Application and development of composite materials in large-scale wind turbine blade

-

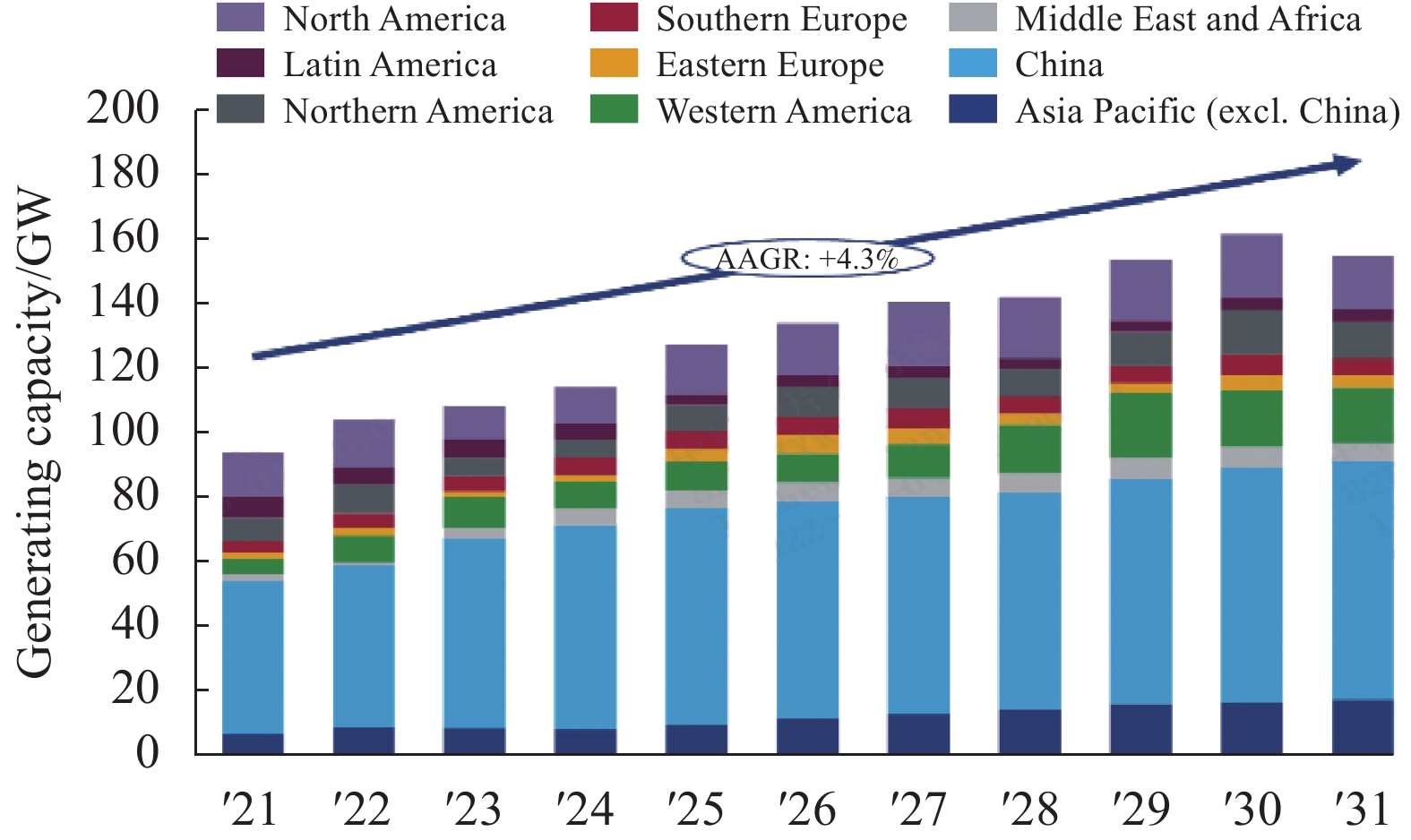

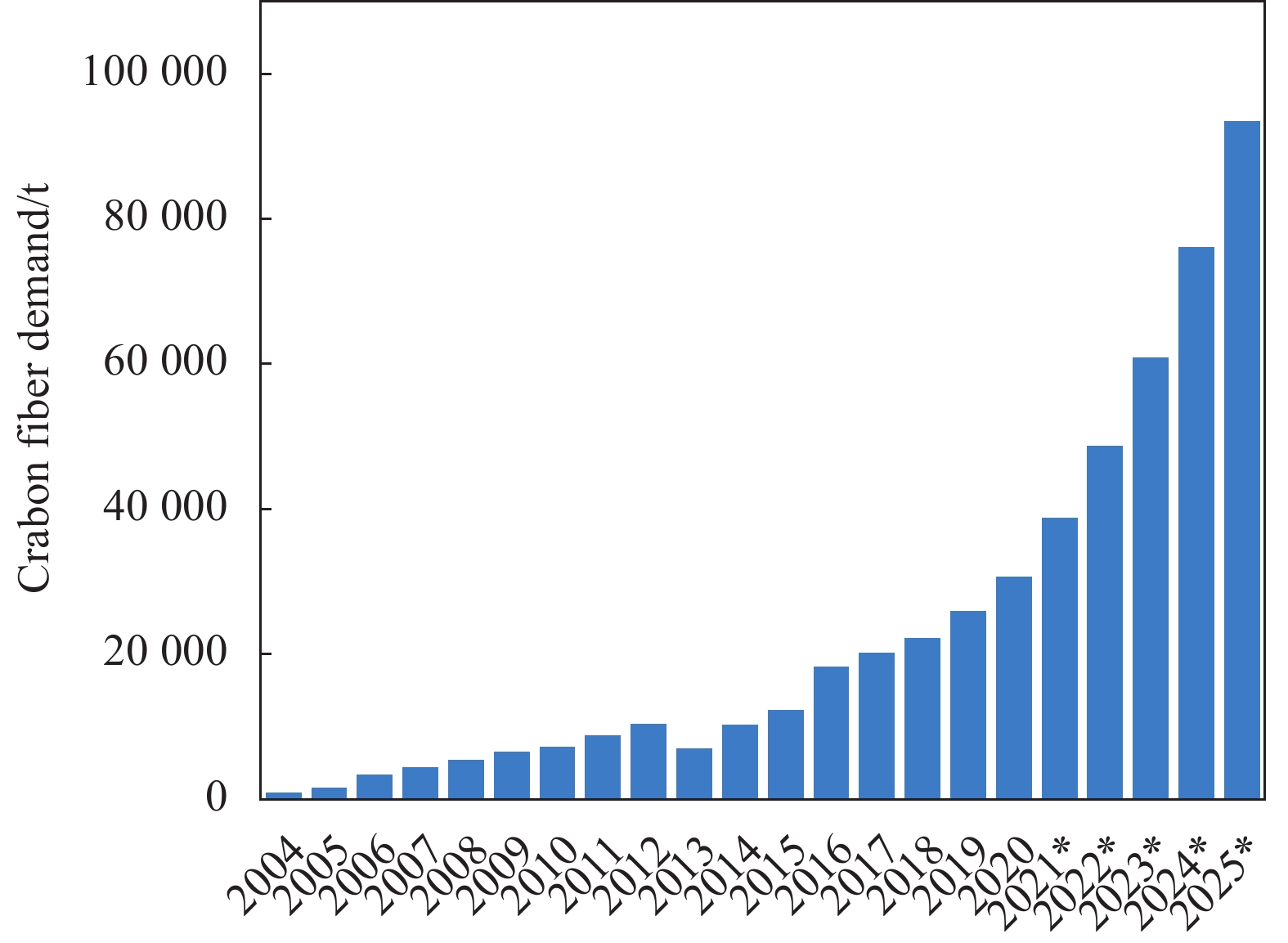

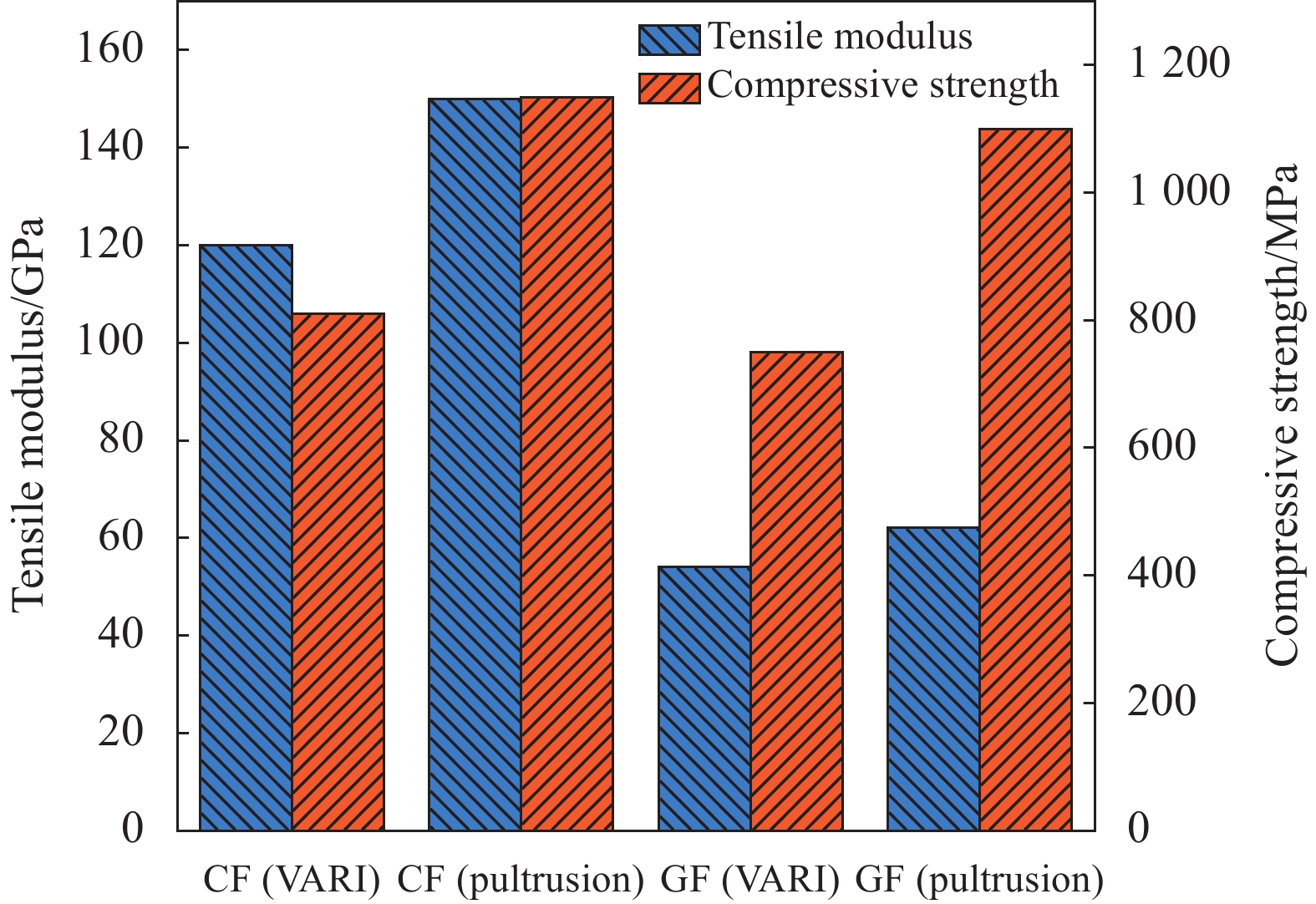

摘要: “30.60”双碳目标的提出,风电行业迎来新的发展机遇。随着中国风电进入平价时代,风电机组通过不断增加单机容量来降低度电成本,由此也对风电叶片长度提出了不断增加的要求。风电叶片面临着“大型化、轻量化与低成本”的矛盾,新材料和新工艺是推动叶片走向风电平价时代的重要手段。本文评述了风电叶片行业的发展与趋势,指出影响叶片性能和成本的关键原材料,系统性地分析了增强纤维、夹芯材料、基体树脂和结构胶4种材料在叶片上的应用现状和发展趋势;探讨了高质量和绿色环保条件下叶片大型化对工艺发展的新要求,新工艺中的预浸料和拉挤技术是未来大叶片应用发展的主要趋势。最后,文章对新材料和新工艺在叶片上的创新应用提出了一些思考与建议,为平价时代风电叶片的大型化发展提供了重要参考。Abstract: With the proposal of "30.60" Double Carbon Project, the wind power industry has ushered in new development opportunities. As China's wind power enters the era of parity, the cost of power per kWh is reduced with the continuous increase of the single capacity of wind turbine system, which also leads to significant increase in the wind blade length. Wind blade is now facing the contradictive requirements of "large-scale, low-cost and lightweight". Both new material and innovative processing technology are of great importance to promote wind power to the parity era. On one hand, several key raw materials, including reinforcing fiber, matrix resin, core and structural adhesive, that affect the performance and cost of wind blade are systematically examined. On the other hand, high quality blades and green environmental protection are of great concern for the wind power industry, which indicates that new processing technology such as prepreg and pultrusion are playing more and more important role in future large scale blade manufacture. Thereafter, with systematic consideration of the materials and processing technologies in the development of wind blade, some suggestions are proposed on the introduction of these materials and technologies, in order to provide some reference for future large-scale wind blade development.

-

Keywords:

- composite material /

- wind turbine blade /

- large-scale /

- core material /

- carbon fiber

-

核技术的应用逐渐广泛,然而,应用核技术会产生高能中子和伽马射线,这些辐射具有强穿透性,会损害人类的身体健康,长时间暴露在辐射环境中,会导致基因突变、癌症甚至死亡[1,2]。因此,高效的辐射屏蔽材料的研究很有必要。

高原子序数和高中子吸收截面的物质分别对于伽马射线和中子辐射具有良好的屏蔽效果[3]。研究人员通常将高原子序数和高中子吸收截面的化合物作为填料,掺杂到基体材料中,研制出可满足应用场合要求的复合屏蔽材料。例如,将CeO2和Er2O3[4]等高原子序数和高中子吸收截面的化合物掺杂到透光性良好的玻璃中,制成可以应用于X光室,CT扫描以及核设施相关领域的观察门窗的玻璃基复合屏蔽材料;金属基材料结构稳定,热学性能好,通过掺杂兼具高原子序数和高中子吸收截面的Gd元素[5]能够有效地提高合金材料的屏蔽性能,可用于极端的辐射环境,例如乏燃料的运输和存储[6];而聚合物基材料具有可设计性强,无毒环保和易加工等优点,应用较为广泛,可制成辐射防护装备[7]、医疗设施屏蔽材料[8]和核反应堆屏蔽材料[9]。

聚乙烯高分子材料富含的轻核元素H能显著慢化快中子[10],然后将其转化为热中子,通过掺杂高热中子吸收截面的材料如B4C[11],可显著提高聚乙烯材料对于热中子的屏蔽性能。含硼聚乙烯复合材料适合作为防中子屏蔽材料,但是由于该复合材料的密度较低,并且碳化硼在俘获热中子的同时会产生次生伽马射线[10],因此需要掺杂高原子序数的化合物以弥补材料对伽马射线屏蔽能力的不足。

本研究以钨酸钠和醋酸铅为原料,十六烷基三甲基溴化铵(CTAB)作为表面活性剂,通过铅离子和钨酸根离子的共沉淀反应制备微米纺锤钨酸铅填料;通过改变CTAB的浓度以及反应时间来控制钨酸铅的晶体生长速度,制备出微观尺寸和比表面积有差异的三种微形貌的钨酸铅;随后分别将形貌可控的微米纺锤钨酸铅和商用的无规形貌的钨酸铅作为填料,与碳化硼和聚乙烯粉末球磨混合再热压制成屏蔽中子和伽马射线的复合材料;研究并阐明钨酸铅填料的微结构对复合材料的热学性能、力学性能和辐射屏蔽性能的影响。

1. 实验部分

1.1 实验试剂

钨酸钠二水合物[Na2WO3·2H2O]、醋酸铅三水合物[(CH3COO)2Pb·3H2O]、十六烷基三甲基溴化铵(CTAB)和碳化硼(上海麦克林有限公司),均为分析纯;高密度聚乙烯(HDPE),(HHW5502LW,中国石化茂名石油化工有限公司)。超纯水由超纯水机(YK-RO-B-15L/H,舒活泉(厦门)人工智能有限公司)制备。

1.2 微米纺锤PbWO4的化学合成

采用铅离子和钨酸根离子的共沉淀法合成钨酸铅填料,称取

3.2985 g Na2WO4·2H2O (10 mmol)和3.7933 g (CH3COO)2Pb·3H2O (10 mmol)溶于50 ml的超纯水中,按照0.001 M、0.05 M和0.3 M 三种浓度称取CTAB并溶于100 ml超纯水中,搅拌至所有样品均充分溶解后,将Na2WO4溶液和CTAB水溶液混合。用滴管将(CH3COO)2Pb溶液滴加至混合溶液中,保温在28℃下反应相应的时间(0.001 M浓度反应时间为30 min,0.05 M和0.3 M浓度反应时间为1H),本文将0.001 M浓度CTAB的反应时间缩短至30 min,以得到三种在微观尺寸和比表面积上差异显著的钨酸铅填料。将反应完成的乳浊液经离心后,得到的沉淀产物在60℃恒温干燥6H。得到的PbWO4填料分别记为PbWO4-I (CTAB浓度为0.001 M)、PbWO4-II (CTAB浓度为0.05 M)和PbWO4-III (CTAB浓度为0.3 M)。1.3 PbWO4-B4C/HDPE复合材料的制备

PbWO4-B4C/HDPE复合板材中PbWO4、B4C和HDPE的质量比为2∶1∶7,碳化硼/聚乙烯板材中B4C和HDPE的质量比为3∶7。使用球磨机(MSK-SFM-3-II,合肥科晶材料技术有限公司)将PbWO4填料、B4C和HDPE粉末混合球磨15 min,球磨速率设置为800 r/min。将360 g混合粉末倒入15×15×1.5 cm的方形热压模具,将模具放置在热压机(R32212017,武汉启恩科技发展有限责任公司)中,将热压机的温度设置为160℃,依次在10 MPa、30 MPa和50 MPa三种压力下分别保温15 min、30 min和1H。最后,关闭加热装置、打开冷却水、经过泄压和脱模等操作后得到复合材料。将复合材料分别记为PbWO4-I-B4C/HDPE; PbWO4-II-B4C/HDPE; PbWO4-III-B4C/HDPE; PbWO4-commercial-B4C/HDPE。

1.4 微米纺锤PbWO4和PbWO4-B4C/HDPE复合材料的表征与测试

采用X射线衍射仪(SmartLab SE,日本理学株式会社),在2θ = 20°~60°下测试得到PbWO4材料的XRD谱图,确定PbWO4的物相组成。采用SEM(Regulus 8100,日本株式会社日立制作所)观察PbWO4填料的微观形貌与结构。采用比表面积和孔径分析仪(ASAP 2460,美国麦克仪器公司),将填料经过200℃下真空干燥6H后,在N2环境下对样品进行BET比表面积分析。采用热重分析仪(TGA 550,美国TA公司)和差示扫描量热仪(Q2000,美国TA公司)测试材料热稳定性,热重测试温度范围为20 ~ 700℃,差热测试温度范围为30~250℃,升温速率皆为10℃/min。采用电子万能材料试验机(AGS-X-50N,日本岛津公司)测试材料的力学性能。采用邵氏硬度计(LX-D-2,东莞三量精密量仪有限公司)测试材料的硬度,重复测量10次,取平均值,得到样品的邵氏硬度值。采用密度计(MDJ-1200T,上海仪昕科学仪器有限公司)测量材料的密度,重复测量5次,取平均值,得到材料的密度。伽马射线屏蔽测试装置由铅准直屏蔽筒、137Cs伽马射线源和便携式辐射探测器组成,示意图如图1(a)所示。具体测试过程如下:(1)使用便携式辐射探测器测量自然环境下的本底伽马射线剂量率读数Iγ0(未放置137Cs伽马射线源和屏蔽材料);(2)测试放置137Cs伽马射线源但未放置屏蔽材料的伽马射线剂量率读数Iγa;(3)测量放置屏蔽材料后经过衰减的伽马射线剂量率读数Iγb;(4)每组数据重复10次,结果取平均值(单位为μSv/h),屏蔽材料对于137Cs伽马射线源的屏蔽率:Sγ=1−(Iγb−Iγ0)/(Iγa−Iγ0)。

中子屏蔽测试装置由聚乙烯准直屏蔽筒、252Cf中子源和中子探测器组成,示意图如图1(b)所示。具体测试过程如下:(1)使用中子探测器测量自然环境下的本底中子剂量率读数In0(未放置252Cf中子源和屏蔽材料);(2)测试放置252Cf中子源但未放置屏蔽材料的中子剂量率读数Ina;(3)测量放置屏蔽材料后经过衰减的中子剂量率读数Inb;(4)每组数据重复10次,结果取平均值(单位为mSv/h),屏蔽材料对于252Cf中子源的屏蔽率:Sn=1−(Inb−In0)/(Ina−In0)。

2. 结果与讨论

2.1 微米纺锤PbWO4填料和PbWO4-B4C/HDPE复合材料的微结构表征

合成的PbWO4填料(PbWO4-I、PbWO4-II和PbWO4-III)和商业PbWO4填料的XRD谱图如图2所示。与标准衍射峰(JCPDS: 19-0708)相比,PbWO4填料的XRD谱图与其吻合度高,这表明合成填料没有杂质相,由于部分晶面的生长受到抑制导致该晶面的衍射峰强度太低,因此在图谱中不明显。合成PbWO4填料的4个主要晶面的衍射峰强度比值见表1,例如r(112 : 204)表示(112)和(204)晶面的衍射峰的强度比,rs(112 : 204)表示从标准衍射卡(JCPDS: 19-0708)中得到的(112)和(204)晶面之间衍射峰的强度比,r/rs(112 : 204)的比值大小可反应(204)晶面相对于(112)晶面得到了促进(比值<1)还是抑制(比值>1)[12]。结果显示,所有纺锤PbWO4填料的r/rs比值的大小关系: r/rs(112 : 204) > 1 > r/rs(112 : 312) > r/rs(112 : 200),这表明(204)晶面的晶体生长受到抑制; (200)和(312)晶面的生长受到促进,且(200)晶面的生长优先度要高于(312)晶面。因此综上所述,合成PbWO4的晶面生长优先度为(200) > (312) > (112) > (204)。

图3为不同浓度的CTAB水溶液,在相应的反应时间下制备的PbWO4以及商业PbWO4的电镜照片。在反应溶液中形成微米纺锤PbWO4主要涉及两种晶体生长机制。在晶体生长的初期主要是“奥斯特瓦尔德熟化过程”[13]。在该过程中,PbWO4首先在过饱和溶液中通过结晶过程形成纳米级的晶核,小晶粒由于表面能较高而易于溶解,随后沉积到周围的大晶粒上[14],大晶粒的生长以小晶粒为代价,大晶粒逐渐长大,小晶粒逐渐消失,最初的形貌无规的纳米级颗粒通过该熟化过程形成棱锥体颗粒,如图3(a)所示,因此PbWO4-I填料的形貌一部分为尚未完成熟化过程的纳米级颗粒,以及完成熟化过程的棱锥体和尺寸较小的微米纺锤颗粒,颗粒尺寸大多在1-2 μm左右。之后是这些棱锥体颗粒沿着一定的晶体取向逐渐生长的过程,这被称为“定向附着生长”机制[15]。相邻的棱锥体颗粒通过共用晶面定向生长进而形成微米纺锤结构,如图3(b)和(c)所示,PbWO4-II微米纺锤颗粒微观尺寸为3-5 μm,而PbWO4-III填料是尺寸大多在5-9 μm之间的较大的微米纺锤结构。CTAB作为一种表面活性剂[16],对溶液中的晶体生长起到一定的促进作用,通过控制CTAB的浓度以得到三种不同的晶体生长形态。商业PbWO4电镜照片如图3(d)所示,多数是大尺寸的块状物,并且周围伴随着一些细碎的颗粒,整体呈现为微观尺寸差异大且形貌无规则的结构。图4为各PbWO4填料的EDS谱图,无杂质峰,且所有谱图显示的Pb : W : O的原子比约为17.8∶16.3∶65.9,与PbWO4的标准原子比1∶1∶4相近,表明PbWO4的纯度较高。

表 1 合成PbWO4填料的不同晶面的衍射峰强度比值Table 1. The intensity ratio of diffraction peaks of different crystal planesMaterial r

(112:200)rs

(112:200)r/rs

(112:200)r

(112:204)rs

(112:204)r/rs

(112:204)r

(112:312)rs

(112:200)r/rs

(112:312)PbWO4-I 2.73 3.33 0.82 4.42 2.86 1.55 3.13 2.86 1.09 PbWO4-II 2.68 0.8 4.37 1.53 2.46 0.86 PbWO4-III 2.65 0.79 3.38 1.18 2.55 0.89 Notes: r value represents the intensity ratio of diffraction peaks of crystal planes; rs value represents the intensity ratio of diffraction peaks of crystal planes in the standard diffraction card (JCPDS: 19-0708). 图5为各PbWO4填料的N2吸附-脱附等温线和孔径分布图,PbWO4-I、PbWO4-II、PbWO4-III和PbWO4-commercial商业填料的比表面积分别为0.64 m2/g、1.02 m2/g、1.76 m2/g和0.21 m2/g。从孔径分布图可以看出,PbWO4填料的比表面积越高,其包含的介孔数量越多; 由于棱锥体颗粒在自组装的过程中会形成很多微小的裂隙,而尺寸越大的微米纺锤PbWO4含有的缝隙就越多,因此其比表面积就越高。

图6为各不同PbWO4填料制成的复合材料的断面SEM图像。从图中可以看出,混合球磨不会对填料形貌造成太大影响,球磨后只产生少量碎片。同时合成的PbWO4在基体中具有良好的均匀分散性,且明显优于商用的PbWO4填料,这是由于合成的三种PbWO4填料的尺寸较小,尺寸大小均一,这更有利于填料在基体中的均匀分布[17]。

2.2 热稳定性

图7为HDPE,B4C/HDPE和各不同PbWO4填料增强复合材料的TGA曲线。由图7(a)可知,所有屏蔽材料的热分解过程都是典型的单步热分解过程。各材料的初始分解温度(T5%)和半分解温度(T50%)列于表2。所有材料的T5%都大于460℃,呈现出良好的热稳定性,因此,掺杂PbWO4和B4C填料并不会对复合材料的热稳定性造成负面影响,并且微米纺锤PbWO4作为填料的复合材料的T5%和T50%都高于形貌无规则的商业PbWO4作为填料的复合材料。由于B4C粉末硬度较高,在与HDPE粉末混合球磨时会进一步地细化HDPE粉末,造成HDPE的分子链断裂,材料的分子量减小,从而导致材料的T5%降低[18],因此所有复合材料的T5%与HDPE相比略有降低。图7(b)为各样品的DSC数据,Tp为DSC曲线吸热峰的峰值温度,对比所有掺杂PbWO4复合材料的Tp可知,随着填料的比表面积的增加,Tp随之增加,复合材料的热稳定性也随之增加;这是由于高比表面积的填料能够在基体材料中提供更多的限制位点[19],填料对基体材料分子链的热振动起到更多的限制,从而提高复合材料的热稳定性[20]。由此可知,通过调控PbWO4的形貌,提高填料的比表面积,能够有效地改善复合材料的热稳定性。

表 2 不同材料的热学性能参数Table 2. Thermal parameters of different materialsMaterial T5%/℃ T50%/℃ Tp/℃ HDPE 471.4 497.7 131.1 B4C/HDPE 464.3 497.1 131.4 PbWO4-commercial-B4C/HDPE 460.5 495.2 130.2 PbWO4-I-B4C/HDPE 464.2 498.4 130.6 PbWO4-II-B4C/HDPE 465.3 499.3 131.5 PbWO4-III-B4C/HDPE 460.7 499.1 132.2 Notes: T5% represents the initial thermal degradation temperature; T50% represents the semi-degradation temperature; Tp represents the peak temperature of the endothermic peak. 2.3 力学性能

图8(a)为HDPE、B4C/HDPE和PbWO4-B4C/ HDPE复合材料的应力应变曲线。各材料的力学性能参数列于表3。通过对比可知,所有复合材料的杨氏模量和屈服应力(σy)均大于HDPE,这是由于刚性填料B4C对HDPE聚合物链段有加固作用,限制了HDPE链段的相对运动[21];并且通过调控PbWO4填料的微观形貌以提高其比表面积,能够有效地提高复合材料的力学性能。例如复合材料的屈服应力从商业PbWO4作为填料的16.67 MPa提高到合成微米纺锤PbWO4-III作为填料的19.78 MPa,拉伸强度(σb)从19.40 MPa提升至20.09 MPa。这是因为高比表面积的填料能够在基体材料中提供更多的限制位点[19],对HDPE基体分子链运动时的阻碍作用更大,对复合材料的力学性能的提升更好。PbWO4填料在提高复合材料屈服应力的同时保留了HDPE基体材料良好的拉伸强度和韧性,这是由于Pb的延展性好,能够产生较大的微观塑性形变[22],使得PbWO4增强复合材料的断裂伸长率高于HDPE。因此高比表面积的PbWO4增强填料对复合材料的力学性能有显著的提升。

表 3 不同材料的力学性能参数Table 3. Mechanical parameters of different materialsMaterial Shore hardness/HD Young’s modulus/MPa Yield stress(σy)/MPa Tensile stress(σb)/MPa Elongation at break/% HDPE 56.6 ± 1.1 206.2 16.01 20.89 369.1 B4C/HDPE 67 ± 2.2 487.5 21.23 19.19 111.7 PbWO4-commercial-B4C/HDPE 57.2 ± 2.1 234.1 16.67 19.40 395.7 PbWO4-I-B4C/HDPE 58.4 ± 2.1 248.4 17.74 19.14 419.9 PbWO4-II-B4C/HDPE 59.3 ± 2.3 325.9 18.26 19.64 493.1 PbWO4-III-B4C/HDPE 59.5 ± 1.7 353.1 19.78 22.09 423.4 图8(b)为所有材料的邵氏硬度柱状图,由图可知,添加了刚性填料B4C之后,材料的硬度得到提高,并且复合材料的硬度与刚性填料的含量正相关[23],因此B4C/HDPE复合材料(B4C含量最高)的硬度要显著优于其他材料;同时微米纺锤PbWO4复合材料的硬度高于商业PbWO4复合材料,这是由于尺寸均一且高比表面积的填料在基体中的均匀分散性更高,对复合材料的刚度和硬度等力学性能的提升作用就更大[24]。

2.4 辐射屏蔽性能

图9是不同材料(厚度为1.5 cm)对中子(a)和伽马射线(b)透射率对比图,从图中可以看出,所有掺杂PbWO4填料的板材,其中子和伽马射线屏蔽率都得到了显著地提升,这是由于Pb和W元素的快中子吸收截面要高于B元素[25,26],而252Cf中子源的主要的中子能量区间在0.1 MeV-10 MeV,属于快中子能量区间[27],因此添加PbWO4有助于提高复合材料对快中子的屏蔽率。同时Pb和W作为高原子序数的材料,能够有效地增加伽马光子与材料的相互作用概率[28],从而提高材料的伽马射线辐射屏蔽率。并且对比不同颗粒尺寸的微米纺锤PbWO4填料以及商业PbWO4填料的中子和伽马射线透射率可知,通过调控PbWO4的晶体生长并提高填料的比表面积,可以增加填料与辐射相互作用概率[29],从而提高材料的辐射屏蔽性能。

图10为HDPE、B4C/HDPE和PbWO4-III-B4C/ HDPE三种屏蔽材料根据比尔-朗伯定律[30]拟合得到的中子和伽马射线衰减曲线。通过密度计测量材料的密度以及根据文献[31]计算得到的屏蔽性能参数列于表4(PbWO4-I-B4C/HDPE、PbWO4-II-B4C/HDPE和PbWO4-commercial-B4C/HDPE复合材料的密度分别为1.192 g·cm−3、1.204 g·cm−3和1.150 g·cm−3)。通过拟合得到的衰减曲线可知,三种材料对于252Cf中子源的屏蔽率要达到95%所需的厚度(S95%,n)分别为15.4 cm、14.8 cm和13.0 cm。中子总截面(Σ)数值分别为0.18 cm−1、0.19 cm−1和0.22 cm−1,这表明PbWO4-III/B4C/HDPE材料对于中子的屏蔽效果最优。三种材料对于137Cs伽马射线源的屏蔽率要达到65%所需的厚度(S65%,γ)分别为15.0 cm、13.3 cm和11.0 cm,并且PbWO4-III-B4C/HDPE材料的线性衰减系数(μ)和质量衰减系数(μm)要大于其他两种材料,同时材料的半值层(HVL,定义为将初始辐射强度降低到一半时所需要的材料厚度)和平均自由程(MFP,定义为粒子在两次连续碰撞之间移动的平均距离)都要小于其他两种材料。这意味着该材料和伽马光子发生相互作用的概率最大。综上所述,PbWO4-III-B4C/HDPE复合材料的辐射屏蔽性能最优。

表 4 不同材料的中子和伽马射线屏蔽性能参数Table 4. Neutron and gamma-ray shielding performance parameters of different materialsMaterial ρ/(g·cm−3) S95%,n/cm Σ/cm−1 S65%,γ/cm μ/cm−1 μm/cm−1 HVL/cm MFP/cm HDPE 0.941 15.4 0.18 15.0 0.067 0.071 10.35 14.92 B4C/HDPE 1.069 14.8 0.19 13.3 0.079 0.074 8.77 12.66 PbWO4-III-B4C/HDPE 1.195 13.0 0.22 11.0 0.099 0.083 8.35 10.10 Notes: ρ represents the density of the material; S95%,n represents the thickness of the material required to achieve 95% shielding against 252Cf neutron source; Σ represents the total neutron cross section; S65%,γ represents the thickness of the material required to achieve 65% shielding against 137Cs gamma-ray source; μ represents linear attenuation coefficient; μm represents mass attenuation coefficient; HVL represents the thickness of the material required to reduce the initial radiation intensity to half. MFP is defined as the average distance a particle moves between two consecutive collisions. 3. 结论

通过WO42-和Pb2+的共沉淀法合成了微米纺锤PbWO4,并控制溶液中表面活性剂十六烷基三甲基溴化铵(CTAB)的浓度以及反应时间来调控PbWO4的微观结构。从而得到微观尺寸和比表面积不同的三种PbWO4填料。通过和形貌无规且颗粒尺寸差异大的商业PbWO4做对比,研究填料的微观尺寸和比表面积对复合材料的热稳定性、力学性能和屏蔽性能的影响。结果表明:

(1)合成的微米纺锤PbWO4填料比表面积高于商业PbWO4,能够在高密度聚乙烯(HDPE)基体中提供更多的限制位点,对于HDPE分子链的热振动阻碍作用更大,从而对复合材料的热稳定性提升更加显著。

(2)比表面积较高的合成微米纺锤PbWO4填料能够在HDPE基体中提供更多的限制位点,更多地限制HDPE基体分子链在受力状态下的相对位移,对复合材料的拉伸强度提升更大,同时Pb具有良好的延展性,能够提高复合材料的断裂伸长率和韧性。

(3)由于Pb和W的快中子吸收截面较高,通过添加PbWO4填料能够显著提高复合材料对于快中子的屏蔽性能,且比表面积高的合成微米纺锤PbWO4填料能够有效增加材料与辐射粒子相互作用的概率,提升材料的辐射屏蔽性能。屏蔽性能最优的PbWO4-III-B4C/HDPE复合材料在1.5 cm的厚度时的Σ、μ和μm分别为0.22 cm−1、0.099 cm−1和0.083 cm−1;厚度为13.0 cm时,中子屏蔽率达95%;厚度为11 cm时,伽马射线屏蔽率达65%,各项性能均优于商业PbWO4复合材料。

-

表 1 叶片用玻璃纤维的主要型号

Table 1 Main types of glass fiber for wind blade

Manufacturer First generation Second generation Third generation Fourth generation Jushi E6 E7 E8 E9 CPIC TM TM+ TMII — CTG TCR HMG S-1 HM THM-1 OCV WS2000 WS3000 WS4000 — 表 2 叶片用碳纤维的主要型号

Table 2 Main type of carbon fiber used for blades

Manufacturer TORAY ZOLTEK SGL Formosa ZFSY Type T720 PX35 CT50 TC35 SY45 Tows/K 36 50 50 48 24 Modulus/GPa 265 242 260 240 230 -

[1] MORTEN D, BEN B. Global wind report 2022[R]. Brussels: Global Wind Energy Council, 2021: 110-140.

[2] ALASTAIR D, MARC B. Global offshore wind report 2021[R]. Brussels: Global Wind Energy Council, 2021: 19-30.

[3] WOOD M. Global wind power market outlook update: Q1 2022[R]. Global conclusions on Q1 forecast, 2022: 7-8.

[4] REDDY S S P, SURESH R, HANAMANTRAYGPINDA M B, et al. Use of composite materials and hybrid composites in wind turbine blades[J]. Materials Today: Proceedings,2021,46:2827-2830. DOI: 10.1016/j.matpr.2021.02.745

[5] AUBRYN C, ANNIKA E, ERIC L. Wind turbine blade material in the United States: Quantities, costs, and end-of-life options[J]. Resources, Conservation & Recycling, 2021, 168: 105439.

[6] COGNE V, PONT S, DOBREV I, et al. Bioinspired turbine blades offer new perspectives for wind energy[J]. Proceedings of the Royal Society of London A: Mathematical, Physical and Engineering Sciences,2017,473(2198):20160726.S. DOI: 10.1098/rspa.2016.0726

[7] MURRAY R E, SCOTT J, DAVID S, et al. Techno-economic analysis of a megawatt-scale thermoplastic resin wind tubine blade[J]. Renewable Energy, 2019, 131: 111-119.

[8] BATURKIN D, AHMAT H O, MASMOUDI R, et al.Valorization of recycled FRP materials from wind turbine blades in concrete[J]. Resources, Conservation & Recycling, 2021, 174: 105807.

[9] GABHALE R R, CHANDRA B D. Comprehensive study of composite materials used in wind turbine blade[J]. International Journal of Latest Trends in Engineering and Technology,2015,6(2):146-155.

[10] PINTO T H L, GUL W, TORRES L A G, et al. Experimental and numerical comparison of impact behavior between thermoplastic and thermoset composite for wind turbine blades[J]. Materials, 2021, 14: 6377.

[11] MURRAY R E, SWAN D, SNOWBERG D, et al. , Manufacturing a 9-meter thermoplastic composite wind turbine blade[C]. ASC 32nd Technical Conference. West Lafayette: Purdue University, 2017.

[12] PETTERSSON J. Analysis and design of an adhesive joint in wind turbine blades[D]. Sweden: Lund University, 2016.

[13] ZHOU H F, DOU H Y, QIN L Z, et al. A review of full scale structural testing of wind turbine blades[J]. Renewable & Sustainable Energy Reviews,2014,33(2):177-187.

[14] 李林致. 刍议风力发电的发展现状及趋势[J]. 中国新通信, 2018, 20(19):203-204. DOI: 10.3969/j.issn.1673-4866.2018.19.180 LI Linzhi. Discussion on the development status and trend of wind power generation[J]. China New Communications,2018,20(19):203-204(in Chinese). DOI: 10.3969/j.issn.1673-4866.2018.19.180

[15] 张文毓. 风电叶片复合材料及其应用[J]. 上海电气技术, 2017, 10(4):55-57. DOI: 10.3969/j.issn.1674-540X.2017.04.014 ZHANG Wenyu. Wind power blade composite material and its application[J]. Shanghai Electric Technology,2017,10(4):55-57(in Chinese). DOI: 10.3969/j.issn.1674-540X.2017.04.014

[16] 林刚. 2020全球碳纤维复合材料市场报告[Z]. 2020: 25-26. LIN Gang. 2020 Global carbon fiber composites market report[Z]. 2020: 25-26(in Chinese).

[17] CRISTIAN L T, EDGAR E M, RODOLFO R B. Effects of the vacuum moulding process on the mechanical properties of cotton/epoxy composite[J]. Fibres and Textile in Eastern Europe,2018,26(3):93-97.

[18] JOAQUIM V, CARLOS G, JAVIER L. Fabric compaction and infiltration during vacuum-assisted resin infusion with and without distribution medium[J]. Journal of Composite Materials,2017,51(5):687-703. DOI: 10.1177/0021998316649783

[19] MOHANT P, KANNY K. Mechanical properties and failure analysis of short kenaf fibre reinforced composites processed by resin casting and vacuum infusion methods[J]. Polymers and Polymer Composites,2018,26(2):189-204. DOI: 10.1177/096739111802600207

[20] 徐立波. VARI工艺影响因素简析[J]. 轻工科技, 2015, 31(6):28-29. XU Libo. Brief analysis of the factors affecting VARI process[J]. Light Industry Technology,2015,31(6):28-29(in Chinese).

[21] 潘利剑, 刘卫平, 陈萍, 等. 真空辅助成型工艺中预成型体的厚度变化与过流控制[J]. 复合材料学报, 2012, 29(5):244-248. DOI: 10.13801/j.cnki.fhclxb.2012.05.011 PAN Lijian, LIU Weiping, CHEN Ping, et al. Thickness variation and overcurrent control of preforms in vacuum assisted forming process[J]. Acta Materiae Compositae Sinica,2012,29(5):244-248(in Chinese). DOI: 10.13801/j.cnki.fhclxb.2012.05.011

[22] COUSINS D S, SUZUKI Y, MURRAY R E, et al. Recycling glass fiber thermoplastic composites from wind turbine blades[J]. Journal of Cleaner Production, 2019, 209: 1252-1263.

[23] 李书乡, 马全胜, 张顺. 中国高性能碳纤维产业的创新发展[J]. 科技导报, 2018, 36(19):73-80. LI Shuxiang, MA Quansheng, ZHANG Shun. Development of high performance carbon fiber industry in China[J]. Science & Technology Review,2018,36(19):73-80(in Chinese).

[24] 阮芳涛, 施建, 徐珍珍, 等. 碳纤维增强树脂基复合材料的回收及其再利用研究进展[J]. 纺织学报, 2019, 40(6):152-157. DOI: 10.13475/j.fzxb.20180802906 RUAN Fangtao, SHI Jian, XU Zhenzhen, et al. Research progress in recycling and reuse of carbon fiber reinforced resin composites[J]. Journal of Textile Research,2019,40(6):152-157(in Chinese). DOI: 10.13475/j.fzxb.20180802906

[25] ALEXANDER S, NATALIE R, LMAN T. Co-curing of CFRP-steel hybrid joints using the vacuum assisted resin infusion process[J]. Applied Composite Materials,2017,24(5):1137-1149. DOI: 10.1007/s10443-016-9575-3

[26] BUCUR I O, MALAEL I, BREBAN S. Horizontal-axis wind turbine blades manufacture with composite materials[C]//IOP Conference Series: Materials Science and Engineering. Iasi, 2020.

[27] FRACASSIF T, DONADON M V. Simulation of vauum assisted resin transfer moling prcess through dynamics ystemanalysis[J]. Journal of Composite Materials,2018,52(27):3759-3771. DOI: 10.1177/0021998318770000

[28] 邢丽英, 蒋诗才, 周正刚. 先进树脂基复合材料制造技术进展[J]. 复合材料学报, 2013, 30(2):1-9. XING Liying, JIANG Shicai, ZHOU Zhenggang. Progress of manufacturing technology development of advanced polymer matrix composites[J]. Acta Materiae Compositae Sinica,2013,30(2):1-9(in Chinese).

[29] 罗益锋, 罗晰旻. 近期碳纤维及其复合材料的新发展[J]. 高科技纤维与应用, 2014, 39(1):1-9. DOI: 10.3969/j.issn.1007-9815.2014.01.001 LUO Yifeng, LUO Ximin. New developments of recent carbon fiber and their composite materials[J]. Hi-Tech Fiber & Application,2014,39(1):1-9(in Chinese). DOI: 10.3969/j.issn.1007-9815.2014.01.001

[30] 高奇. 新形势下我国碳纤维产业发展探讨[J]. 合成纤维工业, 2019, 42(4):58-63. GAO Qi. Discussion on development of China carbon fiber industry under new situation[J]. China Synthetic Fiber Industry,2019,42(4):58-63(in Chinese).

-

下载:

下载: