Fabrication and stamping of Mg-Al laminates

-

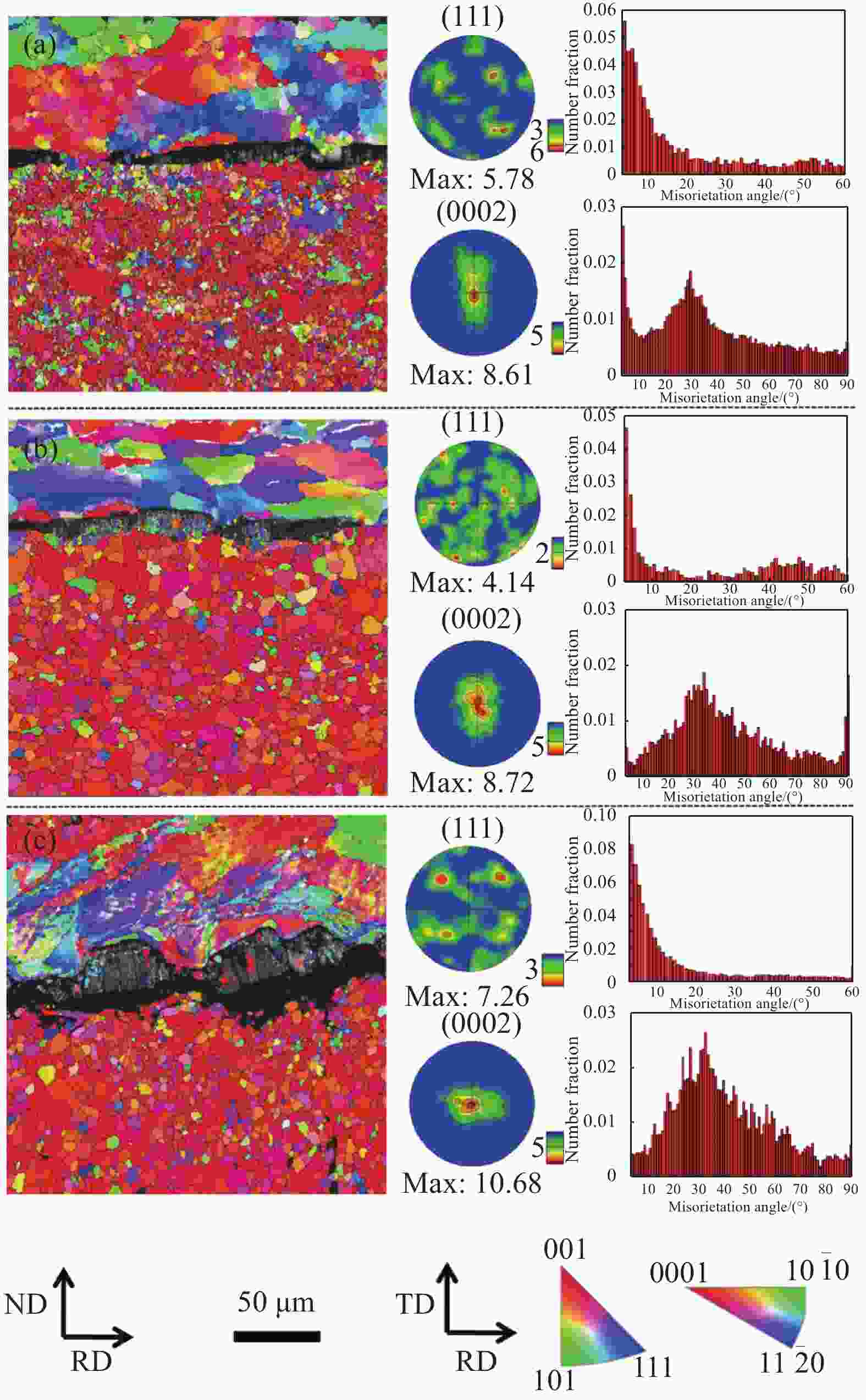

摘要: 镁合金作为目前实际应用中最轻的金属材料,其结构件有望广泛应用于航空航天、轨道交通、汽车、电子等轻量化领域。然而,镁合金不耐腐蚀的缺点严重限制了其在轻量化领域的广泛应用。在镁合金表面包覆一层耐腐蚀性好的铝合金形成镁铝层合板,则能在保护镁合金的同时又能发挥镁合金比强度和比刚度高、减震性能和电磁波屏蔽性能好等优点。本文综述了镁铝层合板常见的制备方法及特点,分析了层合板中组元板及层界面的微观组织结构演变及其对层合板力学性能的影响。介绍了本课题组在镁铝层合板冲压成形及其变形微观机制方面的创新性的研究成果,获得了不同温度下镁铝层合板的成形极限图。如何制备更宽、更薄且层界面处金属间化合物可控的镁铝层合板是未来研究的重点。Abstract: Magnesium (Mg) alloy is the lightest metal material in practical application, and its structural parts are expected to be widely used in aerospace, rail transit, automobile, electronics and other lightweight fields. However, Mg alloy has the disadvantage of corrosion resistance, which seriously limits its wide application in the field of lightweight. Coating Mg alloy with good corrosion resistance aluminum (Al) alloy to form Mg-Al laminate can not only protect Mg alloy, but also play the advantages of high specific strength and specific stiffness of Mg alloy, good shock absorption and electromagnetic shielding performance. In this paper, the preparation methods and characteristics of Mg-Al laminates are reviewed, the microstructure evolution of component plates and layer interfaces in Mg-Al laminates and their influence on mechanical properties of the laminates are analyzed, and the innovative research results of our research group on stamping forming and deformation microscopic mechanism of Mg-Al laminates are introduced. How to prepare wider and thinner Mg-Al laminates with intermetallic compounds controllable at the interface is the focus of future research.

-

Key words:

- Mg-Al laminates /

- layer interface /

- microstructure /

- mechanical properties /

- stamping

-

表 1 不同累积叠轧(ARB)工艺的参数

Table 1. Reported parameters of accumulative roll-bonding (ARB) process

表 2 非轧制工艺的层界面研究

Table 2. Research on layer interface of non-rolling process

Process name Heat treatment temperature

or processing temperatureHeat-up time Intermetallic

phases layersThicknesses of intermetallic phases layers Ref. Explosive welding process Anneal 300℃ 1 h Mg17Al12 and Al3Mg2 8 μm [74] Explosive welding process Anneal 400℃ 2 h Mg17Al12 and Al3Mg2 100 μm [76] Heat pressing process 350℃ 80 min Mg17Al12 and Al3Mg2 10.56 μm [66] Heat pressing process 450℃ 80 min Mg17Al12 and Al3Mg2 38.40 μm [66] Vacuum diffusion welding process 420℃ 30 min Mg17Al12 and Al3Mg2 48 μm [77] Vacuum diffusion welding process 440℃ 30 min Mg17Al12 and Al3Mg2 86 μm [77] -

[1] GAO K, ZHANG X, LIU B, et al. The deformation characteristics, fracture behavior and strengthening-toughening mechanisms of laminated metal composites: A review[J]. Metals,2020,10(1):4. doi: 10.3390/met10010004 [2] BUI T Q, HU X. A review of phase-field models, fundamentals and their applications to composite laminates[J]. Engineering Fracture Mechanics,2021,248:107705. doi: 10.1016/j.engfracmech.2021.107705 [3] YANG Y, XIONG X, CHEN J, et al. Research advances in magnesium and magnesium alloys worldwide in 2020[J]. Journal of Magnesium and Alloys,2021,9(3):705-747. doi: 10.1016/j.jma.2021.04.001 [4] XU T, YANG Y, PENG X, et al. Overview of advancement and development trend on magnesium alloy[J]. Journal of Magnesium and Alloys,2019,7(3):536-544. doi: 10.1016/j.jma.2019.08.001 [5] 宋光玲. 镁合金腐蚀与防护[M]. 北京: 化学工业出版社, 2006: 11-18.SONG Guangling. Corrosion and protection of magnesium alloys[M]. Beijing: Chemical Industry Press, 2006: 11-18(in Chinese). [6] 刘鹏, 李亚江, 王娟. Mg/Al异种材料扩散焊界面组织结构及力学性能[J]. 焊接学报, 2007, 28(6):45-48. doi: 10.3321/j.issn:0253-360X.2007.06.012LIU Peng, LI Yajiang, WANG Juan. Microstructure and properties near interface zone of diffusion-bonded joint for Mg/Al dissimilar materials[J]. Transactions of the China Welding Institution,2007,28(6):45-48(in Chinese). doi: 10.3321/j.issn:0253-360X.2007.06.012 [7] LI L, XIAO L, ZHANG D, et al. Ductilization of a diffusion-bonded heterostructured AZ31/GW103K/AZ31 alloy by interfacial reinforcement[J]. Materials Science and Engineering: A,2022,852:143691. doi: 10.1016/j.msea.2022.143691 [8] JAFARIAN M, KHODABANDEH A, MANAFI S. Evaluation of diffusion welding of 6061 aluminum and AZ31 magnesium alloys without using an interlayer[J]. Materials & Design (1980-2015),2015,65:160-164. [9] 钱乙余, 董占贵, 石素琴, 等. 铝接触反应钎焊的成缝行为[J]. 焊接学报, 2001, 22(5):13-16. doi: 10.3321/j.issn:0253-360X.2001.05.004QIAN Yiyu, DONG Zhangui, SHI Suqin, et al. Behavior of aluminum contact reactive brazing[J]. Transactions of the China Welding Institution,2001,22(5):13-16(in Chinese). doi: 10.3321/j.issn:0253-360X.2001.05.004 [10] 聂海杰, 李红, 龙伟民, 等. 接触反应钎焊技术研究进展[J]. 焊接, 2015(5):25-29. doi: 10.3969/j.issn.1001-1382.2015.05.007NIE Haijie, LI hong, LONG Weimin, et al. Research developments of contact reaction brazing[J]. Welding & Joining,2015(5):25-29(in Chinese). doi: 10.3969/j.issn.1001-1382.2015.05.007 [11] YAN Y B, ZHANG Z W, SHEN W, et al. Microstructure and properties of magnesium AZ31B-aluminum 7075 explosively welded composite plate[J]. Materials Science and Engineering: A,2010,527(9):2241-2245. doi: 10.1016/j.msea.2009.12.007 [12] 张婷婷, 王文先, 袁晓丹, 等. Mg/Al合金爆炸焊连接及其界面接合机制[J]. 机械工程学报, 2016, 52(12):52-58. doi: 10.3901/JME.2016.12.052ZHANG Tingting, WANG Wenxian, YUAN Xiaodan, et al. Interface bonding mechanism of Mg/Al alloy explosive welded[J]. Journal of Mechanical Engineering,2016,52(12):52-58(in Chinese). doi: 10.3901/JME.2016.12.052 [13] CHEN Z, WANG D, CAO X, et al. Influence of multi-pass rolling and subsequent annealing on the interface microstructure and mechanical properties of the explosive welding Mg/Al composite plates[J]. Materials Science and Engineering: A,2018,723:97-108. doi: 10.1016/j.msea.2018.03.042 [14] ZHU B, LIANG W, LI X. Interfacial microstructure, bonding strength and fracture of magnesium-aluminum laminated composite plates fabricated by direct hot pressing[J]. Materials Science and Engineering: A,2011,528(21):6584-6588. doi: 10.1016/j.msea.2011.05.015 [15] 许哲峰. 热压扩散法制备钛钢复合板的研究进展[J]. 热加工工艺, 2017, 46(10):14-17.XU Zhefeng. Research progress of titanium steel composite plate prepared by hot-pressing diffusion method[J]. Hot Working Technology,2017,46(10):14-17(in Chinese). [16] ZHANG X P, YANG T H, CASTAGNE S, et al. Microstructure, bonding strength and thickness ratio of Al/Mg/Al alloy laminated composites prepared by hot rolling[J]. Materials Science and Engineering: A,2011,528(4):1954-1960. [17] MATSUMOTO H, WATANABE S, HANADA S. Fabrication of pure Al/Mg-Li alloy clad plate and its mechanical properties[J]. Journal of Materials Processing Technology,2005,169(1):9-15. doi: 10.1016/j.jmatprotec.2005.03.005 [18] ZHANG X P, YANG T H, LIU J Q, et al. Mechanical properties of an Al/Mg/Al trilaminated composite fabricated by hot rolling[J]. Journal of Materials Science,2010,45(13):3457-3464. doi: 10.1007/s10853-010-4373-z [19] WANG T, LI S, NIU H, et al. EBSD research on the interfacial microstructure of the corrugated Mg/Al laminated material[J]. Journal of Materials Research and Technology,2020,9(3):5840-5847. doi: 10.1016/j.jmrt.2020.03.111 [20] LIU W, LIU Y, WANG T, et al. Analysis of deformation mechanism in corrugated rolling of composite plate[J]. Procedia Manufacturing,2020,50:552-557. doi: 10.1016/j.promfg.2020.08.099 [21] BAE J H, PRASADA RAO A K, KIM K H, et al. Cladding of Mg alloy with Al by twin-roll casting[J]. Scripta Materialia,2011,64(9):836-839. doi: 10.1016/j.scriptamat.2011.01.013 [22] WU K, CHANG H, MAAWAD E, et al. Microstructure and mechanical properties of the Mg/Al laminated composite fabricated by accumulative roll bonding (ARB)[J]. Materials Science and Engineering: A,2010,527(13):3073-3078. [23] CHANG H, ZHENG M Y, GAN W M, et al. Texture evolution of the Mg/Al laminated composite fabricated by the accumulative roll bonding[J]. Scripta Materialia,2009,61(7):717-720. doi: 10.1016/j.scriptamat.2009.06.014 [24] CHEN M C, HSIEH H C, WU W. The evolution of microstructures and mechanical properties during accumulative roll bonding of Al/Mg composite[J]. Journal of Alloys and Compounds,2006,416(1):169-172. [25] 方洪渊, 冯吉才. 材料连接过程中的界面行为[M]. 哈尔滨: 哈尔滨工业大学出版社, 2005: 133-139.FANG Hongyuan, FENG Jicai. Interfacial behavior during material bonding[M]. Harbin: Harbin Institute of Technology Press, 2005: 133-139(in Chinese). [26] 俞笑蓉. 真空扩散焊技术的应用[J]. 机械制造, 1987(12):27-28.YU Xiaorong. Application of vacuum diffusion welding technology[J]. Machinery,1987(12):27-28(in Chinese). [27] SEYYED AFGHAHI S S, JAFARIAN M, PAIDAR M, et al. Diffusion bonding of Al 7075 and Mg AZ31 alloys: Process parameters, microstructural analysis and mechanical properties[J]. Transactions of Nonferrous Metals Society of China,2016,26(7):1843-1851. doi: 10.1016/S1003-6326(16)64295-4 [28] FERNANDUS M J, SENTHILKUMAR T, BALASUBRAMANIAN V. Developing temperature-time and pressure-time diagrams for diffusion bonding AZ31B magnesium and AA6061 aluminium alloys[J]. Transactions of the Indian Institute of Metals,2013,66(2):177-183. doi: 10.1007/s12666-013-0240-3 [29] 赵丽敏. 镁合金AZ31/铝合金6061异种金属接触反应钎焊研究[D]. 大连: 大连理工大学, 2010.ZHAO Limin. Study on contact reactive brazing of magnesium AZ31/aluminum 6061 dissimilar alloys[D]. Dalian: Dalian University of Technology, 2010(in Chinese). [30] LIU L, TAN J, LIU X. Reactive brazing of Al alloy to Mg alloy using zinc-based brazing alloy[J]. Materials Letters,2007,61(11):2373-2377. [31] 王世宇, 李卓然, 张招, 等. Mg/Cu/Al接触反应钎焊工艺及元素扩散行为分析[J]. 焊接学报, 2018, 39(1):13-16, 129.WANG Shiyu, LI Zhuoran, ZHANG Zhao, et al. Analysis of Mg/Cu/Al contact reaction brazing process and element diffusion behavior[J]. Transactions of the China Welding Institution,2018,39(1):13-16, 129(in Chinese). [32] YANG T, WANG K, ZHANG D, et al. Contact-reaction brazing of an AZ31 magnesium/3003 aluminum alloy using a silver-copper-zinc interlayer[J]. Journal of Materials Processing Technology,2017,249:531-537. doi: 10.1016/j.jmatprotec.2017.06.041 [33] 张柯柯, 涂益民. 特种先进连接方法[M]. 哈尔滨: 哈尔滨工业大学出版, 2008: 230-241.ZHANG Keke, TU Yimin. Special advanced welding and joining technology[M]. Harbin: Harbin Institute of Technology Press, 2008: 230-241(in Chinese). [34] 田广民, 李选明, 赵永庆, 等. 层状金属复合材料加工技术研究现状[J]. 中国材料进展, 2013(11):696-701. doi: 10.7502/j.issn.1674-3962.2013.11.09TIAN Guangmin, LI Xuanming, ZHAO Yongqing, et al. Research status of processing technology of laminated metal composite[J]. Materials China,2013(11):696-701(in Chinese). doi: 10.7502/j.issn.1674-3962.2013.11.09 [35] 王建民, 朱锡, 刘润泉. 爆炸焊接的应用与发展[J]. 材料导报, 2006(1):42-45.WANG Jianmin, ZHU Xi, LIU Runquan. Application and development of explosive welding[J]. Materials Review,2006(1):42-45(in Chinese). [36] BALGA D, OSTROUSHKO D, SAKSL K, et al. Structure and mechanical properties of explosive welded Mg/Al bimetal[J]. Archives of Metallurgy and Materials,2014,59(4):1593-1597. [37] KUMAR P, KUMAR GHOSH S, DEB BARMA J, et al. The joining of magnesium and aluminium alloys by inclined arrangement of explosive welding[J]. Materials Today: Proceedings,2023,76:536-541. doi: 10.1016/j.matpr.2022.11.160 [38] KUMAR S, WU C. Eliminating intermetallic compounds via Ni interlayer during friction stir welding of dissimilar Mg/Al alloys[J]. Journal of Materials Research and Technology,2021,15:4353-4369. doi: 10.1016/j.jmrt.2021.10.065 [39] XU Y, KE L M, MAO Y Q, et al. An innovative joint interface design for reducing intermetallic compounds and improving joint strength of thick plate friction stir welded Al/Mg joints[J/OL]. Journal of Magnesium and Alloys, 2022-03-05. https://doi.org/10.1016/j.jma.2022.01.007 [40] PANTELI A, CHEN Y C, STRONG D, et al. Optimization of aluminium-to-magnesium ultrasonic spot welding[J]. JOM,2012,64(3):414-420. doi: 10.1007/s11837-012-0268-6 [41] GAO M, MEI S, LI X, et al. Characterization and formation mechanism of laser-welded Mg and Al alloys using Ti interlayer[J]. Scripta Materialia,2012,67(2):193-196. doi: 10.1016/j.scriptamat.2012.04.015 [42] 朱波. 镁铝复合板热压法制备工艺及其层界面组织性能研究[D]. 太原: 太原理工大学, 2011.ZHU Bo. Fabrication of Mg/Al composite plates by direct hot pressing and the laminate interface structures and properties[D]. Taiyuan: Taiyuan University of Technology, 2011(in Chinese). [43] LI X, LIANG W, ZHAO X, et al. Bonding of Mg and Al with Mg-Al eutectic alloy and its application in aluminum coating on magnesium[J]. Journal of Alloys and Compounds,2009,471(1):408-411. [44] LUO C, LIANG W, CHEN Z, et al. Effect of high temperature annealing and subsequent hot rolling on microstructural evolution at the bond-interface of Al/Mg/Al alloy laminated composites[J]. Materials Characterization,2013,84:34-40. doi: 10.1016/j.matchar.2013.07.007 [45] CHE B, LU L, ZHANG J, et al. Effects of cryogenic treatment on microstructure and mechanical properties of AZ31 magnesium alloy rolled at different paths[J]. Materials Science and Engineering: A,2022,832:142475. doi: 10.1016/j.msea.2021.142475 [46] RAKSHITH M, SEENUVASAPERUMAL P. Review on the effect of different processing techniques on the microstructure and mechanical behaviour of AZ31 magnesium alloy[J]. Journal of Magnesium and Alloys,2021,9(5):1692-1714. doi: 10.1016/j.jma.2021.03.019 [47] 张亚萍, 靳丽, 董杰, 等. 道次压下量和退火工艺对Mg-Zn-Ce-Zr合金微观组织及力学性能的影响[J]. 中国有色金属学报, 2012, 22(11):2985-2991. doi: 10.19476/j.ysxb.1004.0609.2012.11.001ZHANG Yaping, JIN Li, DONG Jie, et al. Effects of per-pass reduction and annealing treatment on microstructures and mechanical properties of Mg-Zn-Ce-Zr alloy[J]. The Chinese Journal of Nonferrous Metals,2012,22(11):2985-2991(in Chinese). doi: 10.19476/j.ysxb.1004.0609.2012.11.001 [48] BARNETT M R. Twinning and the ductility of magnesium alloys: Part I: "Tension" twins[J]. Materials Science and Engineering: A,2007,464(1):1-7. [49] BARNETT M R. Twinning and the ductility of magnesium alloys: Part II: "Contraction" twins[J]. Materials Science and Engineering: A,2007,464(1):8-16. [50] 王东, 马宗义. 轧制工艺对7050铝合金显微组织和力学性能的影响[J]. 金属学报, 2008, 44(1):49-54.WANG Dong, MA Zongyi. Effects of rolling process on microstructure and mechanical property of 7050 aluminum alloy[J]. Acta Metallurgica Sinica,2008,44(1):49-54(in Chinese). [51] 李东锋, 张新明, 刘胜胆, 等. 轧制变形量对Al-5Zn-3Mg-1Cu合金显微组织和力学性能的影响[J]. 华南理工大学学报(自然科学版), 2015, 43(11):75-80.LI Dongfeng, ZHANG Xinming, LIU Shengdan, et al. Effect of rolling deformation on microstructure and mechanical properties of Al-5Zn-3Mg-1Cu alloy[J]. Journal of South China University of Technology (Natural Science Edition),2015,43(11):75-80(in Chinese). [52] YU Z, WANG T, LIU C, et al. Investigation on microstructure, mechanical properties and fracture mechanism of Mg/Al laminated composites[J]. Materials Science and Engineering: A,2022,848:143410. doi: 10.1016/j.msea.2022.143410 [53] 黄庆学, 朱琳, 李玉贵, 等. 一种轧制金属复合板带的方法: CN, 103736728 A[P]. 2014-01-22.HUANG Qingxue, ZHU Lin, LI Yugui, et al. The invention relates to a method for rolling metal composite plate belt: CN, 103736728 A[P]. 2014-01-22(in Chinese). [54] 黄庆学, 朱琳, 周存龙, 等. 一种轧制制备金属复合板带的方法: CN, 103736729 A[P]. 2014-01-22.HUANG Qingxue, ZHU Lin, ZHOU Cunlong, et al. The invention relates to a method for preparing metal composite plate belt by rolling: CN, 103736729 A[P]. 2014-01-22(in Chinese). [55] 王涛, 齐艳阳, 刘江林, 等. 金属层合板轧制复合工艺国内外研究进展[J]. 哈尔滨工业大学学报, 2020, 52(6):42-56. doi: 10.11918/202003114WANG Tao, QI Yanyang, LIU Jianglin, et al. Research progress of metal laminates roll bonding process at home and abroad[J]. Journal of Harbin Institute of Technology,2020,52(6):42-56(in Chinese). doi: 10.11918/202003114 [56] WANG T, LI S, REN Z, et al. Microstructure characterization and mechanical property of Mg/Al laminated composite prepared by the novel approach: Corrugated + flat rolling[J]. Metals,2019,765:138318. [57] NIE H, LIANG W, YANG F, et al. Texture evolution of single-pass hot-rolled 5052/AZ31/5052 clad sheets[J]. JOM,2016,68(8):2274-2287. doi: 10.1007/s11837-016-1923-0 [58] SAITO Y, TSUJI N, UTSUNOMIYA H, et al. Ultra-fine grained bulk aluminum produced by accumulative roll-bonding (ARB) process[J]. Scripta Materialia,1998,39(9):1221-1227. doi: 10.1016/S1359-6462(98)00302-9 [59] SAITO Y, UTSUNOMIYA H, TSUJI N, et al. Novel ultra-high straining process for bulk materials development of the accumulative roll-bonding (ARB) process[J]. Acta Materialia,1999,47(2):579-583. doi: 10.1016/S1359-6454(98)00365-6 [60] LIU H S, ZHANG B, ZHANG G P. Microstructures and mechanical properties of Al/Mg alloy multilayered composites produced by accumulative roll bonding[J]. Journal of Materials Science & Technology,2011,27(1):15-21. [61] CHEN Z J, LIU Q, WANG G J, et al. Deformation inhomogeneities of Mg-Al laminated metal composites fabricated by accumulative roll bonding[J]. Materials Research Innovations,2015,19(sup4):S147-S151. doi: 10.1179/1432891715Z.0000000001533 [62] NIE J, LIU M, WANG F, et al. Fabrication of Al/Mg/Al composites via accumulative roll bonding and their mechanical properties[J]. Materials,2016,9(11):951. doi: 10.3390/ma9110951 [63] HABILA W, AZZEDDINE H, MEHDI B, et al. Investigation of microstructure and texture evolution of a Mg/Al laminated composite elaborated by accumulative roll bonding[J]. Materials Characterization,2019,147:242-252. doi: 10.1016/j.matchar.2018.11.010 [64] MROZ S, WIERZBA A, STEFANIK A, et al. Effect of asymmetric accumulative roll-bonding process on the microstructure and strength evolution of the AA1050/AZ31/AA1050 multilayered composite materials[J]. Materials,2020,13(23):5401. doi: 10.3390/ma13235401 [65] 韩顺昌. 爆炸焊接界面相变与断口组织[M]. 北京: 国防工业出版社, 2011: 149-157.HAN Shunchang. Phase transformation and fractography of interface of explosive welding[M]. Beijing: National Defense Industry Press, 2011: 149-157(in Chinese). [66] CAO M, WANG C J, DENG K K, et al. Effect of interface on mechanical properties of Ti/Al/Mg/Al/Ti laminated composites[J]. Materials Research,2020,23(1):e20190648. [67] 彭治力, 颜家维, 唐靖钊, 等. 电流辅助累积叠轧镁/铝层状复合板的微观形貌及力学性能[J]. 机械工程材料, 2019, 43(12):1-6. doi: 10.11973/jxgccl201912001PENG Zhili, YAN Jiawei, TANG Jingzhao, et al. Microstructure and mechanical properties of Mg/Al multilayered composite sheet by electrically-assisted accumulative roll bonding[J]. Materials for Mechanical Engineering,2019,43(12):1-6(in Chinese). doi: 10.11973/jxgccl201912001 [68] 王跃林. Mg/Al复合板波纹辊轧制成形数值仿真及实验研究[D]. 太原: 太原理工大学, 2019.WANG Yuelin. Numerical simulation and experimental study on roll forming of Mg/Al composite sheets by corrugated roll[D]. Taiyuan: Taiyuan University of Technology, 2019(in Chinese). [69] 张建军. Al/Mg/Al热轧复合板的制备及其微观组织和力学性能研究[D]. 太原: 太原理工大学, 2016.ZHANG Jianjun. Preparation of Al/Mg/AI laminated composite fabricated by hot rolled and investigation of microstructure and mechnaical properties[D]. Taiyuan: Taiyuan University of Technology, 2016(in Chinese). [70] 吴琼, 杨素媛. AZ31/1060爆炸复合板界面区组织与性能研究[J]. 稀有金属, 2016, 40(10):996-1001. doi: 10.13373/j.cnki.cjrm.xy14121503WU Qiong, YANG Suyuan. Microstructure and properties of bonding interface in explosive welded AZ31/1060 composite plate[J]. Chinese Journal of Rare Metals,2016,40(10):996-1001(in Chinese). doi: 10.13373/j.cnki.cjrm.xy14121503 [71] ACARER M, DEMIR B. An investigation of mechanical and metallurgical properties of explosive welded aluminum- dual phase steel[J]. Materials Letters,2008,62(25):4158-4160. doi: 10.1016/j.matlet.2008.05.060 [72] 唐亮亮. 镁/铝复合板爆炸焊接数值模拟及试验分析[D]. 西安: 长安大学, 2019.TANG Liangliang. Numerical simulation and experimental analysis of explosive welding of Mg/Al composite plate[D]. Xi'an: Chang'an University, 2019(in Chinese). [73] MIHARA-NARITA M, ASAI K, SATO H, et al. Interfacial microstructure and mechanical properties of explosively welded Mg/Al alloy plates[J]. Journal of Materials Engineering and Performance,2022,31(9):7039-7048. doi: 10.1007/s11665-022-06843-z [74] 赵平. 镁/铝爆炸复合板轧制过程的数值模拟分析[D]. 西安: 长安大学, 2019.ZHAO Ping. Numerical simulation analysis of rolling process of magnesium/aluminum explosive composite plate[D]. Xi'an: Chang'an University, 2019(in Chinese). [75] 陈志青. 镁/铝爆炸焊复合板热加工过程中结合界面研究[D]. 太原: 太原理工大学, 2019.CHEN Zhiqing. Study on bonding interface of magnesium/ aluminum explosive welding composite plate in hot working process[D]. Taiyuan: Taiyuan University of Technology, 2019(in Chinese). [76] 王东亚. 镁/铝爆炸复合板轧制工艺及界面行为研究[D]. 太原: 太原理工大学, 2017.WANG Dongya. Rolling process and interface behavior of Mg/Al explosive welding composite plate[D]. Taiyuan: Taiyuan University of Technology, 2017(in Chinese). [77] YIN F, LIU C, ZHANG Y, et al. Effect of Ni interlayer on characteristics of diffusion bonded Mg/Al joints[J]. Materials Science and Technology,2018,34(9):1104-1111. doi: 10.1080/02670836.2018.1424382 [78] 罗长增. 两道次热轧Al/Mg/Al复合板的界面微观结构演变及其对复合板力学性能的影响[D]. 山西: 太原理工大学, 2013.LUO Changzeng. Interfacial microstructure evolution of Al/Mg/Al laminates fabricated by two-pass hot rolling and influences of that on mechanical properties[D]. Taiyuan: Taiyuan University of Technology, 2013(in Chinese). [79] CHEN M C, KUO C W, CHANG C M, et al. Diffusion and formation of intermetallic compounds during accumulative roll-bonding of Al/Mg alloys[J]. Materials Transactions,2007,48(10):2595-2598. doi: 10.2320/matertrans.MD200718 [80] RAHMATABADI D, PAHLAVANI M, GHOLAMI M D, et al. Production of Al/Mg-Li composite by the accumulative roll bonding process[J]. Journal of Materials Research and Technology,2020,9(4):7880-7886. doi: 10.1016/j.jmrt.2020.05.084 [81] 中华人民共和国国家质量监督检验检疫总局. 中国国家标准化管理委员会. 金属薄板—成形性能与试验方法—第8部分: 成形极限图(FLD)测定指南: GB/T 15825.8—2008[S]. 北京: 中国标准出版社, 2008.General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China. Standardization Administration of China. Sheet metal—Forming properties and test methods—Part 8: Guide for determination of forming limit diagram (FLD): GB/T 15825.8—2008[S]. Beijing: Standards Press of China, 2008(in Chinese). [82] 中华人民共和国国家质量监督检验检疫总局. 中国国家标准化管理委员会. 金属薄板成形性能与试验方法—第3部分: 拉深与拉深载荷试验: GB/T 15825.3—2008[S]. 北京: 中国标准出版社, 2008.General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China. Standardization Administration of China. Sheet metal forming properties and test methods—Part 3: Deep drawing and deep drawing load test: GB/T 15825.3—2008[S]. Beijing: Standards Press of China, 2008(in Chinese). [83] NIE H, LIANG W, KANG X, et al. Bulging ability and microstructure evolutions of Al/Mg/Al laminate[J]. Journal of Materials Engineering and Performance,2020,29(3):1782-1791. doi: 10.1007/s11665-020-04717-w [84] ROUZBEH A, HASHEMI R, SEDIGHI M. Experimental and numerical study of microstructure, mechanical characteristics, and forming limit curve for Al 1050/Mg-AZ31B two-layer sheets manufactured via roll bonding technique[J]. Journal of Alloys and Compounds,2023,942:169059. doi: 10.1016/j.jallcom.2023.169059 [85] NIE H, CHI C, CHEN H, et al. Microstructure evolution of Al/Mg/Al laminates in deep drawing process[J]. Journal of Materials Research and Technology,2019,8(6):5325-5335. doi: 10.1016/j.jmrt.2019.08.053 [86] LI C, CHI C, LIN P, et al. Deformation behavior and interface microstructure evolution of Al/Mg/Al multilayer composite sheets during deep drawing[J]. Materials & Design,2015,77:15-24. [87] CHEN F K, HUANG T B, CHANG C K. Deep drawing of square cups with magnesium alloy AZ31 sheets[J]. International Journal of Machine Tools and Manufacture,2003,43(15):1553-1559. doi: 10.1016/S0890-6955(03)00198-6 -

下载:

下载: