Effect of ply angle on mode II delamination propagation behavior of CFRP multidirectional laminates

-

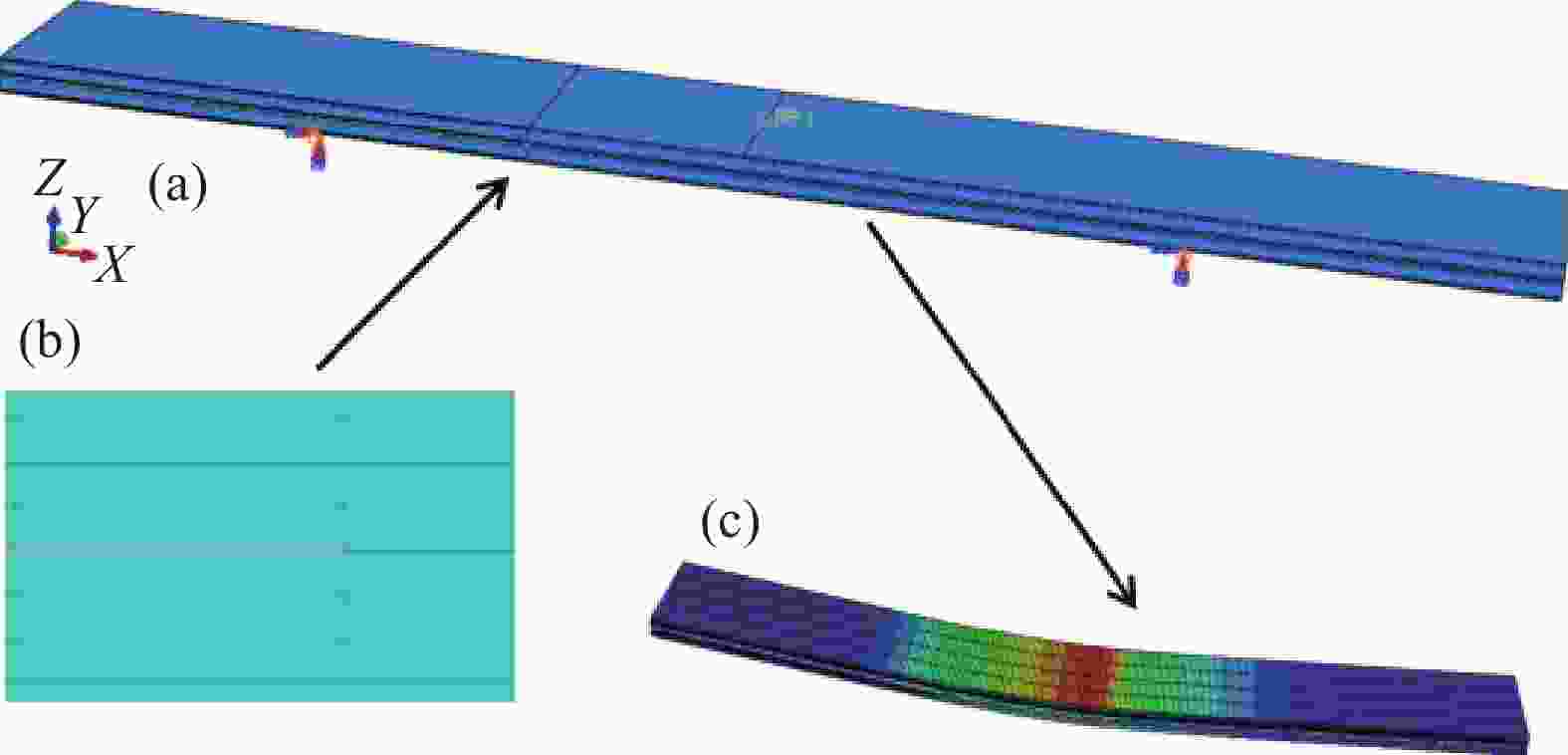

摘要: 碳纤维增强树脂复合材料(CFRP)因其良好的力学性能被逐渐应用于飞机主承力结构中。分层是复合材料层板最常见的损伤形式之一,也是飞机复合材料结构损伤容限设计与分析所关注的焦点问题。对于II型分层,现有研究主要针对单向层板展开,而工程实际中应用较多的是多向层板,对II型分层的铺层角度影响缺乏深入认识。为此,采用试验和数值方法开展了相关研究。首先设计了3种工程实际中常用界面(0°/5°、45°/−45°和90°/90°)的T700/QY9511碳纤维/双马来酰亚胺树脂基复合材料层板,所设计铺层可降低耦合作用并确保II型主导的分层扩展。采用端部开口弯曲装置开展了II型分层试验并测得了断裂韧性。结果表明:铺层角度对断裂韧性和分层失效行为影响显著。采用控制变量法建立了内聚力关键参数模型,在此基础上实现了多向层板II型分层扩展行为的模拟,预测的载荷-位移曲线响应与试验结果吻合很好,说明了有限元模型的有效性。有限元结果表明,基体损伤做功表现出随铺层角度增加而增加的趋势。为揭示基体损伤做功与分层前缘损伤区大小之间的关系,利用用户自定义子程序,模拟了不同界面试样的分层前缘损伤区域。Abstract: Carbon fiber reinforced polymer (CFRP) is gradually used in aircraft main load-bearing structure due to its good mechanical properties. Delamination is one of the most common damage forms of composite laminates, and it is also the focus of damage tolerance design and analysis of aircraft composite structures. For mode II delamination, the existing research mainly focuses on unidirectional laminates, while multidirectional laminates are widely used in engineering practice, and there is a lack of in-depth understanding of the influence of ply angle on mode II delamination. Therefore, experimental and numerical investigations were conducted in this paper. Firstly, three different interfaces (0°/5°, 45°/−45° and 90°/90°) were designed for composite laminates made of T700/QY9511 carbon fiber/bismaleimide prepregs, in order to reduce the coupling effect and ensure the mode II dominant delamination propagation. The mode II delamination test was carried out using end-notched flexure device and the fracture toughness was measured. The results show that the ply angle has a significant effect on the fracture toughness and delamination failure behavior. The control variable method is used for establishing the key parameter model of cohesive zone model. On this basis, the simulation of mode II delamination propagation behavior of multidirectional laminates is realized. The predicted load-displacement curve response is in good agreement with the experimental results, which shows the effectiveness of the finite element model. The finite element results show that the energy dissipated by the matrix damage increases with the increase of interfacial angle. In order to reveal the relationship between the energy dissipated by matrix damage and the size of damage area around the crack tip, the damage area around the crack tip of specimens with different interfaces was simulated by using user-defined subroutine.

-

Key words:

- composite laminate /

- delamination /

- ply angle /

- end-notched flexure /

- fracture toughness

-

图 5 II型分层双线性本构关系

Figure 5. Bilinear constitutive law of mode II delamination

P—Load; σ—Stress; δ—Displacement; K0—Interfacial stiffness; d—Damage variable; σ0II—Interfacial strength; δ0II—Displacement when damage initiation occurs; δfII—Displacement when the interface just loses its bearing capacity

表 1 复合材料多向层板端部开口弯曲(ENF)试样铺层信息

Table 1. Stacking sequences of the composite multidirectional laminate end-notched flexure (ENF) specimens

No. Ply-up Delamination interface Dc Bt Flexural modulus Efx ENF-1 0°16//(5°/−5°/0°6)S 0°/5° 0.0096 0.0063 129.2947 ENF-2 (45°/−45°/0°6)S//(−45°/45°/0°6)S 45°/−45° 0.1527 0.0308 67.9749 ENF-3 (90°/0°/90°/0°5)S//(90°/0°/90°/0°5)S 90°/90° 0.0020 ≈0 69.6301 Notes: Dc and Bt—Dimensionless parameters; //—Location of the prefabricated crack introduced during manufacturing. 表 2 T700/QY9511多向层板ENF试样的挠度和临界载荷值

Table 2. Deflection and critical load values of T700/QY9511 multidirectional laminate ENF specimens

Delamination interface No. Width/

mmDeflection/

mmCritical

load/N0°/5° ENF-1-1 25.01 1.90 1119 ENF-1-2 25.01 2.27 1235 ENF-1-3 25.01 2.16 1067 45°/−45° ENF-2-1 24.94 2.59 1016 ENF-2-2 24.98 2.88 915 ENF-2-3 25.00 2.53 1038 90°/90° ENF-3-1 24.99 2.23 811 ENF-3-2 25.04 2.40 727 ENF-3-3 25.07 2.17 774 表 3 不同分层界面T700/QY9511多向层板ENF试样的断裂韧性试验值

Table 3. Fracture toughness values of T700/QY9511 multidirectional laminate ENF specimens with different interfaces

Delamination interface No. GⅡC/(J·m−2) Average value/( J·m−2) Standard deviation/(J·m−2) Cv/% 0°/5° ENF-1-1 805.22 912.94 133.16 14.59 ENF-1-2 1061.83 ENF-1-3 871.77 45°/−45° ENF-2-1 1000.79 997.57 3.31 0.33 ENF-2-2 997.77 ENF-2-3 994.17 90°/90° ENF-3-1 686.81 660.12 26.51 4.02 ENF-3-2 659.78 ENF-3-3 633.77 Notes: GⅡC—Mode II strain energy release rate; Cv—Coefficient of variation. 表 4 不同界面强度下T700/QY9511多向层板临界载荷模拟值与试验均值对比

Table 4. Simulated and experimental values of critical load of T700/QY9511 multidirectional laminates under various interfacial strengths

Delamination interface Interfacial strength/MPa Simulated result of critical load/N Average test value/N Relative error/% 0°/5° 30 990.3 1140.3 −13.2 40 1113.4 −2.4 50 1154.4 1.2 45°/−45° 50 881.6 989.7 −10.9 60 1012.5 2.3 70 1165.9 17.8 90°/90° 35 701.7 770.7 −9.0 45 781.3 1.4 50 870.8 13.0 表 5 T700/QY9511多向层板分层起始时刻裂尖应变能释放率(SERR)分量

Table 5. Strain energy release rate (SERR) components of crack tip at the delamination initiation moment of T700/QY9511 multidirectional laminates

Delamination

interfaceGI/(J·m−2) GII/( J·m−2) GIII/( J·m−2) GII/

(GI+GII+GIII)0°/5° 0.26 894.08 1.15 1.00 45°/-45° 0.68 950.52 28.32 0.97 90°/90° 0.06 608.03 1.09 1.00 Notes: GI—Mode I strain energy release rate; GII—Mode II strain energy release rate; GIII—Mode III strain energy release rate. -

[1] 杜善义, 关志东. 我国大型客机先进复合材料技术应对策略思考[J]. 复合材料学报, 2008, 25(1):1-10. doi: 10.3321/j.issn:1000-3851.2008.01.001DU Shanyi, GUAN Zhidong. Strategic considerations for development of advanced composite technology for large commercial aircraft in China[J]. Acta Materiae Compositae Sinica,2008,25(1):1-10(in Chinese). doi: 10.3321/j.issn:1000-3851.2008.01.001 [2] 杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, 24(1):1-12. doi: 10.3321/j.issn:1000-3851.2007.01.001DU Shanyi. Advanced composite materials and aerospace engineering[J]. Acta Materiae Compositae Sinica,2007,24(1):1-12(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.01.001 [3] TEIMOURI F, HEIDARI-RARANI M, HAJI ABOUTALEBI F. Finite element modeling of mode I fatigue delamination growth in composites under large-scale fiber bridging[J]. Composite Structures,2021,263:113716. [4] BIN MOHAMED REHAN M S, ROUSSEAU J, FONTAINE S, et al. Experimental study of the influence of ply orientation on DCB mode-I delamination behavior by using multidirectional fully isotropic carbon/epoxy laminates[J]. Composite Structures, 2017, 161(Supplement C): 1-7. [5] 赵丽滨, 龚愉, 张建宇. 纤维增强复合材料层合板分层扩展行为研究进展[J]. 航空学报, 2019, 39(1):1-28.ZHAO L B, GONG Y, ZHANG J Y. A survey on delamination growth behavior in fiber reinforced composite laminates[J]. Acta Aeronautica et Astronautica Sinica,2019,39(1):1-28(in Chinese). [6] 李玉龙, 刘会芳. 加载速率对层间断裂韧性的影响[J]. 航空学报, 2015, 36(8):2620-2650.LI Y L, LIU H F. Loading rate effect on interlaminar fracture toughness[J]. Acta Aeronautica et Astronautica Sinica,2015,36(8):2620-2650(in Chinese). [7] HYUNG Y C, CHANG F. A model for predicting damage in graphite/epoxy laminated composites resulting from low-velocity point impact[J]. Journal of Composite Materials,1992,26(14):2134-2169. doi: 10.1177/002199839202601408 [8] 郭壮壮, 徐武, 余音. 低温环境下测试复合材料I型层间断裂韧性的简易方法[J]. 复合材料学报, 2019, 36(5):1210-1215.GUO Z Z, XU W, YU Y. A simple method for determining the mode I interlaminar fracture toughness of composite at low temperature[J]. Acta Materiae Compositae Sinica,2019,36(5):1210-1215(in Chinese). [9] GARULLI T, CATAPANO A, FANTERIA D, et al. Experimental assessment of fully-uncoupled multi-directional specimens for mode I delamination tests[J]. Composites Science and Technology,2020,200:108421. doi: 10.1016/j.compscitech.2020.108421 [10] LAKSIMI A, AHMED BENYAHIA A, BENZEGGAGH M L, et al. Initiation and bifurcation mechanisms of cracks in multi-directional laminates[J]. Composites Science and Technology,2000,60(4):597-604. doi: 10.1016/S0266-3538(99)00179-7 [11] DAVIDSON B D, KRUGER R, KOING M. Effect of stacking sequence on energy release rate distributions in multidirectional DCB and ENF specimens[J]. Engineering Fracture Mechanics,1996,55(4):557-569. doi: 10.1016/S0013-7944(96)00037-9 [12] OZDIL F, CARLSSON L A, DAVIES P. Beam analysis of angle-ply laminate end-notched flexure specimens[J]. Composites Science and Technology,1998,58(12):1929-1938. doi: 10.1016/S0266-3538(98)00018-9 [13] PEREIRA A B, DE MORAIS A B, MARQUES A T, et al. Mode II interlaminar fracture of carbon/epoxy multidirectional laminates[J]. Composites Science and Technology,2004,64(10):1653-1659. [14] PEREIRA A B, DE MORAIS A B. Mode II interlaminar fracture of glass/epoxy multidirectional laminates[J]. Composites Part A: Applied Science and Manufacturing,2004,35(2):265-272. doi: 10.1016/j.compositesa.2003.09.028 [15] CHAI H. Interlaminar shear fracture of laminated composites[J]. International Journal of Fracture,1990,43(2):117-131. doi: 10.1007/BF00036181 [16] HERRÁEZ M, PICHLER N, PAPPAS G A, et al. Experiments and numerical modelling on angle-ply laminates under remote mode II loading[J]. Composites Part A: Applied Science and Manufacturing,2020,134:105886. doi: 10.1016/j.compositesa.2020.105886 [17] POLAHA J J, DAVIDSON B D, HUDSON R C, et al. Effects of mode ratio, ply orientation and precracking on the delamination toughness of a laminated composite[J]. Journal of Reinforced Plastics and Composites,1996,15(2):141-173. doi: 10.1177/073168449601500202 [18] SALAMAT-TALAB M, SHOKRIEH M M, MOHAGHEGH M. On the R-curve and cohesive law of glass/epoxy end-notch flexure specimens with 0//θ interface fiber angles[J]. Polymer Testing,2020,93:106992. [19] CHOI N S, KINLOCH A J, WILLIAMS J G. Delamination fracture of multidirectional carbon-fiber/epoxy composites under mode I, mode II and mixed-mode I/II loading[J]. Journal of Composite Materials,1999,33(1):73-100. doi: 10.1177/002199839903300105 [20] TAO J, SUN C T. Influence of ply orientation on delamination in composite laminates[J]. Journal of Composite Materials,1998,32(21):1933-1947. doi: 10.1177/002199839803202103 [21] HWANG J H, KWON O, LEE C S, et al. Interlaminar fracture and low-velocity impact of carbon/epoxy composite materials[J]. Mechanics of Composite Materials,2000,36(2):117-130. doi: 10.1007/BF02681828 [22] 中国航空工业总公司. 碳纤维复合材料层合板II型层间断裂韧性GIIC试验方法: HB 7403—1996[S]. 北京: 中国标准出版社, 1996China Aviation Industry Corporation. Test method for mode II interlaminar fracture toughness GIIC of carbon fiber composite laminates: HB 7403—1996[S]. Beijing: China Standards Press, 1996(in Chinese). [23] 李西宁, 王悦舜, 周新房. 复合材料层合板分层损伤数值模拟方法现状[J]. 复合材料学报, 2021, 38(4):1076-1086.LI Xining, WANG Yueshun, ZHOU Xinfang. Status of numerical simulation methods for delamination damage of composite laminates[J]. Acta Materiae Compositae Sinica,2021,38(4):1076-1086(in Chinese). [24] ZHAO L, GONG Y, ZHANG J, et al. Simulation of delamination growth in multidirectional laminates under mode I and mixed mode I/II loadings using cohesive elements[J]. Composite Structures,2014,116:509-522. doi: 10.1016/j.compstruct.2014.05.042 [25] CAMANHO P P, DÁVILA C G, PINHO S T, et al. Prediction of in situ strengths and matrix cracking in composites under transverse tension and in-plane shear[J]. Composites Part A: Applied Science and Manufacturing,2006,37(2):165-176. doi: 10.1016/j.compositesa.2005.04.023 -

下载:

下载: