Preparation and properties of polyphosphazene modified composite separator for lithium-ion battery

-

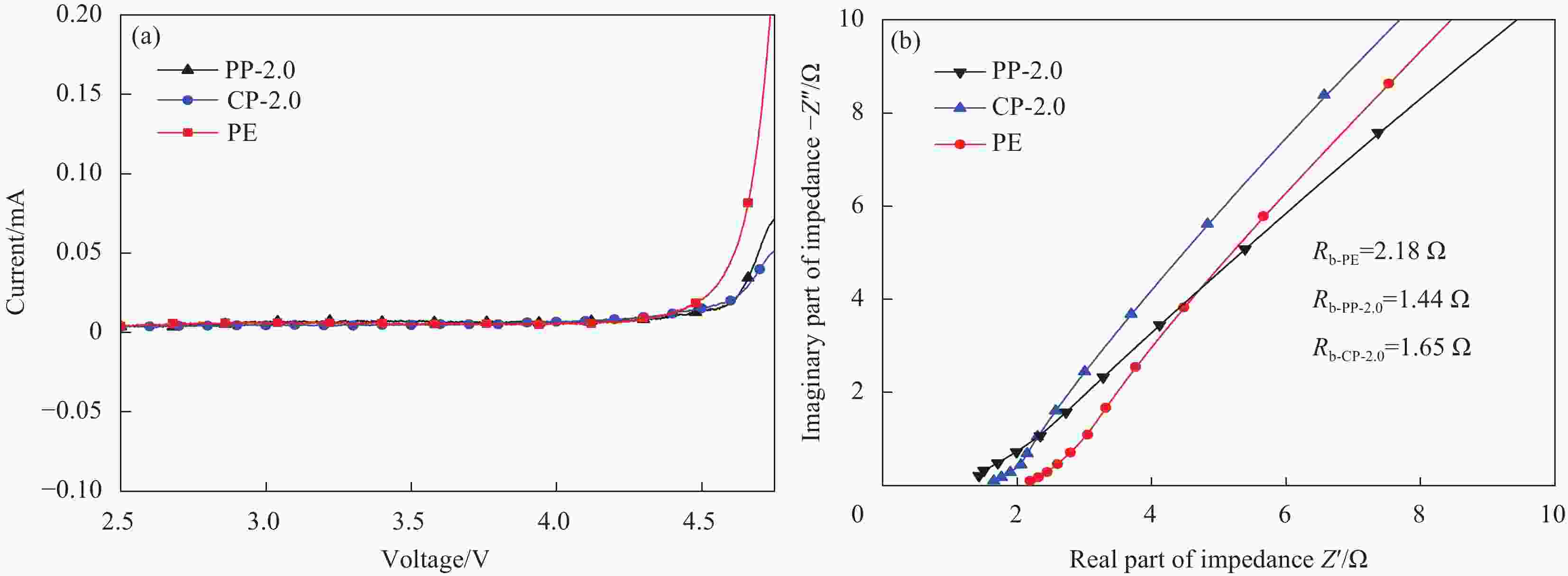

摘要: 锂离子电池要求隔膜具有良好的亲液性和耐热性。本文设计原位限域聚合法,利用聚(环三磷腈-4, 4-磺酰基二苯酚)微球(PZSMS)修饰聚偏氟乙烯(PVDF)纤维基膜,通过单体与引发剂分别引入的策略调控PZSMS的尺寸和分布,促进PVDF纤维表面连续包覆层的形成,获得新型复合膜。对隔膜的理化性能(孔道结构、力学性能、电解液性能和耐热性)和电池性能(循环性能、倍率性能)进行系统研究。结果表明:在优化条件下,复合膜的吸液率和离子电导率分别达到433%和1.47 mS/cm,拉伸强度大于25 MPa,且在150℃、0.5 h内热收缩率低于2%,优于PVDF基膜及市售聚乙烯隔膜(PE)隔膜。在钴酸锂/石墨电池中,优化的复合膜显示出较好的电池充放电性能,如8.0 C时的放电容量为0.5 C时的76%,200次循环后放电容量保持率为97%。因此,原位限域聚合法制备的PZSMS修饰PVDF纤维膜在锂离子电池中显示出较好的应用前景。Abstract: Separators with superior electrolyte property and thermal stability are in urgent need for lithium-ion batteries (LIBs). This work designed a space-confined polymerization method to fabricate an advanced composite separator, in which poly(cyclotriphosphazene-co-4, 4-sulfonyldiphenol) microspheres (PZSMS) grow directly in poly(vinylidene fluoride) (PVDF) membrane as the substrate. To regulate the size and distribution of PZSMS, triethylamine vapor as acid-binding agent is introduced into PVDF membrane separately from the polymeric monomers. The physical-chemical properties and battery performances of PPCS were systematically characterized, such as the structure, tensile strength, electrolyte property and thermal resistance as well as the charge-discharge performance. The results show that under the optimized conditions, the liquid absorbency and ionic conductivity of the composite membrane reach 433% and 1.47 mS/cm, respectively, the tensile strength is greater than 25 MPa, and the thermal shrinkage rate is lower than 2% at 150℃ and 0.5 h, which is better than that of PVDF based membrane and commercial polyethylene (PE) membrane. The LiCoO2/graphite cells with optimized separators exhibit satisfactory discharge capacity retention of 76% at 8.0 C compared with that at 0.5 C and preferable cycling stability with a capacity retention of 97% after 200 cycles. Therefore, PZSMS modified PVDF fibrous membrane prepared by space-confined polymerization method shows a good application prospect in lithium-ion batteries.

-

表 1 聚偏氟乙烯(PVDF)-聚(环三磷腈-4,4-磺酰基二苯酚)微球(PZSMS)复合隔膜的命名

Table 1. Sample naming of poly(vinylidene fluoride) (PVDF)-poly(cyclotriphosphazene-co-4,4-sulfonyldiphenol) microspheres (PZSMS) composite separator

Sample Reaction time/h PVDF — PP-0.5 0.5 PP-1.0 1.0 PP-2.0 2.0 PP-4.0 4.0 CP-2.0 2.0 Notes: PP—PVDF-PZSMS composite separator; CP—Conven-tional composite separator. 表 2 静置不同时间后PE、PP-2.0及CP-2.0膜的界面电阻(Rint)

Table 2. Interfacial resistance (Rint) of PE, PP-2.0, CP-2.0 separators as a function of stabilization time

Sample Rint 1 d 3 d 5 d 7 d PE 303 423 525 571 PP-2.0 249 291 335 355 CP-2.0 270 361 436 464 -

[1] HUANG X, HE R, LI M, et al. Functionalized separator for next-generation batteries[J]. Materials Today,2020,41:143-155. doi: 10.1016/j.mattod.2020.07.015 [2] MITTAL N, OJANGUREN A, CAVASIN N, et al. Transient rechargeable battery with a high lithium transport number cellulosic separator[J]. Advanced Functional Materials,2021,31(33):2101827. doi: 10.1002/adfm.202101827 [3] ZHAI P, LIU K, WANG Z, et al. Multifunctional separators for high-performance lithium ion batteries[J]. Journal of Power Sources,2021,499:229973. doi: 10.1016/j.jpowsour.2021.229973 [4] FRANCIS C F J, KYRATZIS I L, BEST A S. Lithium-ion battery separators for ionic-liquid electrolytes: A review[J]. Advanced Materials,2020,32(18):1904205. doi: 10.1002/adma.201904205 [5] YUAN B, WEN K, CHEN D, et al. Composite separators for robust high rate lithium ion batteries[J]. Advanced Functional Materials,2021,31(32):2101420. doi: 10.1002/adfm.202101420 [6] 张红涛, 胡昊, 顾波, 等. 聚偏氟乙烯-沸石复合锂电隔膜的制备及性能[J]. 复合材料学报, 2017, 34(3):625-631.ZHANG Hongtao, HU Hao, GU Bo, et al. Preparation and performances of PVDF-zeolite composite separator for lithium-ion batteries[J]. Acta Materiae Compositae Sinica,2017,34(3):625-631(in Chinese). [7] LIANG J, CHEN Q, LIAO X, et al. A nano-shield design for separators to resist dendrite formation in lithium-metal batteries[J]. Angewandte Chemie,2020,132(16):6623-6628. doi: 10.1002/ange.201915440 [8] 巩桂芬, 王磊, 徐阿文. 静电纺PMMA/EVOH-SO3Li锂离子电池隔膜复合材料的制备及性能[J]. 复合材料学报, 2018, 35(3):477-484.GONG Guifen, WANG Lei, XU Awen. Preparation and properties of PMMA/EVOH-SO3Li Li-ion battery separator composite by electrospinning[J]. Acta Materiae Compositae Sinica,2018,35(3):477-484(in Chinese). [9] HEIDARI A A, MAHDAVI H. Recent development of polyolefin-based microporous separators for Li-ion batteries: A review[J]. The Chemical Record,2020,20(6):570-595. doi: 10.1002/tcr.201900054 [10] LAGADEC M F, ZAHN R, WOOD V. Characterization and performance evaluation of lithium-ion battery separators[J]. Nature Energy,2019,4(1):16-25. [11] 肖伟, 巩亚群, 王红, 等. 锂离子电池隔膜技术进展[J]. 储能科学与技术, 2016, 5(2):188-196. doi: 10.3969/j.issn.2095-4239.2016.02.010XIAO Wei, GONG Yaqun, WANG Hong, et al. Research progress of separators for lithium-ion batteries[J]. Energy Storage Science and Technology,2016,5(2):188-196(in Chinese). doi: 10.3969/j.issn.2095-4239.2016.02.010 [12] ZHANG X, SUN Q, ZHEN C, et al. Recent progress in flame-retardant separators for safe lithium-ion batteries[J]. Energy Storage Materials,2021,37:628-647. doi: 10.1016/j.ensm.2021.02.042 [13] LI H, WU D, WU J, et al. Flexible, high-wettability and fire-resistant separators based on hydroxyapatite nanowires for advanced lithium-ion batteries[J]. Advanced Materials,2017,29(44):1703548. doi: 10.1002/adma.201703548 [14] SUN G, KONG L, LIU B, et al. Ultrahigh-strength, nonflammable and high-wettability separators based on novel polyimide-core@polybenzimidazole-sheath nanofibers for advanced and safe lithium-ion batteries[J]. Journal of Membrane Science,2019,582:132-139. doi: 10.1016/j.memsci.2019.04.005 [15] KONG L, WANG Y, YU H, et al. In situ armoring: A robust, high-wettability, and fire-resistant hybrid separator for advanced and safe batteries[J]. ACS Applied Materials & Interfaces,2019,11(3):2978-2988. doi: 10.1021/acsami.8b17521 [16] SHENG O, JIN C, LUO J, et al. Mg2B2O5 nanowire enabled multifunctional solid state electrolytes with high ionic conductivity, excellent mechanical properties, and flame retardant performance[J]. Nano Letters,2018,18(5):3104-3112. doi: 10.1021/acs.nanolett.8b00659 [17] HAN Y Y, LIU B, XIAO Z, et al. Interface issues of lithium metal anode for high-energy batteries: Challenges, strategies, and perspectives[J]. InfoMat,2021,3(2):155-174. doi: 10.1002/inf2.12166 [18] YEON D, LEE Y, RYOU M H, et al. New flame-retardant composite separators based on metal hydroxides for lithium-ion batteries[J]. Electrochimica Acta,2015,157:282-289. doi: 10.1016/j.electacta.2015.01.078 [19] WANG T, SALVATIERRA R V, TOUR J M. Detecting Li dendrites in a two-electrode battery system[J]. Advanced Materials,2019,31(14):1807405. doi: 10.1002/adma.201807405 [20] FU W, XU R, ZHANG X, et al. Enhanced wettability and electrochemical performance of separators for lithium-ion batteries by coating core-shell structured silica-poly (cyclotriphosphazene-co-4, 4′-sulfonyldiphenol) particles[J]. Journal of Power Sources,2019,436:226839. doi: 10.1016/j.jpowsour.2019.226839 [21] ZHU J, BREU J, HOU H, et al. Gradient-structured nonflammable flexible polymer membranes[J]. ACS Applied Materials & Interfaces,2019,11(12):11876-11883. [22] LIU K, LIU W, QIU Y, et al. Electrospun core-shell microfiber separator with thermal-triggered flame-retardant properties for lithium-ion batteries[J]. Science Advances,2017,3(1):1601978. doi: 10.1126/sciadv.1601978 [23] XIAO W, CHENG D, HUANG L, et al. An integrated separator/anode assembly based on electrospinning technique for advanced lithium-ion batteries[J]. Electrochimica Acta,2021,389:138776. doi: 10.1016/j.electacta.2021.138776 [24] WEITKAMP R F, NEUMANN B, STAMMLER H G, et al. Phosphorus-containing superbases: Recent progress in the chemistry of electron-abundant phosphines and phosphazenes[J]. Chemistry A European Journal,2021,27(42):10807-10825. doi: 10.1002/chem.202101065 [25] ZHANG J, HUANG X, WEI H, et al. Enhanced electrochemical properties of polyethylene oxide-based composite solid polymer electrolytes with porous inorganic-organic hybrid polyphosphazene nanotubes as fillers[J]. Journal of Solid State Electrochemistry,2012,16(1):101-107. doi: 10.1007/s10008-010-1278-3 [26] TAO X, LI Y, WANG H, et al. Multi-heteroatom-doped dual carbon-confined Fe3O4 nanospheres as high-capacity and long-life anode materials for lithium/sodium ion batteries[J]. Journal of Colloid and Interface Science,2020,565:494-502. doi: 10.1016/j.jcis.2020.01.018 [27] DUFEK E J, STONE M L, JAMISON D K, et al. Hybrid phosphazene anodes for energy storage applications[J]. Journal of Power Sources,2014,267:347-355. doi: 10.1016/j.jpowsour.2014.05.105 [28] HAN H, MA H, YU J, et al. Preparation and performance of novel tetrapheneylphosphonium- functionalized polyphosphazene membranes for alkaline fuel cells[J]. European Polymer Journal,2019,114:109-117. doi: 10.1016/j.eurpolymj.2019.02.022 [29] WEI X, ZHENG D, ZHAO M, et al. Cross-linked polyphosphazene hollow nanosphere-derived N/P-doped porous carbon with single nonprecious metal atoms for the oxygen reduction reaction[J]. Angewandte Chemie International Edition,2020,59(34):14639-14646. doi: 10.1002/anie.202006175 [30] NI Z, YU H, WANG L, et al. Recent research progress on polyphosphazene-based drug delivery systems[J]. Journal of Materials Chemistry B,2020,8(8):1555-1575. doi: 10.1039/C9TB02517K [31] CHEN R, HUANG X, ZHENG R, et al. Flame-retardancy and thermal properties of a novel phosphorus-modified PCM for thermal energy storage[J]. Chemical Engineering Journal,2020,380:122500. doi: 10.1016/j.cej.2019.122500 [32] ZHOU Z, CHEN F, WU L, et al. Heteroatoms-doped 3D carbon nanosphere cages embedded with MoS2 for lithium-ion battery[J]. Electrochimica Acta,2020,332:135490. doi: 10.1016/j.electacta.2019.135490 [33] 崔巍巍, 孟庆朋, 王振宇, 等. 大倍率高耐热聚醚酰亚胺-聚偏氟乙烯芯壳纳米纤维锂离子电池隔膜[J]. 复合材料学报, 2019, 36(1):69-76.CUI Weiwei, MENG Qingpeng, WANG Zhenyu, et al. A high rate and heat-resistant polyether imide-polyvinylidene fluoride core-shell nanofiber separator for lithium-ion battery[J]. Acta Materiae Compositae Sinica,2019,36(1):69-76(in Chinese). [34] CHEN X, XU H, LIU D, et al. A facile one-pot fabrication of polyphosphazene microsphere/carbon fiber hybrid reinforcement and its effect on the interfacial adhesion of epoxy composites[J]. Applied Surface Science,2017,410:530-539. doi: 10.1016/j.apsusc.2017.03.104 [35] LIU Y, WANG N, SUN Z, et al. Selective adsorption of malachite green (MG) and fuchsin acid (FA) by ZIF-67 hybridized polyvinylidene fluoride (PVDF) membranes[J]. Dalton Transactions,2021,50(25):8927-8937. doi: 10.1039/D1DT01000J [36] CHEN Z, FU J, WANG M, et al. Adsorption of cationic dye (methylene blue) from aqueous solution using poly (cyclotriphosphazene-co-4, 4′-sulfonyl-diphenol) nanospheres[J]. Applied Surface Science,2014,289:495-501. doi: 10.1016/j.apsusc.2013.11.022 [37] LIU W, JIN J, HUANG X, et al. A facile strategy for the functionalization of poly [cyclotriphosphazene-co-(4, 4′-sulfonyldiphenol)] materials[J]. Polymer International,2010,59(9):1252-1257. doi: 10.1002/pi.2857 [38] XU L, CHEN Y, LIU P, et al. Fabrication and investigation of PE-SiO2@PZS composite separator for lithium-ion batteries[J]. Materials,2022,15(14):4875. doi: 10.3390/ma15144875 -

下载:

下载: