Construction and functionality of heat conversion wood composite materials based on transition metal compounds

-

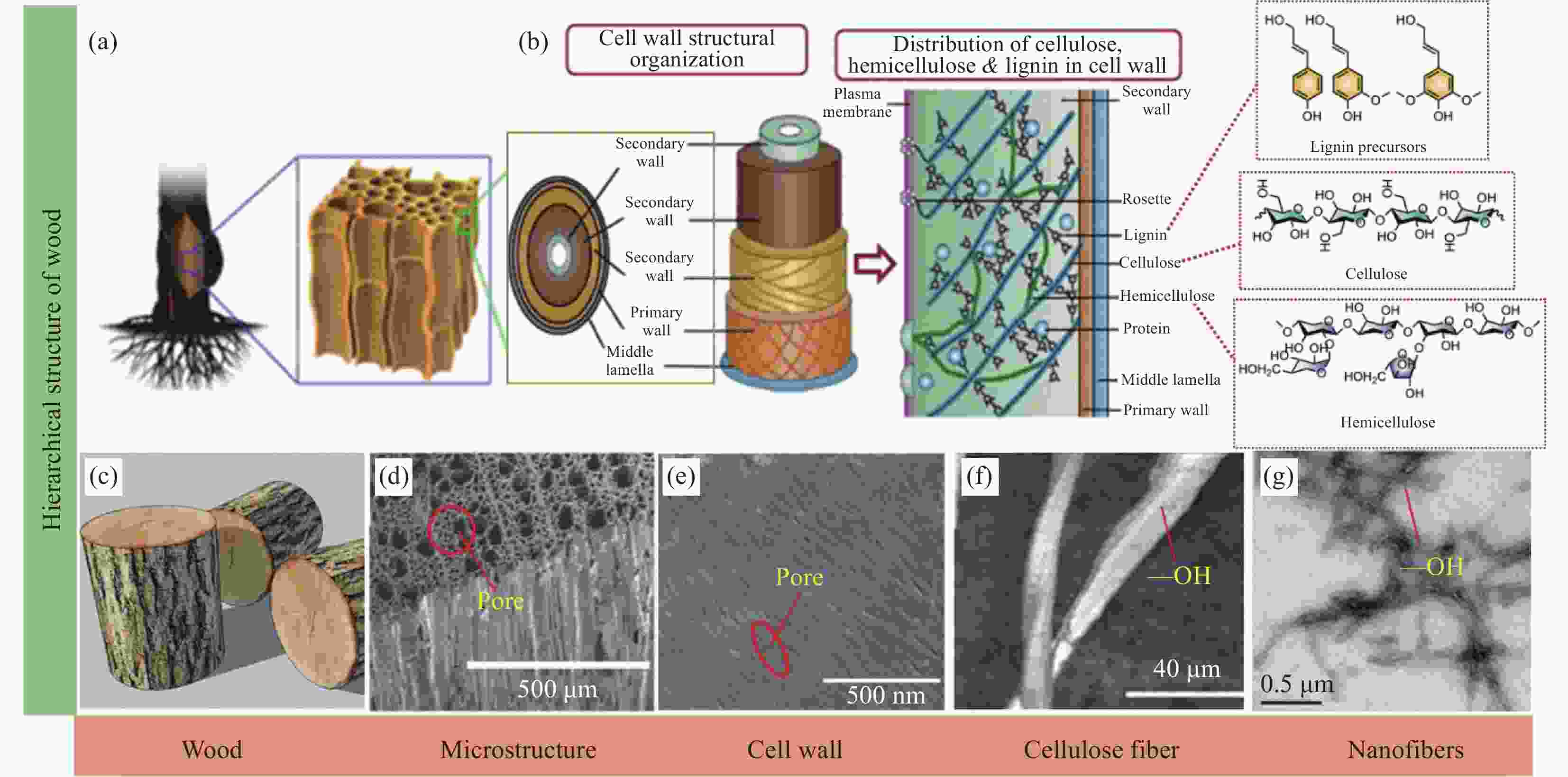

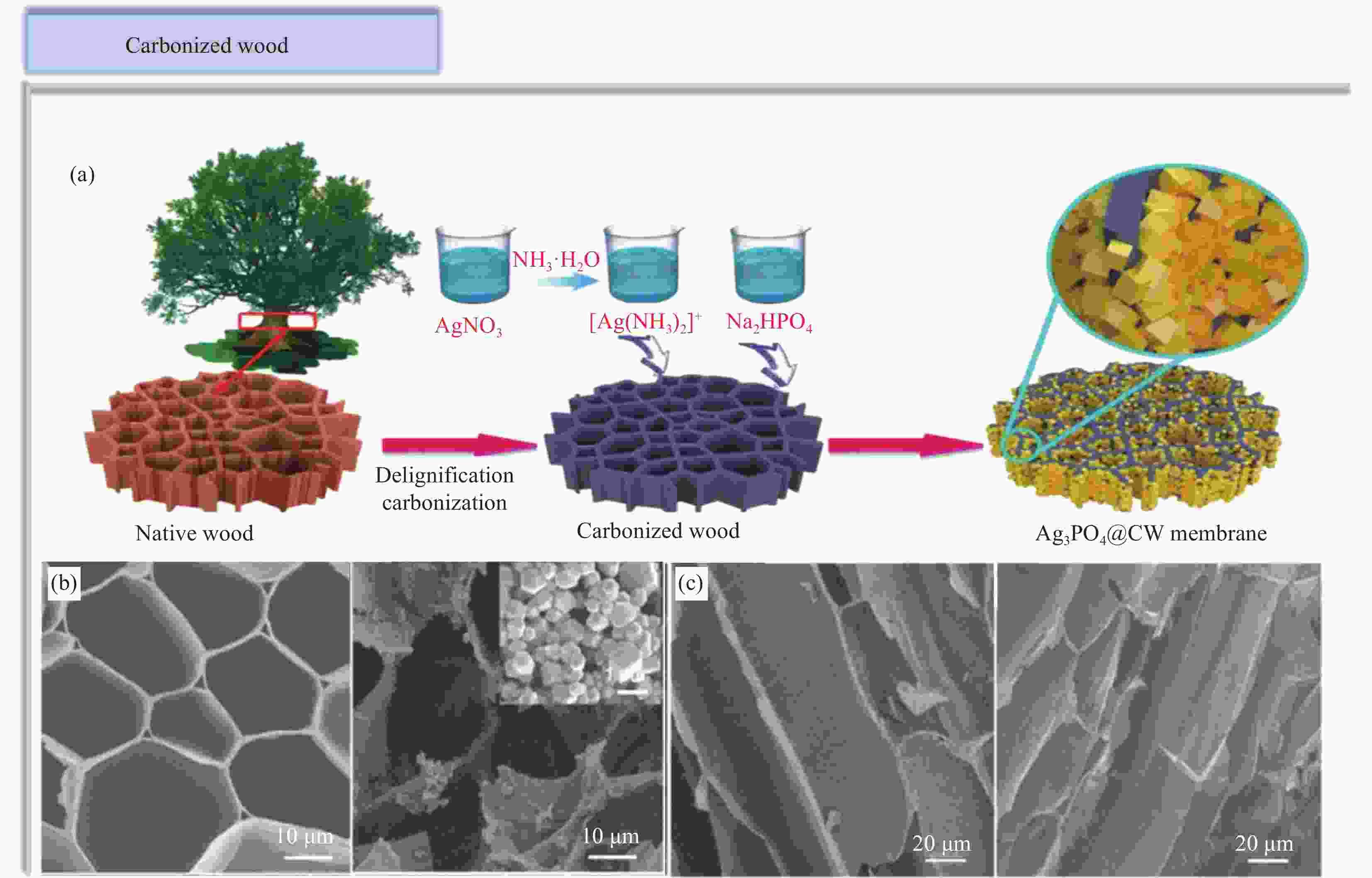

摘要: 热能在社会活动中扮演着不可或缺的角色并存在多种转化形式,过渡金属化合物(Transition metal compound,TMC)因其强关联电子体系和固有的电荷、自旋、轨道等自由度和有序相之间存在着竞争与共存关系,可以在光、电、磁和热能之间实现高效转化。然而,以粉末和晶体形式存在的TMC在使用过程中会出现易氧化聚合、体积变化、转化热能易消散及收集困难等问题,限制其热转化效率。木材具有天然的层级孔隙结构和稳定的力学支撑,借助木材中的化学组分可以与TMC形成共价键、离子键、氢键、范德华力等结合方式,促使TMC均匀负载至木材微纳表面或多孔结构中,形成TMC@木材复合材料。此外,木材具有优异的热管理能力,能够调节热能以提高热转化效率。本文基于木材的木质—纤维素大分子网络构造,详细讨论了TMC与实体木材、脱木质素木材、碳化木材的构筑方法和界面结合机制,进一步分析了基于TMC的非辐射衰变、弛豫损耗和金属-绝缘体转变的热转化机制,概述了TMC@木质复合材料在海水淡化、油水分离、建筑节能和火灾预警领域的功能应用。最后,分析了当前基于TMC构建热转化木材的优势和所面临的挑战,以期为木材的先进功能和能量转化提供一定的思路。Abstract: Thermal energy plays an indispensable role in social activities and can be transformed among various energy sources. Transition metal compound (TMC) enables the efficient conversion of light, electrical and magnetic energy into thermal energy due to the competition and coexistence between its strongly correlated electronic systems and inherent charge, spin, orbital and other degree of freedom and ordered phase. However, used in the form of powder and crystal, TMC owns the problems of oxidation polymerization, volume change, high heat dissipation and collection difficulties, which limits its heat conversion efficiency. Wood has natural hierarchical pore structure and could supply stable mechanical support for TMC. TMC can be uniformly loaded into wood micro-nano surfaces or porous structures by forming covalent bond, ionic bond, hydrogen bond, van der Waals forces with the chemical components of the wood to form TMC@wood composite materials. In addition, wood's excellent thermal management ability can regulate thermal energy to improve heat conversion efficiency. Based on the lign-cellulosic macromolecular network configuration of wood, we discussed the combination method and interfacial binding mechanism of TMC with raw wood, delignification wood and carbonized wood. We further discussed the thermal transformation mechanisms of non-radiative relaxation, relaxation loss and metal-insulator transition of TMC, the functional applications of TMC@wood composite materials in the fields of desalination, oil-water separation, building energy conservation and fire warning are presented. Finally, in view of providing ideas for advanced functionalization and energy conversion of wood, the current advantages and challenges of thermal conversion of TMC@wood are summarized.

-

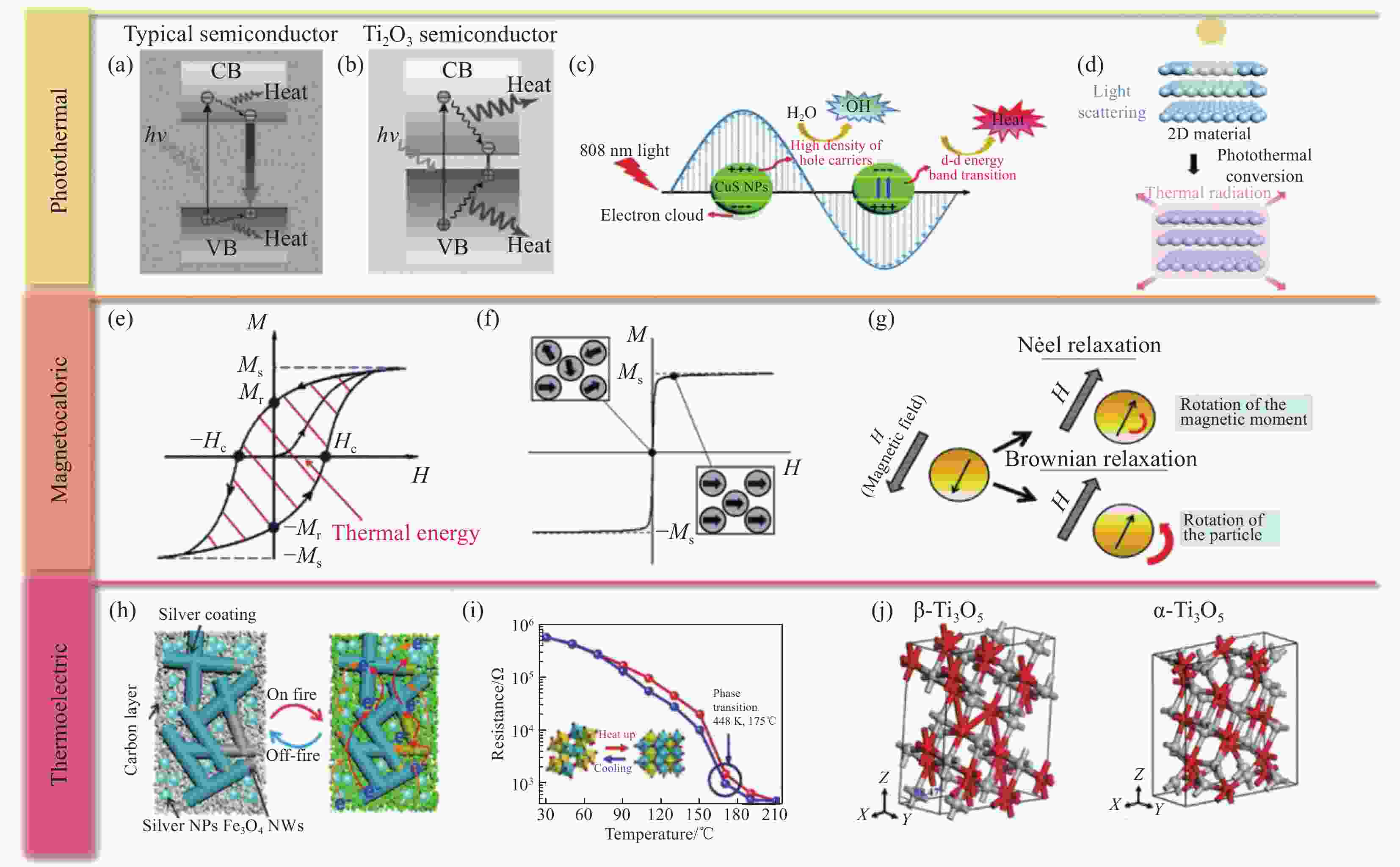

图 3 ((a)~(d)) 不同光热转换机制[29,50-51];((e)~(g)) 不同粒径铁磁性材料磁热转化机制[44];((h)~(j)) 温度-电信号转化机制[9,52]

Figure 3. ((a)-(d)) Different photothermal conversion mechanisms[29,50-51]; ((e)-(g)) Magnetothermal conversion mechanisms of ferromagnetic materials with different particle sizes[44]; ((h)-(j)) Thermoelectric conversion mechanisms[9,52]

CB—Conduction band; VB—Valence band; h—Planck constant; v—Frequency; M—Magnetization intensity; Ms—Specific magnetism; Mr—Residual magnetism; H—Magnetic field intensity; Hc—Coercive force; NPs—Nano particles; NWs—Nanowires

图 7 (a) 蒸发器工作原理;(b) 蒸发器的盐再溶解过程;(c) 天然木材(NW)、涂有高缺陷MoS2的木材(WM-H)合成和微观结构示意图[76];(d) 碳化木-TiO2@TiN超支纳米线蒸发器示意图及TiO2转变为TiN的形貌变化[69]

Figure 7. (a) Working principle of evaporator; (b) Salt redissolution process of evaporator; (c) Schematic diagram of synthesis and microstructure of natural wood (NW), wood coated with highly defective MoS2 (WM-H)[76]; (d) Schematic diagram of carbonized wood-TiO2@TiN hyperbranched nanowires evaporator and morphology change of TiO2 to TiN[69]

图 10 (a) Ti3O5智能涂层的制备和火灾预警机制[9];(b) MXene涂层的火灾预警机制[83];((c)~(d)) 热电响应机制与火灾预警[73]

Figure 10. (a) Preparation and fire warning mechanism of Ti3O5 smart coatings[9]; (b) Fire warning mechanism for MXene coatings[83]; ((c)-(d)) Thermoelectric response mechanism and fire warning[73]

CNC—Cellulose nanocrystals; RT—Room temperature; MMT—Montmorillonoid; UPC—2-ureido-4[1H]-pyrimidinone-containing cellulose; FR—Fire retardant; TE—Thermoelectricity

表 1 TMC@木材复合材料的制备方法

Table 1. Methods of TMC@wood composite preparation

Composite

methodOperational approach Reaction principle Advantage Disadvantage Ref. Painting Apply directly to the wood surface and dry Combination of hydroxyl groups on the wood surface by charge attraction or cross-linking Simplicity of operation Bond between TMC and wood is weak, usually by introducing other substances to act as a binder [62, 70-73] Soaking Wood is soaked in

TMC mother liquor

and then agedWool absorption

of

wood to load TMCSimplicity of operation and mild reaction conditions For raw wood TMC can only dip into the surface load, for delignified and carbonized wood it is possible to load deep inside [59, 67, 74] Vacuum/ultrasonic

impregnationWood is soaked in

TMC mother liquor, and the entire reaction occurs in a vacuumLow-pressure effect

allows TMC to grow evenly in woodMore uniform

growth

of TMCRelatively complex operation [58, 66, 75] Solvothermal

methodWood and TMC

mother liquor is placed in a stainless-steel high-pressure reactor with polytetrafluoroethylene

and then reacted at high temperaturesTMC grow evenly in wood under high

temperature and

pressureUniform and firm growth of the TMC required for the synthesis of the precursor solution in

the wood at high temperaturesComplex reaction

conditions[69, 76-77] 表 2 TMC@木材复合材料的组成、特点和应用领域

Table 2. Components, characteristics, and applications of TMC@wood composites

Wood TMC Combination method TMC@wood Characteristics Applications Basswood

(DW)Fe3O4 Fe3O4 cross-linking of wood surface hydroxyl groups and affinity enhancement by polyvinyl alcohol (cross-section) Fe-D-Wood [72] Evaporation rate 1.3 kg·m−2·h−1, 97% strong light absorption over the entire wavelength range, 73% photothermal conversion efficiency Desalination Balsa wood MoS2 with S defects —

(cross-section)WM-H [76] Evaporation rate of 1.46 kg·m−2·h−1

and heat conversion efficiency of 82.5%Desalination Beech wood (CW) TiO2@TiN —

(cross-section)TO@TNBNs-

CW [69]Evaporation rate 1.5252 kg·m−2·h−1, absorbs 97.42% of the sunlight, thermal conversion efficiency 94.01% Desalination Poplar wood FeNi —

(cross-section)W/FeNi/RGO [71] Evaporation rate 1.5 kg·m−2·h−1, thermal transfer efficiency 99.64% Desalination Paulownia wood MnO2 Mn interacts with O in the hydroxyl group of the wood through covalent coordination or hydrogen bonding (cross-section) K-wood [59] Evaporation rate 1.22 kg·m−2·h−1, efficiency 81.4%, sunlight absorption 94% Solar steam power, seawater desalination Basswood CuFeSe2 By forming Fe-O interactions with wood surface hydroxyl groups

(cross-section)Black wood [58] From 20°C to 51.5°C in 400 s irradiation time, solar thermal efficiency 86.2% Solar steam power, seawater desalination Paulownia wood Ti3C2−

OHTi3C2 surface hydroxyl modification and covalent bonding between the wood via isocyanate (cross-section) Ti3C2-wood [62] Evaporation rate of 1.465 kg·m−2·h−1 and solar energy conversion

efficiency of 96%Solar steam power, seawater desalination Poplar wood VO2 —

(cross-section)W/VO2-Ba [70] Evaporation rate 1.57 kg·m−2·h−1,

solar evaporation efficiency 93.45%Desalination Pinewood (CW) Black TiO2 —

(cross-section)BTW [77] Evaporation rate of 2.04 kg·m−2·h−1

and high solar steam efficiency of 90.06%Seawater desalination and degradation of organic pollutants Balsa wood (CW) Ag3PO4 —

(Impregnation to the interior)Ag3PO4@CW [67] photothermal conversion efficiency

of ~88.0% and a water generation

rate of 1.59 kg·m−2·h−1Desalination of sea water, removal of organic dyes, bacteria, heavy metal ions Balsa wood

(DW)Ti3C2Tx Hydrogen bonding via van der Waals forces and abundant hydroxyl groups (Impregnation to the interior) PDMS@WSM [74] 1.5 kW·m−2 simulated sunlight heats

to 66°C, maximum adsorption capacity of 11.2×105 g in 6 min,

25 mL of crude oil collected in 150 sCrude oil spills, energy conditioning and desalination of high brine Poplar wood (CW) Fe3O4 Formation of Fe-O bonds with

oxygen-containing functional groups of wood (Carbonized wood powder)Fe3O4-GNS/

CWF/

PCMC [75]Temperature rise above 65°C in

150 s, enthalpy of phase change greater than 95 J/g, phase change temperature about 55°C, thermal stability below 300°CEnergy harvesting, conversion and storage Balsa wood (DW) Fe3O4 Hydrogen bonding and van der Waals forces between wood and organic matter, Fe3O4 is located in the lumen of the tube (Impregnation to the interior) Fe3O4/TD/

DW [66]Large latent heat (179 J/g) and good thermal stability below 112°C Multifunctional thermal energy storage Poplar wood Fe3O4 Formation of Fe-O bonds with

oxygen-containing functional groups of wood (Impregnation to the interior)MW [20] From 25.9°C to 70.1°C in 10 minutes

at 35 kHz magnetic fieldArchitectural, decorative and massage furniture Pinus sylvestris Ag2Se Plasma treated substrates, introducing polar groups to provide good adhesion (longitudinal section) TE-FR [73] Fire alarm response time of only

2.0 s and excellent fire resistanceSelf-powered fire warning Fir wood/Beech wood Ti3O5 Interaction with PEI/APP by electrostatic attraction, covalent

cross-linking, hydrogen and ionic bonding (longitudinal section)PEI/APP/

Ti3O5 [52]Fire response time of approx. 3.78 s and significant fire, smoke and weather resistance Fire warning Beech wood Ti3C2Tx Stable bonding of the wood surface to MXene through an intermediate bonding bridge with hydrogen bonding of polydopamine, van der Waals forces and mechanical interlocking interactions

(longitudinal section)PA/C-MXene-Wood [83] Fire reaction time 2.1 s,

photocatalytic removal of VOCsFire warning, photocatalytic removal of VOCs Pinewood Ti3C2Tx Hydrogen bonding interactions (longitudinal section) MFNC [84] Fire alarm triggered within 4 s of combustion, coating with self-

healing and piezoresistive sensing capabilityFire warning, self-healing and pressure sensitive sensors Notes: PEI—Polyetherimide; PA—Polydopamine/ammonium polyphosphate; APP—Ammonium polyphosphate; TE-FR—Thermoelectric flame retardant; MFNC—Multifunctional fire protection nanocoating; TD—1-tetradecanol; GNS—Graphene nanosheets; CWF—Carbonized-wood-flour; PCMC—Phase-change-material composite; BTW—Black titanium dioxide loading on the surface of wood; RGO—Reduced graphene oxide; VOCs—Volatile organic compounds. -

[1] AMMAR Y, JOYCE S, NORMAN R, et al. Low-grade thermal energy sources and uses from the process industry in the UK[J]. Applied Energy,2012,89(1):3-20. doi: 10.1016/j.apenergy.2011.06.003 [2] ZHAO X, ZHANG Z, CHEN J, et al. A review on heat enhancement in thermal energy conversion and management using field synergy principle[J]. Applied Energy,2020,257:113995. doi: 10.1016/j.apenergy.2019.113995 [3] LIU J, LI J, ZHANG S, et al. Antibody-conjugated gold nanoparticles as nanotransducers for second near-infrared photo-stimulation of neurons in rats[J]. Nano Convergence,2022,9(1):13. doi: 10.1186/s40580-022-00304-y [4] YU M, XU P, YANG J, et al. Self-growth of MoS2 sponge for highly efficient photothermal cleanup of high-viscosity crude oil spills[J]. Advanced Materials Interfaces,2020,7(4):1901671. doi: 10.1002/admi.201901671 [5] WAN J, WANG J, GUO H, et al. Constructing ultra-stable photothermal plastics assisted by carbon dots with photo-caged reactivity[J]. Matter,2022,5(9):2864-2881. doi: 10.1016/j.matt.2022.05.036 [6] MEHDAOUI B, MEFFRE A, LACROIX L M, et al. Magnetic anisotropy determination and magnetic hyperthermia properties of small Fe nanoparticles in the superparamagnetic regime[J]. Journal of Applied Physics,2010,107(9):09A324. doi: 10.1063/1.3348795 [7] LI Z, YANG J, LI D, et al. Tuning the reversible magnetocaloric effect in Ni-Mn-In-based alloys through Co and Cu Co-doping[J]. Advanced Electronic Materials,2019,5:1800845. [8] GUO J, XIE L, LIU C, et al. Effect of Co/Ni substituting Fe on magnetocaloric properties of Fe-based bulk metallic glasses[J]. Metals,2021,11(6):950. doi: 10.3390/met11060950 [9] ZHANG S, ZHANG Y, HUANG Y P, et al. Intelligent coating based on metal-insulator transitional Ti3O5 towards fire sensing and protection[J]. Chemical Engineering Journal,2022,450:137910. doi: 10.1016/j.cej.2022.137910 [10] WU K H, JIANG Y, JIAO S, et al. Synthesis of high purity nano-sized transition-metal carbides[J]. Journal of Materials Research and Technology,2020,9(5):11778-11790. doi: 10.1016/j.jmrt.2020.08.053 [11] LANY S. Semiconducting transition metal oxides[J]. Jour-nal Physics Condensed Matter,2015,27(28):283203. doi: 10.1088/0953-8984/27/28/283203 [12] DAGOTTO E. Complexity in strongly correlated electronic systems[J]. Science,2005,309:257-262. doi: 10.1126/science.1107559 [13] NGAI J H, WALKER F J, AHN C H. Correlated oxide physics and electronics[J]. Annual Review of Materials Research,2014,44(1):1-17. doi: 10.1146/annurev-matsci-070813-113248 [14] LI W, WANG C, LU X. Integrated transition metal and compounds with carbon nanomaterials for electrochemical water splitting[J]. Journal of Materials Chemistry A,2021,9(7):3786-3827. doi: 10.1039/D0TA09495A [15] IDRIS I, DONG H S, ANDREW M, et al. Semiconductor photothermal materials enabling efficient solar steam generation toward desalination and wastewater treatment[J]. Desalination,2021(500):114853. [16] WU M B, HUANG S, LIU T Y, et al. Compressible carbon sponges from delignified wood for fast cleanup and enhanced recovery of crude oil spills by joule heat and photothermal effect[J]. Advanced Functional Materials,2020,31(3):2006806. [17] JIANG F, LI T, LI Y, et al. Wood-based nanotechnologies toward sustainability[J]. Advanced Materials,2018,30(1):1703453. doi: 10.1002/adma.201703453 [18] CHEN C, KUANG Y, ZHU S, et al. Structure-property-function relationships of natural and engineered wood[J]. Nature Reviews Materials,2020,5(9):642-666. doi: 10.1038/s41578-020-0195-z [19] JOHN S S, UWE G H, JARMILA P. Size and function in conifer tracheids and angiosperm vessels[J]. American Journal of Botany,2006,93(10):1490-1500. doi: 10.3732/ajb.93.10.1490 [20] GAN W, GAO L, XIAO S, et al. Magnetic wood as an effec-tive induction heating material: Magnetocaloric effect and thermal insulation[J]. Advanced Materials Interfaces,2017,4(22):1700777. doi: 10.1002/admi.201700777 [21] MENON V, RAO M. Trends in bioconversion of lignocellulose: Biofuels, platform chemicals & biorefinery concept[J]. Progress in Energy and Combustion Science,2012,38(4):522-550. doi: 10.1016/j.pecs.2012.02.002 [22] ZHU M, SONG J, LI T, et al. Highly anisotropic, highly transparent wood composites[J]. Advanced Materials,2016,26:5181-5187. [23] XIA Q Q, CHEN C J, LI T, et al. Solar-assisted fabrication of large-scale, patternable transparent wood[J]. Science Advances,2021,7(5):eabd7342. doi: 10.1126/sciadv.abd7342 [24] COURET L, IRLE M, BELLONCLE C, et al. Extraction and characterization of cellulose nanocrystals from post-consumer wood fiberboard waste[J]. Cellulose,2017,24(5):2125-2137. doi: 10.1007/s10570-017-1252-7 [25] WANG W, WANG X, ZHANG Y, et al. Effect of sodium hydroxide pretreatment on physicochemical changes and enzymatic hydrolysis of herbaceous and woody lignocelluloses[J]. Industrial Crops and Products,2020,145:112145. doi: 10.1016/j.indcrop.2020.112145 [26] CAO S, JIANG Q, WU X, et al. Advances in solar evaporator materials for freshwater generation[J]. Journal of Materials Chemistry A,2019,7(42):24092-24123. doi: 10.1039/C9TA06034K [27] GUO X Z, ZHANG Y D, QIN D, et al. Hybrid tandem solar cell for concurrently converting light and heat energy with utilization of full solar spectrum[J]. Journal of Power Sources,2010,195(22):7684-7690. doi: 10.1016/j.jpowsour.2010.05.033 [28] LIU G, XU J, WANG K. Solar water evaporation by black photothermal sheets[J]. Nano Energy,2017,41:269-284. doi: 10.1016/j.nanoen.2017.09.005 [29] WANG J, LI Y, DENG L, et al. High-performance photothermal conversion of narrow-bandgap Ti2O3 nanoparticles[J]. Advanced Materials,2017,29(3):1-6. [30] WANG L, LIU X, DANG Y, et al. Enhanced solar induced photo-thermal synergistic catalytic CO2 conversion by photothermal material decorated TiO2[J]. Solid State Sciences,2019,89:67-73. doi: 10.1016/j.solidstatesciences.2018.12.018 [31] DOMINGOS G H S, RUELLAS T M O, PEÇANHA L O O, et al. ZnO semiconductors obtained by slip casting: Application and reuse in photocatalysis[J]. International Journal of Applied Ceramic Technology,2021,18(3):622-630. doi: 10.1111/ijac.13698 [32] ABID M A, KADHIM D A. Novel comparison of iron oxide nanoparticle preparation by mixing iron chloride with henna leaf extract with and without applied pulsed laser ablation for methylene blue degradation[J]. Journal of Environmental Chemical Engineering,2020,8(5):104138. doi: 10.1016/j.jece.2020.104138 [33] SUN L, LI Z L, LI Z, et al. Design and mechanism of core-shell TiO2 nanoparticles as a high-performance photothermal agent[J]. Nanoscale,2017,9(42):16183-16192. doi: 10.1039/C7NR02848B [34] YANG H, ZHOU J, DUAN Z, et al. Amorphous TiO2 beats P25 in visible light photo-catalytic performance due to both total-internal-reflection boosted solar photothermal conversion and negative temperature coefficient of the forbidden bandwidth[J]. Applied Catalysis B: Environmental,2022,310:121299. doi: 10.1016/j.apcatb.2022.121299 [35] ZHU D, CAI L, SUN Z, et al. Efficient degradation of tetracycline by RGO@black titanium dioxide nanofluid via enhanced catalysis and photothermal conversion[J]. Science of the Total Environment,2021,787:147536. doi: 10.1016/j.scitotenv.2021.147536 [36] QI Y, JIANG J, LIANG X, et al. Fabrication of black In2O3 with dense oxygen vacancy through dual functional carbon doping for enhancing photothermal CO2 hydrogenation[J]. Advanced Functional Materials,2021,31(22):2100908. doi: 10.1002/adfm.202100908 [37] QI F, YANG Z, ZHANG J, et al. Interfacial reaction-induced defect engineering: Enhanced visible and near-infrared absorption of wide band gap metal oxides with abundant oxygen vacancies[J]. ACS Applied Materials & Interfaces,2020,12(49):55417-55425. [38] ZHU L, GAO M, PEH C K N, et al. Solar-driven photothermal nanostructured materials designs and prerequisites for evaporation and catalysis applications[J]. Materials Horizons,2018,5(3):323-343. doi: 10.1039/C7MH01064H [39] STEPHAN L, MOSTAFA A, EL-SAYED. Shape and size dependence of radiative, non-radiative and photothermal properties of gold nanocrystals[J]. International Reviews in Physical Chemistry,2000,19(3):409-453. doi: 10.1080/01442350050034180 [40] DOTAN H, KFIR O, SHARLIN E, et al. Resonant light trapping in ultrathin films for water splitting[J]. Nature Material,2013,12(2):158-164. doi: 10.1038/nmat3477 [41] NERL H C, WINTHER K T, HAGE F S, et al. Probing the local nature of excitons and plasmons in few-layer MoS2[J]. npj 2D Materials and Applications,2017,2:1-9. [42] LIN H, WANG X, YU L, et al. Two-dimensional ultrathin MXene ceramic nanosheets for photothermal conversion[J]. Nano Letter,2017,17(1):384-391. doi: 10.1021/acs.nanolett.6b04339 [43] STARSICH F H L, EBERHARDT C, BOSS A, et al. Coercivity determines magnetic particle heating[J]. Advanced Healthcare Materials,2018,7(19):e1800287. doi: 10.1002/adhm.201800287 [44] SANGAA D, KHONGORZUL B, UYANGA E, et al. An overview of investigation for ferrite magnetic nanomaterial[J]. Solid State Phenomena,2018,271:51-63. doi: 10.4028/www.scientific.net/SSP.271.51 [45] PABLO G, RICCARDO D C, LENAIC L, et al. Water-soluble iron oxide nanocubes with high values of specific absorption rate for cancer cell hyperthermia treatment[J]. ACS Nano,2012,6(4):3080-3091. doi: 10.1021/nn2048137 [46] VAJHADIN F, MAZLOUM-ARDAKANI M, SHAHIDI M, et al. MXene-based cytosensor for the detection of HER2-positive cancer cells using CoFe2O4@Ag magnetic nanohybrids conjugated to the HB5 aptamer[J]. Biosensors and Bioelectronics,2022,195:113626. doi: 10.1016/j.bios.2021.113626 [47] OH Y, LEE N, KANG H W, et al. In vitro study on apoptotic cell death by effective magnetic hyperthermia with chitosan-coated MnFe2O4[J]. Nanotechnology,2016,27(11):115101. doi: 10.1088/0957-4484/27/11/115101 [48] AONO H, YAMANO Y, NISHIMORI T, et al. Heat generation properties in AC magnetic field for Y3Fe5O12 powder material synthesized by a reverse coprecipitation method[J]. Ceramics International,2015,41(7):8461-8467. doi: 10.1016/j.ceramint.2015.03.048 [49] TONG S, QUINTO C A, ZHANG L, et al. Size-dependent heating of magnetic iron oxide nanoparticles[J]. ACS Nano,2017,11(7):6808-6816. doi: 10.1021/acsnano.7b01762 [50] LI M, LIU X, TAN L, et al. Noninvasive rapid bacteria-killing and acceleration of wound healing through photothermal/photodynamic/copper ion synergistic action of a hybrid hydrogel[J]. Biomaterials Science,2018,6(8):2110-2121. doi: 10.1039/C8BM00499D [51] XU D, LI Z, LI L, et al. Insights into the photothermal conversion of 2D MXene nanomaterials: Synthesis, mechanism, and applications[J]. Advanced Functional Materials,2020,30(47):2000712. doi: 10.1002/adfm.202000712 [52] ZHANG M, WANG M, ZHANG M, et al. Flexible and thermally induced switchable fire alarm fabric based on layer-by-layer self-assembled silver sheet/Fe3O4 nanowire composite[J]. ACS Applied Materials & Interfaces,2019,11(50):47456-47467. [53] VICTOR J L, GAUDON M, SALVATORI G, et al. Doubling of the phase transition temperature of VO2 by Fe doping[J]. Journal of Physical Chemistry Letters,2021,12(32):7792-7796. doi: 10.1021/acs.jpclett.1c02179 [54] LEE D, CHUNG B, SHI Y, et al. Isostructural metal-insulator transition in VO2[J]. Science,2018,362:1037-1040. doi: 10.1126/science.aam9189 [55] SHABALIN A G, VALLE J, HUA N, et al. Nanoscale imaging and control of volatile and non-volatile resistive switching in VO2[J]. Small,2020,16(50):2005439. doi: 10.1002/smll.202005439 [56] TOMOHIKO N. Intermediate-temperature sensors based on La0.5Ba0.5MnO3/nano porous anodic aluminum oxide multilayered film thermistors[J]. Journal of Materials Chemistry C,2019(7):5193-5200. [57] LUISA W, WU T L, ADAM S, et al. Single-nanowire Raman microprobe studies of doping, temperature, and voltage-induced metal-insulator transitions of WxV1-xO2 nanowires[J]. ACS Nano,2011,5(11):8861-8867. doi: 10.1021/nn203542c [58] LIU H, CHEN C, WEN H, et al. Narrow bandgap semiconductor decorated wood membrane for high-efficiency solar-assisted water purification[J]. Journal of Materials Che-mistry A,2018,6(39):18839-18846. doi: 10.1039/C8TA05924A [59] LI D, HAN D, GUO C, et al. Facile preparation of MnO2-deposited wood for high-efficiency solar steam generation[J]. ACS Applied Energy Materials,2021,4(2):1752-1762. doi: 10.1021/acsaem.0c02902 [60] SHEN H, CAO J, JIANG J, et al. Anti-weathering properties of a thermally treated wood surface by two-step treatment with titanium dioxide nanoparticle growth and polydimethylsiloxane coating[J]. Progress in Organic Coatings,2018,125:1-7. doi: 10.1016/j.porgcoat.2018.08.011 [61] GAN W, LIU Y, GAO L, et al. Growth of CoFe2O4 particles on wood template using controlled hydrothermal method at low temperature[J]. Ceramics International,2015,41(10):14876-14885. doi: 10.1016/j.ceramint.2015.08.014 [62] MA N, FU Q, HONG Y, et al. Processing natural wood into an efficient and durable solar steam generation device[J]. ACS Applied Materials & Interfaces,2020,12(15):18165-18173. [63] SEGMEHL J S, LAROMAINE A, KEPLINGER T, et al. Magnetic wood by in situ synthesis of iron oxide nanoparticles via a microwave-assisted route[J]. Journal of Materials Chemistry C,2018,6(13):3395-3402. doi: 10.1039/C7TC05849G [64] OSKAR P, INGO B, PETER F. Biomimetics and biotemplating of natural materials[J]. MRS Bulletin,2010,35:219-225. doi: 10.1557/mrs2010.655 [65] ZHENG D, YAO W, SUN C, et al. Solar-assisted self-heating Ti3C2Tx-decorated wood aerogel for adsorption and recovery of highly viscous crude oil[J]. Journal of Hazardous Materials Letters,2022,435:129068. doi: 10.1016/j.jhazmat.2022.129068 [66] YANG H, CHAO W, DI X, et al. Multifunctional wood based composite phase change materials for magnetic-thermal and solar-thermal energy conversion and storage[J]. Energy Conversion and Management,2019,200:112029. doi: 10.1016/j.enconman.2019.112029 [67] XI Y, DU C, LI P, et al. Combination of photothermal conversion and photocatalysis toward water purification[J]. Industrial & Engineering Chemistry Research,2022,61(13):4579-4587. [68] BYRNE C E, NAGLE D C. Carbonized wood monoliths-characterization[J]. Carbon,1997,35(2):267-273. doi: 10.1016/S0008-6223(96)00135-2 [69] REN P, LI J, ZHANG X, et al. Highly efficient solar water evaporation of TiO2@TiN hyperbranched nanowires-carbonized wood hierarchical photothermal conversion material[J]. Materials Today Energy,2020,18:100546. doi: 10.1016/j.mtener.2020.100546 [70] AZIZNEZHAD M, GOHARSHADI E K, MEHRKHAH R, et al. Alkaline earth metals doped VO2 nanoparticles for enhanced interfacial solar steam generation[J]. Materials Research Bulletin,2022,149:111705. doi: 10.1016/j.materresbull.2021.111705 [71] MEHRKHAH R, GOHARSHADI E K, MOHAMMADI M. Highly efficient solar desalination and wastewater treatment by economical wood-based double-layer photoabsorbers[J]. Journal of Industrial and Engineering Che-mistry,2021,101:334-347. doi: 10.1016/j.jiec.2021.05.049 [72] SONG L, ZHANG X F, WANG Z, et al. Fe3O4/polyvinyl alcohol decorated delignified wood evaporator for continuous solar steam generation[J]. Desalination,2021,507:115024. doi: 10.1016/j.desal.2021.115024 [73] XIE H, LAI X, LI H, et al. Skin-inspired thermoelectric nanocoating for temperature sensing and fire safety[J]. Journal of Colloid and Interface Science,2021,602:756-766. doi: 10.1016/j.jcis.2021.06.054 [74] WANG P L, MA C, YUAN Q, et al. Novel Ti3C2Tx MXene wrapped wood sponges for fast cleanup of crude oil spills by outstanding Joule heating and photothermal effect[J]. Journal of Colloid and Interface Science,2022,606:971-982. doi: 10.1016/j.jcis.2021.08.092 [75] CHAO W, YANG H, CAO G, et al. Carbonized wood flour matrix with functional phase change material composite for magnetocaloric-assisted photothermal conversion and storage[J]. Energy,2020,202:117636. doi: 10.1016/j.energy.2020.117636 [76] HE X, ZHANG L, HU X, et al. Formation of S defects in MoS2-coated wood for high-efficiency seawater desalination[J]. Environmental Science-Nano,2021,8(7):2069-2080. doi: 10.1039/D1EN00106J [77] XIAO B, YU F, XIA Y, et al. Wood-based, bifunctional, mulberry-like nanostructured black titania evaporator for solar-driven clean water generation[J]. Energy Technology,2022,10(3):2100679. doi: 10.1002/ente.202100679 [78] WANG H. Low-energy desalination[J]. Nature Nanotechnology,2018,13(4):273-274. doi: 10.1038/s41565-018-0118-y [79] WU L, LI L, LI B, et al. Magnetic, durable, and superhydrophobic polyurethane@Fe3O4@SiO2@fluoropolymer sponges for selective oil absorption and oil/water separation[J]. ACS Applied Materials & Interfaces,2015,7(8):4936-4946. doi: 10.1021/am5091353 [80] LI Q, SUN Q, LI Y, et al. Solar-heating crassula perforata-structured superoleophilic CuO@CuS/PDMS nanowire arrays on copper foam for fast remediation of viscous crude oil spill[J]. ACS Applied Materials & Interfaces,2020,12(17):19476-19482. [81] CHEN Z, SU X, WU W, et al. Superhydrophobic PDMS@TiO2 wood for photocatalytic degradation and rapid oil-water separation[J]. Surface and Coatings Technology,2022,434:128182. doi: 10.1016/j.surfcoat.2022.128182 [82] YANG H, CHAO W, WANG S, et al. Self-luminous wood composite for both thermal and light energy storage[J]. Energy Storage Materials,2019,18:15-22. doi: 10.1016/j.ensm.2019.02.005 [83] ZHANG Y, HUANG Y, LI M C, et al. Bioinspired, stable adhesive Ti3C2Tx MXene-based coatings towards fire warning, smoke suppression and VOCs removal smart wood[J]. Chemical Engineering Journal,2022,452(4):139360. [84] ZENG Q, ZHAO Y, LAI X, et al. Skin-inspired multifunctional MXene/cellulose nanocoating for smart and efficient fire protection[J]. Chemical Engineering Journal,2022,446:136899. doi: 10.1016/j.cej.2022.136899 -

下载:

下载: