Effect of ball milling time on microstructure and oxidation resistance of self-passivating W alloys

-

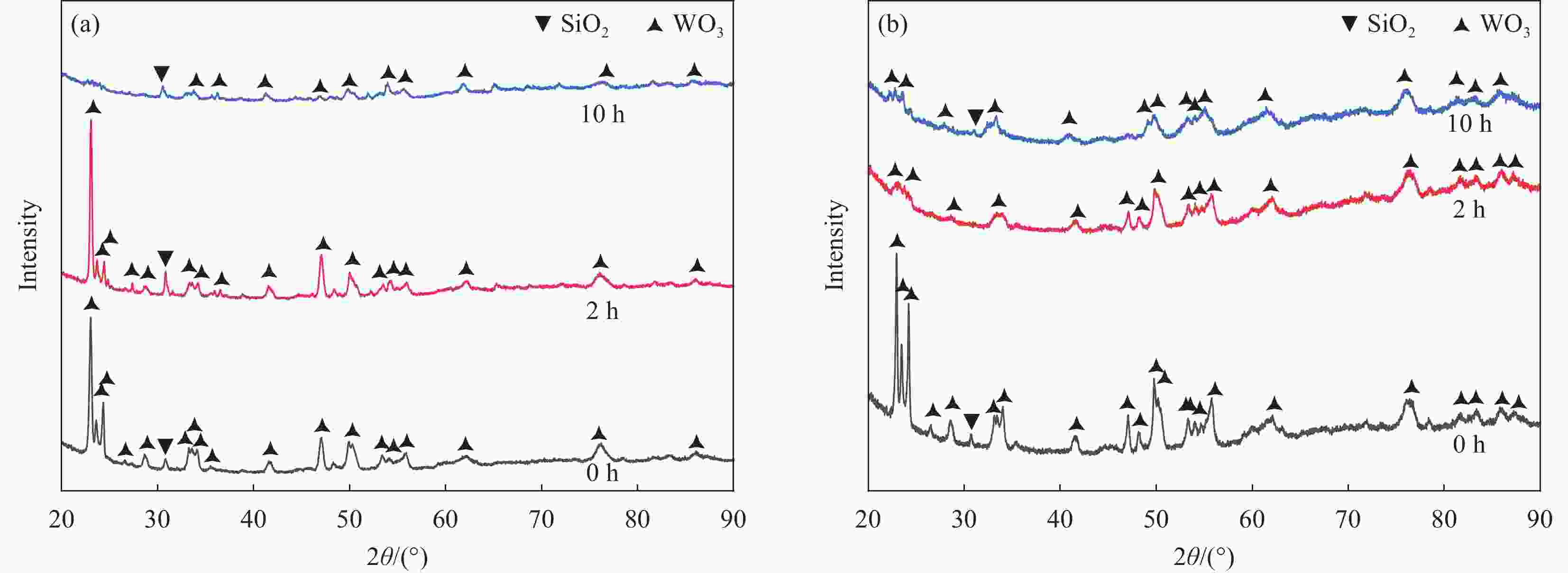

摘要: 自钝化W合金具有优异的抗高温氧化性能,可望用于高温环境中的关键部件。为了揭示合金的组织结构与高温抗氧化性能之间关系,采用机械合金化法结合放电等离子体烧结技术制备了自钝化W-Si合金,研究了不同机械合金化时间对合金显微组织结构的影响,并探究了合金的抗高温氧化性能。结果表明:合金由W、W5Si3和SiOx组成,当球磨时间由4 h增加到20 h,合金中SiOx的含量由16.2%增加到23.6%,而W5Si3的含量由57.8%降低到43.6%,且W和W5Si3的晶粒尺寸均减小,晶粒的细化有助于合金显微硬度的提高。在1000 ℃氧化10 h后,球磨4 h制得的合金增重为37.4 mg,而球磨20 h制得的合金增重达到了141.6 mg,它们的氧化层厚度分别约为167.0 μm和415.7 μm。球磨时间短制得的合金具有更优异的抗氧化性能,这是由于其W5Si3为连续相。W5Si3原位氧化形成的WO3/SiO2复合氧化物亦为连续相,形成了保护性氧化层,对合金的内氧化起到了有效的抑制作用。Abstract: Self-passivating W alloys exhibit excellent high temperature oxidation resistance and are expected to be used in key components in high temperature environments. In order to reveal the relationship between the microstructure and high temperature oxidation resistance of the alloy, a self-passivating W-Si alloy was prepared by mechanical alloying method combined with spark plasma sintering. The effect of different mechanical alloying time on the microstructure of the alloy was studied. And the high temperature oxidation resistance of the alloys was investigated. The results show that the alloys are composed of W, W5Si3 and SiOx phases. When the ball milling time increases from 4 h to 20 h, the content of SiOx in the alloys increases from 16.2% to 23.6%, while the content of W5Si3 decreases from 57.8% to 43.6%, and the grain sizes of W and W5Si3 are both reduced. The grain refinement contri-butes to the improvement of the microhardness of the alloys. After oxidized at 1000 ℃ for 10 h, the mass gain of the alloy prepared by ball milling for 4 h is 37.4 mg, while that of the alloy prepared by ball milling for 20 h reaches 141.6 mg, and their oxide layer thicknesses are about 167.0 μm and 415.7 μm, respectively. The alloy prepared with short ball milling time has better oxidation resistance, because the W5Si3 in this alloy is a continuous phase. The WO3/SiO2 composite oxide formed by in situ oxidation of W5Si3 is also a continuous phase, forming a protective oxide layer and effectively inhibiting the internal oxidation of the alloy.

-

Key words:

- self-passivating /

- W-Si alloy /

- mechanical alloying /

- spark plasma sintering /

- oxidation resistance

-

图 7 W-Si合金在1000℃氧化不同时间的氧化层的SEM图像:((a1)~(a3)) 球磨4 h粉末制得的合金氧化0 h、2 h的合金表面和氧化2 h的氧化层侧表面;((b1)~(b3)) 球磨20 h粉末制得的合金氧化0 h、2 h的合金表面和氧化2 h的氧化层侧表面

Figure 7. SEM images of the oxide layer of the W-Si alloys oxidized for different time: ((a1)-(a3)) Alloy made from the powder milled for 4 h with surface oxidized for 0 h, 2 h and side surface oxidized for 2 h; ((b1)-(b3)) Alloy made from the powder milled for 20 h with surface oxidized for 0 h, 2 h and side surface oxidized for 2 h

表 1 粉末中W的晶粒尺寸和Si在W中的固溶度

Table 1. Grain size of W and solid solubility of Si in W for the powders

Ball milling time/h Grain size/nm Solid solubility/at% 4 41.82 6.81 20 18.91 6.86 表 2 不同球磨时间制得的W-Si合金中各个相的面积含量

Table 2. Area content of each phases in the W-Si alloys prepared by different ball milling time

W-Si alloy SiOx/% W5Si3/% W/% Alloy made from the

powder milled for 4 h16.2 57.8 26.0 Alloy made from the

powder milled for 20 h23.6 43.6 32.8 -

[1] 王猛, 杨明川, 荣光, 等. 穿甲过程中钨合金杆式弹失效模式及数值模拟[J]. 稀有金属材料与工程, 2015, 44(9):2170-2174.WANG Meng, YANG Mingchuan, RONG Guang, et al. Failure model and numerical simulation of the tungsten alloy long rod when piercing into armor target[J]. Rare Metal Materials and Engineering,2015,44(9):2170-2174(in Chinese). [2] ZHOU Y, WANG K, LIU R, et al. High performance tungsten synthesized by microwave sintering method[J]. International Journal of Refractory Metals and Hard Materials,2012,34:13-17. doi: 10.1016/j.ijrmhm.2012.02.016 [3] WANG Y J, PENG H X, ZHOU Y, et al. Influence of ZrC content on the elevated temperature tensile properties of ZrCp/W composites[J]. Materials Science and Engineering A-Structural Materials Properties Microstructure and Processing,2011,528(3):1805-1811. doi: 10.1016/j.msea.2010.11.029 [4] 蔡圳阳, 沈鸿泰, 刘赛男, 等. 难熔金属合金及其高温抗氧化涂层研究现状与展望[J]. 中国有色金属学报, 2020, 30(9):1991-2010. doi: 10.11817/j.ysxb.1004.0609.2020-37623CAI Zhenyang, SHEN Hongtai, LIU Sainan, et al. Review and prospect of refractory metal alloys and high tempera-ture oxidation resistance coatings[J]. The Chinese Journal of Nonferrous Metals,2020,30(9):1991-2010(in Chinese). doi: 10.11817/j.ysxb.1004.0609.2020-37623 [5] LV Y Q, FAN Y, ZHAO S Q, et al. The microstructure evolution, damage behavior and failure analysis of fine-grained W-Y2O3 composites under high transient thermal shock[J]. International Journal of Refractory Metals and Hard Materials,2022,107:105905. doi: 10.1016/j.ijrmhm.2022.105905 [6] MAISONNIERR D, COOK I, PIERRE S, et al. The European power plant conceptual study[J]. Fusion Engineering and Design,2005,75-79:1173-1179. [7] 谭晓月, 王武杰, 吴眉, 等. 自钝化钨合金在未来核聚变装置中的潜在应用与研究现状[J]. 材料热处理学报, 2019, 40(11):13-21.TAN Xiaoyue, WANG Wujie, WU Mei, et al. Potential application and research status of self-passivation tungsten alloy in future fusion devices[J]. Transactions of Materials and Heat Treatment,2019,40(11):13-21(in Chinese). [8] TERENTYEV D, JENUS P, SAL E, et al. Development of irradiation tolerant tungsten alloys for high temperature nuclear applications[J]. Nuclear Fusion,2022,62(8):086035. doi: 10.1088/1741-4326/ac75fe [9] WEBB W W, NORTON J T, WAGNER C. Oxidation of tungsten[J]. Journal of the Electrochemical Society,1956,103(2):107-111. doi: 10.1149/1.2430238 [10] BLACKBURN P E, ANDREW K F, GULBRANSEN E A, et al. Oxidation of tungsten and tungsten based alloys[R]. Arlington: Aemed Services Technical Information Agency, 1961. [11] CIFUENTES S C, MONGE M A, PÉREZ P. On the oxidation mechanism of pure tungsten in the temperature range 600-800℃[J]. Corrosion Science,2012,57:114-121. doi: 10.1016/j.corsci.2011.12.027 [12] KOCH F, BOLT H. Self-passivating W-based alloys as plasma facing material for nuclear fusion[J]. Revstat-Statistical Journal,2007,T128:100-105. [13] WU B D, YANG X S, ZHOU Y Z, et al. Laser melting depo-sited self-passivating 90 W-10 Cr coatings on reduced activation ferritic/martensitic steel using 90 W-7 Ni-3 Fe interlayers[J]. Journal of Nuclear Materials,2021,553:153029. doi: 10.1016/j.jnucmat.2021.153029 [14] YAN J, LI X, WANG Z L, et al. Comparison of surface morphologies and helium retention of nanocrystalline W and W-Cr films prepared by magnetron sputtering[J]. Nuclear Materials and Energy,2020,22:100733. doi: 10.1016/j.nme.2020.100733 [15] KLEIN F, GILBERT M R, LITNOVSKY A, et al. Tungsten-chromium-yttrium alloys as first wall armor material: Yttrium concentration, oxygen content and transmutation elements[J]. Fusion Engineering and Design,2020,158:111667. doi: 10.1016/j.fusengdes.2020.111667 [16] MACKOVA A, FERNANDES S, MATEJICEK J, et al. Radiation damage evolution in pure W and W-Cr-Hf alloy caused by 5 MeV Au ions in a broad range of DPA[J]. Nuclear Materials and Energy,2021,29:101085. doi: 10.1016/j.nme.2021.101085 [17] CALVO A, GARCIA-ROSALES C, KOCH F, et al. Manufacturing and testing of self-passivating tungsten alloys of different composition[J]. Nuclear Materials and Energy,2016,9(C):422-429. [18] LITNOVSKY A, WEGENER T, KLEIN F, et al. Advanced smart tungsten alloys for a future fusion power plant[J]. Plasma Physics and Controlled Fusion,2017,59(6):064003. [19] WEGENER T, KLEIN F, LITNOYSKY A, et al. Development and analyses of self-passivating tungsten alloys for DEMO accidental conditions[J]. Fusion Engineering and Design,2017,124:183-186. doi: 10.1016/j.fusengdes.2017.03.072 [20] LIU W, DI J, ZHANG W X, et al. Oxidation resistance behavior of smart W-Si bulk composites[J]. Corrosion Science,2022,163:108222. [21] 柳炜. 面向等离子体自钝化W-Si合金的制备与性能研究[D]. 武汉: 华中科技大学, 2020.LIU Wei. Preparation and properties of self-passivating tungsten-silicon alloys for plasma facin[D]. Wuhan: Huazhong University of Science and Technology, 2020(in Chinese). [22] 韩勇, 范景莲, 刘涛, 等. 球磨改性和表面活性剂添加对超细98 W-1 Ni-1 Fe粉末性能的影响[J]. 中国有色金属学报, 2012, 22(12):3409-3415.HAN Yong, FAN Jinglian, LIU Tao, et al. Effect of ball milling modification and surfactant addition on properties of ultrafine 98 W-1 Ni-1 Fe powder[J]. The Chinese Jour-nal of Nonferrous Metals,2012,22(12):3409-3415(in Chinese). [23] OKAMOTO H. Supplemental literature review of binary phase diagrams: Al-Mg, Bi-Sr, Ce-Cu, Co-Nd, Cu-Nd, Dy-Pb, Fe-Nb, Nd-Pb, Pb-Pr, Pb-Tb, Pd-Sb, and Si-W[J]. Jour-nal of Phase Equilibria and Diffusion, 2015, 36: 183-195. [24] LIU W, DI J, XUE L H, et al. Phase evolution progress and properties of W-Si composites prepared by spark plasma sintering[J]. Journal of Alloys and Compounds,2018,766:739-747. doi: 10.1016/j.jallcom.2018.07.038 [25] GULBRANSEN E A, ANDREW K F. Kinetics of the oxidation of pure tungsten from 500° to 1300 ℃[J]. Journal of the Electrochemical Society,1960,107(7):619-628. doi: 10.1149/1.2427787 -

下载:

下载: