Experimental study on mechanical properties of CFRP bar bond-type anchorage system under impact

-

摘要: 为明确纵向冲击作用下碳纤维增强树脂复合材料(Carbon fiber-reinforced polymer,CFRP)筋粘结式锚固系统的力学性能,以锚固长度(50 mm、100 mm、150 mm、200 mm)为参数,对8组共计24个采用超高性能混凝土(Ultra-high performance concrete,UHPC)作为粘结介质的CFRP压纹筋及其粘结式锚具组装件进行了静力拉拔和纵向冲击试验。试验结果表明:较短锚固长度(50 mm、100 mm和150 mm)下,静力和冲击试件均发生CFRP筋拔出的滑移破坏,但静力作用下试件的滑移破坏由筋材表面肋的剪切破坏导致,而冲击作用下试件的滑移破坏是CFRP筋材整体滑出所致。当锚固长度提高至200 mm时,静力试件发生CFRP筋拉伸爆裂破坏,而冲击试件仍发生滑移破坏。随着锚固长度由50 mm提高至100 mm和150 mm,锚固系统的静态平均粘结强度分别提高27.1%和47.5%,动态平均粘结强度分别提高27.4%和37.8%;当锚固长度增大至200 mm时,试件的动态平均粘结强度较锚固长度为50 mm试件增大48.3%。相比于静力拉伸试件,冲击作用会显著降低锚固系统的粘结强度,在应变率为1.62~2.03 s−1时,动态平均粘结强度较相应的静态强度降低约53%。此外,建立了冲击作用下CFRP筋粘结式锚具动态平均粘结强度及临界锚固长度的实用计算公式。

-

关键词:

- 碳纤维增强树脂复合材料(CFRP)筋 /

- 超高性能混凝土(UHPC) /

- 粘结式锚具 /

- 冲击 /

- 粘结强度

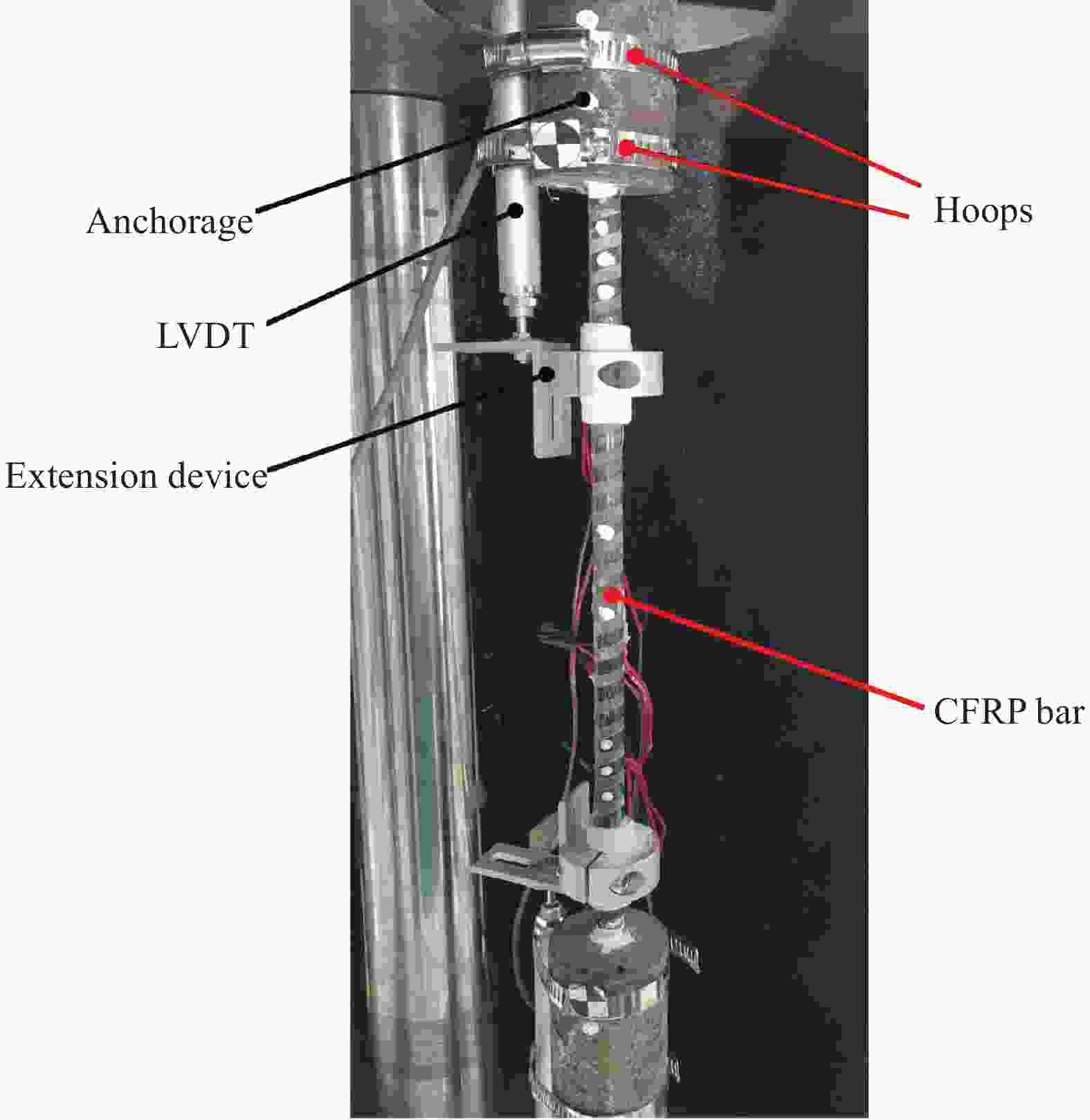

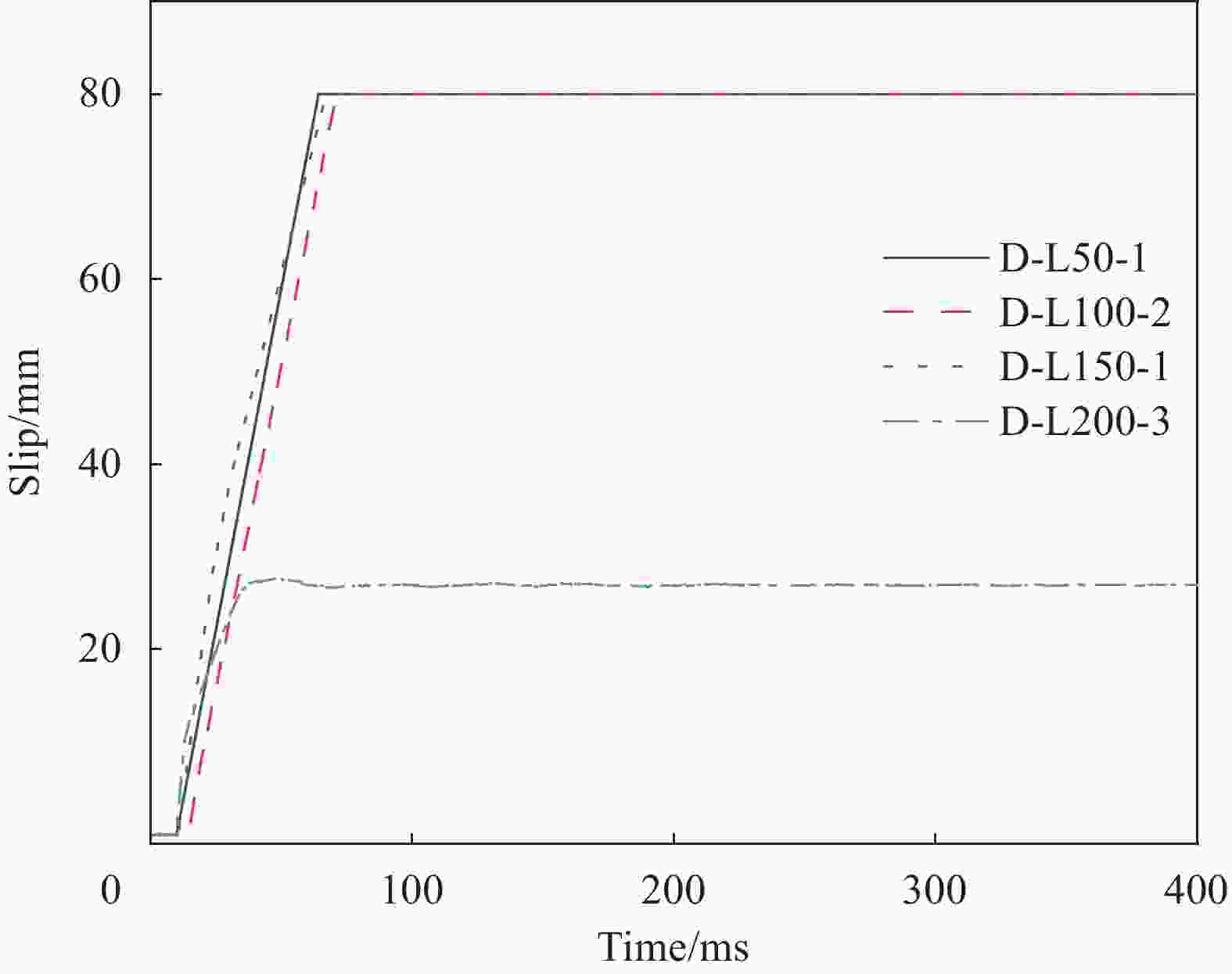

Abstract: To understand the bond behavior of the ultra-high performance concrete (UHPC) filled bond-type anchorage for carbon fiber-reinforced polymer (CFRP) bars under impact loads, static tensile and longitudinal impact tests were conducted on 24 specimens in eight groups with different anchorage lengths (50 mm, 100 mm, 150 mm and 200 mm). The results show that for the specimens with short anchorages of 50 mm, 100 mm and 150 mm, the sliding failure of anchorages occurs in both static and impact tests. The reason for the slip failure under static tension is the complete shear failure of the surface ribs of CFRP bar, while that under impact loads is the slip of the entire CFRP bar without severe shear damage on the surface ribs. As the anchorage length increases to 200 mm, the bar ruptures in the static tests, whereas slip failure is still observed in the impact tests. When the anchorage length increases from 50 mm to 100 mm and 150 mm, the static bond strengths of the anchorages increase by 27.1% and 47.5%, respectively, and the dynamic bond strengths increase by 27.4% and 37.8%, respectively; as the length increases to 200 mm, the dynamic bond strength is 48.3% higher than that of specimens with a anchorage length of 50 mm. The bond strength is adversely affected by the impact loads and decreases by 53% in strain rate range of 1.62 to 2.03 s−1 compared with the associated static one. Besides, prediction formulas for determining the dynamic bond strength and critical anchorage length of the bond-type anchorages for CFRP tendons were established. -

表 1 试件参数

Table 1. Parameters of the test specimens

Specimen

codeLength of reliable anchorage/mm Length of experimental anchorage/mm Free length/

mmLength of

specimen/mmS-L50 500 50 300 890 S-L100 500 100 300 940 S-L150 500 150 300 990 S-L200 500 200 300 1040 D-L50 500 50 300 890 D-L100 500 100 300 940 D-L150 500 150 300 990 D-L200 500 200 300 1040 Notes: In specimen codes, the first nomenclature indicates the test type (S for static tensile test and D for dynamic impact test); and the second letter is used to differentiate the anchorage length (50 to 200 mm denoted by L50 to L200). For example, S-L50—Static specimen with a bond length of 50 mm for the experimental anchorage. 表 2 UHPC配合比

Table 2. Mix proportion of UHPC

kg/m3 Cement Silica fume Quartz flour Quartz sand Water reducer Water binder ratio 1 0.25 0.25 1.1 0.02 0.22 表 3 CFRP筋粘结式锚固系统静力和冲击试验主要结果

Table 3. Typical results of CFRP bar bond-type anchorage system from the static and impact tests

Specimen $ \dot \varepsilon $/s−1 $ \bar{ \dot \varepsilon} $/s−1 Tmax/kN $ {\bar T_{\max }} $/kN $ {\bar \tau _{{\rm{m}}} } $/MPa S0/mm $ {\bar S_{ 0}} $/mm S-L50-1 32.27 2.21 S-L50-2 − − 31.63 32.16 20.90 1.96 2.28 S-L50-3 32.58 2.67 S-L100-1 83.36 4.84 S-L100-2 − − 80.82 81.76 26.57 4.22 4.49 S-L100-3 81.11 4.41 S-L150-1 143.29 7.27 S-L150-2 − − 140.90 142.26 30.82 6.69 6.94 S-L150-3 142.58 6.87 S-L200-1 164.67 6.92 S-L200-2 − − 161.91 163.69 26.60 6.59 6.79 S-L200-3 164.49 6.85 D-L50-1 1.67 15.59 3.36 D-L50-2 1.54 1.62 15.84 15.31 9.95 3.43 3.37 D-L50-3 1.65 14.50 3.33 D-L100-1 1.70 40.43 6.13 D-L100-2 1.84 1.76 39.55 39.02 12.68 5.62 5.72 D-L100-3 1.74 37.08 5.41 D-L150-1 1.99 65.12 8.31 D-L150-2 1.76 1.84 59.83 63.28 13.71 8.22 8.26 D-L150-3 1.76 64.89 8.25 D-L200-1 2.12 95.21 10.09 D-L200-2 2.01 2.03 85.16 90.84 14.76 9.86 9.94 D-L200-3 1.96 92.15 9.87 Notes: $ \dot \varepsilon $, Tmax and S0—Strain rate, maximum tension force and slip of the loading end corresponding to Tmax,respectively; $ \bar{ \dot \varepsilon }$, $ {\bar T_{\max }} $, $ {\bar S_{ 0}} $ and $ {\bar \tau _{\rm{m}}} $—Average value of the strain rate, maximum tension force, slip of loading end corresponding to Tmax, and average bond strength, respectively. 表 4 CFRP筋粘结式锚固系统动、静态平均粘结强度对比

Table 4. Comparison between the static and dynamic average bond strength of CFRP bond-type anchorage

Length of reliable anchorage/mm Static bond stress τs,m/MPa Dynamic bond stress τd,m/MPa τd,m/τs,m/% 50 20.90 9.95 47.6 100 26.57 12.68 47.7 150 30.82 13.71 44.5 表 5 CFRP筋粘结式锚固系统静态粘结强度实测值与式(3)计算值比较

Table 5. Comparisons of the tested and predicted static bond strength of CFRP bond-type anchorage obtained by equation (3)

Specimen code Tested results of τs,m/MPa Calculated results of τs,m from equation (3)/MPa Deviation/% (1) (2) $ \dfrac{{(2) - (1)}}{{(1)}} $ S-L50 20.90 21.70 3.8 S-L100 26.57 25.58 −3.7 S-L150 30.82 29.45 −4.4 表 6 CFRP筋粘结式锚固系统动态粘结强度实测值与式(5)计算值比较

Table 6. Comparisons of the tested and predicted dynamic bond strength of CFRP bond-type anchorage obtained by equation (5)

Specimen code Tested results of τd,m/MPa Calculated results of τd,m from equation (5)/MPa Deviation/% (1) (2) $ \dfrac{{(2) - (1)}}{{(1)}} $ D-L50 9.95 10.20 2.5 D-L100 12.68 12.02 −5.2 D-L150 13.71 13.84 0.9 D-L200 14.76 15.66 6.1 -

[1] 叶列平, 冯鹏. FRP在工程结构中的应用与发展[J]. 土木工程学报, 2006, 39(3):24-36. doi: 10.3321/j.issn:1000-131X.2006.03.004YE Lieping, FENG Peng. Applications and development of fiber-reinforced polymer in engineering structures[J]. China Civil Engineering Journal,2006,39(3):24-36(in Chinese). doi: 10.3321/j.issn:1000-131X.2006.03.004 [2] 冯鹏. 复合材料在土木工程中的发展与应用[J]. 复合材料科学与工程, 2014(9):99-104. doi: 10.3969/j.issn.1003-0999.2014.09.013FENG Peng. Development and application of composite in civil engineering[J]. Composites Science and Engineering,2014(9):99-104(in Chinese). doi: 10.3969/j.issn.1003-0999.2014.09.013 [3] WANG X, WU Z. Evaluation of FRP and hybrid FRP cables for super long-span cable-stayed bridges[J]. Composite Structures,2010,92(10):2582-2590. doi: 10.1016/j.compstruct.2010.01.023 [4] WU J, CHEN S R. Probabilistic dynamic behavior of a long-span bridge under extreme events[J]. Engineering Structures,2011,33(5):1657-1665. doi: 10.1016/j.engstruct.2011.02.002 [5] 方亚威. 不同温度作用下碳纤维复合材料筋的静力和抗冲击性能研究[D]. 长沙: 湖南大学, 2020.FANG Yawei. Investigation on static and impact behavior of carbon fiber reinforced polymer bar with considering temperature effect[D]. Changsha: Hunan University, 2013(in Chinese). [6] PINCHEIRA J A, WOYAK J P. Anchorage of carbon fiber reinforced polymer (CFRP) tendons using cold-swaged sleeves[J]. PCI Journal,2001,46(6):100-111. doi: 10.15554/pcij.11012001.100.111 [7] WANG L, ZHANG J, XU J, et al. Anchorage systems of CFRP cables in cable structures—A review[J]. Construction and Building Materials,2018,160:82-99. doi: 10.1016/j.conbuildmat.2017.10.134 [8] 梅葵花, 吕志涛, 张继文. CFRP 筋黏结型锚具试验研究及实桥应用分析[J]. 中国公路学报, 2016, 29(1):53-60. doi: 10.3969/j.issn.1001-7372.2016.01.007MEI Kuihua, LV Zhitao, ZHANG Jiwen. Experimental study and practical application of bond-type anchorage for CFRP tendons[J]. China Journal of Highway and Transport,2016,29(1):53-60(in Chinese). doi: 10.3969/j.issn.1001-7372.2016.01.007 [9] 方志, 方川, 蒋正文, 等. 高温后CFRP筋及其黏结式锚固系统的力学性能[J]. 复合材料学报, 2021, 38(12): 4031-4041.FANG Zhi, FANG Chuan, JIANG Zhengwen, et al. Mecha-nical properties of CFRP bar and bond-type anchorage system after elevated temperature exposure[J]. Acta Materiae Compositae Sinica, 2021, 38(12): 4031-4041(in Chinese). [10] 方志, 梁栋, 蒋田勇. 不同黏结介质中 CFRP 筋锚固性能的试验研究[J]. 土木工程学报, 2006, 39(6):47-51. doi: 10.3321/j.issn:1000-131X.2006.06.008FANG Zhi, LIANG Dong, JIANG Tianyong. Experiment investigation on the anchorage performance of CFRP tendon in different bond mediums[J]. China Civil Engineering Journal,2006,39(6):47-51(in Chinese). doi: 10.3321/j.issn:1000-131X.2006.06.008 [11] 蒋田勇, 方志. CFRP筋黏结式锚具锚固性能试验[J]. 中国公路学报, 2004, 24(1):68-77.JIANG Tianyong, FANG Zhi. Experiment on anchorage performance of bond-type anchorage for CFRP tendon[J]. China Journal of Highway and Transport,2004,24(1):68-77(in Chinese). [12] 方志, 龚畅, 杨剑, 等. CFRP 预应力筋黏结式锚固系统的抗疲劳性能[J]. 公路交通科技, 2012, 29(7):58-63. doi: 10.3969/j.issn.1002-0268.2012.07.010FANG Zhi, GONG Chang, YANG Jian, et al. Fatigue behavior of bond-type anchorage with CFRP tendon[J]. Journal of Highway and Transportation Research and Development,2012,29(7):58-63(in Chinese). doi: 10.3969/j.issn.1002-0268.2012.07.010 [13] 方志, 王常林, 张洪侨, 等. 碳纤维绞线在活性粉末混凝土中锚固性能的试验研究[J]. 中国公路学报, 2016, 29(6): 198-206.FANG Zhi, WANG Changlin, ZHANG Hongqiao, et al. Experimental study on anchoring performance of CFRP strand in reactive powder concrete[J]. China Journal of Highway and Transport, 2016, 29(6): 198-206(in Chinese). [14] ZHANG K Y, FANG Z, NANNI A, et al. Experimental study of a large scale ground anchor system with FRP tendon and UHPC grout medium[J]. Journal of Composites for Construction,2015,19(4):04014073. [15] 谢旭, 朱越峰, 申永刚. 大跨度钢索和 CFRP 索斜拉桥车桥耦合振动研究[J]. 工程力学, 2007 (z1): 53-61.XIE Xu, ZHU Yuefeng, SHEN Yonggang. Study on vibration of long-span cable-stayed bridge with steel and CFRP cables due to moving vehicles[J]. Engineering Mechanics, 2007(z1): 53-61(in Chinese). [16] 张羽, 方志, 卢江波, 等. 大跨混凝土斜拉桥施工过程中结构的断索动力响应[J]. 振动与冲击, 2021, 40(5): 237-246.ZHANG Yu, FANG Zhi, LU Jiangbo, et al. Broken cable-induced dynamic response of long-span concrete cable stayed bridge during construction[J]. Journal of Vibration and Shock, 2021, 40(5): 237-246(in Chinese). [17] KHALIL N, ASSAAD J J. Bond properties between smooth carbon fibre-reinforced polymer bars and ultra-high performance concrete modified with polymeric latexes and fibres[J]. European Journal of Environmental and Civil Engineering,2022, 26(13):6211-6228. [18] YOO D Y, YOON Y S. Bond behavior of GFRP and steel bars in ultra-high-performance fiber-reinforced concrete[J]. Advanced Composite Materials,2017,26(6):493-510. doi: 10.1080/09243046.2016.1197493 [19] 李维博. 冲击荷载作用下CFRP筋—混凝土界面力学性能试验研究[D]. 长沙: 湖南大学, 2017.LI Weibo. Experiment study on dynamic bond behavior of CFRP rebar to concrete interface under impact loads[D]. Changsha: Hunan Universuty, 2017(in Chinese). [20] XIONG Z, WEI W, HE S, et al. Dynamic bond behaviour of fibre-wrapped basalt fibre-reinforced polymer bars embedded in sea sand and recycled aggregate concrete under high-strain rate pull-out tests[J]. Construction and Building Materials,2021,276:122195. doi: 10.1016/j.conbuildmat.2020.122195 [21] 中国建筑材料联合会. 纤维增强复合材料筋基本力学性能试验方法: GB/T 30022—2013[S]. 北京: 中国标准出版社, 2013.China Building Materials Federation. Test method for basic mechanical properties of fiber reinforced polymer bar: GB/T 30022—2013[S]. Beijing: China Standards Press, 2013(in Chinese). [22] 刘练. 不同应变率下混凝土动态力学性能试验研究[D]. 长沙: 湖南大学, 2017.LIU Lian. Experimental study on dynamic mechanical properties of concrete under different strain rates[D]. Changsha: Hunan University, 2017(in Chinese). [23] FANG Y, FANG Z, JIANG R, et al. Transverse static and low-velocity impact behavior of CFRP wires under pretension[J]. Journal of Composites for Construction,2019,23(5):04019041. doi: 10.1061/(ASCE)CC.1943-5614.0000970 [24] 李正辉. 落石冲击下拱形明洞落石冲击荷载及荷载效应研究[D]. 成都: 西南交通大学, 2017.LI Zhenghui. Research on rock-fall impaction loads and loads effects of arch open tunnel under the impact of rock[D]. Chengdu: Southwest Jiaotong University, 2017(in Chinese). [25] 章豪. 落石撞击对钢混组合梁桥上部结构的动力响应分析[D]. 武汉: 武汉理工大学, 2020.ZHANG Hao. Dynamic response analysis of superstructure of stecl-concrete composite beam bridge in rockfalls impact[D]. Wuhan: Wuhan University of Technology, 2020(in Chinese). [26] 黄道斌. 碳纤维拉索的温度效应及车撞响应研究[D]. 长沙: 湖南大学, 2019.HUANG Daobin. Investigation on temperature effect and vehicle impact response of CFRP cables[D]. Changsha: Hunan University, 2019(in Chinese). [27] 张羽. 大跨混凝土斜拉桥断索后结构受力性能及倒塌破坏研究[D]. 长沙: 湖南大学, 2020.ZHANG Yu. Investigation on structural performance and progressive collapse of a1ong-span concrete cable-stayed bridge subjected to cable loss[D]. Changsha: Hunan University, 2020(in Chinese). [28] LI L, MAI G, HE S, et al. Experimental study on bond behaviour between recycled aggregate concrete and basalt fibre-reinforced polymer bars under different strain rates[J]. Construction and Building Materials,2021,290:123218. doi: 10.1016/j.conbuildmat.2021.123218 [29] SHOKRIEH M M, OMIDI M J. Investigation of strain rateeffects on in-plane shear properties of glass/epoxy composites[J]. Composite Structures,2009,91(1):95-102. doi: 10.1016/j.compstruct.2009.04.035 [30] 蒋田勇, 安磊. FRP筋混凝土界面疲劳黏结性能试验研究[J]. 公路交通科技, 2017, 34(3):70-79.JIANG Tianyong, AN Lei. Experiment study on fatigue bonding performence of interface between FRP tendons and concrete[J]. Journal of Highway and Transportation Research and Development,2017,34(3):70-79(in Chinese). [31] 郭书峰, 诸葛萍, 孙莉莉, 等. 碳纤维复合材料筋-环氧树脂胶界面传力机理研究[J]. 工业建筑, 2017, 47(4):111-115. doi: 10.13204/j.gyjz201704023GUO Shufeng, ZHUGE Ping, SUN Lili, et al. Research on load-transferring mechanism of the interface of CFRP tendon-epoxy resin[J]. Industrial Construction,2017,47(4):111-115(in Chinese). doi: 10.13204/j.gyjz201704023 [32] BOUETTE B, CAZENEUVE C, OYTANA C. Effect of strain rate on interlaminar shear properties of carbon/epoxy composites[J].Composites Science and Technology, 1992, 45(4): 313-321. [33] BROWN K A, BROOKS R, WARRIOR N A. The static and high strain rate behaviour of a commingled E-glass/polypropylene woven fabric composite[J]. Compo-sites Science and Technology,2010,70(2):272-283. [34] PAPADAKIS N, REYNOLDS N, PHARAOH M W, et al. Strain rate effects on the shear mechanical properties of a highly oriented thermoplastic composite material using a contacting displacement measurement methodology-Part A: Elasticity and shear strength[J]. Composites Science and Technology,2004,64(5):729-738. doi: 10.1016/j.compscitech.2003.08.001 [35] 蒋田勇, 方志. 极限状态时CFRP筋黏结式锚具黏结应力分布[J]. 公路交通科技, 2007(12): 75-78, 92.JIANG Tianyong, FANG Zhi. Bond stress distribution of bond-type anchors of CFRP tendons under the ultimate tensile capacity[J]. Journal of Highway and Transportation Research and Development, 2007(12): 75-78, 92(in Chinese). [36] HARDING J, WELSH L M. A tensile testing technique for fibre-reinforced composites at impact rates of strain[J]. Journal of Materials Science, 1983, 18(6): 1810-1826. -

下载:

下载: