Effects of graphene oxide on mechanical properties of 3D printed cement-based materials

-

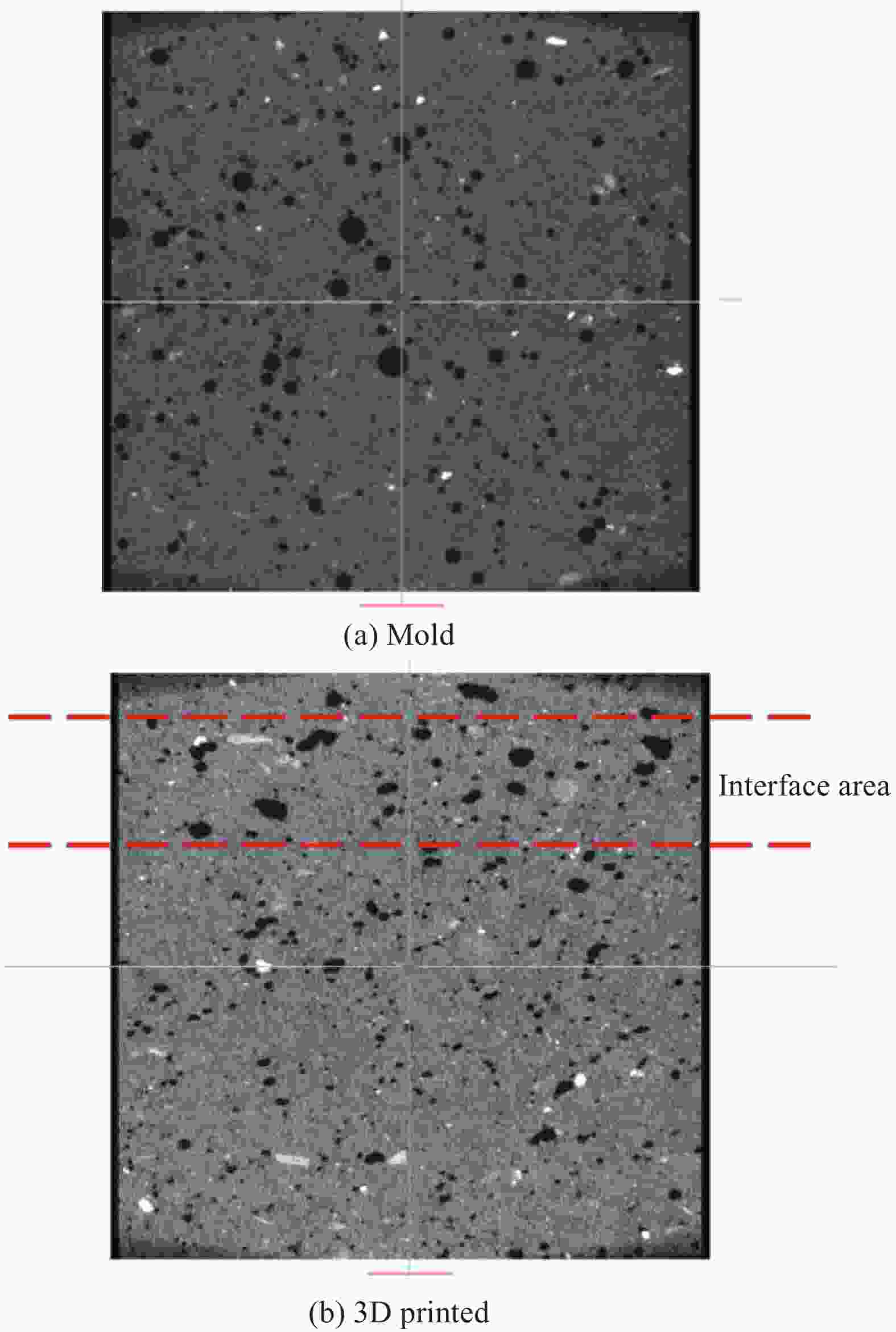

摘要: 氧化石墨烯(GO)拥有较大的比表面积,化学结构式中存在大量的含氧基团,使其在水泥基材料中具有出色的亲水性能和分散性能,可有效改善水泥基材料微观结构、增强其力学性能。本文基于Dinger-Funk模型进行3D打印水泥基材料配合比设计,研究了不同掺量GO对3D打印水泥基材料性能的影响。结果表明:添加0.03wt%~0.05wt%GO后,加速了水泥水化进程,有利于3D打印水泥基材料各个方向力学性能的增强。与未掺入GO组别相比,掺入0.03wt%GO后,打印试块X方向、Y方向、Z方向的28天抗压强度分别增长12.07%、11.93%、17.42%,28天抗折强度分别增长30.61%、21.13%、13.70%。3D打印试件孔隙在层间界面相对集中,呈现不规则的形状,造成3D打印试块力学性能各向异性行为,3D打印试块抗压强度的各向异性不明显,而抗折强度的各向异性行为显著。Abstract: Graphene oxide (GO) has a large specific surface area, and there are a large number of oxygen-containing groups in the chemical structure, which makes it have excellent hydrophilic properties and dispersing properties in cement-based materials. GO can effectively improve the microstructure of cement-based materials and enhance its mechanical properties. In this paper, based on the Dinger-Funk model, the mix ratio design of 3D printing cement-based materials was carried out, and the effect of different dosages of GO on the properties was studied. The results show that: The addition of 0.03wt%-0.05wt%GO accelerates the cement hydration process, which is beneficial to the enhancement of the mechanical properties of 3D printed cement-based materials in all directions. Compared with the group without GO, after adding 0.03wt%GO, the 28 days compressive strength of the 3D printed specimens in the X, Y, and Z directions increase by 12.07%, 11.93%, and 17.42%, respectively, and the 28 days flexural strength increase by 30.61%, 21.13%, and 13.70%, respectively. The pores of the 3D printed specimen are re-latively concentrated at the interface between layers, showing an irregular shape, resulting in anisotropic behavior of the mechanical properties of the 3D printed specimens. The anisotropy of the compressive strength of the 3D printed specimen is not obvious, while the anisotropic behavior of the flexural strength is significant.

-

Key words:

- graphene oxide (GO) /

- 3D printing /

- mechanical properties /

- anisotropy /

- microstructure

-

表 1 胶凝材料的化学组成

Table 1. Chemical composition of cementitious materials

Material Dosage of admixture/wt% CaO SiO2 Al2O3 Fe2O3 MgO Other Cement 63.37 20.35 5.10 3.34 2.05 5.79 Fly ash 4.01 53.97 31.15 4.16 1.01 5.70 表 2 不同GO掺量3D打印水泥基材料的配合比

Table 2. Mixing ratio of 3D printing cement-based materials with different GO content

Specimen Mass ratio of components Dosage of admixture/wt% Cement Fly ash Stone powder Machine-made

sand IMachine-made

sand ⅡWater Viscosity modifier Retarder Water reducer GO C 0.9 0.1 0.38 0.5 0.62 0.4 0.30 0.05 0.90 0 0.01wt%GO/C 0.95 0.01 0.03wt%GO/C 1.05 0.03 0.05wt%GO/C 1.15 0.05 0.07wt%GO/C 1.30 0.07 Note: The mass ratio of the cementitious material was set to 1, stone powder, machine-made sand I, machine-made sand Ⅱ, and water were all added according to the radio of the cementitious material, and the viscosity modifier, retarder, water reducer, and GO were all added according to the percentage of the cementitious material. -

[1] LE T T, AUSTIN S A, LIM S, et al. Hardened properties of high-performance printing concrete[J]. Cement and Concrete Research,2012,42(3):558-566. doi: 10.1016/j.cemconres.2011.12.003 [2] BONG S H, XIA M, NEMATOLLAHI B, et al. Ambient temperature cured 'just-add-water' geopolymer for 3D concrete printing applications[J]. Cement and Concrete Composites,2021,121:104060. doi: 10.1016/j.cemconcomp.2021.104060 [3] PANDA B, SINGH G B, UNLUER C, et al. Synthesis and characterization of one-part geopolymers for extrusion based 3D concrete printing[J]. Journal of Cleaner Production,2019,220:610-619. doi: 10.1016/j.jclepro.2019.02.185 [4] ZHANG Y, ZHANG Y S, YANG L, et al. Hardened properties and durability of large-scale 3D printed cement-based materials[J]. Materials and Structures,2021,54(1):45. doi: 10.1617/s11527-020-01599-1 [5] ZHANG H, ZHU L M, ZHANG F, et al. Effect of fiber content and alignment on the mechanical properties of 3D printing cementitious composites[J]. Materials,2021,14(9):2223. doi: 10.3390/ma14092223 [6] 王里, 王伯林, 白刚, 等. 3D打印混凝土各向异性力学性能研究[J]. 实验力学, 2020, 35(2):243-250. doi: 10.7520/1001-4888-18-188WANG Li, WANG Bolin, BAI Gang, et al. Experimental study on the mechanical anisotropy of 3D printed concrete[J]. Journal of Experimental Mechanics,2020,35(2):243-250(in Chinese). doi: 10.7520/1001-4888-18-188 [7] DING T, XIAO J Z, ZOU S, et al. Hardened properties of layered 3D printed concrete with recycled sand[J]. Cement and Concrete Composites,2020,113:103724. doi: 10.1016/j.cemconcomp.2020.103724 [8] MA G W, LI Z J, WANG L, et al. Mechanical anisotropy of aligned fiber reinforced composite for extrusion-based 3D printing[J]. Construction and Building Materials,2019,202:770-783. doi: 10.1016/j.conbuildmat.2019.01.008 [9] WOLFS R J M, BOS F P, SALET T A M. Hardened properties of 3D printed concrete: The influence of process parameters on interlayer adhesion[J]. Cement and Concrete Research,2019,119:132-140. doi: 10.1016/j.cemconres.2019.02.017 [10] PHAM L, TRAN P, SANJAYAN J. Steel fibres reinforced 3D printed concrete: Influence of fibre sizes on mechanical performance[J]. Construction and Building Materials,2020,250:118785. doi: 10.1016/j.conbuildmat.2020.118785 [11] SREEJA K, NARESH KUMAR T N. Effect of graphene oxide on fresh, hardened and mechanical properties of cement mortar[J]. Materials Today: Proceedings,2021,46:2235-2239. doi: 10.1016/j.matpr.2021.03.574 [12] INDUKURI C S R, NERELLA R. Enhanced transport properties of graphene oxide based cement composite material[J]. Journal of Building Engineering,2021,37:102174. doi: 10.1016/j.jobe.2021.102174 [13] LONG W J, GU Y C, XIAO B X, et al. Micro-mechanical properties and multi-scaled pore structure of graphene oxide cement paste: Synergistic application of nanoindentation, X-ray computed tomography, and SEM-EDS analysis[J]. Construction and Building Materials,2018,179:661-674. doi: 10.1016/j.conbuildmat.2018.05.229 [14] 吕生华, 丁怀东, 孙婷, 等. 萘系减水剂/氧化石墨烯复合材料对水泥石微观结构和性能的影响[J]. 陕西科技大学学报(自然科学版), 2014, 32(5):42-47.LYU Shenghua, DING Huaidong, SUN Ting, et al. Effect of naphthalene superplasticizer/graphene oxide composite on microstructure and mechanical properties of hardened cement paste[J]. Journal of Shaanxi University of Science & Technology (Natural Science Edition),2014,32(5):42-47(in Chinese). [15] 吕生华, 张佳, 朱琳琳, 等. 氧化石墨烯对水泥基复合材料微观结构的调控作用及对抗压抗折强度的影响[J]. 化工学报, 2017, 68(6):2585-2595. doi: 10.11949/j.issn.0438-1157.20161575LYU Shenghua, ZHANG Jia, ZHU Linlin, et al. Regulation of graphene oxide on microstructure of cement composites and its impact on compressive and flexural strength[J]. CIESC Journal,2017,68(6):2585-2595(in Chinese). doi: 10.11949/j.issn.0438-1157.20161575 [16] 中华人民共和国国家质量监督检验检验总局. 中国国家标准化管理委员会. 水泥胶砂流动度测定方法: GB/T 2419—2005[S]. 北京: 中国标准出版社, 2015.General Administration of Quality Supervision, Inspection and Inspection of the People's Republic of China. State Administration for Standardization of China. Determination method for fluidity of cement mortar: GB/T 2419—2005[S]. Beijing: China Standards Press, 2015(in Chinese). [17] 陕西省建筑科学研究院. 建筑砂浆基本性能试验方法: JGJ/T 70—2009[S]. 北京: 中国建筑工业出版社, 2009.Shanxi Provincial Building Research Institute. Standard for test method of performance on building mortar: JGJ/T 70−2009[S]. Beijing: China Architecture & Building Press, 2009(in Chinese). [18] 中国国家质量技术监督局. 水泥胶砂强度检测方法: GB/T 17671−1999[S]. 北京: 中国标准出版社, 2014.State Administration of Quality and Technical Supervision of China. Test method for cement mortar strength: GB/T 17671—1999[S]. Beijing: China Standard Press, 2014(in Chinese). [19] DINGER D R, FUNK J E. Particle-size analysis routines available on cerabull[J]. American Ceramic Society Bulletin,1989,68(8):1406-1408. [20] BONG S H, NEMATOLLAHI B, NAZARI A, et al. Method of optimisation for ambient temperature cured sustainable geopolymers for 3D printing construction applications[J]. Materials,2019,12(6):902. doi: 10.3390/ma12060902 [21] CHEN Y, RODRIGUEZ C R, LI Z M, et al. Effect of different grade levels of calcined clays on fresh and hardened pro-perties of ternary-blended cementitious materials for 3D printing[J]. Cement and Concrete Composites,2020,114:103708. doi: 10.1016/j.cemconcomp.2020.103708 [22] PANDA B, PAUL S C, HUI L J, et al. Additive manufacturing of geopolymer for sustainable built environment[J]. Jour-nal of Cleaner Production,2017,167:281-288. doi: 10.1016/j.jclepro.2017.08.165 [23] SANJAYAN J G, NEMATOLLAHI B, XIA M, et al. Effect of surface moisture on inter-layer strength of 3D printed concrete[J]. Construction and Building Materials,2018,172:468-475. doi: 10.1016/j.conbuildmat.2018.03.232 [24] MA G W, ZHANG J F, WANG L, et al. Mechanical characterization of 3D printed anisotropic cementitious material by the electromechanical transducer[J]. Smart Materials and Structures,2018,27(7):075036. doi: 10.1088/1361-665X/aac789 [25] MA L, ZHANG Q, JIA Z J, et al. Effect of drying environment on mechanical properties, internal RH and pore structure of 3D printed concrete[J]. Construction and Building Materials,2022,315:125731. doi: 10.1016/j.conbuildmat.2021.125731 [26] CHUNG S Y, HAN T S, YUN T S, et al. Evaluation of the anisotropy of the void distribution and the stiffness of lightweight aggregates using CT imaging[J]. Construction and Building Materials,2013,48:998-1008. doi: 10.1016/j.conbuildmat.2013.07.082 [27] DIAMOND S. Delayed ettringite formation-Processes and problems[J]. Cement and Concrete Composites,1996,18(3):205-215. doi: 10.1016/0958-9465(96)00017-0 [28] YANG H S, LI W W, CHE Y J. 3D printing cementitious materials containing nano-CaCO3: Workability, strength, and microstructure[J]. Frontiers in Materials,2020,7:260. doi: 10.3389/fmats.2020.00260 -

下载:

下载: