Effect of Ti811 and TC4 titanium alloy substrate on microstructures and properties of laser cladding self-lubricating composite coatings

-

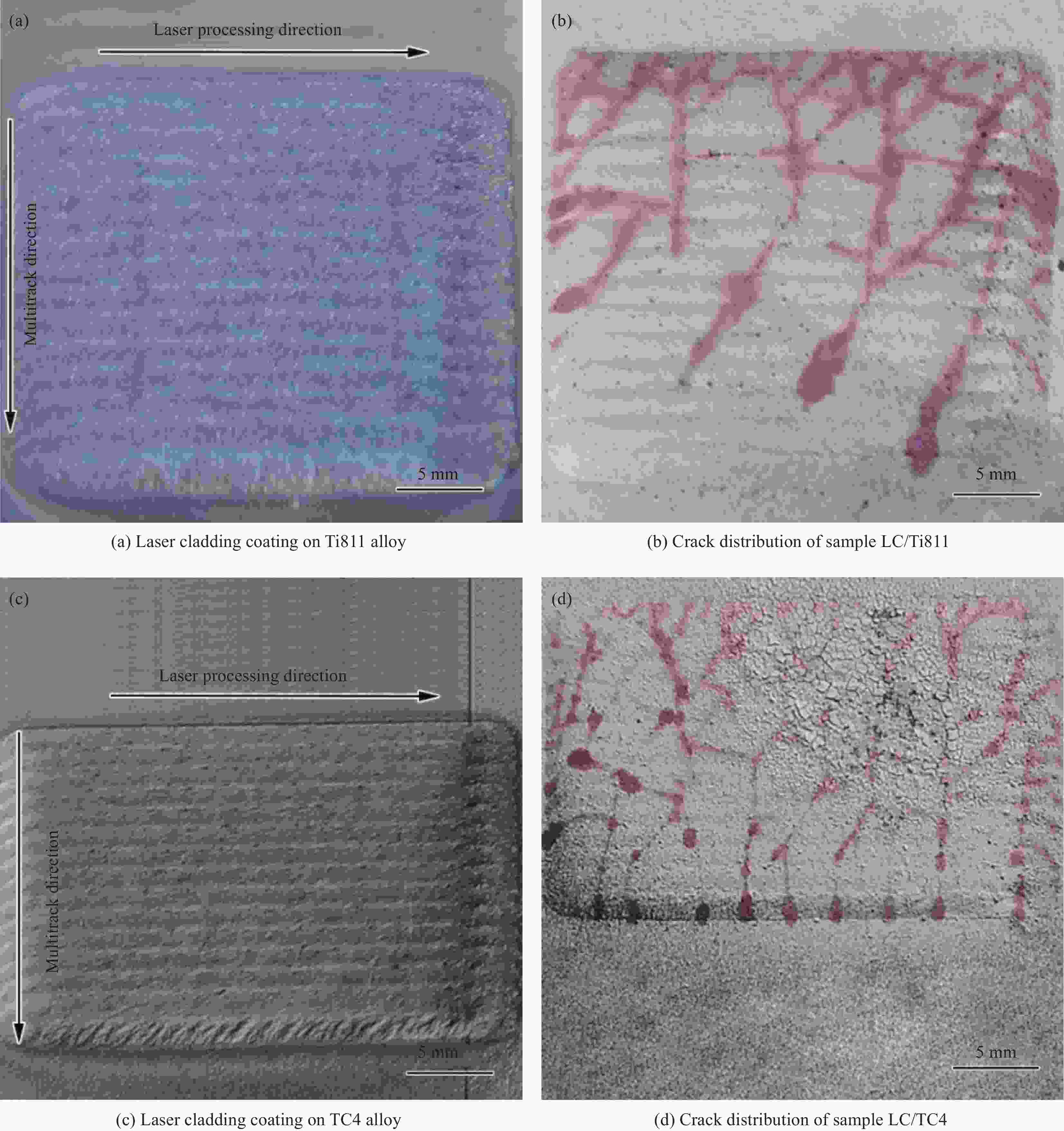

摘要: 为研究不同钛合金基材对激光熔覆自润滑耐磨涂层组织与性能的影响,采用同轴送粉技术,在Ti811合金和TC4合金表面分别熔覆TC4、Ni45、Al2O3、MoS2和稀土氧化物Y2O3混合粉末,用渗透测试观察熔覆层表面裂纹分布,利用SEM、EDS、XRD等测试技术分析激光熔覆层的元素分布及物相组成,并表征熔覆层的显微硬度和摩擦磨损性能。基材元素成分不同导致涂层物相差异,V元素含量高的TC4合金涂层α-Ti的析出比Ti811合金的少;并且基材的热物理性能对涂层裂纹分布、组织形貌与性能具有显著影响,导热系数低且密度高的TC4合金激光熔覆温度梯度较小,涂层裂纹面积较小,稀释率大,涂层组织更粗大;由于Ti811合金导热性好,冷却速度高,涂层组织更细小,硬度更高,平均硬度达到1303.5 HV0.5。两种熔覆层磨损量降低,摩擦系数均降至0.3以下。硬质相强化和软质相润滑的共同作用可提高熔覆表面的耐磨性能。Abstract: In order to research the effect of substrate on microstructure and properties of laser cladding self-lubricating coating, laser cladding was carried out on the surface of Ti811 alloy and TC4 alloy by coaxial powder-feeding laser cladding technology using TC4, Ni45, Al2O3, MoS2 and rare earth oxide Y2O3 powder mixture as cladding material. The surface crack distribution of cladding layer was observed by penetration test. The elemental distribution and microstructure of coatings were analyzed by SEM, EDS and XRD. Microhardness and tribological properties of the coatings were examined. The results show that the element composition on the substrate can cause the difference of cladding layer phases. Because of the high content of element V, the precipitation of α-Ti on TC4 alloy is less than that of the laser cladding layer on Ti811 alloy. The thermal conductivity of substrates has a significantly impact on the microstructure and performance of the coatings. Because of low thermal conductivity and high density, TC4 alloy has low temperature gradient during laser cladding. As a result, the coating on TC4 alloy has less cracks, higher dilution rate, and coarser microstructure. The average hardness of coating on Ti811 substrate reaches up to 1303.5 HV0.5 attributes to its good conductivity and high cooling rate. The wear mass losing of the cladding coatings on two alloys is significantly reduced, and the average friction coefficient drops to below 0.3. Due to the reinforcement of hard phase and anti-fiction of soft phase, laser cladding coatings on different substrates both have excellent wear resistance property.

-

Key words:

- laser cladding /

- composite coatings /

- titanium alloy /

- microstructure /

- tribological properties

-

表 1 Ti811和TC4合金主要化学成分

Table 1. Main chemical composition of Ti811 and TC4 alloy

wt% Material Al V Mo C N Fe O Ti Ti811 8.10 0.99 1.05 0.03 0.01 0.05 0.06 Banlance TC4 6.01 3.80 – 0.10 0.05 0.30 0.20 Banlance 表 2 TC4和Ni45粉末主要化学成分

Table 2. Main chemical composition of TC4 and Ni45 powders

wt% Material Al V Fe C N O H Cr B Si Ni Ti TC4 5.5-6.8 3.5-4.5 0.30 0.10 0.05 0.20 0.015 – – – – Bal. Ni45 – – 3.00 0.35 – – – 8.9 1.8 4.0 Bal. – 表 3 激光熔覆试验工艺参数

Table 3. Process parameters of laser cladding experiment

Laser

power/WLaser scanning

velocity/(mm·min−1)Beam

diameter/mmPower feeding

rate/(r·min−1)Discharge of power

gas/(L·min−1)Protective gas

flow/(L·min−1)Laser focal

length/mmMulti-path

rate/%900 400 3 1.4 7 11 16 50 表 4 Ti811和TC4合金与熔覆层主要生成物在20℃下的性能[27-29]

Table 4. Performances of Ti811 alloy, TC4 alloy and major products in cladding layer at 20℃[27-29]

Material Density/

(kg·m–3)Thermal conductivity/

(W·m−1·K−1)Coefficient of linear

expansion/(μm·℃−1)Elastic modulus/

GPaYield strength/ MPa Elongation/

%Hardness/

HVTi811 4350 7.25 8.53 118 950 17 390 TC4 4440 6.43 9.00 100 830 10 330 TiC 4990 – 6.50-7.15 440 – – – Ti2Ni 5770 – 4.05 128 – – – 表 5 不同基材激光熔覆层特征相能谱分析结果

Table 5. Energy spectrum analysis results of feature phase of laser cladding coating with different substrate

C O Al Si Ti V Cr Ni Sample LC/Ti811 A1 wt% 17.34 – 4.4 – 65.42 1.94 1.99 8.91 at% 45.11 – 5.09 – 42.67 1.19 1.19 4.74 A2 wt% 12.66 – 6.05 – 56.1 1.99 2.38 20.82 at% 36.49 – 7.76 – 40.54 1.36 1.59 12.27 A3 wt% – – 7.89 1.83 55.22 2.29 3.27 29.17 at% – – 13.79 3.08 54.35 2.12 2.97 23.42 A4 wt% 7.51 – 3.93 – 85.24 0.28 0.47 2.58 at% 23.97 – 5.58 – 68.21 0.21 0.34 1.68 A5 wt% 4.27 – 4.49 – 88.38 – – 2.86 at% 14.72 – 6.89 – 76.38 – – 2.02 A6 wt% 7.31 6.85 7.43 – 60.98 – – 17.42 at% 21.13 14.86 9.55 – 44.17 – – 10.29 Sample LC/TC4 B1 wt% 14.43 – 3.01 – 65.42 0.74 1.47 14.93 at% 44.16 4.1 42.67 0.54 2.04 6.49 B2 wt% 13.32 – 5.2 – 57.15 1.13 2.68 20.52 at% 37.44 7.00 44.04 0.82 1.91 8.68 B3 wt% 2.84 – 4.9 – 86.51 0.88 2.57 2.92 at% 9.35 7.17 78.97 0.69 1.95 1.87 B4 wt% – 3.97 8 – 51.80 2.56 4.74 28.84 at% 10.98 13.11 47.81 2.22 4.03 21.72 -

[1] 张喜燕, 赵永庆, 白晨光. 钛合金及应用[M]. 北京: 化学工业出版社, 2005.ZHANG Xiyan, ZHAO Yongqing, BAI Chenguang. Titanium alloy and its application[M]. Beijing: Chemical Industry Press, 2005(in Chinese). [2] 邓炬. 钛与航空[J]. 钛工业进展, 2004, 21(2):6-15. doi: 10.3969/j.issn.1009-9964.2004.02.001DENG Ju. Titanium and aerospace[J]. Titanium Industry Progress,2004,21(2):6-15(in Chinese). doi: 10.3969/j.issn.1009-9964.2004.02.001 [3] 刘彬, 刘延斌, 杨鑫, 等. TITANIUM 2008: 国际钛工业, 制备技术与应用的发展现状[J]. 粉末冶金材料科学与工程, 2009, 14(2):67-73. doi: 10.3969/j.issn.1673-0224.2009.02.001LIU Bin, LIU Yanbin, YANG Xin, et al. TITANIUM 2008: The international titanium industry, preparation technology and application development[J]. Powder Metallurgy Materials Science and Engineering,2009,14(2):67-73(in Chinese). doi: 10.3969/j.issn.1673-0224.2009.02.001 [4] 金和喜, 魏克湘, 李建明, 等. 航空钛合金研究进展[J]. 中国有色金属学报, 2015, 25(2):280-292.JIN Hexi, WEI Kexiang, LI Jianming, et al. Research development of titanium alloy in aerospace industry[J]. The Chinese Journal of Nonferrous Metals,2015,25(2):280-292(in Chinese). [5] LÜTJERING G, WILLIAMS J C. Titanium (engneering materials and processes)[M]. Manchester: Springer, 2003: 251-255. [6] MOLINARI A, STRAFFELINI G, TESI B, et al. Dry sliding wear mechanisms of the Ti6Al4V alloy[J]. Wear,1997,208(12):105-112. [7] 张志强, 杨凡, 张宏伟, 等. 含稀土TiCx增强钛基激光熔覆层组织与耐磨性[J]. 航空学报, 2021, 42(7):624115.ZHANG Zhiqiang, YANG Fan, ZHANG Hongwei, et al. Microstructure and wear resistance of TiCx reinforced Ti-based laser cladding coating with rare earth[J]. Acta Aeronautica et Astronautica Sinica,2021,42(7):624115(in Chinese). [8] 张蕾涛, 刘德鑫, 张伟樯, 等. 钛合金表面激光熔覆涂层的研究进展[J]. 表面技术, 2020, 49(8):97-104.ZHANG Leitao, LIU Dexin, ZHANG Weiqiang, et al. Research progress of laser cladding coating on titanium alloy surface[J]. Surface Technology,2020,49(8):97-104(in Chinese). [9] SOUZA C A C, RIBEIRO D V, KIMINAMI C S. Corrosion re-sistance of Fe-Cr-based amorphous alloys: An overview[J]. Journal of Non-crystalline Solids,2016,442:56-66. doi: 10.1016/j.jnoncrysol.2016.04.009 [10] 李响, 来佑彬, 于锦, 等. 高能束熔覆制备耐磨涂层技术研究现状与展望[J]. 表面技术, 2021, 50(2):134-159.LI Xiang, LAI Youbin, YU Jin, et al. Research status and prospect of wear-resistant coating prepared by high power density beam cladding[J]. Surface Technology,2021,50(2):134-159(in Chinese). [11] ZHAO Y, YU T B, SUN J Y, et al. Microstructure and properties of laser cladded B4C/TiC/Ni-based composite coating[J]. International Journal of Refractory Metals and Hard Materials,2020,86:105112. doi: 10.1016/j.ijrmhm.2019.105112 [12] 孙荣禄, 牛伟, 雷贻文, 等. 钛合金TC4激光熔覆NiCrBSi+Ni/MoS2涂层组织和摩擦磨损性能[J]. 材料热处理学报, 2014, 35(6):157-162.SUN Ronglu, NIU Wei, LEI Yiwen, et al. Microstructure and tribological properties of laser clad NiCrBSi+Ni/MoS2 coating on TC4 titanium alloy[J]. Transactions of Materials and Heat Treatment,2014,35(6):157-162(in Chinese). [13] LIU X B, MENG X J, LIU H Q, et al. Development and characterization of laser clad high temperature self-lubrication wear resistant composite coatings on Ti-6Al-4V alloy[J]. Materials & Design,2014,55(6):404-409. [14] 石皋莲, 吴少华, 陆小龙, 等. TA2钛合金表面激光熔覆Ti2SC/TiS自润滑耐磨复合涂层组织与性能[J]. 材料热处理学报, 2016, 37(7):198-202.SHI Gaolian, WU Shaohua, LU Xiaolong, et al. Microstructure and property of laser clad Ti2SC/TiS self-lubrication anti-wear composite coating on TA2 titanium alloy[J]. Transactions of Materials and Heat Treatment,2016,37(7):198-202(in Chinese). [15] 刘亚楠, 孙荣禄, 张天刚, 等. CeO2含量对激光熔覆自润滑涂层微观组织和性能的影响[J]. 激光与光电子学进展, 2018, 55(11):277-284.LIU Yanan, SUN Ronglu, ZHANG Tiangang, et al. Effect of CeO2 content on microstructure and properties of laser cladded self-lubricant coatings[J]. Chinese Journal of Lasers,2018,55(11):277-284(in Chinese). [16] 王勇刚, 刘和剑, 回丽, 等. 激光熔覆原位自生碳化物增强自润滑耐磨复合涂层的高温摩擦学性能[J]. 材料工程, 2019, 47(5):72-78. doi: 10.11868/j.issn.1001-4381.2018.000409WANG Yonggang, LIU Hejian, HUI Li, et al. High tempera-ture tribological properties of laser cladding in-situ carbide reinforced self-lubricating[J]. Journal of Materials Engineering,2019,47(5):72-78(in Chinese). doi: 10.11868/j.issn.1001-4381.2018.000409 [17] 刘发兰, 赵树森, 高文焱, 等. 基材属性对Ni60A-WC激光熔覆涂层性能的影响[J]. 中国有色金属学报, 2014, 24(5):1319-1326.LIU Falan, ZHAO Shusen, GAO Wenyan, et al. Effect of substrate on Ni60A-WC laser cladding coatings[J]. The Chinese Journal of Nonferrous Metals,2014,24(5):1319-1326(in Chinese). [18] 高广睿, 刘道新, 张晓化. Ti811 合金的高温微动疲劳行为[J]. 中国有色金属学报, 2005, 15(1):38-43. doi: 10.3321/j.issn:1004-0609.2005.01.006GAO Guangrui, LIU Daoxin, ZHANG Xiaohua. The high temperature of Ti811 alloy micro fatigue behavior[J]. The Chinese Journal of Nonferrous Metals,2005,15(1):38-43(in Chinese). doi: 10.3321/j.issn:1004-0609.2005.01.006 [19] 郑启池, 金亚娟, 李瑞峰, 等. 功率输入对激光熔覆镍基涂层组织和裂纹生成的影响[J]. 江苏科技大学学报(自然科学版), 2017, 31(3):293-297.ZHENG Qichi, JIN Yajuan, LI Ruifeng, et al. Effect of power input on microstructure and crack formation of Ni based coating by laser cladding[J]. Journal of Jiangsu University Science and Technology (Natural Science Edition),2017,31(3):293-297(in Chinese). [20] ZHOU S F, ZENG X Y, HU Q W, et al. Analysis of crack behavior for Ni-based WC composite coatings by laser cladding and crack-free realization[J]. Applied Surface Science,2008,255(5):1646-1653. doi: 10.1016/j.apsusc.2008.04.003 [21] 张磊, 陈小明, 刘伟, 等. 激光熔覆Ni基合金裂纹的形成机理及敏感性[J]. 激光与光电子学进展, 2019, 56(11):168-175.ZHANG Lei, CHEN Xiaoming, LIU Wei, et al. Formation mechanism and sensitivity of cracks in laser-cladded Ni-based-alloy coatings[J]. Laser & Optoelectronics Process,2019,56(11):168-175(in Chinese). [22] KADOLKAR P B, WATKINS T R, DE HOSSON J T M, et al. State of residual stress in laser-deposited ceramic compo-site coatings on aluminum alloys[J]. Acta Materialia,2007,55(4):1203-1214. doi: 10.1016/j.actamat.2006.07.049 [23] 余廷, 邓琦林, 张伟, 等. 激光熔覆NiCrBSi合金涂层的裂纹形成机理[J]. 上海交通大学学报, 2012, 46(7):1043-1048.YU Ting, DENG Qilin, ZHANG Wei, et al. Study on cracking mechanism of laser clad NiCrBSi coating[J]. Journal of Shanghai Jiaotong University,2012,46(7):1043-1048(in Chinese). [24] 钟燕. 异种金属摩擦焊先顶后刹过程的数值模拟及工艺研究[D]. 西安: 西北工业大学, 2006.ZHONG Yan. Different metal friction welding numerical simulation on forging process and parameter study[D]. Xi'an: Northwestern Polytechnical University, 2006(in Chinese). [25] 鲁耀钟, 雷卫宁, 任维彬, 等. 激光熔覆 Inconel718合金裂纹分析及裂纹控制研究[J]. 表面技术, 2020, 49(9):233-243.LU Yaozhong, LEI Weining, REN Weibin, et al. Crack analysis and control of laser cladding Inconel718 alloy[J]. Surface Technology,2020,49(9):233-243(in Chinese). [26] 路世盛, 周建松, 王凌倩, 等. 钛合金表面激光熔覆陶瓷涂层的研究进展[J]. 表面技术, 2019, 48(11):82-90.LU Shisheng, ZHOU Jiansong, WANG Lingqian, et al. Development of laser cladding ceramic coatings on titanium alloy surface[J]. Surface Technology,2019,48(11):82-90(in Chinese). [27] MARKOVSKY P E, SAVVAKIN D G, IVASISHIN O M, et al. Mechanical behavior of titanium-based layered structures fabricated using blended elemental powder metallurgy[J]. Journal of Materials Engineering and Performance,2019,28(9):5772-5792. doi: 10.1007/s11665-019-04263-0 [28] 梁广冰, 朱锦洪, 尹丹青, 等. TC4钛合金激光熔覆路径选择数值模拟研究[J]. 河南科技大学学报(自然科学版), 2021, 42(6):12-18.LIANG Guangbing, ZHU Jinhong, YIN Danqing, et al. Numerical simulation of laser cladding path selection for TC4 titanium alloy[J]. Journal of Henan University of Science and Technology (Natural Science),2021,42(6):12-18(in Chinese). [29] 王田. 航空发动机压气机叶片用Ti-811合金棒材热连轧工艺研究[D]. 西安: 西安建筑科技大学, 2019.WANG Tian. Research on the hot tandem rolling process of Ti-811 alloy in aero-engine compressor blade[D]. Xi’an: Xi’an University of Architecture and Technology, 2019(in Chinese). [30] 谢映光, 王成磊, 张可祥, 等. 数值模拟和稀土调控改性结合优化铝合金表面激光熔覆[J]. 表面技术, 2020, 49(12):144-155.XIE Yingguang, WANG Chenglei, ZHANG Kejian, et al. Optimizing laser cladding on aluminum alloy surface with numerical simulation and rare earth modification[J]. Surface Technology,2020,49(12):144-155(in Chinese). [31] 李德英, 张坚, 赵龙志, 等. 超声作用下激光熔覆SiC/316L复合涂层残余应力数值模拟[J]. 复合材料学报, 2016, 33(10):2270-2276.LI Deying, ZHANG Jian, ZHAO Longzhi, et al. Numerical simulation of residual stress in SiC/316L composite coating by ultrasonic aided laser cladding[J]. Acta Materiae Compositae Sinica,2016,33(10):2270-2276(in Chinese). [32] 邹海贝. TC4钛合金热处理强化工艺及相变行为研究 [D]. 秦皇岛: 燕山大学, 2019.ZOU Haibei. Study on heat treatment strengthening and phase transformation behavior of TC4 titanium alloy[D]. Qinhuangdao: Yanshan University, 2019(in Chinese). [33] QUAZIL M, FAZAL M, HASEEB A, et al. Effect of rare earth elements and their oxides on tribo-mechanical perfor-mance of laser claddings: A review[J]. Journal of Rare Earths,2016,34(6):549-564. doi: 10.1016/S1002-0721(16)60061-3 [34] 张天刚, 庄怀风, 姚波, 等. Y2O3对钛基激光熔覆层组织与性能的影响[J]. 复合材料学报, 2020, 27(6):1390-1400.ZHANG Tiangang, ZHUANG Huaifeng, YAO Bo, et al. Effect of Y2O3 on microstructure and properties fo Ti-based laser cladding layer[J]. Acta Materiae Compositae Sinica,2020,27(6):1390-1400(in Chinese). [35] 章小峰, 王爱华, 张祥林, 等. 激光熔覆Ni45-CaF2-WS2自润滑涂层组织与性能[J]. 中国有色金属学报, 2008, 18(2):215-219. doi: 10.3321/j.issn:1004-0609.2008.02.004ZHANG Xiaofeng, WANG Aihua, ZHANG Xianglin, et al. Microstructure and tribological properties of laser cladding Ni45-CaF2-WS2 self-lubrication coating[J]. The Chinese Journal of Nonferrous Metals,2008,18(2):215-219(in Chinese). doi: 10.3321/j.issn:1004-0609.2008.02.004 [36] 刘亚楠, 谷米, 孙荣禄, 等. 钛合金表面激光熔覆原位制备TiC/Ti2Ni复合涂层微观组织与性能研究[J]. 中国激光, 2021, 48(14):1402011. doi: 10.3788/CJL202148.1402011LIU Yanan, GU Mi, SUN Ronglu, et al. Micro structure and properties of in-situ TiC/Ti2Ni composite coating prepared via laser cladding on titanium alloy[J]. Chinese Journal of Lasers,2021,48(14):1402011(in Chinese). doi: 10.3788/CJL202148.1402011 [37] ZHANG P L, LIU X P, LU Y L, et al. Microstructure and wear behavior of Cu-Mo-Si coatings by laser cladding[J]. Applied Surface Science,2014,311(30):709-714. [38] 高秋实, 闫华, 秦阳, 等. 钛合金表面激光熔覆Ti-Ni+TiN+MoS2/TiS自润滑复合涂层[J]. 材料研究学报, 2018, 32(12):921-928. doi: 10.11901/1005.3093.2018.163GAO Qiushi, YAN Hua, QIN Yang, et al. Self-lubricating wear resistant composite coating Ti-Ni+TiN+MoS2/TiS prepared on Ti-6Al-4V alloy by laser cladding[J]. Chinese Journal of Materials Research,2018,32(12):921-928(in Chinese). doi: 10.11901/1005.3093.2018.163 [39] 雷临苹, 叶宏, 宋坤, 等. Al2O3-TiO2对铝合金表面激光熔覆NiAl涂层组织性能的影响[J]. 表面技术, 2018, 47(10):145-150.LEI Linping, YE Hong, SONG Kun, et al. Effect of Al2O3-TiO2 on microstructure and properties of NiAl coating by laser cladding on aluminum alloy[J]. Surface Technology,2018,47(10):145-150(in Chinese). -

下载:

下载: