Preparation of polyimides containing carborane moiety and the thermal resistance mechanism

-

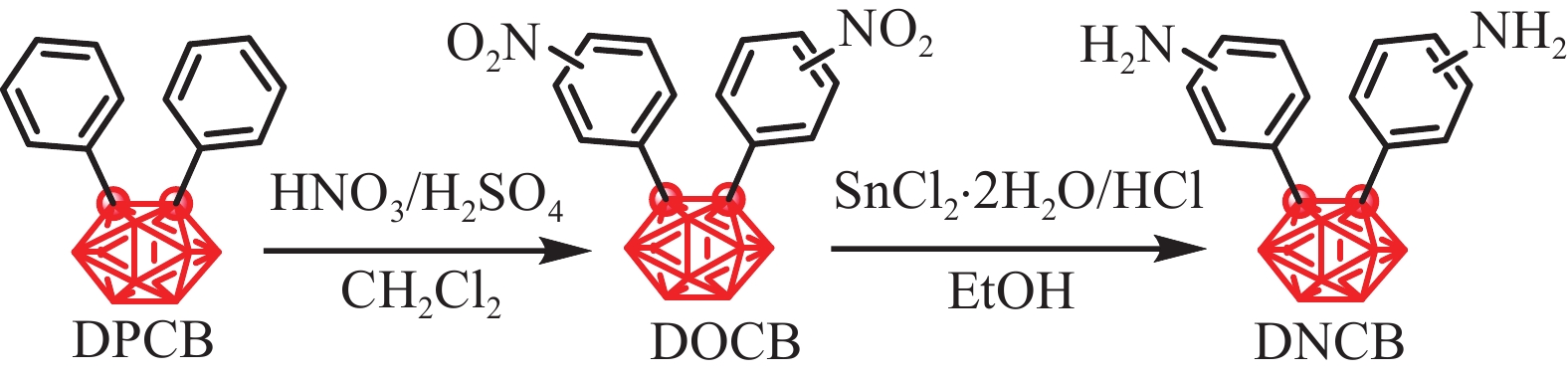

摘要: 聚酰亚胺是先进复合材料重要的基体材料之一。在聚酰亚胺主链中成功引入碳硼烷笼状单元,制备出一系列有机-无机杂化的聚酰亚胺材料。从单体设计入手,设计合成了含邻碳硼烷单元的二胺单体(DNCB),再与4,4'-二氨基二苯醚(ODA)和3,3',4,4'-苯甲酮四羧酸二酐(BTDA)进行共聚反应,合成前驱体聚酰胺酸(PAA)溶液并制备PAA薄膜,再经高温热亚胺化处理得到含碳硼烷单元的聚酰亚胺。对制备的聚酰亚胺材料的耐热性能和耐热氧化稳定性进行了系统研究,结果表明,碳硼烷单元的引入使聚酰亚胺基体的热稳定性和热氧化稳定性得到显著提升。当二胺单体中DNCB摩尔分数为40%时,N2气氛下,5wt% 热失重温度T5%提升近13℃,T10%提升近43℃,质量残留率高达82.6wt%;空气氛围下,T5%提升近36℃,T10%提升近64℃,质量残留率高达83.1wt%。X-射线光电子能谱(XPS)及扫描电镜(SEM)结果表明在聚酰亚胺主链中引入碳硼烷笼状单元后在高温环境中易在材料表面形成氧化硼(B2O3)钝化层,从而显著提升材料的耐热氧化稳定性。Abstract: A series of polyimide materials were successfully prepared by embedding o-carborane cage structure into polyimide main chains. First, the diamine monomer (DNCB) containing o-carborane unit was designed and synthesized, and then copolymerized with 4,4'-diaminodiphenyl ether (ODA) and 3,3',4,4'-benzophenone tetracarboxylic anhydride (BTDA) to synthesize the polyamic acid (PAA) precursor solution. PAA films were prepared by solution casting method, and then polyimide films containing different contents of carborane unit were obtained after high-temperature thermal imidization. Thermogravimetric analysis (TGA) shows that the addition of DNCB significantly improves the thermal stability and thermal oxidation stability of polyimide materials. When the molar content of DNCB in all diamines reaches 40%, the temperature corresponding to 5wt% mass loss (T5%) increases by nearly 13℃, T10% increases by nearly 43℃ and the mass residual rate was as high as 82.6wt%. Under the air atmosphere, T5% increases by nearly 36℃, T10% increases by nearly 64℃, and the mass residual rate reaches as high as 83.1wt%. This is due to the oxidation of carborane cage and the formation of multi-layer passivation protective layer on the surface of the film, which prevents the degradation of internal polymer materials in contact with oxygen.

-

表 1 聚酰亚胺的DNCB摩尔分数汇总

Table 1. Summary of DNCB mole percent of polyimides

Code BTDA∶ODA∶DNCB (Molar ratio) DNCB content

(Molar percentage)PI 100∶100∶0 — 10DNCB/PI 100∶90∶10 10.0 20DNCB/PI 100∶80∶20 20.0 30DNCB/PI 100∶70∶30 30.0 40DNCB/PI 100∶60∶40 40.0 表 2 20DNCB/PI中各元素的理论值和测试值

Table 2. Calculated and experimental values of different elements in the 20DNCB/PI

Elemental content C/at% N/at% O/at% B/at% Calculated value 69.01 5.48 18.14 4.23 XPS analysis 72.47 4.24 17.71 5.58 表 3 xDNCB/PI的分子量

Table 3. Molecular weight data of xDNCB/PI

Code Mn/(g·mol−1) Mw/(g·mol−1) PDI PI 93815 193315 2.06 10DNCB/PI 74001 176173 2.38 20DNCB/PI 69068 105342 1.53 30DNCB/PI 65757 98810 1.50 40DNCB/PI 54147 78799 1.45 Notes: Mn—Number-average molecular weight; Mw—Weight-average molecular weight; PDI—Polymer dispersity index. 表 4 N2氛围下xDNCB/PI的热重分析数据

Table 4. TGA data of xDNCB/PI in N2

Code T5%/℃ T10%/℃ Residue at

900℃/wt%PI 554.3 574.4 60.3 10DNCB/PI 562.0 589.4 65.8 20DNCB/PI 562.1 595.0 69.1 30DNCB/PI 562.6 601.9 78.1 40DNCB/PI 566.9 617.4 82.6 Notes: T5%—Temperature for 5wt% mass loss; T10%—Temperature for 10wt% mass loss. 表 5 空气氛围下xDNCB/PI的热重分析数据

Table 5. TGA data of xDNCB/PI in air

Code T5%/℃ T10%/℃ Residue at 900℃/wt% PI 545.5 572.4 0.6 10DNCB/PI 556.4 579.7 13.6 20DNCB/PI 561.5 586.8 39.0 30DNCB/PI 564.8 589.3 67.3 40DNCB/PI 581.8 635.9 83.1 -

[1] QU X M, JI M, FAN L, et al. Thermoset polyimide matrix resins with improved toughness and high Tg for high temperature carbon fiber composites[J]. High Performance Polymers,2011,23(4):281-289. doi: 10.1177/0954008311403839 [2] KARGER-KOCSIS J, MAHMOOD H, PEGO-RETTI A. Recent advances in fiber/matrix interphase engineering for polymer composites[J]. Progress in Materials Science,2015,73:1-43. doi: 10.1016/j.pmatsci.2015.02.003 [3] LAU K S Y. High-performance polyimides and high tempera-ture resistant polymers[M]. California: Chemco Systems, Inc., 2014: 297-424. [4] 刘仪, 莫松, 潘玲英, 等. 耐高温有机无机杂化聚酰亚胺树脂及其复合材料[J]. 宇航材料工艺, 2018, 48(3):1-5.LIU Yi, MO Song, PAN Lingying, et al. High temperature resistant organic-inorganic hybrid polyimide resin and its composite materials[J]. Aerospace Materials & Technology,2018,48(3):1-5(in Chinese). [5] 王天琦, 肖国勇, 鲁云华, 等. 镧系金属有机骨架/聚酰亚胺复合材料的制备及其性能[J]. 复合材料学报, 2018, 35(11):2927-2934.WANG Tianqi, XIAO Guoyong, LU Yunhua, et al. Preparation and properties of lanthanide metal-organic frameworks/polyimide composites[J]. Acta Materiae Compositae Sinica,2018,35(11):2927-2934(in Chinese). [6] LIU Z Y, LIU Y, QIU W L, et al. Molecularly engineered 6FDA-based polyimide membranes for sour natural gas separation[J]. Angewandte Chemie International Edition,2020,59(35):14877-14883. doi: 10.1002/anie.202003910 [7] WU A X, DRAYTON J A, RODRIGUEZ K M, et al. Influence of aliphatic and aromatic fluorine groups on gas permeability and morphology of fluorinated polyimide films[J]. Macromolecules,2020,53(13):5085-5095. doi: 10.1021/acs.macromol.0c01024 [8] PARK Y S, JEE M H, BAIK D H. Preparation and characterization of electrospun multi-layered polyimide nanoweb with enhanced mechanical properties[J]. Fibers and Polymers, 2021, 23(2): 360-365. [9] QIAN G T, CHEN H Q, SONG G L, et al. Superheat-resistant polyimides with ultra-low coefficients of thermal expansion[J]. Polymer,2020,196:188482. [10] LIAN R H, LEI X F, XUE S Y, et al. Janus polyimide films with outstanding AO resistance, good optical transparency and high mechanical strength[J]. Applied Surface Science,2021,535:147654. doi: 10.1016/j.apsusc.2020.147654 [11] LIU Y W, TANG A, TAN J H, et al. Structure and gas barrier properties of polyimide containing a rigid planar fluorene moiety and an amide group: Insights from molecular simulations[J]. ACS Omega,2021,6(6):4273-4281. doi: 10.1021/acsomega.0c05278 [12] LIU T Q, ZHENG F, MA X R, et al. High heat-resistant polyimide films containing quinoxaline moiety for flexible substrate applications[J]. Polymer,2020,209:122963. doi: 10.1016/j.polymer.2020.122963 [13] MEKURIA T D, WANG L, ZHANG C H, et al. Synthesis and characterization of high strength polyimide/silicon nitride nanocomposites with enhanced thermal and hydrophobic properties[J]. Chinese Journal of Chemical Engineering,2021,32:446-453. doi: 10.1016/j.cjche.2020.09.066 [14] OU X H, CHEN S S, LU X M, et al. Enhancement of thermal conductivity and dimensional stability of polyimide/boron nitride films through mechanochemistry[J]. Composites Communications,2021,23:100549. doi: 10.1016/j.coco.2020.100549 [15] OTHMAN M B H, RAMLI R, ARIFF Z M, et al. Thermal properties of polyimide system containing silicone segments[J]. Journal of Thermal Analysis and Calorimetry,2012,109(3):1515-1523. doi: 10.1007/s10973-011-1893-y [16] LI X M, WU J Y, TANG C Y, et al. High temperature resistant polyimide/boron carbide composites for neutron radiation shielding[J]. Composites Part B: Engineering,2019,159:355-361. doi: 10.1016/j.compositesb.2018.10.003 [17] VINOGRADOVA S V, VALETSKII P M, KABACHII Y A. Polymers with arylenedicarbadodecaborane fragments in the chain[J]. Russian Chemical Reviews,1995,64(4):365-388. doi: 10.1070/RC1995v064n04ABEH000155 [18] ENDO Y, SONGKRAM C, YAMASAKI R, et al. Molecular construction based on icosahedral carboranes and aromatic N,N'-dimethylurea groups. Aromatic layered molecules and a transition metal complex[J]. Journal of Organometallic Chemistry,2002,657(1):48-58. [19] HUANG X, ZHANG Q H, MENG Z, et al. Greatly enhanced thermo-oxidative stability of polybenzoxazine thermoset by incorporation of m-carborane[J]. Journal of Polymer Science Part A: Polymer Chemistry,2015,53(8):973-980. doi: 10.1002/pola.27525 [20] LI N, ZENG F L, QU D Z, et al. Synthesis and characterization of carborane-containing polyester with excellent thermal and ultrahigh char yield[J]. Journal of Applied Polymer Science,2016,133(46):44202. [21] CUI M L, ZHANG L L, LOU P P, et al. Study on thermal degradation mechanism of heat-resistant epoxy resin modified with carboranes[J]. Polymer Degradation and Stability,2020,176:10913. [22] GOYAL S, FORRESTER M J, COVERDELL D, et al. High-temperature-performance cyanate ester composites with carboranes[J]. Macromolecules,2021,54(19):9155-9164. doi: 10.1021/acs.macromol.1c01410 -

下载:

下载: