Research progress of graphene reinforced copper matrix composites

-

摘要: 铜(Cu)基复合材料具有优异的力学、热学、电学及耐磨和耐腐蚀等性能,广泛应用于各种工业技术领域。石墨烯(Graphene,Gr)具有二维平面结构和优异的综合性能,是金属基复合材料理想的增强相。石墨烯增强铜基复合材料拓展了铜及其合金的应用范围,适当的制备方法可以使其在保持优异导电导热性能的同时拥有更好的力学性能。石墨烯在铜基体中的存在形式主要以还原氧化石墨烯、石墨烯纳米片或与金属氧化物/碳化物纳米颗粒连接,旨在增强两者之间的界面结合。因此,石墨烯在铜基体中的结构完整性及存在形式直接影响了其性能的优劣。本文综述了Cu/Gr复合材料的制备及模拟方法、复合材料的性能评价及力学性能与功能特性的相互影响规律。指明Cu/Gr复合材料的发展关键在于:(1) 分散性与界面结合;(2) 三维石墨烯结构的构建;(3) 界面结合对力学性能与功能特性的影响及两者间的相互协调。Abstract: Copper (Cu) matrix composites have excellent mechanical, thermal, electrical, wear and corrosion resistance properties, and are widely used in industrial fields. Graphene (Gr) is an ideal reinforcement phase for metal matrix composites due to its two-dimensional features and excellent physical properties. Gr reinforced Cu have expanded the applications of Cu and its alloys. Appropriate preparation methods can achieve excellent electrical and thermal conductivity while maintaining the excellent mechanical properties. Gr in Cu matrix mainly exist in the form of reduced GO (r-GO), graphene nanosheets or connected with metal oxide/carbide nanoparticles to enhance the interface bonding. Therefore, the structural integrity and the form of graphene in Cu matrix directly affect its performances. In this review paper, the preparation and simulation methods of Cu/Gr composites, the evaluation on the performances and the interaction between mechanical and functional properties are summarized. The key to the development of Cu/Gr composites is suggested: (1) dispersion and interfacial bonding; (2) construction of three-dimensional graphene structures; (3) the effect of interfacial bonding on the mechanical and functional properties.

-

图 2 通过分子水平混合方法制备还原氧化石墨(RGO)/Cu纳米复合材料的工艺示意图:(a) 原始石墨;(b) 采用Hummers方法制备氧化石墨烯(GO);(c) 铜盐在GO溶液中的分散;(d) 在GO上,Cu离子氧化成Cu氧化物;(e) CuO和GO的还原;(f) 烧结RGO/Cu纳米粉末[14]

Figure 2. Schematic of fabrication process of reduced graphite oxide (RGO)/Cu nanocomposite: (a) Pristine graphite; (b) Graphene oxide (GO) fabricated by the Hummers method; (c) Dispersion of Cu salt in GO solution; (d) Oxidation from Cu ions to Cu-oxide on the GO; (e) Reduction of Cu-oxide and GO; (f) Sintered RGO/Cu nanocomposite powders[14]

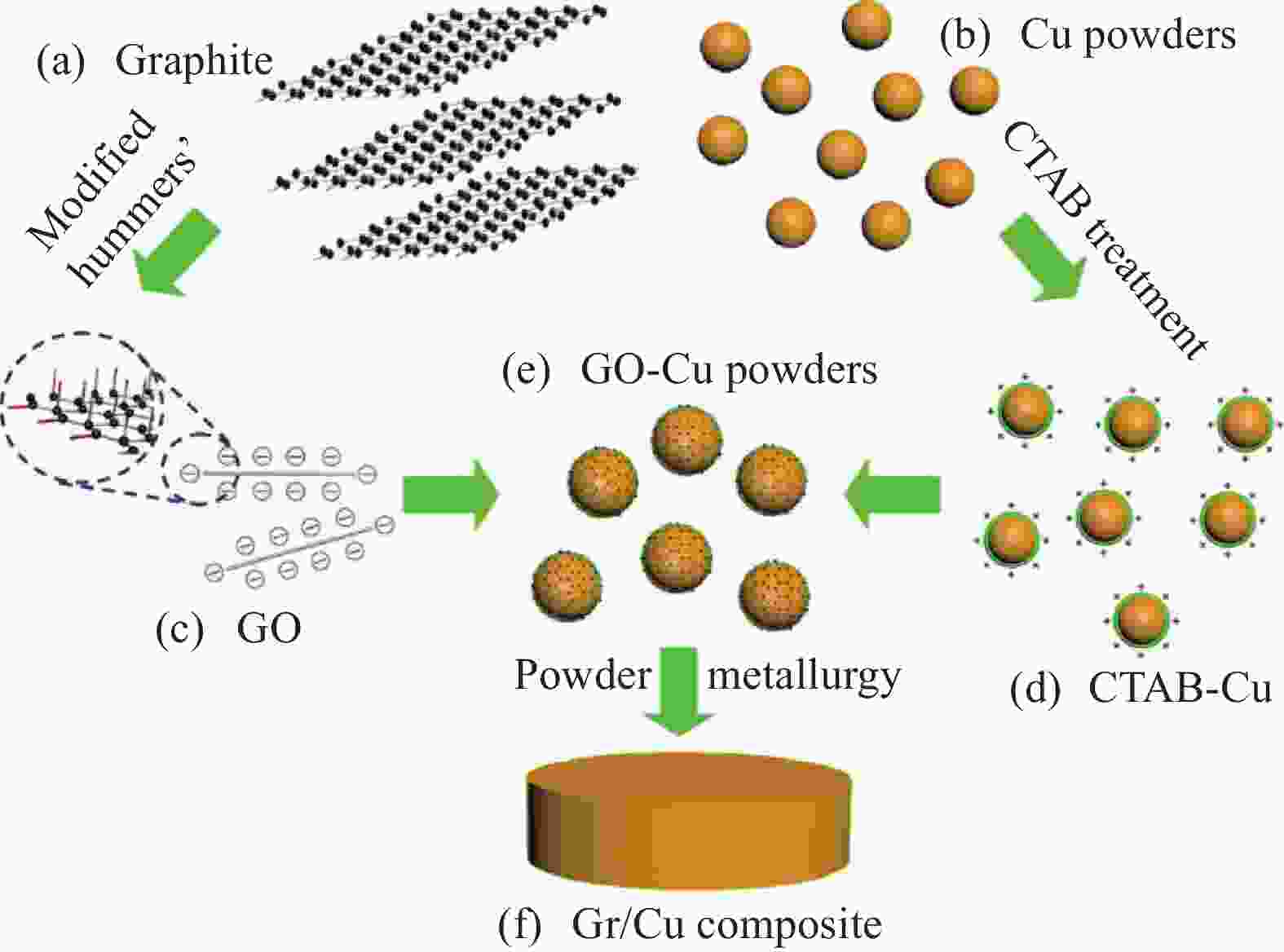

图 3 Gr/Cu复合材料制造工艺示意图:(a) 石墨;(b) 铜粉;(c) 带负电荷的GO;(d) 带正电荷的CTAB改性铜粉(CTAB-Cu);(e) GO-Cu粉末;(f) Gr/Cu复合材料[24]

Figure 3. Schematic of the fabrication process of Gr/Cu composite: (a) Graphite; (b) Cu powders; (c) GO with the negative charge; (d) CTAB modified Cu powders (CTAB-Cu) with the positive charge; (e) GO-Cu powders; (f) Gr/Cu composite[24]

图 4 整体制造过程及Gr网络状形貌示意图:(a) 用蔗糖作为混合前体包覆铜粉;(b) 混合前体经过快速热退火(RTA)过程生长类石墨烯纳米片(GLNs);(c) 利用热压将GLNs内接成Cu基体中的连续网络结构;(d) 采用热轧法制备全致密三维石墨烯状纳米片网络(3D-GLNN)/Cu复合材料;热压3D-GLNN/Cu复合材料中Cu刻蚀后3D-GLNN的SEM图像 (e) 和TEM图像 (f);(g) 3D-GLNN的Y型互连区HRTEM图像,其中A层和B层合并为A+B层;(h) 热压3D-GLNN/Cu中3D-GLNN的FIB-3D重建结果快照[16]

Figure 4. Schematic illustration of overall fabrication processes and Gr microstructure characterizations: (a) Cu powders were firstly coated with sucrose as a hybrid precursor; (b) Hybrid precursor was then subjected to rapid thermal annealing (RTA) process for growing graphene-like nanosheets (GLNs); (c) GLNs were interconnected into a continuous network structure in the Cu matrix by using hot-pressing; (d) Fully-densified 3D graphene-like nanosheet network (3D-GLNN)/Cu bulk composites were fabricated by hot-rolling. SEM image (e) and TEM image (f) of 3D-GLNN after Cu etching in the hot-pressed 3D-GLNN/Cu composites. Scale bar, 5 μm (e); 200 nm (f); (g) HRTEM image of the Y-type interconnection area of 3 D-GLNN, where the layer A and layer B merged into layer A+B. Scale bar, 5 nm; (h) Snapshot of FIB-3D reconstruction results of 3D-GLNN in the h hot-pressed 3D-GLNN/Cu (model size:3.85 × 2.14 × 2.00 μm)[16]

EtOH—Ethyl alcohol

图 6 镀镍石墨烯(NCG)/Cu复合箔制备及表征性能示意图:(a) NCG/Cu的制备;(b) 沉积后衬底的数字照片;(c) 复合箔的截面SEM图像;(d) 应力-应变曲线;(e) 不同浓度NCG复合箔的热导率和热扩散率[18]

Figure 6. Schematic diagram of preparation and characterization of nickel plated graphene (NCG)/Cu composite foi: (a) Preparation of NCG/Cu; (b) Digital photograph of the substrate after deposition; (c) Cross-sectional SEM image of the composite foil; (d) Stress-strain curves; (e) Thermal conductivity and thermal diffusivity of the composite foil with different concentrations of NCG[18]

图 7 多层Gr/Cu复合材料的模型与拉伸应力-应变曲线:(a) 锯齿状Gr;(b) 扶手椅状Gr;插图(c)~(f)是曲线的特写视图,插图(e)和(f)是屈服点;(g) 含三层Gr的Gr/Cu体系初始模型[20]

Figure 7. Model and tensile stress-strain curves of Multilayer Gr/Cu composite: (a) Zigzag Gr; (b) Armchair Gr; Insets (c)-(f) are the close-up views of the curves, inserts (e) and (f) are the yield points; (g) Initial model of Gr/Cu system with three Gr layers[20]

图 8 Gr/Ni复合材料的原子构型:(a) Gr/Ni复合材料及其嵌入的Gr单元的原子构型(上插图显示弛豫过程中能量随时间的演化);((b)~(c)) Gr/Ni复合材料的代表性体积单元(RVE)和其嵌入的Gr;(d) Gr-1曲线区域-1上有孔状缺陷;(e) Gr-2在直区域-2上有孔状缺陷[49]

Figure 8. Atomic configuration of Gr/Ni composites: (a) Atomic configurations of the Gr/Ni composite and its embedded Gr unit (the upper inset shows the energy evolution by time during relaxation); ((b)-(c)) Representative volume element (RVE) of the Gr/Ni composite and its embedded Gr; (d) Gr-1 with hole-like defects on curved region-1; (e) Gr-2 with hole-like defects on straight region-2[49]

图 9 复合材料的原子构型:(a) 原始石墨烯(PG);((b)~(d)) 含1%、10%、50%氢原子的氢功能化石墨烯(1%HFG、10%HFG、50%HFG);((e)~(h)) 具有1%官能团的甲基、乙基、丙基和丁基功能化石墨烯(1%CH3 FG、1%C2H5 FG、1%C3H7 FG 和1%C4H9 FG);((i)~(j)) Gr/Cu纳米复合材料的透视图和正面图[50]

Figure 9. Atomic configurations of composites: (a) Pristine graphene (PG); ((b)-(d)) Hydrogen functionalized graphene (HFG) with 1%, 10%, 50% hydrogen atoms (denoted as 1%HFG, 10%HFG, 50%HFG); ((e)-(h)) Methyl, ethyl, propyl, and butyl functionalized graphene with 1% functional groups (1%CH3 FG,1%C2 H5 FG,1%C3 H7 FG and 1%C4 H9 FG); ((i)-(j)) Perspective view and front view of Gr/Cu nanocomposites[50]

表 1 不同方法制备Gr/Cu复合材料的力学性能

Table 1. Mechanical properties of Gr/Cu composites prepared by different methods

Experimental classification Processing route Material Yield strength/MPa Maximum

strength/MPaHardness (HV) Elogation/% Ref. RGO MLM+SPS

MLM+self-assemble+SPS

charge

adsorption+ thermal

reduction+hot-press sintering

Oxygen plasma treatment2.5vol%Gr/Cu

Pure Cu

2.5vol%RGO/Cu

2.5vol%CNT-RGO/Cu

Pure Cu

0.3wt%RGO+Cu

0.6wt%RGO+Cu

0.9wt%RGO+Cu

P-1vol%GNP/Cu

1vol%GNP/Cu73.9

82.2

107.4

90.8

188

158284

294

450

601

191.3

206.3

226.7

231.97.2

7.5

11.8

14.4

21

12[14]

[66]

[67-68]Gr Plasma assisted milling

treatment

vacuum hot-press sintering

pulse electrodeposition

accumulative roll-compositing

wet milling and hot-press sintering

nanoporous Cu + rolling + sintering

CVD+ball-milling+SPSCu

Gr/Cu

PAM-Gr/Cu

Pure Cu

Gr/Cu-50

Gr/Cu-80

1.6 g/L-Gr/Cu

Gr/Cu

0.6wt%Gr/Cu

Cu

800-Gr/Cu

Ball-milled Cu

Ball-milled Gr@Cu396

474

505

156

281

65.2

154.3197

231

260

422

516

549

274

686

290.47

245

354

218.3

254.948.6

70.4

78.51.66

0.80

0.96

18.7

16.5

49.3

35.2[17]

[43]

[70]

[27]

[71]

[72]

[73]Add metal

elementChemically reducing+SPS+Ni

electroless deposition

engineering design methodology+SPS

impregnation reduction+in situ reactionCu

0.8vol% GPL/Cu

0.8vol% Ni-GPL/Cu

30 mg/L-NCG/Cu

Pure Cu

GNPs/Cu

GNPs-W/Cu

0.11vol%Mo2C@

1.6%GNPs/Cu68.97

110.16

234.25172

131

245

338.7

103.50±2.28

171.85±1.53

295.65±1.12

303

6

9

30.2±0.8

10.8±0.3

13.5±0.9[74]

[18]

[33]

[32]Notes: GNPs—Graphene nanosheets; GPL—Graphene platelet; NCG—Nickel-plated graphene. 表 2 不同方法制备Gr/Cu复合材料的导电性能

Table 2. Electric conductivity of Gr/Cu composites prepared by different methods

Experimental

classificationProcessing route Material Electrical conductivity/

%IACSRef. RGO MLM+self-assemble

charge adsorption

+thermal reduction+hot-press sintering2.5vol%RGO/Cu

2.5vol%CNT-RGO/Cu

Pure Cu

0.3wt%RGO+Cu

0.6wt%RGO+Cu

0.9wt%RGO+Cu83

85

99

93

90

85[66]

[67]Gr Plasma assisted milling

treatment

vacuum hot-press sintering

SPS

HP

accumulative roll-compositing

wet milling and hot-press

sinteringGr/Cu

PAM-Gr/Cu

Pure Cu

Gr/Cu-50

Gr/Cu-80

Gr/Cu

Gr/Cu

Gr/Cu

0.6wt%Gr/Cu71.3

75.5

95.65

94.85

93.2

108.6

98.8

>70

97.5[17]

[43]

[15]

[27]

[71]Add metal

elementimpregnation reduction+in situ reaction 0.11vol%Mo2C@

1.6%GNPs/Cu>90 [32] Note: IACS—International annealed copper standard; CNT—Carbon nanotube. 表 3 不同方法制备的Gr/Cu复合材料的导热性

Table 3. Thermal conductivity of Gr/Cu composites prepared by different methods

Experimental

classificationProcessing route Material Thermal conductivity/

(W·(m·K)−1)Ref. RGO Sintered

charge adsorption +

thermal reduction +

hot-press sintering

pulsed-current co-electro depositionPTG/Cu-CuxO+Cu+0.1wt%PTG

UTG+Cu+0.1wt%UTG

Pure Cu

0.3wt%RGO+Cu

0.6wt%RGO+Cu

0.9wt%RGO+Cu

FGr/Cu168.5

64.8

375

405

413

364

497[21]

[67]

[89]Gr Electroless plating method

Vacuum hot pressing5%GNP/Cu

20%GNP/Cu

GP/Cu298.7

221.4

968[94]

[88]Add metal element Electroless deposition

Vacuum hot pressing+PM30 mg/L-NCG/Cu

B4C-B@Gr/Cu431.2

676[18]

[95]Notes: PTG—Plasma treated graphene; UTG—Untreated graphene; FGr—Functionalization of graphene with conjugated 4-ethynylaniline; GP—Graphene paper. -

[1] NASTASI-ANDREWS R J. Optical properties and electronic structure of dilute Cu-Au, Cu-Zn, Cu-Al, Cu-Ga, Cu-Si, Cu-Ge, Cu-Sn, and Cu-As alloys[J]. Physical Review B,1977,16(10):4314-4323. doi: 10.1103/PhysRevB.16.4314 [2] MURASHKIN M Y, SABIROV I, SAUVAGE X, et al. Nanostructured Al and Cu alloys with superior strength and electrical conductivity[J]. Journal of Materials Science,2016,51(1):33-49. doi: 10.1007/s10853-015-9354-9 [3] SHAN L Y, WANG X L, CHANG Y L, et al. Improving the mechanical performance of Cu Cr alloy by dissolving Cu in the Cr second phase[J]. Materials Characterization,2021,176:111104. doi: 10.1016/j.matchar.2021.111104 [4] CHU K J, REN F Z, ZHU W W, et al. Tribological and corrosion behaviors of bulk Cu-W nanocomposites fabricated by mechanical alloying and warm pressing[J]. Journal of Alloys & Compounds,2016,676:164-172. [5] NOVOSELOV K S, GEIM A K, MOROZOV S V, et al. Electric field effect in atomically thin carbon films[J]. Science,2004,306(5696):666-9. doi: 10.1126/science.1102896 [6] LEE C, WEI X, KYSAR J W, et al. Measurement of the elastic properties and intrinsic strength of monolayer graphene[J]. Science,2008,321(5887):385-388. doi: 10.1126/science.1157996 [7] BALANDIN A A, GHOSH S, BAO W, et al. Superior thermal conductivity of single-layer graphene. Nano Letters[J]. Nano Letters,2008,8(3):902-907. doi: 10.1021/nl0731872 [8] KIM P, SHI L, MAJUMDAR A, et al. Thermal transport measurements of individual multiwalled nano-tubes[J]. Physical Review Letters,2001,87(21):215502. doi: 10.1103/PhysRevLett.87.215502 [9] DU X, SKACHKO I, BARKER A, et al. Approaching ballistic transport in suspended graphene[J]. Nature Nanotechnology, 2008, 3(8): 491-495. [10] LÓPEZ G A, MITTEMEIJER E J. The solubility of C in solid Cu-ScienceDirect[J]. Scripta Materialia,2004,51(1):1-5. doi: 10.1016/j.scriptamat.2004.03.028 [11] WEI N, ZHOU Y, YAO Y, et al. Surface reconstruction with a sandwich-like C/Cu/C catalyst for selective and stable CO2 electroreduction[J]. ACS Applied Materials & Interfaces, 2022, 14(11): 13261-13270. [12] 赵乃勤, 郭斯源, 张翔, 等. 基于增强相构型设计的石墨烯/Cu复合材料研究进展[J]. 金属学报, 2021, 57(9):1087-1106.ZHAO N Q, GUO S Y, ZHANG X, et al. Progress on graphene/copper composites focusing on reinforcement configuration design: A review[J]. Acta Metallurgica Sinica,2021,57(9):1087-1106(in Chinese). [13] QU W L, ZHANG J X, ZHANG S D, et al. Copper matrix composites reinforced by three-dimensional netlike graphene towards enhanced mechanical property and wear resistance[J]. Composites Communications,2022,32:101187. doi: 10.1016/j.coco.2022.101187 [14] HWANG J, YOON T, JIN S H, et al. Enhanced mechanical properties of graphene/copper nanocomposites using a molecular-level mixing process[J]. Advanced Materials,2013,25(46):6724-6729. doi: 10.1002/adma.201302495 [15] YANG J, HE Y, ZHANG X H, et al. Improving the electrical conductivity of copper/graphene composites by reducing the interfacial impurities using spark plasma sintering diffusion bonding[J]. Journal of Materials Research and Technology,2021,15:3005-3015. doi: 10.1016/j.jmrt.2021.09.100 [16] ZHANG X, XU Y, WANG M C, et al. A powder-metallurgy-based strategy toward three-dimensional graphene-like network for reinforcing copper matrix composites[J]. Nature Communications,2020,11(1):2775. doi: 10.1038/s41467-020-16490-4 [17] DONG Z L, PENG Y F, ZHANG X H, et al. Plasma assisted milling treatment for improving mechanical and electrical properties of in-situ grown graphene/copper compo-sites[J]. Composites Communications,2021,24:100619. doi: 10.1016/j.coco.2020.100619 [18] WEI C L, YE N, HONG L K, et al. Scalable preparation of ultrathin graphene-reinforced copper composite foils with high mechanical properties and excellent heat dissipation[J]. ACS Applied Materials & Interfaces,2021,13(18):21714-21723. [19] LEE S, GHAFFARIAN H, KIM W, et al. A study on dislocation mechanisms of toughening in Cu-graphene nanolayered composite[J]. Nano Letters,2022,22(1):188-195. doi: 10.1021/acs.nanolett.1c03599 [20] PENG W X, SUN K. Effects of Cu/graphene interface on the mechanical properties of multilayer Cu/graphene composites[J]. Mechanics of Materials,2020,141:103270. doi: 10.1016/j.mechmat.2019.103270 [21] DENG S J, ZHANG X, ZHANG K, et al. Thermal interface material with graphene enhanced sintered copper for high temperature power electronics[J]. Nanotechnology,2021,32(31):315710. doi: 10.1088/1361-6528/abfc71 [22] YANG Z Y, WANG L D, LI J, et al. Lateral size effect of reduced graphene oxide on properties of copper matrix composites[J]. Materials Science and Engineering: A,2021,820:141579. doi: 10.1016/j.msea.2021.141579 [23] XIONG D B, CAO M, GUO Q, et al. Graphene-and-copper artificial nacre fabricated by a preform impregnation process: Bioinspired strategy for strengthening-toughening of metal matrix composite[J]. ACS Nano,2015,9(7):6934-6943. doi: 10.1021/acsnano.5b01067 [24] GAO X, YUE H Y, GUO E J, et al. Mechanical properties and thermal conductivity of graphene reinforced copper matrix composites[J]. Powder Technology,2016,301:601-607. doi: 10.1016/j.powtec.2016.06.045 [25] SHI L, LIU M B, YANG Y J, et al. Achieving high strength and ductility in copper matrix composites with graphene network[J]. Materials Science and Engineering: A,2021,828:142107. doi: 10.1016/j.msea.2021.142107 [26] YANG Z Y, WANG L D, CUI Y, et al. High strength and ductility of graphene-like carbon nanosheet/copper composites fabricated directly from commercial oleic acid coated copper powders[J]. Nanoscale,2018,10:16990-16995. doi: 10.1039/C8NR04451A [27] CHEN F, MEI Q S, LI J Y, et al. Fabrication of graphene/copper nanocomposites via in-situ delamination of graphite in copper by accumulative roll-compositing[J]. Composites Part B: Engineering,2021,216:108850. doi: 10.1016/j.compositesb.2021.108850 [28] JIANG R R, ZHOU X F, LIU Z P. Electroless Ni-plated graphene for tensile strength enhancement of copper[J]. Materials Science and Engineering: A,2017,679:323-328. doi: 10.1016/j.msea.2016.10.029 [29] LI M, SONG Z L, GONG M F, et al. WC+Co+graphene platelet composites with improved mechanical, tribological and thermal properties[J]. Ceramics International,2021,47(21):30852-30859. doi: 10.1016/j.ceramint.2021.07.266 [30] CHU K, WANG F, LI Y B, et al. Interface and mechanical/thermal properties of graphene/copper composite with Mo2C nanoparticles grown on graphene[J]. Composites Part A: Applied Science and Manufacturing, 2018, 109: 267-279. [31] CHU K, WANG F, WANG X H, et al. Interface design of graphene/copper composites by matrix alloying with titanium[J]. Materials & Design,2018,144:290-303. [32] GUO S Y, ZHANG X, SHI C S, et al. Enhanced mechanical properties and electrical conductivity of graphene nanoplatelets/Cu composites by in situ formation of Mo2C nanoparticles[J]. Materials Science and Engineering: A,2019,766:138365. doi: 10.1016/j.msea.2019.138365 [33] DONG L L, FU Y Q, LIU Y, et al. Interface engineering of graphene/copper matrix composites decorated with tungsten carbide for enhanced physico-mechanical properties[J]. Carbon,2021,173:41-53. doi: 10.1016/j.carbon.2020.10.091 [34] ZHAN K, LI F J, WANG W Z, et al. Preparation and mechanism of Cu/GO/Cu laminated composite foils with improved thermal conductivity and mechanical property by architectural design[J]. Journal of Alloys and Compounds,2022,904:164085. doi: 10.1016/j.jallcom.2022.164085 [35] TEKLU A, BARRY C, PALUMBO M, et al. Mechanical characterization of reduced graphene oxide using AFM[J]. Advances in Condensed Matter Physics,2019,2019:8713965. [36] XU H F, MA L B, JIN Z. Nitrogen-doped graphene: Synthesis, characterizations and energy applications[J]. Journal of Energy Chemistry,2018,27(1):146-160. doi: 10.1016/j.jechem.2017.12.006 [37] ZHAO L, LEE T, RYU S, et al. Mechanical robustness of metal nanocomposites rendered by graphene functionalization[J]. Nano Letters,2021,21(13):5706-5713. doi: 10.1021/acs.nanolett.1c01438 [38] LI Z, FU X D, GUO Q, et al. Graphene quality dominated interface deformation behavior of graphene-metal composite: The defective is better[J]. International Journal of Plasticity,2018,111:253-265. doi: 10.1016/j.ijplas.2018.07.020 [39] LIU Z Y, WANG L H, ZAN Y N, et al. Enhancing strengthening efficiency of graphene nano-sheets in aluminum matrix composite by improving interface bonding[J]. Composites Part B: Engineering,2020,199:108268. doi: 10.1016/j.compositesb.2020.108268 [40] LIN Y C, CAO Y, JANG J H, et al. The synthesis and characterization of graphene oxides based on a modified approach[J]. Journal of Thermal Analysis and Calorimetry,2014,116(3):1249-1255. doi: 10.1007/s10973-013-3545-x [41] DONG Z L, ZHAO S Y, ZHANG Y Y, et al. Evaluating and manipulating bonding strength at multilayer graphene-copper interface via plasma functionalization[J]. Materials Science and Engineering: A,2022,848:143391. doi: 10.1016/j.msea.2022.143391 [42] LI T, WANG Y, YANG M, et al. High strength and conductivity copper matrix composites reinforced by in-situ graphene through severe plastic deformation processes[J]. Journal of Alloys and Compounds,2020,815:156703. [43] GAO Z S, ZUO T T, WANG M, et al. In-situ graphene enhanced copper wire: A novel electrical material with simultaneously high electrical conductivity and high strength[J]. Carbon,2022,186:303-312. doi: 10.1016/j.carbon.2021.10.015 [44] CHU K, WANG X H, WANG F, et al. Largely enhanced thermal conductivity of graphene/copper composites with highly aligned graphene network[J]. Carbon,2018,127:102-112. doi: 10.1016/j.carbon.2017.10.099 [45] ZHANG C, LU C, MICHAL G, et al. Strong strain hardening in graphene/nanotwinned metal composites revealed by molecular dynamics simulations[J]. International Journal of Mechanical Sciences,2021,201:106460. doi: 10.1016/j.ijmecsci.2021.106460 [46] CHOUDHARY A, MALAKKAL L, SIRIPURAPU R K, et al. First principles calculations of hydrogen storage on Cu and Pd-decorated graphene[J]. International Journal of Hydrogen Energy,2016,41(39):17652-17656. doi: 10.1016/j.ijhydene.2016.07.147 [47] BAI T Y, QIAO Y Y, WANG X D, et al. Finite element method modeling of temperature gradient-induced Cu atomic thermomigration in Cu/Sn/Cu micro solder joint[J]. Microelectronics Reliability,2022,129:114479. doi: 10.1016/j.microrel.2022.114479 [48] YANG Y J, LIU M B, ZHOU S Q, et al. Construction of graphene network in Ni matrix composites: A molecular dynamics study of densification process[J]. Carbon,2022,191:55-66. doi: 10.1016/j.carbon.2022.01.044 [49] YANG Y J, LIU M B, ZHOU S Q, et al. Strengthening behaviour of continuous graphene network in metal matrix composites[J]. Carbon,2021,182:825-836. doi: 10.1016/j.carbon.2021.06.067 [50] LI J M, XU Y X, WANG M C, et al. Deformation mechanism of copper reinforced by three-dimensional graphene under torsion and tension[J]. Modelling and Simulation in Materials Science and Engineering,2022,30(2):025004. doi: 10.1088/1361-651X/ac40d2 [51] ZHAO S Y, ZHANG Y Y, YANG J, et al. Significantly improved interfacial shear strength in graphene/copper nanocomposite via wrinkles and functionalization: A molecular dynamics study[J]. Carbon,2021,174:335-344. doi: 10.1016/j.carbon.2020.12.026 [52] 华军, 宋郴, 段志荣, 等. 石墨烯/铜复合材料剪切性能的分子动力学模拟[J]. 复合材料学报, 2018, 35(3):632-639.HUA J, SONG C, DUAN Z R, et al. Molecular dynamics simulations of the shear mechanical properties of graphene/copper composites[J]. Acta Materiae Compo-sitae Sinica,2018,35(3):632-639(in Chinese). [53] PENG W X, SUN K. Interface structures and dislocation nucleation of Cu/graphene interface via molecular dynamic simulations[J]. Materialia,2021,18:101131. doi: 10.1016/j.mtla.2021.101131 [54] SHUANG F, AIFANTIS K E. Dislocation-graphene interactions in Cu/graphene composites and the effect of boundary conditions: A molecular dynamics study[J]. Carbon,2021,172:50-70. doi: 10.1016/j.carbon.2020.09.043 [55] YAN S J, HONG Q H, CHEN X, et al. Reduced graphene oxide–refined Cu matrix composites: An experimental and first-principles study[J]. Crystal Research and Technology,2019,54(2):1800191. doi: 10.1002/crat.201800191 [56] SHIN S E, CHOI H J, SHIN J H, et al. Strengthening behavior of few-layered graphene/aluminum composites[J]. Carbon,2015,82:143-151. doi: 10.1016/j.carbon.2014.10.044 [57] ZHAO L Y, LU H M, GAO Z J. microstructure and mechanical properties of Al/graphene composite produced by high-pressure torsion[J]. Advanced Engineering Materials,2015,17(7):976-981. doi: 10.1002/adem.201400375 [58] LI J, ZHANG P, HE H, et al. Enhanced the thermal conductivity of flexible copper foil by introducing graphene[J]. Materials & Design,2020,187:108373. [59] ZHANG S, WANG F, HUANG P. Enhanced Hall-Petch strengthening in graphene/Cu nanocomposites[J]. Jour-nal of Materials Science & Technology,2021,87:176-183. [60] SANSOZ F, KE X. Hall–Petch strengthening limit through partially active segregation in nanocrystalline Ag-Cu alloys[J]. Acta Materialia,2022,225:117560. doi: 10.1016/j.actamat.2021.117560 [61] 王江伟, 陈映彬, 祝祺, 等. 金属材料的晶界塑性变形机制[J]. 金属学报, 2022, 58(6):726-745. doi: 10.11900/0412.1961.2021.00594WANG J W, CHEN Y B, ZHU Q, et al. Grain boundary dominated plasticity in metallic materials[J]. Acta Metallurgica Sinica,2022,58(6):726-745(in Chinese). doi: 10.11900/0412.1961.2021.00594 [62] OROWAN E. Zur Kristallplastizita¨t. III. U¨ ber den. Mechanismus des Gleitvorgages[J]. Zeitschrift fur Physikalische,1934,89:634-659. doi: 10.1007/BF01341480 [63] ARDELL A J. Precipitation hardening[J]. Metallurgical and Materials Transactions A-Physical Metallurgy and Material,1985,16:2131-2165. doi: 10.1007/BF02670416 [64] LI Q F, QIAN Z B, CHEN J Y, et al. Preparation and mechanical properties of layered Cu/Gr composite film[J]. Coatings,2021,11(5):502. doi: 10.3390/coatings11050502 [65] TJONG S C. Recent progress in the development and properties of novel metal matrix nanocomposites reinforcedwith carbon nanotubes and graphene nanosheets[J]. Materials Science and Engineering: R: Reports,2013,74(10):281-350. doi: 10.1016/j.mser.2013.08.001 [66] WEI X, TAO J M, LIU Y H, et al. High strength and electrical conductivity of copper matrix composites reinforced by carbon nanotube-graphene oxide hybrids with hierarchical structure and nanoscale twins[J]. Diamond and Related Materials,2019,99:107537. doi: 10.1016/j.diamond.2019.107537 [67] ZHANG X, WAN D Q, PENG K, et al. Enhancement of thermal conductivity and mechanical properties of Cu-reduced graphene oxide composites by interface modification[J]. Journal of Materials Engineering and Perfor-mance,2019,28(8):5165-5171. doi: 10.1007/s11665-019-04212-x [68] CHU K, LIU Y P, WANG J, et al. Oxygen plasma treatment for improving graphene distribution and mechanical properties of graphene/copper composites[J]. Materials Science and Engineering: A,2018,735:398-407. doi: 10.1016/j.msea.2018.08.064 [69] ZHANG X Y, LIU Y, LIU X B, et al. In-situ grown few-layer graphene reinforced Ni matrix composites with simultaneously enhanced strength and ductility[J]. Materials Science and Engineering: A, 2021, 828: 142118. [70] WEI K X, ZHOU H R, JIA F L, et al. Mechanical behaviors of graphene/copper matrix composite foils fabricated by pulse electrodeposition[J]. Surfaces and Interfaces,2021,24:101142. doi: 10.1016/j.surfin.2021.101142 [71] GU Y, HU L. Effect of graphene addition on microstructure and properties of graphene/copper composite[J]. IOP Conference Series: Earth and Environmental Science,2021,615(3):032002. [72] QIAO Z J, ZHOU T, KANG J L, et al. Three-dimensional interpenetrating network graphene/copper composites with simultaneously enhanced strength, ductility andconductivity[J]. Materials Letters,2018,224:37-41. doi: 10.1016/j.matlet.2018.04.069 [73] LI X H, YAN S J, CHEN X, et al. Microstructure and mechanical properties of graphene-reinforced copper matrix composites prepared by in-situ CVD, ball-milling, and spark plasma sintering[J]. Journal of Alloys and Compounds,2020,834:155182. doi: 10.1016/j.jallcom.2020.155182 [74] LI M X, CHE H W, LIU X Y, et al. Highly enhanced mechanical properties in Cu matrix composites reinforced with graphene decorated metallic nanoparticles[J]. Journal of Materials Science,2014,49(10):3725-3731. doi: 10.1007/s10853-014-8082-x [75] GÜLER Ö, BAĞCI N. A short review on mechanical properties of graphene reinforced metal matrix composites[J]. Journal of Materials Research and Technology,2020,9(3):6808-6833. doi: 10.1016/j.jmrt.2020.01.077 [76] YANG L Z, ZHOU B Z, MA L S, et al. Architectured interfacial interlocking structure for enhancing mechanical properties of Al matrix composites reinforced with graphene nanosheets[J]. Carbon,2021,183:685-701. doi: 10.1016/j.carbon.2021.07.034 [77] YUE H Y, YAO L H, GAO X, et al. Effect of ball-milling and graphene contents on the mechanical properties and fracture mechanisms of graphene nanosheets reinforced copper matrix composites[J]. Journal of Alloys and Compounds,2017,691:755-762. doi: 10.1016/j.jallcom.2016.08.303 [78] 郭俊贤, 王波, 杨振宇. 石墨烯/Cu复合材料力学性能的分子动力学模拟[J]. 复合材料学报, 2014, 31(1):152-157. doi: 10.3969/j.issn.1000-3851.2014.01.022GUO J X, WANG B, YANG Z Y. Molecular dynamics simulations on mechanical properties of graphene/Cu composites[J]. Acta Materiae Compositae Sinica,2014,31(1):152-157(in Chinese). doi: 10.3969/j.issn.1000-3851.2014.01.022 [79] ZHANG, D D, ZHAN Z J. Experimental investigation of interfaces in graphene materials/copper composites from a new perspective[J]. RSC Advances,2016,6(57):52219-52226. doi: 10.1039/C6RA07606H [80] ZHANG, X, SHI C H, LIU E Z, et al. Achieving high strength and high ductility in metal matrix composites reinforced with a discontinuous three-dimensional graphene-like network[J]. Nanoscale,2017,9(33):11929-11938. doi: 10.1039/C6NR07335B [81] ZUO T T, XUE J L, RU Y D, et al. The improved softening resistance and high electrical conductivity of the 3 D graphene enhanced copper-based composite fabricated by liquid carbon source[J]. Materials Letters,2021,283:128895. doi: 10.1016/j.matlet.2020.128895 [82] TAO J M, CHEN X F, HONG P, et al. Microstructure and electrical conductivity of laminated Cu/CNT/Cu compo-sites prepared by electrodeposition[J]. Journal of Alloys and Compounds,2017,717:232-239. doi: 10.1016/j.jallcom.2017.05.074 [83] YAN Z Z, YANG L, HAN J M, et al. Molding fabrication of copper azide/porous graphene with high electrostatic safety by self-assembly of graphene oxide[J]. Nanotechnology, 2021, 32(38): 385704. [84] WEI B W, QU D, HU C F, et al. Synthesis and physical properties of graphene nanosheets reinforced copper composites[J]. Advanced Materials Research, 2013, 833: 310-314. [85] YOU C P, ZENG L F, GAO R, et al. A dual heterogeneous laminated microstructure design for improving the mechanical properties and electrical conductivity of copper alloys[J]. Materials Characterization,2022,187:111878. doi: 10.1016/j.matchar.2022.111878 [86] WANG M, WANG L D, SHENG J, et al. Direct synthesis of high-quality graphene on Cu powders from adsorption of small aromatic hydrocarbons: A route to high strength and electrical conductivity for graphene/Cu composite[J]. Journal of Alloys and Compounds,2019,798:403-413. doi: 10.1016/j.jallcom.2019.05.273 [87] LU T X, CHEN C G, LI P, et al. Enhanced mechanical and electrical properties of in situ synthesized nano-tungsten dispersion-strengthened copper alloy[J]. Materials Science and Engineering: A,2021,799:140161. doi: 10.1016/j.msea.2020.140161 [88] LIU D K, ZHAO J X, NING Y Y, et al. Constructing zebra skin structured graphene/copper composites with ultrahigh thermal conductivity[J]. Composites Communications,2021,25:100704. doi: 10.1016/j.coco.2021.100704 [89] LI X F, TAN C L, JIANG J T, et al. New construction of electron thermal conductive route for high-efficient heat dissipation of graphene/Cu composite[J]. Carbon,2021,177:107-114. doi: 10.1016/j.carbon.2021.01.157 [90] JIA F L, WEI K X, WEI W, et al. Enhanced thermal conductivity and tensile strength of copper matrix composite with few-layer graphene nanoplates[J]. Journal of Materials Engineering and Performance,2021,30:7682-7689. doi: 10.1007/s11665-021-05902-1 [91] PAN X L, DEBIJE M G, SCHENNING A, et al. Enhanced thermal conductivity in oriented polyvinyl alcohol/graphene oxide composites[J]. ACS Applied Materials and Interfaces,2021,13(24):28864-28869. doi: 10.1021/acsami.1c06415 [92] WANG X L, LIU Y, WANG X, et al. Tuning thermal expansion coefficient of copper-multilayer graphene thermal management materials through tailoring interfacial microstructure[J]. Journal of Alloys and Compounds,2021,862:158709. doi: 10.1016/j.jallcom.2021.158709 [93] CAO H J, XIONG D B, TAN Z Q, et al. Thermal properties of in situ grown graphene reinforced copper matrix laminated composites[J]. Journal of Alloys and Compounds,2019,771:228-237. doi: 10.1016/j.jallcom.2018.08.274 [94] ZHANG J, HAN J H. Thermal properties and failure mechanism of graphene nanoplatelet-reinforced copper composites fabricated using electroless plating[J]. Journal of Alloys and Compounds,2022,893:162233. doi: 10.1016/j.jallcom.2021.162233 [95] BAI H, XUE C, LYU J L, et al. Thermal conductivity and mechanical properties of flake graphite/copper compo-site with a boron carbide-boron nano-layer on graphite surface[J]. Composites Part A: Applied Science and Manu-facturing,2018,106:42-51. doi: 10.1016/j.compositesa.2017.11.019 [96] CUI R, HAN Y, ZHU Z X, et al. Investigation of the structure and properties of electrodeposited Cu/graphene composite coatings for the electrical contact materials of an ultrahigh voltage circuit breaker[J]. Journal of Alloys and Compounds,2019,777:1159-1167. doi: 10.1016/j.jallcom.2018.11.096 [97] SHU S C, ZHANG Q, IHDE J, et al. Surface modification on copper particles toward graphene reinforced copper matrix composites for electrical engineering application[J]. Journal of Alloys and Compounds: An Interdisciplinary Journal of Materials Science and Solid-state Chemistry and Physics,2022,891:162058. [98] MAI Y J, LING H J, CHEN F X, et al. Electrochemically reduced graphene oxide nanosheet coatings as solid lubricants in humid air[J]. Materials Research Bulletin,2018,102:324-329. doi: 10.1016/j.materresbull.2018.02.035 [99] LIAO J N, GUO W, PENG P. Direct laser writing of copper-graphene composites for flexible electronics[J]. Optics and Lasers in Engineering,2021,142:106605. doi: 10.1016/j.optlaseng.2021.106605 [100] RHO H, JANG Y S, KIM S, et al. Porous copper–graphene heterostructures for cooling of electronic devices[J]. Nanoscale,2017:7565-7569. [101] RAGHUPATH Y, KAMBOJ A, REKHA M Y, et al. Copper-graphene oxide composite coatings for corrosion protection of mild steel in 3.5% NaCl[J]. Thin Solid Films,2017,636:107-115. doi: 10.1016/j.tsf.2017.05.042 -

下载:

下载: