Experimental study on fatigue behavior of compact-tension specimens strengthened by CFRP

-

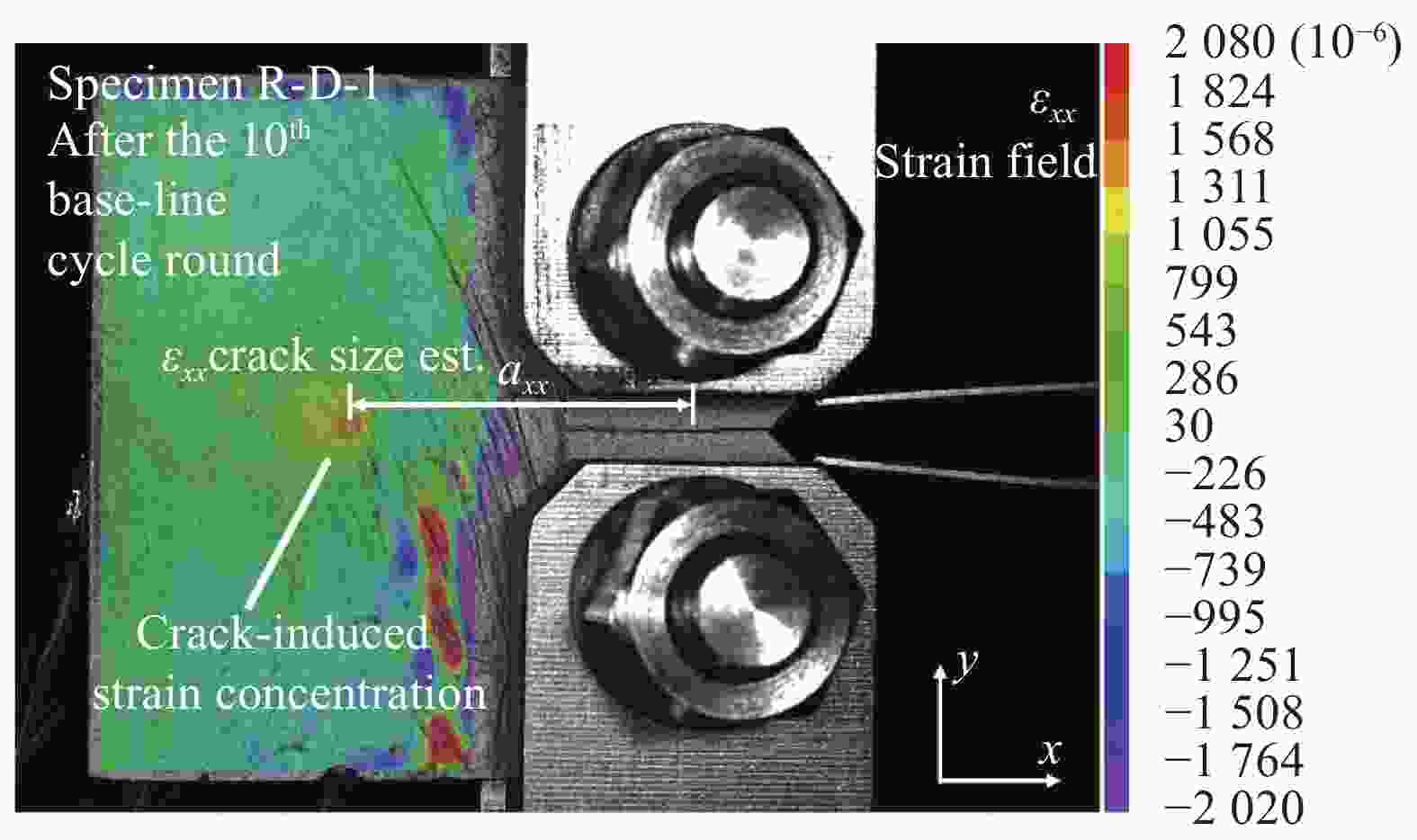

摘要: 以紧凑拉伸试件(Compact-tension specimen,CT试件)为研究对象,针对未补强及不同碳纤维增强树脂复合材料(Carbon fiber reinforced polymer,CFRP)粘贴补强工况的CT试件开展疲劳试验。以CFRP材料类别、单/双面粘贴与CFRP材料用量作为变量,运用沙滩纹加载制度与非接触式全场应变测量(Digital image correlation,DIC)技术记录测量疲劳裂纹扩展长度与试件CFRP表面应变场,分析CFRP粘贴延长疲劳寿命的作用,从疲劳寿命与疲劳裂纹扩展速率入手,比较疲劳试验结果用以指导CFRP粘贴加固疲劳损伤钢构件。结果表明粘贴CFRP发挥其抗拉和抗压作用可以减小乃至抑制疲劳裂纹扩展速率的增长,从而有效推迟试件疲劳破坏,在特定工况下可最多延长试件疲劳寿命至未补强状态下的3.14倍。其中,双面粘贴的加固效果明显优于单面粘贴;增加碳纤维布的铺贴层数对疲劳寿命的增长具有一定的贡献;碳纤维复材板与试件粘接边缘的脱胶导致其补强效果不及刚度相似的碳纤维布;粘接界面是补强体系破坏过程中的薄弱环节,碳纤维复材板加固试件的破坏模式主要为胶层破坏与复材板脱胶,碳纤维布加固试件的破坏模式为以最内层碳纤维布脱胶与分层主导,含有小范围胶层破坏的混合状态。含裂纹钢构件CFRP粘贴加固的材料与工艺值得进一步改良研究。Abstract: Fatigue tests were conducted on one bare and five carbon fiber reinforced polymer (CFRP)-repaired steel compact-tension specimens (CT specimens) to compare the fatigue behavior effects of bonded CFRP plates or carbon fiber sheets. CFRP type, patch configuration and material quantity were designated as three variables in the experiment. Beach marking technique and digital image correlation (DIC) technology were employed to measure and record fatigue crack propagation as well as strain distribution of the specimens’ surfaces. The techniques helped to explain the resistance contribution from CFRP patches under fatigue loading. The fatigue test results were analyzed in terms of fatigue life and fatigue crack growth rates (FCGR) to offer practical instructions on adhesively-bonded CFRP repair strategy. Results show that CFRP patches reduce and even forestall the growth of FCGR to prolong the fatigue life. In one case the fatigue life of a CFRP-repaired specimen increases to 314% compared to theunrepaired specimen. Double-side strengthening outperforms the single-side counterpart. The increase of carbon fiber sheet layers extends the fatigue life within a limit. CFRP plates show a disadvantage compared with carbon fiber sheets with a similar stiffness due to their pasting defect sensitivity. CFRP debonding and delamination predominate the failure modes in carbon fiber sheet-repaired specimens while adhesive layer failure and CFRP debonding reign in the CFRP plate-repaired ones. It can be inferred that interfaces are the weaknesses in fatigue failure and deserve further improvement.

-

表 1 试件编号与补强工况

Table 1. Specimen number and repair parameters

Specimen Patch configuration CFRP material type CFRP layer number each side U-1 Unrepaired

(Benchmark)− − R-S-2 Single-side strengthening Carbon fiber sheet

(FTS-C8-30)2 R-D-1 Double-side strengthening 1 R-D-2 2 R-D-4 4 R-D-1 P CFRP plate

(HM-1.4 T)1 Notes: U-1—Unrepaired specimen; In specimen R-S/D-X (P), R—Repaired specimens, S/D—Single/double-side strengthening, X—Layer number of carbon fiber sheet or CFRP plate on each side, P after X—CFRP plate, otherwise the material type is carbon fiber sheet; CFRP—Carbon fiber reinforced polymer. 表 2 材料性质

Table 2. Material properties

Material Tensile modulus/GPa Tensile strength/MPa Thickness/mm Steel 199.66 356.28 (Yield) 7.68* 496.5 (Ultimate) Carbon fiber sheet 681.3 (Longitudinal) 1967 (Longitudinal) 0.143 26.2 (Transverse) 205 (Transverse) CFRP plate 162 (Longitudinal) 2439 (Longitudinal) 1.4 Adhesive 4 26 0.65-1.31 Note: *—After rust removal. 表 3 沙滩纹加载制度与结果

Table 3. Beach marking loading scenario and results

Specimen Base-line cycles per round Marker load cycles per round Completed round number before failure (Marker number) U-1 12 000 7 200 7 R-S-2 15 130 9 000 8 R-D-1 18 090 10 000 10 R-D-2 18 090 10 000 16 R-D-4 20 110 13 500 12 R-D-1 P 18 000 10 000 12 表 4 CFRP加固紧凑拉伸钢试件疲劳寿命试验结果

Table 4. Fatigue life test results of the compact-tension (CT) specimens strengthened by CFRP

Specimen Base-line cycles NB Marker load cycles NM Converted fatigue life Fatigue life extension ratio U-1 95 037 50 400 101 337 1.00 (Benchmark) R-S-2 131 329 72 000 140 329 1.38 R-D-1 190 124 100 000 202 624 2.00 R-D-2 298 486 160 000 318 486 3.14 R-D-4 251 800 162 000 272 050 2.68 R-D-1 P 224 100 120 000 239 100 2.36 -

[1] CIUPACK Y, LEDECKY L, KASPER Y, et al. Strengthening of steel structures with fatigue cracks using adhesively bonded non-prestressed and prestressed CFRP lamellas[C]//The Proceedings of the 13th International Conference “Modern Building Materials, Structures and Techniques” (MBMST 2019). Vilnius: Vilnius Gediminas Technical University Press, 2019: 252-260. [2] 吴刚, 刘海洋, 吴智深, 等. 不同纤维增强复合材料加固钢梁疲劳性能试验研究[J]. 土木工程学报, 2012, 45(4):21-28. doi: 10.15951/j.tmgcxb.2012.04.010WU Gang, LIU Haiyang, WU Zhishen, et al. Experimental study of the fatigue performance of steel beams strengthened with different fiber reinforced polymers[J]. China Civil Engineering Journal,2012,45(4):21-28(in Chinese). doi: 10.15951/j.tmgcxb.2012.04.010 [3] AHMED S, THOSTENSON E T, SCHUMACHER T, et al. Integration of carbon nanotube sensing skins and carbon fiber composites for monitoring and structural repair of fatigue cracked metal structures[J]. Composite Structures,2018,203:182-192. [4] TENG J G, YU T, FERNANDO D. Strengthening of steel structures with fiber-reinforced polymer composites[J]. Journal of Constructional Steel Research,2012,78:131-143. doi: 10.1016/j.jcsr.2012.06.011 [5] FENG P, HU L, ZHAO X L, et al. Study on thermal effects on fatigue behavior of cracked steel plates strengthened by CFRP sheets[J]. Thin-Walled Structures,2014,82:311-320. doi: 10.1016/j.tws.2014.04.015 [6] YU Q Q, ZHAO X L, AL MAHAIDI R, et al. Tests on cracked steel plates with different damage levels strengthened by CFRP laminates[J]. International Journal of Structural Stability and Dynamics,2014,14(6):1-26. [7] WANG H T, WU G, JIANG J B. Fatigue behavior of cracked steel plates strengthened with different CFRP systems and configurations[J]. Journal of Composites for Construction,2016,20(3):04015078. doi: 10.1061/(ASCE)CC.1943-5614.0000647 [8] 叶华文, KONIG Christian, UMMENHOFER Thomas, 等. 预应力CFRP板加固钢板受拉疲劳性能试验研究[J]. 西南交通大学学报, 2009, 44(6):824-829. doi: 10.3969/j.issn.0258-2724.2009.06.005YE Huawen, KONIG Christian, UMMENHOFER Thomas, et al. Experimental investigation of fatigue behavior of tension steel plate reinforced with prestressed CFRP lami-nates[J]. Journal of Southwest Jiaotong University,2009,44(6):824-829(in Chinese). doi: 10.3969/j.issn.0258-2724.2009.06.005 [9] COLOMBI P, FAVA G, SONZOGNI L. Fatigue crack growth in CFRP-strengthened steel plates[J]. Composites Part B: Engineering,2015,72:87-96. doi: 10.1016/j.compositesb.2014.11.036 [10] 陈涛, 摇铖. CFRP加固含混合型边裂纹钢板的疲劳性能试验研究[J]. 建筑结构学报, 2021, 42(2):206-212. doi: 10.14006/j.jzjgxb.2020.c175CHEN Tao, YAO Cheng. Experimental study on fatigue properties of CFRP-repaired steel plates with a mixed-mode edge crack[J]. Journal of Building Structures,2021,42(2):206-212(in Chinese). doi: 10.14006/j.jzjgxb.2020.c175 [11] 叶华文, UMMENHOFER T, 强士中. 预应力CFRP板加固钢梁抗弯疲劳试验研究[J]. 公路交通科技, 2009, 26(12):50-55. doi: 10.3969/j.issn.1002-0268.2009.12.011YE Huawen, UMMENHOFER T, QIANG Shizhong. Experimental study of flexural fatigue performance of steel girder reinforced by prestressed CFRP plate[J]. Journal of Highway and Transportation Research and Development,2009,26(12):50-55(in Chinese). doi: 10.3969/j.issn.1002-0268.2009.12.011 [12] CHEN T, GU X, QI M, et al. Experimental study on fatigue behavior of cracked rectangular hollow-section steel beams repaired with prestressed CFRP plates[J]. Journal of Composites for Construction,2018,22(5):04018034. doi: 10.1061/(ASCE)CC.1943-5614.0000872 [13] SCHIJVE J. Fatigue of structures and materials[M]. Second edition. Delft: Springer, 2009. [14] LESIUK G, KATKOWSKI M, CORREIA J, et al. Fatigue crack growth rate in CFRP reinforced constructional old steel[J]. International Journal of Structural Integrity,2018,9(3):381-395. doi: 10.1108/IJSI-08-2017-0050 [15] HASSAN M M, SHAFIQ M A, MOURAD S A. Experimental study on cracked steel plates with different damage levels strengthened by CFRP laminates[J]. International Journal of Fatigue,2021,142:105914. [16] LESIUK G, KATKOWSKI M, DUDA M, et al. Improvement of the fatigue crack growth resistance in long term ope-rated steel strengthened with CFRP patches[J]. Procedia Structural Integrity,2017,5:912-919. doi: 10.1016/j.prostr.2017.07.109 [17] LESIUK G, PEDROSA B A S, ZIETY A, et al. Minimal inva-sive diagnostic capabilities and effectiveness of CFRP-patches repairs in long-term operated metals[J]. Metals,2020,10:984. doi: 10.3390/met10070984 [18] 中华人民共和国国家质量监督检验检疫总局, 中国国家标准化管理委员会. 金属材料拉伸试验 室温试验方法: GB/T 228.1—2010[S]. 北京: 中国标准出版社, 2010.General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China, Standardization Administration of the People's Republic of China. Metallic materials-Tensile testing-Method of test at room temperature: GB/T 228.1—2010[S]. Beijing: China Standards Press, 2010(in Chinese). [19] CHEN T, HUANG C. Fatigue tests on edge cracked four-point bend steel specimens repaired by CFRP[J]. Compo-site Structures, 2019, 219: 31-41. [20] HUNTSMAN. Araldite 2014 Technical Data Sheet[Z]. Huntsman Advanced Materials (Switzerland) GmbH, 2004. [21] American Society for Testing and Materials. Standard test method for measurement of fatigue crack growth rates: ASTM E647-15[S]. West Conshohocken: American Society for Testing and Materials International, 2015. [22] 董亮, 童乐为, 彭洋, 等. 应用Beach marking方法检测钢结构疲劳裂纹扩展[J]. 结构工程师, 2011, 27:179-183.DONG Liang, TONG Lewei, PENG Yang, et al. Application of beach marking method in the detection of fatigue crack propagation of steel structures[J]. Structural Engineers,2011,27:179-183(in Chinese). [23] LI L, CHEN T, GU X, et al. Heat activated SMA-CFRP composites for fatigue strengthening of cracked steel plates[J]. Journal of Composites for Construction,2020,24(6):04020060. doi: 10.1061/(ASCE)CC.1943-5614.0001072 [24] British Standards Institution. Guide to methods for assessing the acceptability of flaws in metallic structures: BS 7910:2019[S]. United Kingdom: BSI Standards Limited, 2019. [25] CHEN T, LI L, ZHANG N, et al. Fatigue performance test on inclined central cracked steel plates repaired with CFRP strand sheets[J]. Thin-Walled Structures, 2018, 130: 414-423. [26] LIU H, XIAO Z, ZHAO X L, et al. Prediction of fatigue life for CFRP-strengthened steel plates[J]. Thin-Walled Structures,2009,47(10):1069-1077. doi: 10.1016/j.tws.2008.10.011 [27] CHEN T, HUANG C, HU L, et al. Experimental study on mixed-mode fatigue behavior of center cracked steel plates repaired with CFRP materials[J]. Thin-Walled Structures,2019,135:486-493. doi: 10.1016/j.tws.2018.11.030 [28] PARIS P, ERDOGAN F. A critical analysis of crack propagation laws[J]. Journal of Fluids Engineering, Transactions of the ASME,1963,85(4):528-533. [29] 郑云, 叶列平, 岳清瑞. CFRP加固疲劳损伤钢结构的断裂力学分析[J]. 工业建筑, 2005, 35(10):79-82. doi: 10.3321/j.issn:1000-8993.2005.10.024ZHENG Yun, YE Lieping, YUE Qingrui. Fracture mecha-nics analysis of steel structures with fatigue damages strengthened by CFRP[J]. Industrial Construction,2005,35(10):79-82(in Chinese). doi: 10.3321/j.issn:1000-8993.2005.10.024 [30] 邹广平, 汪艳伟, 唱忠良, 等. 基于数字散斑相关法的紧凑拉伸试样断裂韧性实验研究[J]. 实验力学, 2015, 30(3):275-281. doi: 10.7520/1001-4888-14-190ZOU Guangping, WANG Yanlei, CHANG Zhongliang, et al. Experimental study of compact tension specimen fracture toughness based on digital speckle correlation method[J]. Journal of Experimental Mechanics,2015,30(3):275-281(in Chinese). doi: 10.7520/1001-4888-14-190 [31] 高红俐, 刘欢, 齐子诚, 等. 基于DIC谐振载荷作用下疲劳裂纹尖端位移应变场测量[J]. 兵器材料科学与工程, 2016, 39(1):16-22. doi: 10.14024/j.cnki.1004-244x.20160104.003GAO Hongli, LIU Huan, QI Zicheng, et al. Measurement of displacement and strain fields of fatigue crack tip under resonant loading based on DIC method[J]. Ordnance Material Science and Engineering,2016,39(1):16-22(in Chinese). doi: 10.14024/j.cnki.1004-244x.20160104.003 [32] TAVARES P J, VIRIATO N, VAZ A P, et al. A dedicated illumination system for fatigue crack-growth measurement[J]. Measurement,2016,90:85-93. doi: 10.1016/j.measurement.2016.04.042 [33] HU L, WANG Y, FENG P, et al. Debonding development in cracked steel plates strengthened by CFRP laminates under fatigue loading: Experimental and boundary element method analysis[J]. Thin-Walled Structures,2021,166:108038. [34] ZHAO X L, ZHANG L. State-of-the-art review on FRP strengthened steel structures[J]. Engineering Structures,2007,29(8):1808-1823. doi: 10.1016/j.engstruct.2006.10.006 [35] TALREJA R, SINGH C V. Damage and failure of composite materials[M]//Damage and Failure of Composite Materials. First edition. Cambridge: Cambridge University Press, 2012. -

下载:

下载: