Research and application of advanced resin matrix composites for aerospace shuttle vehicles abroad

-

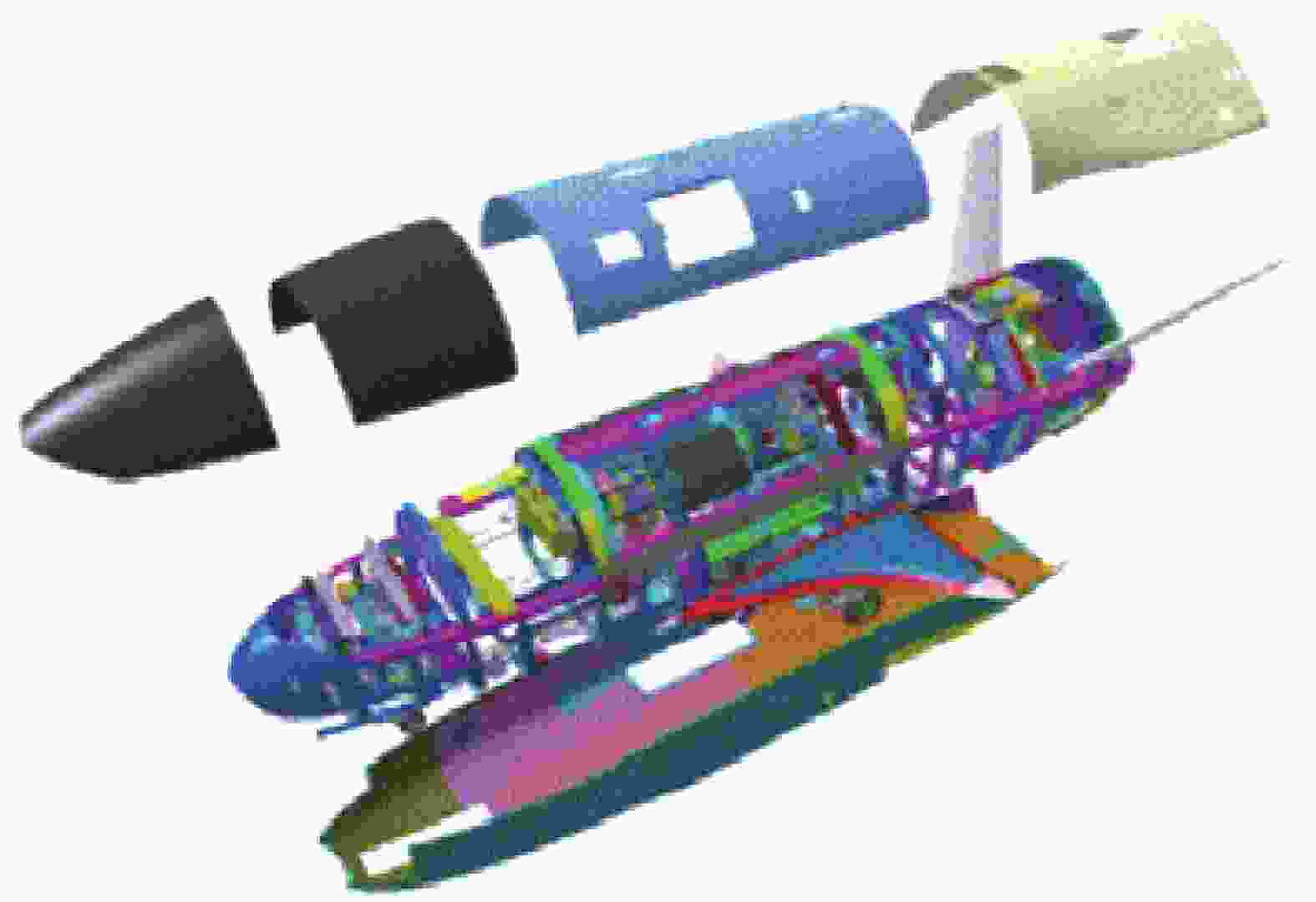

摘要: 先进树脂基复合材料技术是空天往返飞行器轻量化结构系统设计与研制的重要基础支撑。本文首先阐述了国外空天往返飞行器用先进树脂基复合材料类型及性能,典型轻质复合材料结构制造工艺应用及发展情况,然后介绍了世界主要国家空天往返飞行器的复合材料结构研制应用进展情况,包括美国X系列飞行器、日本HOPE-X空天飞行器的复合材料应用情况,最后介绍了飞行器复合材料结构的技术发展趋势。Abstract: Advanced resin matrix composite technology is an important basic support for the design and manufacture of lightweight structural system of aerospace shuttle vehicles. Firstly, the type and properties of advanced resin matrix composites used in foreign aerospace vehicles, the manufacturing technology, application and development of typical lightweight composite structure were described. And then the vehicular composite structures manufacture and application in major countries were introduced, including the composite application of “X Series” vehicles in USA and HOPE-X vehicles in Japan. Finally, the technical development trend of aircraft composite structure was introduced.

-

Key words:

- aerospace shuttle vehicle /

- composite /

- structure /

- process /

- manufacture /

- application

-

图 2 树脂基复合材料的树脂基体发展演变:耐中温和高温树脂

Figure 2. Development and evolution of resin matrix of resin matrix composites: Intermediate and high temperature resistant resins

ATF—Advanced tactic fighter; PETI—Phenylethynyl terminated polyimide; BMI—Bismaleimide; HSCT—High speed civil transport; LARC—Langley research center; CASTS—Composites for advanced space transportation systems

表 1 国外空天往返飞行器用典型树脂基复合材料信息

Table 1. Typical resin matrix composites for foreign aerospace shuttle vehicles

No. Type Grade Reinforcement Resin Tg/℃ Typical mechanical properties σ/MPa Ε/GPa τ/MPa CAI/MPa 1 CFRP T300/934 T300(FA) 934 210 628 63 83 − 2 CFRP T300/LTM45EL UD LTM45 210

(Post treatment at 175℃)1338 128 79 − 3 CFRP IM7/977-2 IM-7(UD) 977-2 205 2606 169 112 254 4 CFRP IM7/8552 IM-7(UD) 8552 201 2648 162 139 214 5 CFRP IM7/5250-4 IM-7(UD) 5250-4 288 2618 162 139 248 6 CFRP IM7/5260 IM-7(UD) 5260 274 2691 165 159 345 7 CFRP T650/5250-4 T650(FA) 5250-4 273 910 72 − − 8 GFRP F50-HRP GF PF − − − − − 9 CFRP IM7/PETI-5 IM-7(UD) PETI-5 270

(Post treatment at 350℃)1913 170 99 320 Notes: CFRP—Carbon fiber reinforced resin matrix composites; GFRP—Glass fiber reinforced resin matrix composites; GF—Glass fiber; PF—Phenol formaldehyde resin; σ—Tensile strength; E—Tensile modulus; τ—Shear strength of the short beam; CAI—Compression strength after impacting; FA—Fabric; UD—Unidirectional band; F50-HRP—Grade of GFRP; Tg—Glass transition temperature: PETI-5—Polyimide resin; IM-7—Carbon fiber: LTM45—Epoxy resin. 表 2 国外空天往返飞行器典型复合材料结构及其制造方案

Table 2. Typical composite structure and manufacturing process for foreign aerospace shuttle vehicles

No. Segment Frame name Structural style Manufacturing

materialsManufacturing

processApplication 1 Wing Wing full size

test pieceHoneycomb sandwich structure IM7/5250-4+

HRH-327 GF/PI honeycombBonding curing process Reusable vehicle prototype 2 Wing Wing box Rib/beam orthogonal

skeleton structureCF/BMI composite Bonding curing process Reusable vehicle prototype 3 Fuselage Liquid hydrogen tank skin Conical shell structure IM7/977-2+Korex

paper honeycombAutomated placement+

Autoclave processX-33 4 Wing Wing skin Large size curved laminated structure LTM45EL low temperature curing composite Oven curing process X-34 5 Airframe Lower fuselage, wing, upper fuselage Complicated integrated structure IM7/5250-4(Fuselage)+

IM7/PETI-5(Wing)Integral co-curing process X-37B 6 Fuselage Skin panel, lower panel Large curved laminated structure − Vacuum infusion process HOPE-X 7 Fuselage Longitudinal beam, bulkhead, ring rib High dimensional accuracy, small-middle laminated structure − Prepreg layup+Autoclave process HOPE-X 8 Airframe Blended wing body, upper fuselage Complicated integrated structure − Bonding curing process HOPE-X Notes: PI—Polyimide; CF—Carbon fiber; BMI—Bismaleimide resin; HOPE-X—H-Ⅱ orbiting plane experimental. 表 3 国外空天往返飞行器典型复合材料应用情况

Table 3. Application of typical composite materials in foreign aerospace shuttle vehicles

No. Application Segment Frame name Structural style Manufacturing materials Manufacturing process 1 X-33 Fuselage Upper TPS composite panel structure Laminated structure − Hot pressing process Aft thrust structure Laminated structure − Hot pressing process Wing Skin Laminated structure IM7/5250-4 composite Hot pressing process Inter-tank section Laminated structure IM7/5250-4 composite Hot pressing process Liquid hydrogen tank Tank skin Honeycomb sandwich

structureIM7/977-2+

Korex paper honeycombHot pressing process Horizontal septum, vertical septum Laminated structure IM7/977-2 composite Hot pressing process Bulkhead, extended bulkhead Honeycomb sandwich

structureIM7/977-2 composite Hot pressing process Ring, longeron Laminated structure 3D woven materials RTM process 2 X-34 Fuselage Composite sandwich member Honeycomb sandwich

structureLTM45EL CFRP Autoclave process Wing Skin Laminated structure LTM45EL CFRP Vacuum bag pressing process Frame member Laminated structure LTM45EL CFRP − Rudder Composite sandwich member Honeycomb sandwich

structureLTM45EL CFRP Co-curing process Tank − − LTM45EL CFRP − 3 X-40 Fuselage Honeycomb sandwich

structureCF/epoxy composite − Wing, flaperon, tail, resistance plate − CF/BMI composite − 4 X-40A Fuselage Honeycomb sandwich structure CF/epoxy composite − 5 X-37A Air frame Laminated and honeycomb

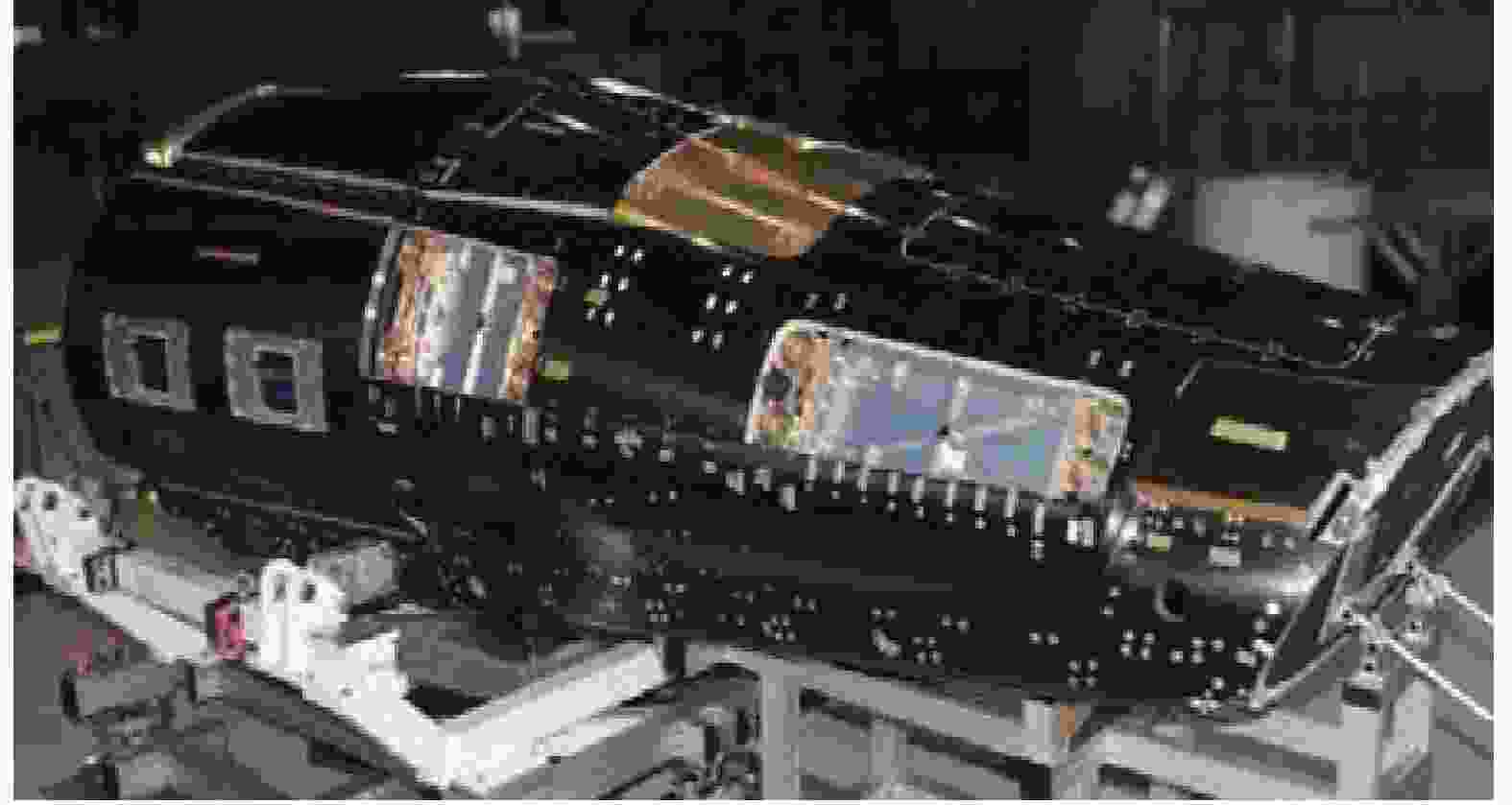

sandwich structureCF/BMI composite − 6 X-37B Fuselage Upper wall panel, lower wall panel honeycomb sandwich

structureIM7/5250-4 composite+

Flexcore+F50-HRP

compositeHot pressing process+

Bonding curing processCover plate, longitudinal beam Laminated structure IM7/5250-4 composite Hot pressing process Resistance plate Laminated structure IM7/PETI-5 composite Hot pressing process Body flap honeycomb sandwich

structureIM7/PETI-5 composite+

Titanium alloy honeycombHot pressing process Wing Upper skin, lower skin, beam, sleeve beam honeycomb sandwich

structureIM7/PETI-5 composite+

Titanium alloy honeycombHot pressing process 7 HOPE-X Fuselage Skin panel, lower panel Large curved

laminated structureCFRP Vacuum infusion process Fuselage Longitudinal beam, bulkhead, ring rib High dimensional accuracy,

small-middle

laminated structureCFRP Prepreg layup+Autoclave process Air frame Blended wing body, upper fuselage Complicated integrated structure CFRP Bonding curing process 8 IXV Air frame Beam, cover plate,

wall panel− CFRP − -

[1] 汤一华, 余梦伦, 杨勇, 等. 第二代可重复使用运载器及其再入制导技术[J]. 导弹与航天运载技术, 2010(1):26-31. doi: 10.3969/j.issn.1004-7182.2010.01.006TANG Yihua, YU Menglun, YANG Yong, et al. Second generation reusable launch vehicle and its reentry guidance technologies[J]. Missile and Space Vehicles,2010(1):26-31(in Chinese). doi: 10.3969/j.issn.1004-7182.2010.01.006 [2] 杨华保, 王建. 重复使用飞行器双层式结构连接研究[J]. 航空计算技术, 2013, 43(2):9-11. doi: 10.3969/j.issn.1671-654X.2013.02.003YANG Huabao, WANG Jian. Study on joint of reusable launch vehicle’s double-shell structure[J]. Aeronautical Computing Technique,2013,43(2):9-11(in Chinese). doi: 10.3969/j.issn.1671-654X.2013.02.003 [3] 邢丽英, 包建文, 礼嵩明, 等. 先进树脂基复合材料发展现状和面临的挑战[J]. 复合材料学报, 2016, 33(7):1327-1338.XING Liying, BAO Jianwen, LI Songming, et al. Development status and facing challenge of advanced polymer matrix composites[J]. Acta Materiae Compositae Sinica,2016,33(7):1327-1338(in Chinese). [4] 杨智勇, 张博明, 解永杰, 等. 碳纤维复合材料空间反射镜制造技术研究进展[J]. 复合材料学报, 2017, 34(1):1-11.YANG Zhiyong, ZHANG Boming, XIE Yongjie, et al. Research progress on carbon fiber composite mirror technol-ogy[J]. Acta Materiae Compositae Sinica,2017,34(1):1-11(in Chinese). [5] 高禹, 张志松, 王柏臣, 等. 空天飞行器用炭/双马复合材料环境损伤行为的研究现状[J]. 高分子材料科学与工程, 2013, 29(6):165-168.GAO Yu, ZHANG Zhisong, WANG Baicheng, et al. Investi-gation of the environmental damage behaviors for carbon/bismaleimide composite used in aerospace flying vehicle[J]. Polymer Material Science and Engineering,2013,29(6):165-168(in Chinese). [6] HAN J H, KIM C G. Low earth orbit space environment si-mulation and its effects on graphite/epoxy composites[J]. Composite Structures,2006,72(2):218-226. doi: 10.1016/j.compstruct.2004.11.007 [7] HAROLD J K, DARRYL S. R. Graphite/epoxy composite adapters for the space shuttle/centaur vehicle[R]. NASA Technical Paper-3014, 1992. [8] 美国CMH-17协调委员会. 复合材料手册: 聚合物基复合材料. 第2卷, 材料性能[M]. 汪海, 沈真, 等译. 上海: 上海交通大学出版社, 2016.CMH-17 Coordinating Committee. Composites material handbook: Polymer matrix matrix composites. Volume 2, Material properties[M]. WANG Hai, SHEN Zhen, et al. Translate. Shanghai: Shanghai Jiaotong University Press, 2016(in Chinese). [9] 卢兆勇, 郑义, 隋阳, 等. 美国空天飞机计划验证飞行器结构、材料工艺及试验技术[J]. 航天制造技术, 2013(5):5-11.LU Zhaoyong, ZHENG Yi, SUI Yang, et al. Research of structure, material processing and test of the United States space airplane[J]. Aerospace Manufacturing Technology,2013(5):5-11(in Chinese). [10] 赵渠森. 先进战斗机用复合材料树脂基体[J]. 高科技纤维与应用, 2000, 25(3):21-28.ZHAO Qusen. Composite resin matrix for advanced mili-tary aircraft[J]. Hi-Tech Fiber & Application,2000,25(3):21-28(in Chinese). [11] 包建文. 高效低成本复合材料及其制造技术[M]. 北京: 国防工业出版社, 2012: 33-68.BAO Jianwen. High-efficient and law-cost manufacturing technology for advanced composites[M]. Beijing: National Defense Industry Press, 2012: 33-68(in Chinese). [12] THEODORE F. J, THOMAS S. G. High temperature poly-imide materials in extreme temperature environments[C]. 42nd AIAA/ASMBASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference and Exhibit, Seattle, 2001. [13] HATAKEYAMA S J, MCLVER K L. A high-temperature polymide composite for use on future reusable space vehicles[C]. AIAA Space 2000 Conference and Exposition, California, 2000. [14] HOU T H, JENSEN B J, HERGENROTHER P. M. Processing and Properties of IM7/PETI Composites[J]. Journal of Composite Materials,1996,30(1):109-122. doi: 10.1177/002199839603000107 [15] JOHNSON W S, PAVLICK M M, OLIVER M S. Determination of interlaminar toughness of IM7/977-2 composites at temperature extremes and different thicknesses[R]. NASA Final Report, Ga Tech Project Number E-18-A19, 2005. [16] CHARLES E H, JAMES H S, MARK J. S et al. An assessment of the state-of-the-art in the design and manufacturing of large composite structures for aerospace vehicles[R]. NASA Technical Memorandum, TM-2001-210844, 2001. [17] TANG Y, XIEY, PAN W P, et al. Thermal properties of PETI-5/IM7[J]. Thermochimica Acta,2000,357-358:239-249. doi: 10.1016/S0040-6031(00)00394-4 [18] PASRICHA A, TUTTLE M E, EMERY A F. Time-dependent response of IM7/5260 composites subjected to cyclic thermo-mechanical loading[J]. Composites Science and Technology,1995,55:49-56. doi: 10.1016/0266-3538(95)00095-X [19] DANIEL L, TUMINO G , HENRIKSEN T . Advanced compo-site technology in reusable launch vehicle (RLV)[C]. AIAA Space 2004 Conference and Exhibit, California, 2004. [20] CLINTON R G, MCMAHON W M, JOHNSTON N J, et al. Large composite structures processing technologies for reusable launch vehicles[C]. 4th Conference on Aerospace Materials, Processes, and Environmental Technology. Alabama, 2000. [21] COOK S A. The reusable launch vehicle technology program and the X-33 advanced technology demonstrator[R]. NASA Technical Memorandum, NASA-TM-111868, 1996. [22] DRAGONE T L. Structural innovations in design, manufacture, and testing on the X-34 reusable launch vehicle[C]. AIAA Space 2000 Conference and Exposition, California, 2000. [23] TENNEY D R, DAVIS J G, PIPES R B, et al. NASA composite materials development: lessons learned and future challenges[R]. NASA Report, LF99-9370, 2009. [24] 彭小波. 可重复使用新型航天飞行器结构设计[M]. 北京: 中国宇航出版社, 2006.PENG Xiaobo. Structural design of new reusable space vehicles [M] Beijing: China Astronautic Publishing House, 2006(in Chinese). [25] STARNES J H, DEXTER H B, JOHNSTON N J. Composite structures and materials research at NASA langley research center[R]. The NATO Research and Technology Agency Applied Vehicle Technical Panel Specialists' Meeting on Low Cost Composite Structure, Loen, 2001. [26] PENDLETON E, BIGGS R, COCHRAN R, et al. Integrated composite structures demonstration for future space launch vehicle airframe applications[C]. 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference, Hawaii, 2012. [27] TENNEY D R, DAVIS J G, JOHNSTON N J, et al. Structural framework for flight: NASA’s role in development of advanced composite materials for aircraft and space structures[R]. NASA Report, CR-2011-217076, 2011. [28] 吴建刚, 王晓广, 栗琳. 美国空天飞行器技术发展分析[C]. 第五届中国航空学会青年科技论坛, 南昌, 2012.WU Jiangang, WANG Xiaoguang, LI Lin. Analysis of U. S. aerospace vehicle technology development[C]. 5th Youth Science and Technology Forum of CAAC, Nanchang, 2012(in Chinese). [29] LETCHWORTH G F. X-33 reusable launch vehicle demonstrator, spaceport and range[R]. AIAA Space 2011 Conference, California, 2011. [30] 牛文, 李文杰, 叶蕾. 美国X-33空天飞行器项目回顾与总结[J]. 飞航导弹, 2014(7):13-17.NIU Wen, LI Wenjie, YE Lei. Review and summary of Ameri-can X-33 aerospace vehicle project[J]. Aerodynamic Missile Jounal,2014(7):13-17(in Chinese). [31] 冷洪霞, 卢亮, 吕剑. 美国X系列技术验证飞行器的发展[C]//张传超. 2013中国无人机系统峰会论文集. 北京: 航空工业出版社, 2013: 56-63.LENG Hongxia, LU Liang, LV Jian. Development of X series technology verification aircraft in the United States[C]//ZHANG Chuanchao. Proceedings of 2013 China UAV System Summit. Beijing: Aviation Industry Press, 2013: 56-63(in Chinese). [32] FREEMAN D C, TALAY T A, AUSTIN R E. Reusable launch vehicle technology program[C]. 47th International Astronautical Congress, Beijing, 1996. [33] CLINTON R G, EFFINGER M, SMITH D, et al. NASA’s earth-to-orbit space transportation pragram: A material overview[C]. 23rd Annual Conference on Composites, Mater-ials, and Structure, Florida, 1999. [34] 宋博, 李高峰. 美国X-37B轨道试验飞行器的发展及分析[J]. 飞航导弹, 2012(12): 3-9.SONG Bo, LI Gaofeng. Development and analysis of Ameri-can X-37B test vehicle[J]. Aerodynamic Missile Jounal, 2012(12): 3-9(in Chinese). [35] 吴奇龙, 谈何易, 周斌. X-37B太空作战平台应用构想[J]. 飞航导弹, 2020(11): 26-30.WU Qilong, TAN Heyi, ZHOU bin. Application conception of X-37B space combat platform[J]. Aerodynamic Missile Jounal, 2020(11): 26-30(in Chinese). [36] TURNER S. Flight demonstrations of orbital space plane (OSP) technologies[C]. AIAA/ICAS International Air and Space Symposium and Exposition, Ohio, 2003. [37] PAEZ C A. The development of the X-37 re-entry vehicle[C]. 40th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit, Florida, 2004. [38] ASADA S, NISHIWAKI K, NIITSU M, et al. Development of HOPE-X all-composite prototype ptructure[C]. AIAA/NAL-NASDA-ISAS 10th International Space Planes and Hypersonic Systems and Technologies Conference, Kyoto, 2001. [39] UZAWA K, NISHIWAKI K, NIITSU M, et al. Low cost fabircation of HOPE-X all-composite prototype ptructure[J]. Advanced Composite Materials,2005,14(3):289-304. doi: 10.1163/1568551054922593 [40] MALUCCHI G, ZACCAGNINO E, DROCCOA, et al. The European re-entry program, from IXV to ISV-GNC/avionics development status and challenges[C]. AIAA Guidance, Navigation, and Control (GNC) Conference, Massachusetts, 2013. [41] URBINATI F, BECCHIO V, VITA G. Design, development and manufacturing of the IXV aeroshell panels[C]. 13th European Conference on Spacecraft Structures, Materials & Environmental Testing, Braunschweig, 2014. [42] 康开华. 英国“云霄塔”空天飞机的最新进展[J]. 国际太空, 2014(7):42-50.KANG Kaihua. Latest development of British SKYLON vehicle[J]. Space International,2014(7):42-50(in Chinese). [43] 牛文, 李文杰, 胡冬, 等. 2014 年国外高超声速技术发展动态回顾[J]. 飞航导弹, 2015(1):27-34.NIU Wen, LI Wenjie, HU Dong, et al. Review on the development of hypersonic technology abroad in 2014[J]. Aerodynamic Missile Jounal,2015(1):27-34(in Chinese). [44] 牛文, 叶蕾, 李文杰等. 美国国防预先研究计划局启动XS-1空天飞行器项目[J]. 飞航导弹, 2014, 11:25-29.NIU Wen, YE Lei, LI Wenjie, et al. USA defence advaced research projects agency (DARPA) launches XS-1 aerospace vehicle program[J]. Aerodynamic Missile Jounal,2014,11:25-29(in Chinese). -

下载:

下载: