Effect of few-layer graphene on the fluidity and mechanical properties of cement paste

-

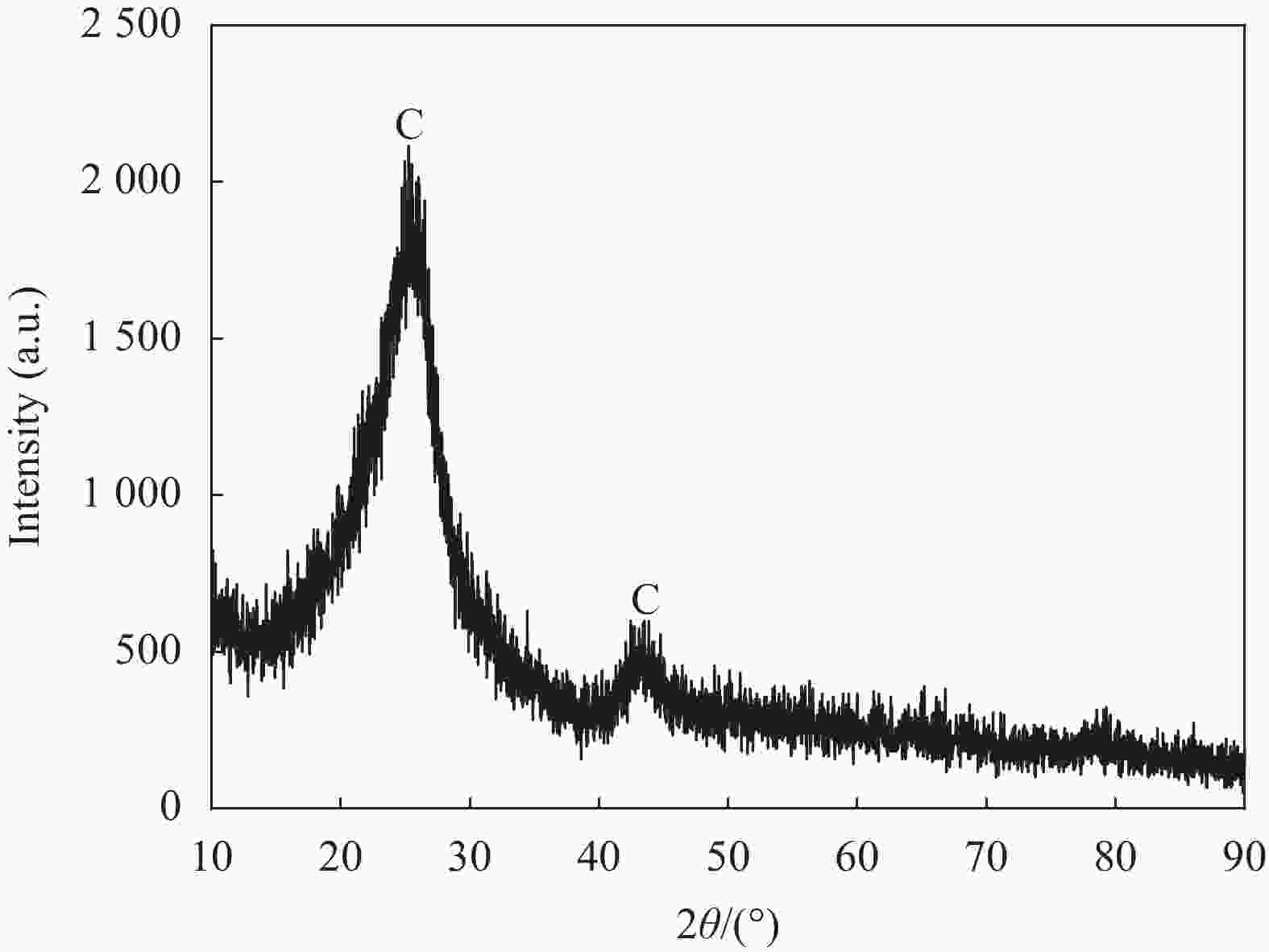

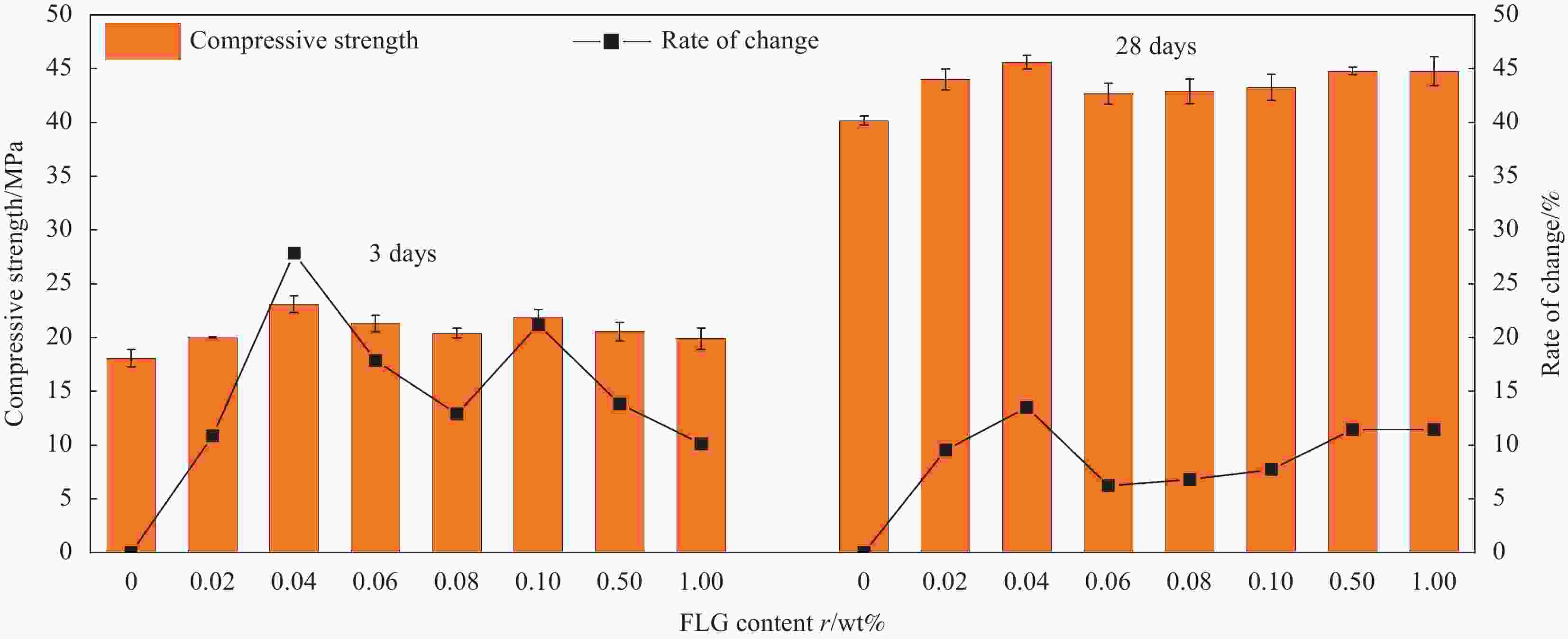

摘要: 系统研究了少层石墨烯(FLG)对水泥净浆流动性能和力学性能(抗压强度和抗折强度)的影响,通过SEM、XRD、EDS剖析了FLG对净浆力学性能影响的作用机制。同时利用AFM、Raman、SEM等技术表征了FLG的层数和结构。结果表明:FLG的层数在3~6层,呈现六角型蜂窝结构,有层间堆叠现象。FLG的掺入能降低净浆的流动性,净浆3 天和28 天抗压强度分别提升了27.84%和13.52%,3 天和28天抗折强度分别提升了12.92%和19.68%。FLG具有模板效应,能够促进水泥水化产物的生长,改变水化晶体的形状、尺寸,使其有形成完整、致密的趋势,使净浆结构更加密实。Abstract: The effects of few-layer graphene (FLG) on the fluidity and mechanical properties (compressive strength and flexural strength) of cement paste were systematically studied. The mechanism of the effect of FLG on the mechanical properties of cement paste was analyzed by SEM, XRD and EDS. Meanwhile, the layers and structures of FLG were characterized by AFM, Raman and SEM techniques. The results show that the number of FLG layers is 3-6, showing a hexagonal honeycomb structure with interlayer stacking. The incorporation of FLG can reduce the fluidity of the paste. The 3 days and 28 days compressive strength values of the paste increase by 27.84% and 13.52%, respectively, and the 3 days and 28 days flexural strength values increase by 12.92% and 19.68%, respectively. The template effect of FLG can promote the growth of cement hydration products, change the shape and size of hydration crystals, and make it form a complete and dense trend, and make the paste structure more dense.

-

Key words:

- few-layer graphene /

- cement paste /

- fluidity /

- mechanical properties /

- hydration products

-

表 1 FLG参数

Table 1. Parameters of FLG

Type Specific area/

(m2·g−1)Tap density/

(g·cm−3)pH Moisture/% Mass fraction of carbon/wt% Mass fraction of oxygen/wt% Mass fraction of sulfur/wt% FLG 458.55 0.022 7.10 0.54 ≥98.0 <1.0 <0.1 表 2 P·O 42.5水泥化学分析结果

Table 2. Chemical analysis results of P·O 42.5 cement

wt% SiO2 Al2O3 Fe2O3 CaO MgO SO3 Na2O K2O Cl− f-CaO R2O 21.47 7.17 3.11 60.04 2.90 2.77 0.11 0.70 0.024 0.57 0.57 Notes: f-CaO—Free calcium oxide; R2O—Alkali oxides. 表 3 P·O 42.5水泥物理性能检测结果

Table 3. Physical performance test results of P·O 42.5 cement

Density/

(g·cm−3)Degree of powder Setting time Stability Flexural

strength/MPaCompressive

strength/MPaSpecific

surface area/

(m2·kg−1)Screening

allowance of

80 μm/%Consistency/

%Initial

setting/

minFinal

setting/

minRay type

method/

mm3 days 28 days 3 days 28 days 3.06 351 0.28 28.0 170 235 0.5 5.6 8.9 29.0 57.3 表 4 FLG/水泥(PC)净浆复合材料试件编号

Table 4. Specimen number of FLG/portland cement (PC) net slurry composite

Specimen FLG content/wt% 0wt%FLG/PC 0.00 0.02wt%FLG/PC 0.02 0.04wt%FLG/PC 0.04 0.06wt%FLG/PC 0.06 0.08wt%FLG/PC 0.08 0.1wt%FLG/PC 0.10 0.5wt%FLG/PC 0.50 1wt%FLG/PC 1.00 表 5 养护28天FLG/PC净浆复合材料水化产物的元素组成及质量分数

Table 5. Elemental composition and mass fraction of hydration products of FLG/PCnet slurry composite after curing for 28 days

Element content/wt% 0wt%FLG/PC 0.04wt%FLG/PC 1wt%FLG/PC C 8.17 13.04 6.70 O 50.74 51.77 43.84 Mg 0.36 0.69 0.47 Al 2.73 1.74 4.57 Si 7.89 7.80 10.51 S 1.71 1.21 1.50 K 1.02 1.66 1.95 Ca 27.38 22.09 30.46 -

[1] LI V C. High-performance and multifunctional cement-based composite material[J]. Engineering,2019,5(2):250-260. doi: 10.1016/j.eng.2018.11.031 [2] PEYVANDI A, SOROUSHIAN P, FARHADI N, et al. Evaluation of the reinforcement efficiency of low-cost graphite nanomaterials in high-performance concrete[J]. KSCE Journal of Civil Engineering,2018,22(10):3875-3882. doi: 10.1007/s12205-018-0168-6 [3] FU C, XIE C Y, LIU J, et al. A comparative study on the effects of three nano-materials on the properties of cement-based composites[J]. Materials,2020,13(4):857. doi: 10.3390/ma13040857 [4] SUMESH M, ALENGARAM U J, JUMAAT M Z, et al. Incorporation of nano-materials in cement composite and geopolymer based paste and mortar—A review[J]. Construction and Building Materials,2017,148:62-84. doi: 10.1016/j.conbuildmat.2017.04.206 [5] HE W, JIAO Z N, WANG Y W, et al. Research on the mechanical properties and electrical conductivity of cement mortar based on recycled nano-iron boride[J]. Waste Disposal & Sustainable Energy,2021, 3(2):1-10. [6] PAUL S C, ROOYEN A V, VAN ZIJL G P A G, et al. Properties of cement-based composites using nanoparticles: A comprehensive review[J]. Construction and Building Materials,2018,189:1019-1034. doi: 10.1016/j.conbuildmat.2018.09.062 [7] PAUL S C, VAN ROOYEN A S, VAN ZIJL G P A G, et al. Properties of cement-based composites using nanoparticles: A comprehensive review[J]. Construction and Building Materials, 2018, 189: 1019-1034. [8] SINGH L P, ALI A, TYAGI I, et al. Durability studies of nano-engineered fly ash concrete[J]. Construction and Building Materials,2019,194(10):205-215. [9] ALWASH D, KALFAT R, DU H J, et al. Development of a new nano modified cement based adhesive for FRP strengthened RC members[J]. Construction and Building Materials,2021,277(1):122318. [10] PAWEL S, MOHAMED A E, DIETMAR S. The influence of nanomaterials on the thermal resistance of cement-based composites—A review[J]. Nanomaterials,2018,8(7):465. doi: 10.3390/nano8070465 [11] ZHAO Z, QI T, ZHOU W, et al. A review on the properties, reinforcing effects, and commercialization of nanomaterials for cement-based materials[J]. Nanotechnology Reviews,2020,9(1):303-322. doi: 10.1515/ntrev-2020-0023 [12] PRASAD H, SITARAM N. Performance of nano materials for the strength development in concrete cube used as partial replacement for cement at different temperatures[J]. Materials Today: Proceedings,2021,45(6):7253-7258. [13] FAKHRY Z, SALMAN A J, ALQADHI R. Microstructural analysis for cement mortar with different nano materials[J]. Materials Science Forum,2020,1002:615-626. doi: 10.4028/www.scientific.net/MSF.1002.615 [14] GEIM A K. Graphene: Status and prospects[J]. Science,2009,324(5934):1530-1534. doi: 10.1126/science.1158877 [15] TAKAI K, TSUJIMURA S, KANG F, et al. Preparation of graphene[J]. Graphene,2020:39-171. [16] SEDAGHAT A, RAM M K, ZAYED A, et al. Investigation of physical properties of graphene-cement composite for structural applications[J]. Journal of Composite Materials,2014,4(1):12-21. doi: 10.4236/ojcm.2014.41002 [17] CAO M L, ZHANG H X, ZHANG C. Effect of graphene on mechanical properties of cement mortars[J]. Journal of Central South University,2016,23(4):919-925. doi: 10.1007/s11771-016-3139-4 [18] LI G, YUAN J B, ZHANG Y H, et al. Microstructure and mechanical performance of graphene reinforced cementitious composites[J]. Composites Part A: Applied Science and Manufacturing,2018,114:188-195. doi: 10.1016/j.compositesa.2018.08.026 [19] DIMOV D, AMIT I, GORRIE O, et al. Ultrahigh perfor-mance nanoengineerd graphene-concrete composites for multifunctional applications[J]. Advanced Functional Materials,2018,28(23):1-12. [20] VEGA M D, VASQUEZ M. Plasma-functionalized exfoliated multilayered graphene as cement reinforcement[J]. Composites Part A: Applied Science and Manufacturing,2019,160:573-585. doi: 10.1016/j.compositesb.2018.12.055 [21] KIM B, TAYLOR T, TROY A, et al. The effects of graphene oxide flakes on the mechanical properties of cement mortar[J]. Computers & Concrete,2018,21(3):261-267. [22] LEE S J, JEONG S H, KIM D U, et al. Effects of graphene oxide on pore structure and mechanical properties of cementitious composites[J]. Composite Structures,2020,234:111709. doi: 10.1016/j.compstruct.2019.111709 [23] HO V D, NG C T, OZBAKKALOGLU T, et al. Investigating the reinforcing mechanism and optimized dosage of pristine graphene for enhancing mechanical strengths of cementitious composites[J]. RSC Advances,2020,10(70):42777-42789. doi: 10.1039/D0RA07639B [24] LIU J, FU J, YANG Y, et al. Study on dispersion, mechanical and microstructure properties of cement paste incorporating graphene sheets[J]. Construction and Building Materials, 2019, 199: 1-11. [25] LI H Y, DING S Q, ZHANG L Q, et al. Rheological behaviors of cement pastes with multi-layer graphene[J]. Construction and Building Materials, 2021, 269: 121327. [26] RAO C, SUBRAHMANYAM K S, MATTE H R, et al. Graphene: Synthesis, functionalization and properties[J]. Modern Physics Letters B,2011,25(7):427-451. doi: 10.1142/S0217984911025961 [27] NOVOSELOV K S. Nobel lecture: Graphene: Materials in the flatland[J]. Reviews of Modern Physics,2011,83(3):837-849. doi: 10.1103/RevModPhys.83.837 [28] 中国国家标准化管理委员会. 混凝土外加剂匀质性试验方法: GB/T 8077—2000[S]. 北京: 中国标准出版社, 2000.Standardization Administration of the People's Republic of China. Test method for uniformity of concrete admixture: GB/T 8077—2000[S]. Beijing: Standards Press of China, 2000(in Chinese). [29] 中国国家标准化管理委员会. 水泥胶砂强度检测方法: GB/T 17671—1999[S]. 北京: 中国标准出版社, 1999.Standardization Administration of the People's Republic of China. Cement mortar strength testing method: GB/T 17671—1999[S]. Beijing: Standards Press of China, 1999(in Chinese). [30] SILVA D L, CAMPOS J L E, FERNANDES T F D, et al. Raman spectroscopy analysis of number of layers in mass-produced graphene flakes[J]. Carbon,2020,161:181-189. doi: 10.1016/j.carbon.2020.01.050 [31] HE Y J, ZHAO X G, LU L N, et al. Effect of C/S ratio on morphology and structure of hydrothermally synthesized calcium silicate hydrate[J]. Journal of Wuhan University of Technology,2011,26(4):770-773. doi: 10.1007/s11595-011-0308-z -

下载:

下载: