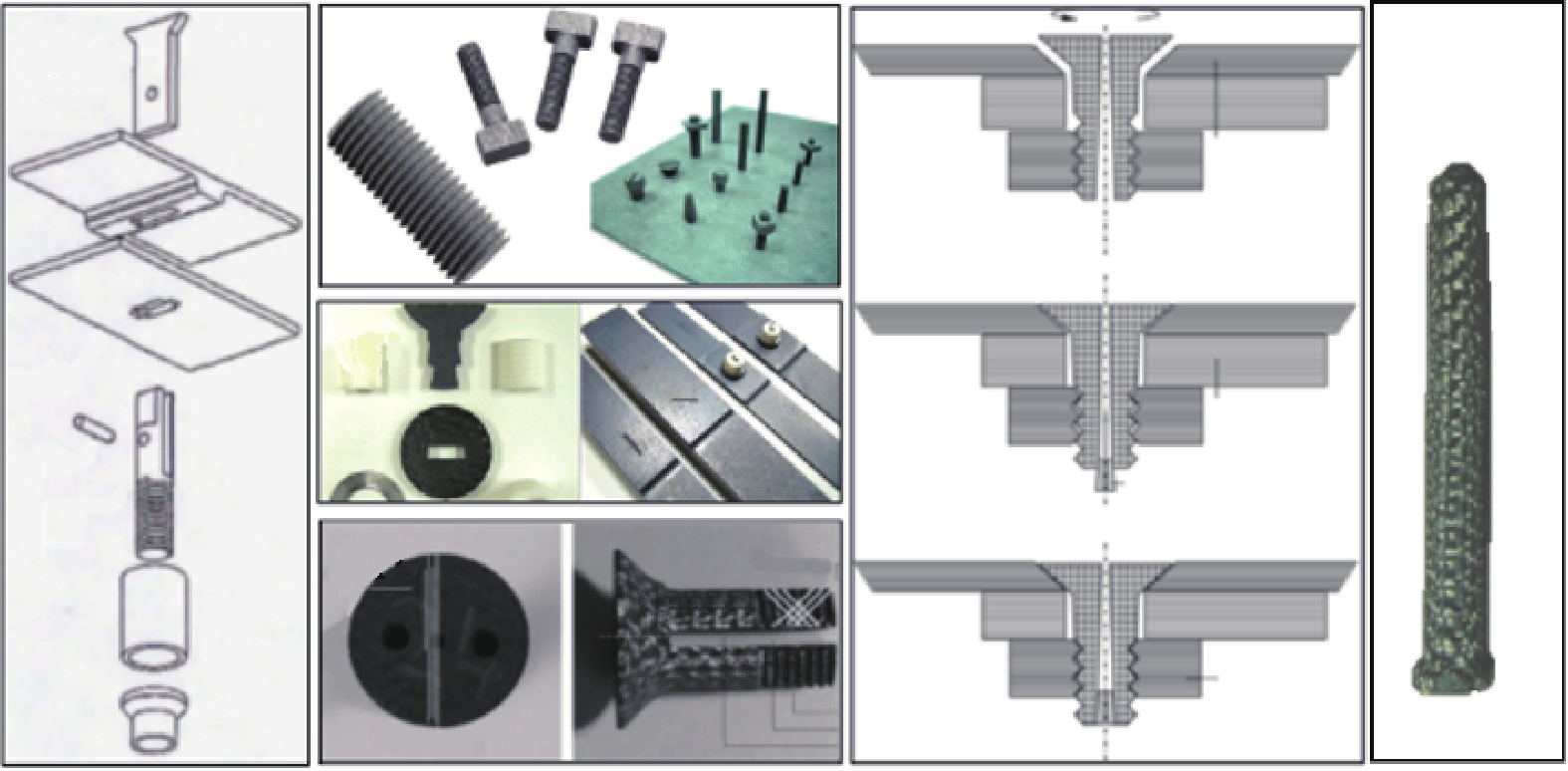

| [16] |

GLASS D. Ceramic matrix composite (CMC) thermal protection systems (TPS) and hot structures for hypersonic vehicles[C]//15th AIAA International Space Planes and Hypersonic Systems and Technologies Conference. Dayton, 2008.

|

| [17] |

XU H, ZHANG L, CHENG L. The yarn size dependence of tensile and in-plane shear properties of three-dimensional needled textile reinforced ceramic matrix composites[J]. Materials and Design,2015,67:428-435. doi: 10.1016/j.matdes.2014.11.061

|

| [18] |

INNOCENTI L, DUJARRIC C, RAMUSAT G. An overview of the FLPP and the technology developments in RLV stage structures for elevated temperature applications[C]//The 4th European Workshop on Hot Structures and Thermal Protection Systems for Space Vehicle. Palermo, 2003, 521: 57-64.

|

| [19] |

LANGE H, STEINACHER A, HANDRICK K, et al. Status of CMC open flap development for expert[C]//Proceedings of the 5th European Workshop on Thermal Protection Systems and Hot Structures. Grenoble, 2006, 631: 41-51.

|

| [20] |

LANGE H, STEINACHER A, HANDRICK K, et al. Status of flap development for future re-entry vehicles (pre-x) [C]//Proceedings of the 5th European Workshop on Thermal Protection Systems and Hot Structures. Grenoble, 2006, 631: 21-30.

|

| [21] |

MüHLRATZER A, PFEIFFER H. CMC body flaps for the X-38 experimental space vehicle[C]//The 26th Annual Conference on Composites, Advanced Ceramics, Materials, and Structures: Ceramic Engineering and Science Proceedings. London, 2008, 23(3): 331-338.

|

| [22] |

PICHON T, SOYRIS P, FOUCAULT A, et al. C/SiC based rigid external thermal protection system for future reusable launch vehicles: Generic shingle, pre-X/FLPP anticipated development test studies[C]//Proceedings of the 5th European Workshop on Thermal Protection Systems and Hot Structures. Grenoble, 2006, 631: 9-19.

|

| [23] |

REIMER T. Thermal and mechanical design of the expert C/C-SiC nose[C]//Proceedings of the 5th European Workshop on Thermal Protection Systems and Hot Structures. Grenoble, 2006, 631: 30-42.

|

| [24] |

SALMON T, LELEU F, MOULIN J, et al. Experimentation plan for thermal protections and hot structures on pre-x: Current status[C]//The 4th European Workshop on Hot Structures and Therma Protection Systems for Space Vehicles. Palermo, 2003, 521: 45-52.

|

| [25] |

TUMINO G. European development and qualification status and challenges in hot structures and thermal protection systems for space transportation concepts[C]//The 4th European Workshop on Hot Structures and Therma Protection Systems for Space Vehicles. Palermo, 2003, 521: 39-43.

|

| [26] |

ULLMANN T, REIMER T, HALD H, et al. Reentry flight testing of a C/C-SiC structure with yttrium silicate oxidation protection[C]//AIAA Paper: International Space Planes and Hypersonic Systems and Technologies Conference. London, 2006: 2006-8127.

|

| [27] |

VOLAND R T, HUEBNER L D, MCCLINTON C R. X-43 A hypersonic vehicle technology development[J]. Acta Astronautica,2006,59(1):181-191.

|

| [28] |

ZHANG Q, LI G. A review of the application of C/SiC composite in thermal protection system[J]. Multidiscipline Modeling in Materials and Structures,2009,5(2):199-203. doi: 10.1163/157361109787959903

|

| [29] |

董慧民, 李小刚, 马绪强, 等. 聚合物基复合材料凸头螺栓连接研究进展[J/OL]. 北京航空航天大学学报: 1-18[2023-03-17]. https://doi.org/10.13700/j.bh.1001-5965.2022.0682.DONG Huimin, LI Xiaogang, MA Xuqiang, et al. Research progress in mechanically fastened polymer-matrix composite joints with protruding-head bolts[J]. Journal of Beijing University of Aeronautics and Astronautics: 1-18[2023-03-17]. https://doi.org/10.13700/j.bh.1001-5965.2022.0682(in Chinese).

|

| [30] |

孙涛, 周金宇. 碳纤维复合材料螺栓连接性能综述[J]. 现代制造工程, 2018, 456(9): 154-160.SUN Tao, ZHOU Jinyu. Summary for the connection performance of carbon fiber composite bolt[J]. Modern Ma-nufacturing Engineering, 2018, 456(9): 154-160(in Chinese).

|

| [31] |

CURTIN W. In situ fiber strength in ceramic-matrix composites from fracture mirrors[J]. Journal of the American Ceramic Society,2005,77(4):1075-1078.

|

| [32] |

CURTIN W. Theory of mechanical properties of ceramic-matrix composites[J]. Journal of the American Ceramic Society,2005,74(11):2837-2845.

|

| [33] |

EVANS A G. Perspective on the development of high-toughness ceramics[J]. Journal of the American Ceramic Society,1990,73(2):187-206. doi: 10.1111/j.1151-2916.1990.tb06493.x

|

| [34] |

EVANS A G. Overview No. 125 design and life prediction issues for high-temperature engineering ceramics and their composites[J]. Acta Materialia,1997,45(1):23-40. doi: 10.1016/S1359-6454(96)00143-7

|

| [35] |

EVANS A G, MARSHALL D B. Overview No. 85 the mechanical behavior of ceramic matrix composites[J]. Acta Metallurgica,1989,37(10):2567-2583. doi: 10.1016/0001-6160(89)90291-5

|

| [36] |

EVANS A G, ZOK F W. The physics and mechanics of fiber-reinforced brittle-matrix composites[J]. Journal of Materials Science,1994,29(15):3857-3896. doi: 10.1007/BF00355946

|

| [37] |

HE M Y, EVANS A G, CURTIN W A. The ultimate tensile strength of metal and ceramic-matrix composites[J]. Acta Metallurgica,1993,41(3):871-878. doi: 10.1016/0956-7151(93)90021-J

|

| [38] |

HEREDIA F, SPEARING S, EVANS A, et al. Mechanical properties of continuous-fiber-reinforced carbon matrix composite and relationship to constituent properties[J]. Journal of the American Ceramic Society,2005,75(11):3017-3025.

|

| [39] |

RICE R W. Ceramic matrix composite toughening mechanisms: An update[C]//Proceedings of the 9th Annual Conference on Composites and Advanced Ceramic Materials. London, 2008, 6: 589-607.

|

| [40] |

HE Z B, ZHANG L T, CHEN B, et al. Static response and failure behavior of 2D C/SiC cantilever channel beam[J]. Applied Composite Materials,2015,22(5):525-541. doi: 10.1007/s10443-014-9421-4

|

| [41] |

HE Z B, ZHANG L T, CHEN B, et al. Microstructure and mechanical properties of SiC bonded joints prepared by CVI[J]. International Journal of Adhesion,2016,64:15-22. doi: 10.1016/j.ijadhadh.2015.09.009

|

| [42] |

HE Z B, ZHANG L T, ZHANG Y, et al. Microstructural characterization and failure analysis of 2D C/SiC two-layer beam with pin-bonded hybrid joints[J]. International Journal of Adhesion,2015,57:70-78. doi: 10.1016/j.ijadhadh.2014.10.008

|

| [43] |

SINGH M, ASTHANA R. Advanced joining and integration technologies for ceramic matrix composite systems[M]. Ceramic Matrix Composites: Fiber Reinforced Ceramics. London: Wiley-VCH Verlag GmbH & Co. KGaA, 2008: 303-325.

|

| [44] |

SINGH M, MATSUNAGA T, LIN H T, et al. Microstructure and mechanical properties of joints in sintered SiC fiber-bonded ceramics brazed with Ag-Cu-Ti alloy[J]. Materials Science and Engineering: A,2012,557:69-76. doi: 10.1016/j.msea.2012.05.110

|

| [45] |

谭志勇, 张中原, 郑日恒, 等. 飞行器典型结构的热适配分体螺栓连接技术[J]. 航空学报, 2020, 41(8):288-294.TAN Zhiyong, ZHANG Zhongyuan, ZHENG Riheng, et al. Connection technique for thermal adaptive bolts with split-piece design in typical vehicle structures[J]. Acta Aeronautica et Astronautica Sinica,2020,41(8):288-294(in Chinese).

|

| [46] |

MILLER R J R, JARMON D C, MOREE J C. Design and validation of high temperature composite fasteners[C]//39th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference and Exhibit. California, 1998.

|

| [47] |

VERRILLI M, BARNETT T, SUN J, et al. Evaluation of post-exposure properties of SiC/SiC combustor liners tested in the RQL sector rig[C]//The 26th Annual Conference on Composites, Advanced Ceramics, Materials, and Structures: A: Ceramic Engineering and Science Proceedings. London, 2008, 23: 550-562.

|

| [48] |

VERRILLI M J, BREWER D. Characterization of ceramic matrix composite fasteners exposed in a combustor linear rig test[J]. Journal of Engineering for Gas Turbines and Power,2004,126(1):45-49. doi: 10.1115/1.1639005

|

| [49] |

LI G, ZHANG C, HU H, et al. Preparation and properties of C/SiC bolts via precursor infiltration and pyrolysis process[J]. Rare Metals,2011,30(1):572-575.

|

| [50] |

LI G, ZHANG C, HU H, et al. Preparation and mechanical properties of C/SiC nuts and bolts[J]. Materials Science and Engineering: A,2012,547:1-5. doi: 10.1016/j.msea.2012.03.045

|

| [51] |

LI G D, WU X F, ZHANG C R, et al. Theoretical simulation and experimental verification of C/SiC joints with pins or bolts[J]. Materials and Design,2014,53:1071-1076. doi: 10.1016/j.matdes.2013.08.001

|

| [52] |

MEI H, CHENG L, KE Q, et al. High-temperature tensile properties and oxidation behavior of carbon fiber reinforced silicon carbide bolts in a simulated re-entry environment[J]. Carbon,2010,48(11):3007-3013. doi: 10.1016/j.carbon.2010.01.056

|

| [53] |

陈永当, 李楠, 尉寄望, 等. 多轴向经编预制体碳化硅陶瓷基复合材料铆钉剪切性能研究[J]. 产业用纺织品, 2021, 39(11):26-31.CHEN Yongdang, LI Nan, WEI Jiwang et al. Study on shear property of SiC-CMCs pin with multi-axial warp knitted fabric preform[J]. Technical Textiles,2021,39(11):26-31(in Chinese).

|

| [54] |

LI X, TAN Z, ZHANG Y, et al. Shear behaviors and failure mechanisms of 2D C/SiC pins prepared by chemical vapor infiltration[J]. Ceramics International,2020,46(10):16693-16699. doi: 10.1016/j.ceramint.2020.03.243

|

| [55] |

ZHANG Y, ZHANG L, ZHANG J, et al. Effects of z-pin's porosity on shear properties of 2D C/SiC z-pinned joint[J]. Composite Structures,2017,173:106-114. doi: 10.1016/j.compstruct.2017.04.013

|

| [56] |

张毅. CVI-2D C/SiC复合材料铆接单元的力学行为与失效机制[D]. 西安: 西北工业大学, 2017.ZHNAG Yi. Mechanical behaviors and failure mechanisms of z-pinned joints for 2D C/SiC composite prepared by chemical vapor infiltration[D]. Xi'an: Northwestern Polytechnical University, 2017(in Chinese).

|

| [57] |

LIU Y, LI L, ZHANG Z, et al. Monotonic and cyclic loading/unloading tensile behavior of 3D needle-punched C/SiC ceramic-matrix composites[J]. Materials,2021,14(1):57-73.

|

| [58] |

LU Z, CAO J, SONG Z, et al. Research progress of ceramic matrix composite parts based on additive manufacturing technology[J]. Virtual and Physical Prototyping,2019,14(4):333-348. doi: 10.1080/17452759.2019.1607759

|

| [59] |

刘杰, 李海滨, 刘小瀛. 3D针刺C/SiC复合材料螺栓的低成本制备及力学性能[J]. 航空学报, 2013, 34(7):1724-1730.LIU Jie, LI Haibin, LIU Xiaoying. Low cost preparation and mechanical property of three-dimensional needled C/SiC bolts[J]. Acta Aeronautica et Astronautica Sinica,2013,34(7):1724-1730(in Chinese).

|

| [60] |

梅辉. 陶瓷基复合材料螺栓的制备方法: 中国, CN200810018039.0[P]. 2008-04-25.MEI Hui. Preparation of ceramic matrix composite bolts: China, CN200810018039.0[P]. 2008-04-25(in Chinese).

|

| [61] |

张立同, 成来飞, 梅辉. 先进复合材料丛书 陶瓷基复合材料[M]. 北京: 中国铁道出版社, 2020: 30-52.ZHANG Litong, CHENG Laifei, MEI Hui. Advanced composites series-ceramic matrix composites[M]. Beijing: China Railway Press, 2020: 30-52(in Chinese).

|

| [62] |

孙乐, 王成, 李晓飞, 等. C/C复合材料预制体的研究进展[J]. 航空材料学报, 2018, 38(2):86-95.SUN Le, WANG Cheng, LI Xiaofei, et al. Research progress on preforms of C/C composites[J]. Acta Aeronautica et Astronautica Sinica,2018,38(2):86-95(in Chinese).

|

| [63] |

戚云超, 方国东, 梁军, 等. 三维针刺C/C-SiC复合材料预制体工艺参数优化[J]. 材料工程, 2020, 48(1):27-33.QI Yunchao, FANG Guodong, LIANG Jun, et al. Optimization of process parameters of three-dimensional needled preforms for C/C-SiC composites[J]. Journal of Materials Engineering,2020,48(1):27-33(in Chinese).

|

| [64] |

王玲玲, 冯雁, 刘苏骅, 等. 针刺C/C-SiC复合材料薄壁圆筒弯曲性能研究[J]. 固体火箭技术, 2021, 44(4):506-512.WANG Lingling, FENG Yan, LIU Suhua, et al. Bending performance of the needled C/C-SiC composites thin-walled cylinder[J]. Journal of Solid Rocket Technology,2021,44(4):506-512(in Chinese).

|

| [65] |

KE Q Q, CHENG L F, TONG Q Y, et al. Microstructure and properties of joints of 2D C/SiC composites by riveting[J]. Rare Matel Materials and Engineering,2006,35(9):1497-1500.

|

| [66] |

成来飞. 陶瓷基复合材料的连接方法: 中国, ZL200410026366.2[P]. 2005-03-23.CHENG Laifei. Joining of ceramic matrix composite: China, ZL200410026366.2[P]. 2005-03-23(in Chinese).

|

| [67] |

LI G D, ZHANG Y D, ZHANG C R, et al. Design, preparation and properties of online-joints of C/SiC-C/SiC with pins[J]. Composites Part B: Engineering,2013,48:134-139. doi: 10.1016/j.compositesb.2012.09.093

|

| [68] |

童长青, 成来飞, 刘永胜, 等. PIP工艺对2D C/SiC-ZrB2复合材料结构和力学性能的影响[J]. 宇航材料工艺, 2011, 41(3):42-45.TONG Changqing, CHENG Laifei, LIU Yongsheng, et al. Effect of PIP process on microstructure and mechanical properties of 2D C /SiC-ZrB2 composites[J]. Aerospace Materials and Technology,2011,41(3):42-45(in Chinese).

|

| [69] |

陈照峰, 张立同, 成来飞, 等. PIP结合CVI制备氧化铝-莫来石陶瓷基复合材料[J]. 无机材料学报, 2003, 18(3):638-644.CHEN Zhaofeng, ZHANG Litong, CHENG Laifei, et al. Preparation of C fiber reinforced alumina-mullite composite by PIP and CVI[J]. Journal of Inorganic Materials,2003,18(3):638-644(in Chinese).

|

| [70] |

ALMEIDA R S M, FARHANDI H, TUSHTEV K, et al. Joining oxide ceramic matrix composites by ionotropic gelation[J]. International Journal of Applied Ceramic Technology,2020,17(4):1574-1581. doi: 10.1111/ijac.13507

|

| [71] |

庞生洋, 胡成龙, 杨鸷, 等. 预制体结构对C/C复合材料力学性能、断裂行为以及热物性能的影响[J]. 机械工程学报, 2018, 54(9):97-107.PANG Shengyang, HU Chenglong, YANG Zhi, et al. Effects of preform structures on the mechanical properties, fracture behaviors and thermophysical properties of C/C composites[J]. Journal of Mechanical Engineering,2018,54(9):97-107(in Chinese).

|

| [72] |

EGAN B, MCCARTHY C T, MCCARTHY M A, et al. Static and high-rate loading of single and multi-bolt carbon-epoxy aircraft fuselage joints[J]. Composites Part A: Applied Science and Manufacturing,2013,53:97-108. doi: 10.1016/j.compositesa.2013.05.006

|

| [73] |

成大先. 机械设计手册(联接与紧固)[M]. 北京: 化学工业出版社, 2017.CHENG Daxian. Handbook of mechanical design (joining and fastening)[M]. Beijing: Chemical Industry Press, 2017(in Chinese).

|

| [74] |

EKH J, SCHÖN J. Load transfer in multirow, single shear, composite-to-aluminium lap joints[J]. Composites Science and Technology,2006,66(7):875-885.

|

| [75] |

KUMAR S, PAINULY A, KAMAL A, et al. Studies on fiber orientation of carbon fiber preforms for fabrication of C/SiC fasteners[J]. Transactions of the Indian National Academy of Engineering,2021,6:49-55. doi: 10.1007/s41403-020-00173-z

|

| [76] |

谭志勇, 王捷冰, 孟繁夫, 等. 配合条件对C/SiC在线铆接单元的力学性能影响[J/OL]. 复合材料学报: 1-11[2023-03-17]. https://doi.org/10.13801/j.cnki.fhclxb.20220930.004.TAN Zhiyong, WANG Jiebing, MENG Fanfu, et al. Effect of fit conditions on mechanical properties of C/SiC online riveting unit[J]. Acta Materiae Compositae Sinica: 1-11[2023-03-17]. https://doi.org/10.13801/j.cnki.fhclxb.20220930.004(in Chinese).

|

| [77] |

FUKUOKA T, TAKAKI T. Mechanical behaviors of bolted joint in various clamping configurations[J]. Journal of Pressure Vessel Technology,1998,120(3):226-231. doi: 10.1115/1.2842050

|

| [78] |

卢越, 张海鹏. 陶瓷基复合材料螺栓渐进损伤计算与强度预测[J]. 设备管理与维修, 2020, 41(2): 406-411.LU Yue, ZHANG Haipeng. Progressive damage calculation and strength prediction of ceramic matrix composite bolts[J]. Plant Maintenance Engineering, 2020, 41(2): 406-411(in Chinese).

|

| [79] |

张毅, 成来飞, 李晓萍, 等. 基于长棒状预制体结构的陶瓷基复合材料螺栓及销钉制备方法: 中国, CN202110866507.5[P]. 2021-11-05.ZHANG Yi, CHENG Laifei, LI Xiaoping, et al. Preparation of ceramic matrix composite bolts and pins based on long rod-shaped precast structure: China, CN202110866507.5[P]. 2021-11-05(in Chinese).

|

| [80] |

LISSART N, LAMON J. Damage and failure in ceramic matrix minicomposites: Experimental study and model[J]. Acta Materialia,1997,45(3):1025-1044. doi: 10.1016/S1359-6454(96)00224-8

|

| [81] |

EVANS A G, MARSHALL D B. The mechanical behavior of ceramic matrix composites[C]//Proceedings of the 7th International Conference on Fracture (ICF7). Oxford: Pergamon, 1989: 3593-3641.

|

| [82] |

陈中青. 飞机振动区内的螺纹联接件的防松探讨[J]. 中国科技博览, 2010(31):586-586.CHEN Zhongqing. Discussion on anti-loosening of threaded connections in the vibration zone of the aircraft[J]. China Science and Technology Exposition,2010(31):586-586(in Chinese).

|

| [83] |

JUNKER G H. New criteria for self-loosening of fasteners under vibration[J]. Sae Transaction, 1969, 44(10):14-16.

|

| [84] |

郝秉磊, 殷小玮, 刘小瀛, 等. C/SiC陶瓷基复合材料螺栓连接件的振动响应特性及防松性能[J]. 复合材料学报, 2014, 31(3):653-660.HAO Binglei, YIN Xiaowei, LIU Xiaoying, et al. Vibration response characteristics and looseness-proof perfor-mances of C/SiC ceramic matrix composite bolted fastenings[J]. Acta Materiae Compositae Sinica,2014,31(3):653-660(in Chinese).

|

| [85] |

王旻睿, 谭志勇, 何顶顶, 等. 高温环境复合材料螺栓连接振动的防松试验[J]. 振动测试与诊断, 2018, 38(6):1169-1175.WANG Minrui, TAN Zhiyong, HE Dingding, et al. Anti-loosening experiment of composite bolted stryctures under high temperature and vibration circumstance[J]. Journal of Vibration, Measurement and Diagnosis,2018,38(6):1169-1175(in Chinese).

|

| [86] |

SASE N, NISHIOKA K, KOGA S, et al. An anti-loosening screw-fastener innovation and its evaluation[J]. Journal of Materials Processing Technology,1998,77(1):209-215.

|

| [87] |

ZAKI A, NASSAR S, YANG X. Criterion for preventing self-loosening of preloaded countersunk head threaded fasteners[J]. Journal of Vibration and Acoustics,2011,133(4):041013. doi: 10.1115/1.4003596

|

| [88] |

LAMOUROUX F, CAMUS G. Oxidation effects on the mechanical properties of 2D woven C/SiC composites[J]. Journal of the European Ceramic Society,1994,14(2):177-188. doi: 10.1016/0955-2219(94)90105-8

|

| [89] |

LAMOUROUX F, CAMUS G, THéBAULT J. Kinetics and mechanisms of oxidation of 2D woven C/SiC composites: I, Experimental approach[J]. Journal of the American Ceramic Society,1994,77(8):2049-2057. doi: 10.1111/j.1151-2916.1994.tb07096.x

|

| [90] |

LAMOUROUX F, NASLAIN R, JOUIN J-M. Kinetics and mechanisms of oxidation of 2D woven C/SiC composites: II, Theoretical approach[J]. Journal of the American Ceramic Society,1994,77(8):2058-2068. doi: 10.1111/j.1151-2916.1994.tb07097.x

|

| [91] |

VERRILLI M, BREWER D. Characterization of ceramic matrix composite fasteners exposed in a combustor liner rig test[C]//ASME Turbo Expo 2002: Power for Land, Sea, and Air. London, 2002: 23-28.

|

| [92] |

KUSHWAHA J, KUMAR V, SINNUR K H. Development and evaluation of carbon-carbon threaded fasteners for high temperature applications[J]. Defence Science Journal,2012,62(5):348-355. doi: 10.14429/dsj.62.2395

|

| [93] |

KUMAR S, PAINULY A, KAMAL A, et al. Development of C/SiC fasteners for high-temperature applications[J]. Materials Performance and Characterization,2021,10(10):253-267.

|

| [94] |

刘小冲, 刘小瀛, 董宁, 等. 均匀承载的陶瓷基复合材料销钉制备方法: 中国, CN201910139555.7[P]. 2019-04-26.LIU Xiaochong, LIU Xiaoying, DONG Ning, et al. Preparation of ceramic matrix composite pins with uniform load: China, CN201910139555.7[P]. 2019-04-26(in Chinese).

|

| [95] |

GAVALDA DIAZ O, AXINTE D A, BUTLER-SMITH P, et al. On understanding the microstructure of SiC/SiC ceramic matrix composites (CMCs) after a material removal process[J]. Materials Science and Engineering: A,2019,743(7):1-11.

|

| [96] |

AN Q, CHEN J, MING W, et al. Machining of SiC ceramic matrix composites: A review[J]. Chinese Journal of Aeronautics,2021,34(4):540-567. doi: 10.1016/j.cja.2020.08.001

|

| [97] |

GAVALDA DIAZ O, GARCIA LUNA G, LIAO Z, et al. The new challenges of machining ceramic matrix composites (CMCs): Review of surface integrity[J]. International Journal of Machine Tools and Manufacture,2019,139:24-36. doi: 10.1016/j.ijmachtools.2019.01.003

|

| [98] |

YUAN J, LIU Z, PANG J, et al. In-situ evaluation of the damaging process of C/SiC composite material bolts under tensile loading[J]. Composites Part C: Open Access,2021,6:100196. doi: 10.1016/j.jcomc.2021.100196

|

| [99] |

GAO X, LEI B, ZHANG Y, et al. Identification of microstructures and damages in silicon carbide ceramic matrix composites by deep learning[J]. Materials Characterization,2023,196:112608. doi: 10.1016/j.matchar.2022.112608

|

| [100] |

LI T, DUAN Y, JIN K, et al. Dynamic compressive fracture of C/SiC composites at different temperatures: Microstructure and mechanism[J]. International Journal of Impact Engineering,2017,109:391-399. doi: 10.1016/j.ijimpeng.2017.08.001

|

| [101] |

WANG F, CHENG L, LIANG S. Effects of microstructure defects on the internal friction of C/SiC composites[J]. Materials Science and Engineering: A,2019,750:1-6. doi: 10.1016/j.msea.2019.02.038

|

| [102] |

SHISHESAZ M, HOSSEINI M. A review on stress distribution, strength and failure of bolted composite joints[J]. Applied and Computational Mechanics,2018,49(2):415-429.

|

下载:

下载: