Research progress in carbon-based fibrous materials for interfacial photothermal steam generation

-

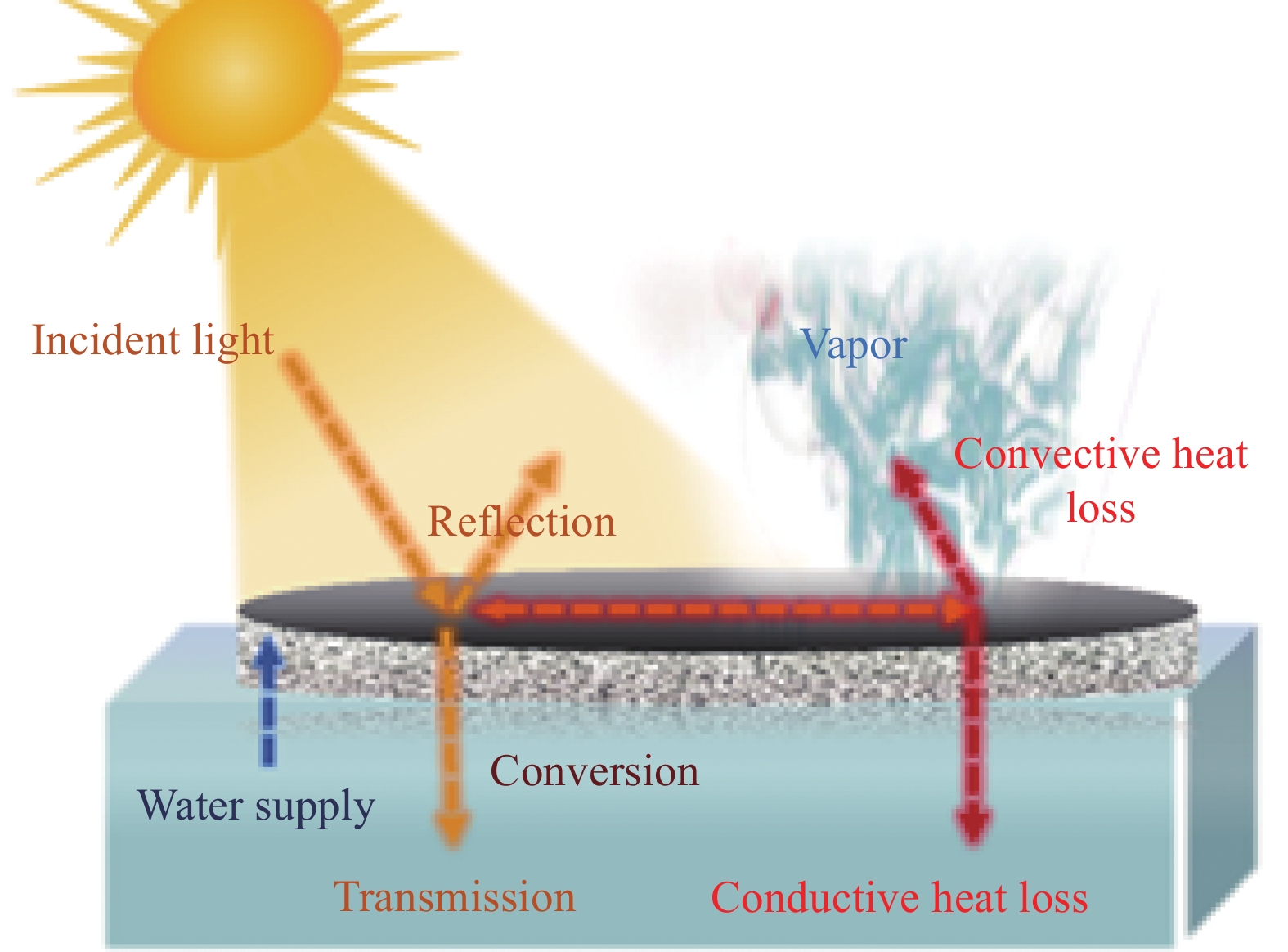

摘要: 淡水资源日益匮乏已成为严峻的世界性难题。为了促进界面光热水蒸发系统的发展和碳基纤维材料在界面光热水蒸发领域的应用,本文对界面光水蒸发用碳基纤维材料的最新研究进展进行综述。首先介绍了界面光热水蒸发系统的设计原理,其次系统分析了不同碳基材料的光热转换机制和结构特点及纤维材料用于水蒸发系统的性能优势。并以不同碳基纤维材料为切入点,重点介绍了碳基纤维材料的制备方法、性能优势。最后对碳基纤维材料在界面光热水蒸发领域所面临的挑战进行了探究。Abstract: The increasing scarcity of freshwater resources has become a serious global problem. In order to promote the development of interfacial photothermal steam generation systems and the application of carbon-based fibrous materials in the field of interfacial steam generation. This paper reviews the latest research progress on carbon-based fibrous materials for interfacial photothermal steam generation. Firstly, the design principle of the interfacial steam generation system is introduced, followed by the systematic analysis of the photothermal conversion mechanism and structural characteristics of different carbon-based materials, as well as the performance advantages of fibrous materials applied to steam generation. With different carbon-based fiber materials as the entry point, the preparation methods and performance advantages of carbon-based fiber materials are elaborated. Finally, the challenges faced by carbon-based fibrous materials in the field of interfacial photothermal steam generation are explored.

-

表 1 碳基纤维材料性能总结

Table 1. Summary of the properties of carbon-based fibrous materials

Type Composition Preparation

methodSolar absorption efficiency/% Evaporation rate/(kg·m−2·h−1)* Evaporation efficiency/% Stability Ref Carbonized fabrics PDA-carbonized cotton Carbonization 93.8 1.54 88.8 10 cycles [52] Carbonized cellulose papers Carbonization 92.2 0.96 65.8 20 cycles [53] Activated carbon fiber cloth Carbonization and activation >95 1.59 93.3 12 h [54] Silk one-step Carbonization process 82 1.25 — 3 days [65] Carbon loaded fabrics RGO-silk-fabric Immersing in the GO and reduced >90 1.48 102 30 cycles [50] PDA/CB@PP

non-woven

fabricDip-coating in CB and situ polymerizing with PDA >95 1.67 91.5 — [56] CB/SA ramie

fabricImmersing in CB/SA solution 92.9-95.3 1.81 96.6 — [34] Cotton-CNT fabrics Dyeing in CNT ink 95.7 1.59 89.6 20 cycles [31] Carbon fiber based fabrics Carbon fiber and cotton yarn mixture fabric The craft of textile weaving >90 1.87 83.7 10 h [59] Carbon fiber Hydrothermal carbonization in glucose solution 93 1.47 92.5 20 cycles [60] Electrostatic

spinning

fabricsCNT@PAN nonwoven fabrics Electrospinning 90.8 1.44 81 15 cycles [61] GO/PVA membrane Blend electrospinning 91.7 1.42 94.2 16 cycles [62] CB/PMMA-PAN Sequential electrospinning

and spraying97 1.30 72 More than 16 days [33] 3D fabrics Carbon fiber-cotton based cone Basket-weaving strategy 90 3.27 194.4 6 cycles [63] W-cotton cloth-NCC Depositing carbonized carrot 95.5 1.57 85.9 7 cycles [64] 3D rGO/SA aerogel

sheetSpray coating and freezing drying 97 7.60 178.6 40 cycles [66] Active carbon Juncus effusus Decorating with activated carbon particles 97-98 2.23 — 8 h [67] Notes: *—Water evaporation rates were measured under 1 kW·m−2; PDA—Polydopamine; CB—Carbon black; PP—Polypropylene; SA—Sodium alginate; PVA—Polyvinyl alcohol; PMMA—Polymethyl methacrylate; NCC—Carbonized carrot powder modified cotton cloth with Nafion coating on one side; GO—Graphene oxide; rGO—Reduced graphene oxide. -

[1] GAO S W, DONG X L, HUANG J Y, et al. Bioinspired soot-deposited janus fabrics for sustainable solar steam generation with salt-rejection[J]. Glob Chall,2019,3(8):1800117. [2] LI G P, LU L. Modeling and performance analysis of a fully solar-powered stand-alone sweeping gas membrane distillation desalination system for island and coastal households[J]. Energy Conversion and Management,2020,205:112375. [3] MENG X Y, XU W L, LI Z H, et al. Coupling of hierarchical Al2O3/TiO2 nanofibers into 3D photothermal aerogels toward simultaneous water evaporation and purification[J]. Advanced Fiber Materials,2020,2(2):93-104. doi: 10.1007/s42765-020-00029-9 [4] KIM H, KIM T, ABD AZIZ A, et al. Structural heterogeneity yet high similarity of the microbial community on reverse osmosis membrane-driven biofilms during seawater desalination[J]. Environmental Science: Water Research& Technology,2020,6(11):3066-3079. [5] CHANG J, ZUO J, LU K J, et al. Membrane development and energy analysis of freeze desalination-vacuum membrane distillation hybrid systems powered by LNG regasification and solar energy[J]. Desalination,2019,449:16-25. doi: 10.1016/j.desal.2018.10.008 [6] GIACALONE F, CATRINI P, GURRERI L, et al. Exergy analysis of electrodialysis for water desalination: Influence of irreversibility sources[J]. Energy Conversion and Management,2022,258:115314. [7] DONG X Y, SI Y, CHEN C J, et al. Reed leaves inspired silica nanofibrous aerogels with parallel-arranged vessels for salt-resistant solar desalination[J]. ACS Nano,2021,15(7):12256-12266. doi: 10.1021/acsnano.1c04035 [8] BIAN Y, TANG K, TIAN L Y, et al. Sustainable solar evaporation while salt accumulation[J]. ACS Applied Materials & Interfaces,2021,13(4):4935-4942. doi: 10.1021/acsami.0c17177 [9] HUANG L, WANG Y P, HE R J, et al. Solar-driven co-generation of electricity and water by evaporation cooling[J]. Desalination,2020,488:114533. [10] TAO P, NI G, SONG C Y, et al. Solar-driven interfacial evaporation[J]. Nature Energy,2018,3(12):1031-1041. doi: 10.1038/s41560-018-0260-7 [11] HAN X H, DING S Q, FAN L W, et al. Janus biocomposite aerogels constituted of cellulose nanofibrils and MXenes for application as single-module solar-driven interfacial evaporators[J]. Journal of Materials Chemistry A,2021,9(34):18614-18622. doi: 10.1039/D1TA04991G [12] CHEN Z C, LI A, CHEN X M. Porous graphene/polyimide membrane with a three-dimensional architecture for rapid and efficient solar desalination via interfacial evaporation[J]. ACS Sustainable Chemistry & Engineering,2020,8(36):13850-13858. doi: 10.1021/acssuschemeng.0c05306 [13] WANG C B, WANG J L, LI Z T, et al. Superhydrophilic porous carbon foam as a self-desalting monolithic solar steam generation device with high energy efficiency[J]. Journal of Materials Chemistry A,2020,8(19):9528-9535. doi: 10.1039/D0TA01439G [14] GE C, SONG Z H, YUAN Y, et al. Solar steam generation by porous conducting polymer hydrogel[J]. Solar Energy,2022,240:237-245. doi: 10.1016/j.solener.2022.05.038 [15] ZHANG D, CAI Y X, LIANG Q Q, et al. Scalable, flexible, durable, and salt-tolerant CuS/bacterial cellulose gel membranes for efficient interfacial solar evaporation[J]. ACS Sustainable Chemistry& Engineering,2020,8(24):9017-9026. doi: 10.1021/acssuschemeng.0c01707 [16] FU Y, WANG G, MEI T, et al. Accessible graphene aerogel for efficiently harvesting solar energy[J]. ACS Sustainable Chemistry & Engineering,2017,5(6):4665-4671. doi: 10.1021/acssuschemeng.6b03207 [17] ZHAO X Z, LIU C K. Enhanced solar evaporation efficiency based on the inserted preheating zone of silver nanowires[J]. Solar Energy,2020,195:304-309. doi: 10.1016/j.solener.2019.11.054 [18] HAO L, LIU N, NIU R, et al. High-performance salt-resistant solar interfacial evaporation by flexible robust porous carbon/pulp fiber membrane[J]. Science China Materials,2022,65(1):201-212. doi: 10.1007/s40843-021-1721-6 [19] HE J X, FAN Y K, XIAO C H, et al. Enhanced solar steam generation of hydrogel composite with aligned channel and shape memory behavior[J]. Composites Science and Technology,2021,204:108633. [20] 李成欣, 高助威, 刘钟馨, 等. 氧化石墨烯负载无纺布复合膜的制备及光热转换性能[J]. 复合材料学报, 2021, 38(12):4255-4262. doi: 10.13801/j.cnki.fhclxb.20210304.001LI C X, GAO Z W, LIU Z X, et al. Preparation of graphene oxide supported non-woven fabric composite membrane and its photothermal conversion performance[J]. Acta Materiae Compositae Sinica,2021,38(12):4255-4262(in Chinese). doi: 10.13801/j.cnki.fhclxb.20210304.001 [21] HAN J, XING W Q, YAN J, et al. Stretchable and superhydrophilic polyaniline/halloysite decorated nanofiber compo-site evaporator for high efficiency seawater desalination[J]. Advanced Fiber Materials, 2022, 4(5): 1233-1245. [22] ZHAO F, GUO Y H, ZHOU X Y, et al. Materials for solar-powered water evaporation[J]. Nature Reviews Materials,2020,5(5):388-401. doi: 10.1038/s41578-020-0182-4 [23] LUO Y Q, SONG F, WU J M, et al. A nature-inspired suspended solar evaporator for water desalination of high-salinity brines[J]. Chemical Engineering Journal,2021,421(1):129824. [24] FAN X Q, YANG Y, SHI X L, et al. A MXene-based hierarchical design enabling highly efficient and stable solar-water desalination with good salt resistance[J]. Advanced Functional Materials,2020,30(52):2007110. [25] LI Y, HONG W P, LI H R, et al. Solar absorber with tunable porosity to control the water supply velocity to accelerate water evaporation[J]. Desalination,2021,511:115113. [26] ZHANG Y X, XIONG T, NANDAKUMAR D K, et al. Structure architecting for salt-rejecting solar interfacial desalination to achieve high-performance evaporation with in situ energy generation[J]. Advanced Science,2020,7(9):1903478. [27] XIE Z J, ZHU J T, ZHANG L B. Three-dimensionally structured polypyrrole-coated setaria viridis spike composites for efficient solar steam generation[J]. ACS Applied Materials & Interfaces,2021,13(7):9027-9035. doi: 10.1021/acsami.0c22917 [28] PHAM T T, NGUYEN T H, NGUYEN T A H, et al. Durable, scalable and affordable iron (III) based coconut husk photothermal material for highly efficient solar steam generation[J]. Desalination,2021,518:115280. [29] LI S Y, QIU F, XIA Y G, et al. Integrating a self-floating janus TPC@CB sponge for efficient solar-driven interfacial water evaporation[J]. ACS Applied Materials & Interfaces,2022,14(17):19409-19418. doi: 10.1021/acsami.2c01359 [30] FINNERTY C, ZHANG L, SEDLAK D L, et al. Synthetic graphene oxide leaf for solar desalination with zero liquid discharge[J]. Environmental Science & Technology,2017,51(20):11701-11709. doi: 10.1021/acs.est.7b03040 [31] KOU H, LIU Z X, ZHU B, et al. Recyclable CNT-coupled cotton fabrics for low-cost and efficient desalination of seawater under sunlight[J]. Desalination,2019,462:29-38. doi: 10.1016/j.desal.2019.04.005 [32] ZHANG Q, XU W L, WANG X B. Carbon nanocomposites with high photothermal conversion efficiency[J]. Science China Materials,2018,61(7):905-914. doi: 10.1007/s40843-018-9250-x [33] XU W C, HU X Z, ZHUANG S D, et al. Flexible and salt resistant janus absorbers by electrospinning for stable and efficient solar desalination[J]. Advanced Energy Materials,2018,8(14):1702884. [34] GAO C, ZHU J J, BAI Z Q, et al. Novel ramie fabric-based draping evaporator for tunable water supply and highly efficient solar desalination[J]. ACS Applied Materials & Interfaces,2021,13(6):7200-7207. doi: 10.1021/acsami.0c20503 [35] CHEN C J, KUANG Y D, HU L B. Challenges and opportunities for solar evaporation[J]. Joule,2019,3(3):683-718. doi: 10.1016/j.joule.2018.12.023 [36] XU N, HU X Z, XU W C, et al. Mushrooms as efficient solar steam-generation devices[J]. Advanced Materials,2017,29(28):1606762. [37] LIU C, HONG K V, SUN X, et al. An 'antifouling' porous loofah sponge with internal microchannels as solar absorbers and water pumpers for thermal desalination[J]. Journal of Materials Chemistry A,2020,8(25):12323-12333. doi: 10.1039/D0TA03872E [38] DAO V D, CHOI H S. Carbon-based sunlight absorbers in solar-driven steam generation devices[J]. Global Challenges,2018,2(2):1700094. [39] ITO Y, TANABE Y, HAN J H, et al. Multifunctional porous graphene for high-efficiency steam generation by heat localization[J]. Advanced Materials,2015,27(29):4302-4307. doi: 10.1002/adma.201501832 [40] LI Y J, GAO T T, YANG Z, et al. Graphene oxide-based evaporator with one-dimensional water transport enabling high-efficiency solar desalination[J]. Nano Energy,2017,41:201-209. doi: 10.1016/j.nanoen.2017.09.034 [41] HU X Z, XU W C, ZHOU L, et al. Tailoring graphene oxide-based aerogels for efficient solar steam generation under one sun[J]. Advanced Materials,2017,29(5):1604031. [42] GUAN W X, GUO Y H, YU G H. Carbon materials for solar water evaporation and desalination[J]. Small,2021,17(48):2007176. [43] YANG X D, YANG Y B, FU L N, et al. An ultrathin flexible 2D membrane based on single-walled nanotube-MoS2 hybrid film for high-performance solar steam generation[J]. Advanced Functional Materials,2018,28(3):1704505. [44] WANG Y C, ZHANG L B, WANG P. Self-floating carbon nanotube membrane on macroporous silica substrate for highly efficient solar-driven interfacial water evaporation[J]. ACS Sustainable Chemistry & Engineering,2016,4(3):1223-1230. doi: 10.1021/acssuschemeng.5b01274 [45] HU T, LI L X, YANG Y F, et al. A yolk@shell superhydrophobic/superhydrophilic solar evaporator for efficient and stable desalination[J]. Journal of Materials Chemistry A,2020,8(29):14736-14745. doi: 10.1039/D0TA04917D [46] CHEN C J, LI Y J, SONG J W, et al. Highly flexible and efficient solar steam generation device[J]. Advanced Materials,2017,29(30):1701756. [47] ZHANG C, XIAO P, NI F, et al. Programmable interface asymmetric integration of carbon nanotubes and gold nanoparticles toward flexible, configurable, and surface-enhanced raman scattering active all-in-one solar-driven evaporators[J]. Energy Technology: Generation, Conversion, Storage, Distribution,2019,7(11):1900787. [48] XIAO P, GU J C, ZHANG C, et al. A scalable, low-cost and robust photo-thermal fabric with tunable and programmable 2D/3D structures towards environmentally adaptable liquid/solid-medium water extraction[J]. Nano Energy,2019,65:104002. [49] WAN P, GU X B, OUYANG X L, et al. A versatile solar-powered vapor generating membrane for multi-media purification[J]. Separation and Purification Technology,2021,260:117952. [50] ZHANG Q, XIAO X F, WANG G, et al. Silk-based systems for highly efficient photothermal conversion under one sun: Portability, flexibility, and durability[J]. Journal of Materials Chemistry A,2018,6(35):17212-17219. doi: 10.1039/C8TA05193C [51] ZHANG J, LONG H R, ZHANG P H. Structure and characterization of carbonized cotton knitted fabric[J]. Textile Research Journal, 2022, 92(19-20) : 3719-3732. [52] WU X, WU L M, TAN J, et al. Evaporation above a bulk water surface using an oil lamp inspired highly efficient solar-steam generation strategy[J]. Journal of Materials Chemistry A,2018,6(26):12267-12274. doi: 10.1039/C8TA03280G [53] LIN X F, YANG M J, HONG W, et al. Commercial fiber products derived free-standing porous carbonized-membranes for highly efficient solar steam generation[J]. Frontiers in Materials,2018,5:6217-6221. doi: 10.3389/fmats.2018.00008 [54] FANG Q L, LI T T, LIN H B, et al. Highly efficient solar steam generation from activated carbon fiber cloth with matching water supply and durable fouling resistance[J]. ACS Applied Energy Materials,2019,2(6):4354-4361. doi: 10.1021/acsaem.9b00562 [55] SHANG M Y, XU S H, LI J L, et al. CuS hollow nanospheres/cellulose composite film as a recyclable interfacial photothermal evaporator for solar steam generation[J]. Energy Technology,2022,10(2): 2100805. [56] SUN S J, SUN B B, WANG Y M, et al. Carbon black and polydopamine modified non-woven fabric enabling efficient solar steam generation towards seawater desalination and wastewater purification[J]. Separation and Purification Technology,2022,278:119621. [57] 陈根余, 陶能如, 李明全, 等. 碳纤维复合材料激光制孔技术研究进展[J]. 复合材料学报, 2022, 39(4):1395-1410. doi: 10.13801/j.cnki.fhclxb.20211115.002CHEN G Y, TAO N R, LI M Q, et al. Research progress of laser drilling technology for carbon fiber reinforced composites[J]. Acta Materiae Compositae Sinica,2022,39(4):1395-1410(in Chinese). doi: 10.13801/j.cnki.fhclxb.20211115.002 [58] TONG D D, SONG B. A high-efficient and ultra-strong interfacial solar evaporator based on carbon-fiber fabric for seawater and wastewater purification[J]. Desalination,2022,527:115586. [59] ZHANG Q, XIAO X F, ZHAO G M, et al. An all-in-one and scalable carbon fibre-based evaporator by using the weaving craft for high-efficiency and stable solar desalination[J]. Journal of Materials Chemistry A,2021,9(17):10945-10952. doi: 10.1039/D1TA01295A [60] LI T T, FANG Q L, XI X F, et al. Ultra-robust carbon fibers for multi- media purification via solar- evaporation[J]. Journal of Materials Chemistry A,2019,7(2):586-593. doi: 10.1039/C8TA08829B [61] ZHU B, KOU H, LIU Z X, et al. Flexible and washable CNT-embedded PAN nonwoven fabrics for solar-enabled evaporation and desalination of seawater[J]. ACS Applied Materials & Interfaces,2019,11(38):35005-35014. doi: 10.1021/acsami.9b12806 [62] GUO X X, GAO H, WANG S Y, et al. Scalable, flexible and reusable graphene oxide-functionalized electrospun nanofibrous membrane for solar photothermal desalination[J]. Desalination,2020,488:114535. [63] BU Y M, ZHOU Y H, LEI W W, et al. A bioinspired 3D solar evaporator with balanced water supply and evaporation for highly efficient photothermal steam generation[J]. Jour-nal of Materials Chemistry A,2022,10(6):2856-2866. doi: 10.1039/D1TA09288J [64] QIN Z, SUN H, TANG Y N, et al. Bioinspired hydrophilic-hydrophobic janus composites for highly efficient solar steam generation[J]. ACS Applied Materials & Interfaces,2021,13(16):19467-19475. doi: 10.1021/acsami.1c02026 [65] QI P, REN J, LING S J. Animal silk-derived amorphous carbon fibers for electricity generation and solar steam evaporation[J]. Frontiers in Chemistry,2021,9:669797. [66] GAO T, WU X, WANG Y D, et al. A hollow and compressible 3D photothermal evaporator for highly efficient solar steam generation without energy loss[J]. Solar RRL,2021,5(5):2100053. [67] ZHANG Q, REN L P, XIAO X F, et al. Vertically aligned Juncus effusus fibril composites for omnidirectional solar evaporation[J]. Carbon,2020,156:225-233. doi: 10.1016/j.carbon.2019.09.067 [68] XU J T, JIANG S X, WANG Y X, et al. Photo-thermal conversion and thermal insulation properties of ZrC coated polyester fabric[J]. Fibersand Polymers,2017,18(10):1938-1944. doi: 10.1007/s12221-017-1237-z [69] TESSEMA A A, WU C M, MOTORA K G, et al. Highly-efficient and salt-resistant CsxWO3@g-C3N4/PVDF fiber membranes for interfacial water evaporation, desalination, and sewage treatment[J]. Composites Science and Technology,2021,211:108865. doi: 10.1016/j.compscitech.2021.108865 -

下载:

下载: