Experiment and molecular dynamics simulation of cellulose nanocrystals cement-based composites

-

摘要: 探究纤维素纳米晶须(CNC)及其包覆聚乙烯(PE)纤维对砂浆性能的影响。采用XRD分析水化产物、核磁共振技术(NMR)测量试块孔隙率、SEM表征纤维水泥基复合材料界面、EDS测量水化硅酸钙(C-S-H)的钙硅比,使用分子动力学模拟(MD)分析两种官能化CNC和水泥基体间的吸附能、动力学特性和回转半径。 结果表明:CNC促进了水泥水化且增强了水化产物致密性,限制了基体的孔隙发育,提升了砂浆力学性能;不同官能团与水泥水化物之间的吸附存在差别,影响CNC的增强效果;CNC涂层可以增强纤维与水泥基体的界面粘结,提高复合材料协同工作性能。

-

关键词:

- 水泥基复合材料 /

- 分子动力学模拟 /

- 官能化纤维素纳米晶须 /

- 吸附界面 /

- 纤维

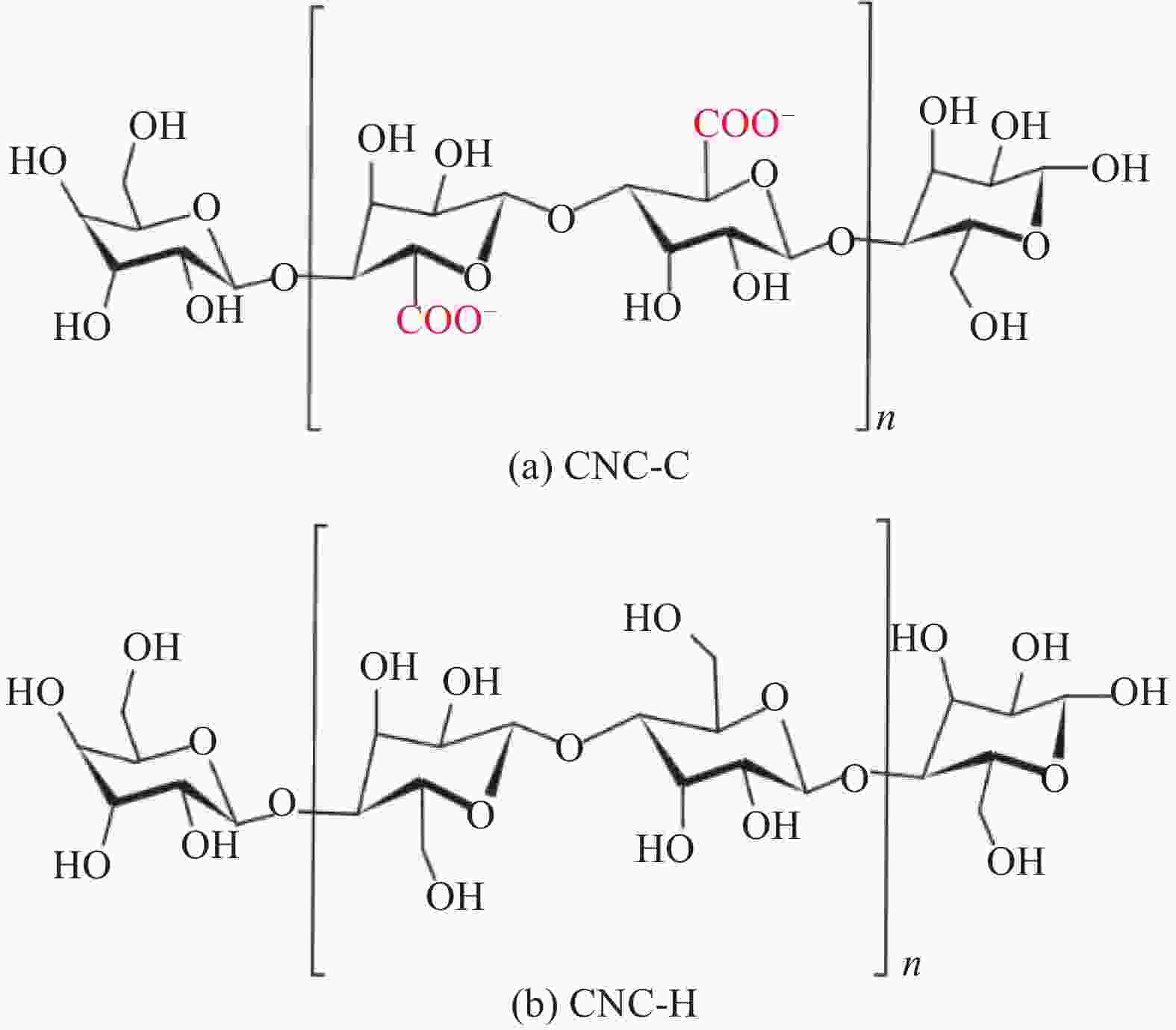

Abstract: To explore the effects of cellulose nanocrystals (CNC) and coated CNC polyethylene (PE) fibers on the performance of mortar, XRD was employed to analyze the hydration products, and nuclear magnetic resonance (NMR) technique was taken to measure porosity. Calcium-silicon ratio of calcium silicate hydrate (C-S-H) was measured by EDS and PE/C-S-H interface was characterized by SEM. The adsorption energies, kinetic properties and gyration of radius between the two CNCs and C-S-H were analyzed by molecular dynamics simulations (MD). The needle-like CNC promotes hydration and affects the compactness of the hydration products, curbs the development of pores and improves the mechanical properties of the mortar. There are differences in the adsorption between different functional groups and cement matrix, which affects the reinforcement effect of cellulose nanocrystals. CNC coating improves the bonding between the fibers and the cement matrix, improving the synergistic performance of composite materials. -

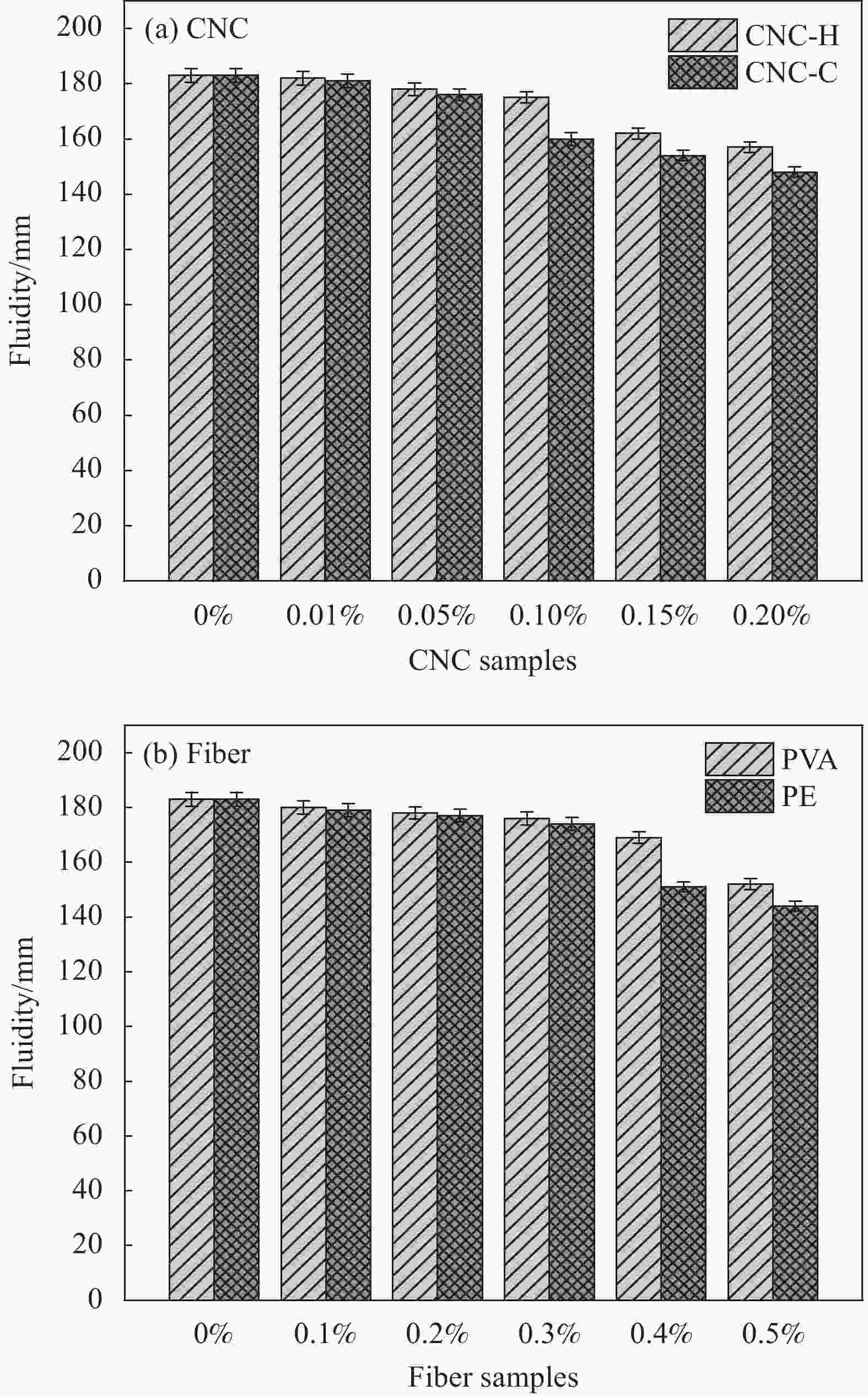

图 3 泥浆的XRD图谱 (a)、溶解峰 (b) 和水化热 (c) 结果;CNC-C (d)、CNC-H (e)、PE (f)、PVA (g) 和CNC纤维 (h) 的砂浆抗折强度

Figure 3. XRD patterns (a), dissolution peak (b) and hydration heat (c) of mortar; Flexural strength of CNC-C (d), CNC-H (e), PE (f), PVA (g) and CNC fiber (h)

CH—Calcium hydroxide; C3S—Tricalcium silicate; C2S—Dicalcium silicate

图 4 CNC-C (a)、CNC-H (b) 砂浆的3天抗压强度;CNC-C (a)、CNC-H (b)、PE (c)、PVA (d) 和CNC纤维 (e) 的28天抗压强度及不同掺量的CNC-C和CNC-H砂浆 T2图谱 (f)

Figure 4. Compressive strength of CNC-C (a), CNC-H (b) mortar of 3 days; Compressive strength of CNC-C (a), CNC-H (b), PE (c), PVA (d) and CNC fiber (e) mortar of 28 days and T2 distribution spectra of different dosages CNC-C and CNC-H mortar (f)

表 1 PE及PVA纤维的物理及力学性能指标

Table 1. Physical and mechanical properties of PE and PVA fibers

Fiber Length/

mmDiameter/

μmElastic modulus/

GPaTensile strength/

MPaDensity/

(kg·m−3)PE 9 24 120 3000 970 PVA 9 20 40 1600 1300 表 2 普通硅酸盐水泥化学成分(P·O 42.5)

Table 2. Composition of ordinary portland cement (P·O 42.5)

Composition SiO2 Al2O3 Fe2O3 CaO MgO Loss Proportion

/%21.44 5.95 3.05 61.42 3.97 4.35 表 3 不同实验组砂浆质量成分

Table 3. Mass composition of different experimental groups

g Notation Sand Cement Water Plain fiber CNC-C CNC-H CNC-C coated

polyethyleneCNC-H coated

polyethyleneA 1350 450 247.5 0 0 0 0 0 C-0.01 1350 450 247.5 0 0.045 0 0 0 C-0.05 1350 450 247.5 0 0.225 0 0 0 C-0.10 1350 450 247.5 0 0.450 0 0 0 C-0.15 1350 450 247.5 0 0.675 0 0 0 C-0.20 1350 450 247.5 0 0.900 0 0 0 H-0.01 1350 450 247.5 0 0 0.045 0 0 H-0.05 1350 450 247.5 0 0 0.225 0 0 H-0.10 1350 450 247.5 0 0 0.450 0 0 H-0.15 1350 450 247.5 0 0 0.675 0 0 H-0.20 1350 450 247.5 0 0 0.900 0 0 PE-0.10 1350 450 247.5 0.745 0 0 0 0 PE-0.20 1350 450 247.5 1.490 0 0 0 0 PE-0.30 1350 450 247.5 2.235 0 0 0 0 PE-0.40 1350 450 247.5 2.980 0 0 0 0 PE-0.50 1350 450 247.5 3.725 0 0 0 0 PVA-0.10 1350 450 247.5 0.998 0 0 0 0 PVA-0.20 1350 450 247.5 1.997 0 0 0 0 PVA-0.30 1350 450 247.5 2.995 0 0 0 0 PVA-0.40 1350 450 247.5 3.994 0 0 0 0 PVA-0.50 1350 450 247.5 4.992 0 0 0 0 PEC-0.30 1350 450 247.5 0 0 0 2.235 0 PEH-0.30 1350 450 247.5 0 0 0 0 2.235 Notes: CNC-C—Carboxylated CNC; CNC-H—Hydroxylated CNC; A—Control mortar sample; C—CNC-C mortar sample; H—CNC-H mortar sample; PEC—CNC-C coating fiber mortar sample; PEH—CNC-H coating fiber sample. Additionally, the number means the dosage of enhancement material. Such as C-0.01—Ratio of CNC-C is 0.01%; PE-0.1—Addition of PE fiber is 0.1%. -

[1] MIGUEL M, GONZALO M, OSMAN G, et al. Recycling polypropylene and polyethylene wastes in production of polyester based polymer mortars[J]. Construction and Building Materials,2021,274:121487. doi: 10.1016/j.conbuildmat.2020.121487 [2] 叶卓然, 罗靓, 潘海燕, 等. 超高分子量聚乙烯纤维及其复合材料的研究现状与分析[J]. 复合材料学报, 2022, 39(9):4286-4309. doi: 10.13801/j.cnki.fhclxb.20220803.002YE Z R, LUO L, PAN H Y, et al. Research status and analysis of ultra-high molecular weight polyethylene fiber and its composites[J]. Acta Materiae Compositae Sinica,2022,39(9):4286-4309(in Chinese). doi: 10.13801/j.cnki.fhclxb.20220803.002 [3] VANIN D, ANDRADE V, FIORENTIN T, et al. Claudimir antonio carminatti, hazim Ali Al-Qureshi, cement pastes modified by cellulose nanocrystals: A dynamic moduli evolution assessment by the impulse excitation technique[J]. Materials Chemistry and Physics,2020,239:122038. [4] LEE H, KIM W. Long-term durability evaluation of fiber-reinforced ECC using wood-based cellulose nanocrystals[J]. Construction and Building Materials,2020,238:117754. doi: 10.1016/j.conbuildmat.2019.117754 [5] LEE H, KIM S. A study on the drying shrinkage and mechanical properties of fiber reinforced cement compo-sites using cellulose nanocrystals[J]. International Jour-nal of Concrete Structures and Materials,2019,13(1):1-11. doi: 10.1186/s40069-018-0311-2 [6] MONTES F, FU T, YOUNGBLOOD J P, et al. Rheological impact of using cellulose nanocrystals (CNC) in cement pastes[J]. Construction and Building Materials,2020,235:117497-117506. doi: 10.1016/j.conbuildmat.2019.117497 [7] FU T, MONTES F, SURANENI P. The influence of cellulose nanocrystals on the hydration and flexural strength of portland cement pastes[J]. Polymers,2017,9:1-16. doi: 10.3390/polym9010001 [8] DANUTA B H, MONIKA S C, MONIKA J H, et al. Effect of cellulose nanofibrils and nanocrystals on physical properties of concrete[J]. Construction and Building Materials,2019,223:1-11. doi: 10.1016/j.conbuildmat.2019.06.145 [9] ANJU T, DHAMODHARAN R. Surface modified microcrystalline cellulose from cotton as a potential mineral admixture in cement mortar composite[J]. Cement and Concrete Composites,2016,74:147-153. doi: 10.1016/j.cemconcomp.2016.09.003 [10] LU Z, YU J, YAO J, et al. Experimental and molecular modeling of polyethylene fiber/cement interface strengthened by graphene oxide[J]. Cement and Concrete Composites,2020,112:103676. doi: 10.1016/j.cemconcomp.2020.103676 [11] ALKHATEB H, AL-OSTAZ A, LI X. Materials genome for graphene-cement nanocomposites[J]. Journal of Nanomechanics and Micromechanics, 2013, 3(3): 67-77. [12] HOU D, LU Z, LI X, et al. Reactive molecular dynamics and experimental study of graphene-cement composites: Structure, dynamics and reinforcement mechanisms[J]. Carbon,2017,115:188-208. doi: 10.1016/j.carbon.2017.01.013 [13] 中国国家标准化管理委员会. 水泥胶砂流动度测定方法: GB/T 2419—2005[S]. 北京: 中国标准出版社, 2005.Standardization Administration of the People’s Republic of China. Test method for fluidity of cement mortar: GB/T 2419—2005[S]. Beijing: China Standards Press, 2021(in Chinese). [14] 中国国家标准化管理委员会. 水泥胶砂强度检验方法(ISO法): GB/T 17671—2021[S]. 北京: 中国标准出版社, 2021.Standardization Administration of the People’s Republic of China. Test method of cement mortar strength (ISO method): GB/T 17671—2021[S]. Beijing: China Standards Press, 2021(in Chinese). [15] ZHANG Q, SUN H, LIU W, et al. Effect of rGO on the mechanical strength, hydration and micromorphology of cement incorporated silica fume[J]. Construction and Building Materials,2021,300:124325. doi: 10.1016/j.conbuildmat.2021.124325 [16] CAO Y, ZAVATERRI P, YOUNGBLOOD J, et al. The influence of cellulose nanocrystal additions on the performance of cement paste[J]. Cement and Concrete Compo-sites,2015,56:73-83. doi: 10.1016/j.cemconcomp.2014.11.008 [17] CAO Y, TIAN N, BAHR D, et al. The influence of cellulose nanocrystals on the microstructure of cement paste[J]. Cement and Concrete Composites,2016,74:164-173. doi: 10.1016/j.cemconcomp.2016.09.008 [18] CAO Y, ZAVATTIERI P, YOUNGBLOOD J, et al. The relationship between cellulose nanocrystal dispersion and strength[J]. Construction and Building Materials,2016,119:71-79. doi: 10.1016/j.conbuildmat.2016.03.077 [19] 郑逢时. UHMWPE纤维表面处理及其水泥砂浆性能研究[D]. 西安: 长安大学, 2014.ZHENG F S. Surface treatment of UHMWPE fiber and its performance in cement mortar[D]. Xi'an: Chang'an University, 2014(in Chinese). [20] HE Y. Effect of C/S ratio on morphology and structure of hydrothermally synthesized calcium silicate hydrate[J]. Journal of Wuhan University of Technology (Materials Science Edition),2011,26(4):770-773. doi: 10.1007/s11595-011-0308-z [21] 何威, 许吉航, 焦志男. 少层石墨烯对水泥净浆流动性能及力学性能的影响[J]. 复合材料学报, 2021, 39(11):5637-5649. doi: 10.13801/j.cnki.fhclxb.20211112.001HE W, XU J, JIAO Z. Effect of few-layer graphene on the fluidity and mechanical properties of cement paste[J]. Acta Materiae Compositae Sinica,2021,39(11):5637-5649(in Chinese). doi: 10.13801/j.cnki.fhclxb.20211112.001 [22] 覃丽芳, 曲波, 史才军, 等. 钙硅比对铝硅酸盐凝胶形成与特性的影响[J]. 材料导报, 2020, 34(12):12057-12063. doi: 10.11896/cldb.19070122QIN L F, QU B, SHI C J, et al. Effect of Ca/Si ratio on the formation and characteristics of synthetic aluminosilicate hydrate gels[J]. Materials Report,2020,34(12):12057-12063(in Chinese). doi: 10.11896/cldb.19070122 [23] 管申. 纳米材料对水泥基材料水化和性能的影响[D]. 哈尔滨: 哈尔滨工业大学, 2017.GUAN S. The effect of nanomaterials on the hydration and properties of cement-based materials[D]. Harbin: Harbin Institute of Technology, 2017(in Chinese). [24] FAN Q, MENG X, LI Z, et al. Experiment and molecular dynamics simulation of functionalized cellulose nanocrystals as reinforcement in cement composites[J]. Construction and Building Materials,2022,341:27879. [25] FAN Q, WANG Z, MENG X, et al. Multi-scale analysis of the strengthening mechanism of functionalized graphene as reinforcement in cement composites[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2022,651:129729. doi: 10.1016/j.colsurfa.2022.129729 [26] ZHAO L, ZHU S, WU H, et al. The improved resistance against the degradation of sisal fibers under the environment of cement hydration by surface coating of graphene oxide (GO) based membranes[J]. Construction and Building Materials,2021,305:124694. doi: 10.1016/j.conbuildmat.2021.124694 [27] 吴畏, 王统伟, 汪德成, 等. 基于Gaussian和LAMMPS模拟的氧化钙脱除氯化氢机制[J]. 东南大学学报(自然科学版), 2020, 50(1):1-10. doi: 10.3969/j.issn.1001-0505.2020.01.001WU W, WANG T W, WANG D C, et al. Mechanism of HCl removed by CaO based on Gaussian and LAMMPS simulation[J]. Journal of Southeast University (Natural Science Edition),2020,50(1):1-10(in Chinese). doi: 10.3969/j.issn.1001-0505.2020.01.001 [28] ZHANG Y, YANG T, JIA Y. Molecular dynamics study on the weakening effect of moisture content on graphene oxide reinforced cement composite[J]. Chemical Physics Letters, 2018, 708: 177-182. [29] SANCHEZ F, ZHANG L. Interaction energies, structure, and dynamics at functionalized graphitic structure-liquid phase interfaces in an aqueous calcium sulfate solution by molecular dynamics simulation[J]. Carbon, 2010, 48: 1210-1223. [30] HOU D, YANG Q, WANG P. Unraveling disadhesion mechanism of epoxy/CSH interface under aggressive conditions[J]. Cement and Concrete Research, 2021, 146: 106489. [31] 杨进波, 赵钲洋, 尹航. 基于分子动力学的C-S-H凝胶性能研究[J]. 材料导报, 2021, 35(5):5095-5101. doi: 10.11896/cldb.19120140YANG J B, ZHAO Z Y, YIN H. Research development on molecular dynamics of C-S-H gels[J]. Material Report,2021,35(5):5095-5101(in Chinese). doi: 10.11896/cldb.19120140 [32] SANCHEZ F, ZHANG L. Molecular dynamics modeling of the interface between surface-functionalized graphitic structures and calcium-silicate-hydrate: Interaction energies, structure, and dynamics[J]. Journal of Colloid and Interface Science,2008,323(2):349-358. doi: 10.1016/j.jcis.2008.04.023 [33] RAMASAMY J, AMANULLAH M. Nanocellulose for oil and gas field drilling and cementing applications[J]. Journal of Petroleum Science and Engineering,2020,184:106292. doi: 10.1016/j.petrol.2019.106292 [34] 曾靖. 水化硅酸钙/氧化石墨烯复合材料力学性能的分子动力学模拟[D]. 重庆: 重庆大学, 2015.ZENG J. Molecular dynamics simulation of mechanical properties of calcium-silicate-hydrate/graphene oxide composites [D]. Chongqing: Chongqing University, 2015(in Chinese). [35] HOU D, YU J, WANG P. Molecular dynamics modeling of the structure, dynamics, energetics and mechanical pro-perties of cement-polymer nanocomposite[J]. Composite Pare B: Engineering, 2019, 162: 433-444. [36] 杨铁军, 魏金龙, 马冰洋, 等. 水分在托贝莫来石中运动特性的分子动力学模拟研究[J]. 硅酸盐通报, 2020, 39(4):1085-1091. doi: 10.16552/j.cnki.issn1001-1625.2020.04.011YANG T J, WEI J L, MA B Y, et al. Molecular dynamics study of the motion characteristics of water in tobermorite[J]. Bulletin of the Chinese Ceramic Society,2020,39(4):1085-1091(in Chinese). doi: 10.16552/j.cnki.issn1001-1625.2020.04.011 [37] ZHAO H, WANG Y, YANG Y, et al. Effect of hydrophobic groups on the adsorption conformation of modified polycarboxylate superplasticizer investigated by molecular dynamics simulation[J]. Applied Surface Science,2017,407:8-15. doi: 10.1016/j.apsusc.2017.02.132 -

下载:

下载: