Static behavior of CFRP full cover adjusted steel plate with center crack

-

摘要: 碳纤维增强树脂复合材料(CFRP)加固钢板时,往往只将CFRP粘贴于钢板的局部,容易遭受由于试件偏心和搭接边缘应力集中所产生的剥离应力的影响,而粘贴方式采用全覆盖时能大幅度减小剥离应力。开展了30个CFRP全覆盖胶粘加固带缺陷钢板的轴向拉伸试验,并设置了单向防剥离夹具,研究了胶粘剂类型、缺陷长度和碳纤维板厚度对加固效果及破坏模式的影响。结果表明:CFRP板加固效果显著,试件的抗拉强度明显提高;不同胶粘剂对试件的破坏模式影响较大,由HJY胶制作的试件主要为被粘物的破坏,而SIKA30胶及WSB胶均出现了胶粘剂/钢脱粘的现象;而随着缺陷长度的增加,破坏模式有明显的变化,由CFRP板破坏变为CFRP板、钢板破坏或胶粘剂/钢脱粘,而试件的抗拉强度受胶粘剂类型影响较小,受缺陷的大小影响较大,当缺陷增大时,试件的抗拉强度明显降低;基于内聚力模型对静力力学试验进行了数值模拟;通过有限元分析得知,胶粘剂的破坏是先由缺陷附近破坏,再扩展至两端;而增加CFRP板的厚度能显著提高试件的抗拉强度。

-

关键词:

- 碳纤维增强树脂复合材料 /

- 加固 /

- 全覆盖 /

- 数值模拟 /

- 参数分析

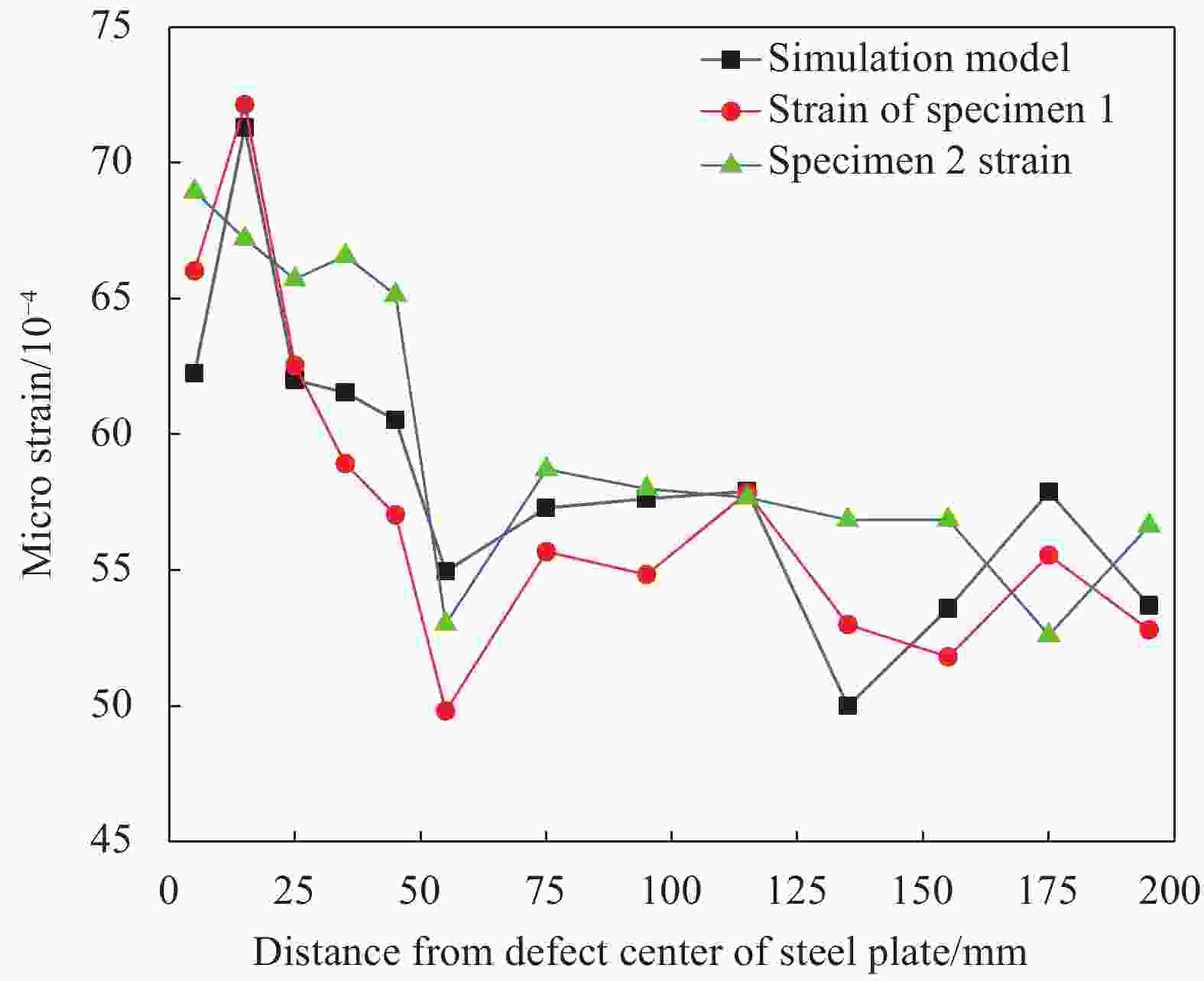

Abstract: When carbon fiber reinforced polymer (CFRP) is used to strengthen steel plate, CFRP is usually only adhered to the local part of the steel plate, which is susceptible to the influence of the peeling stress caused by the eccentricity of the specimen and the stress concentration at the lap edge. However, the peeling stress can be greatly reduced by using the full covering bonding method. The axial tensile tests of 30 CFRP reinforced steel plates with defects were carried out, and the unidirectional anti-stripping clamp was set up. The effects of adhesive type, defect length and thickness of carbon fiber plate on the reinforcement effect and failure mode were studied. The results show that the reinforcement effect of CFRP plate is significant, and the tensile strength of the specimen is signifi-cantly improved. Different adhesives have a great influence on the failure mode of the specimen. The specimen made of HJY adhesive is mainly destroyed by the adhesive, while the debonding phenomenon of the adhesive/steel appears in both Sika30 adhesive and WSB adhesive. With the increase of the defect length, the failure mode changes from the failure of CFRP plate to the failure of CFRP plate, steel plate or adhesive/steel debonding. The tensile strength of the specimen is less affected by the type of adhesive, but more affected by the size of the defect. When the defect increases, the tensile strength of the specimen decreases significantly. Based on the cohesive force model, the static mechanical tests were numerically simulated. The finite element analysis shows that the damage of adhesive starts from near the defect and then extends to both ends. However, increasing the thickness of CFRP plate can significantly increase the tensile strength of the specimen. -

表 1 碳纤维增强聚合物复合材料(CFRP)板、钢材及胶粘剂材料参数

Table 1. Material parameters of carbon fiber reinforced polymer composite (CFRP) plate, steel and adhesive

Types of materials Tensile strength/MPa Modulus of elasticity/GPa Elongation at break/% CFRP plate 1800 161.2 1.1 Q345qD steel plate 514 206 18 HJY glue 34.0 4.10 0.86 SIKA30 glue 25.3 12.13 0.22 WSB glue 41.8 2.7 1.5 表 2 CFRP加固带缺陷钢板试件参数及试验结果

Table 2. Parameters and test results of CFRP strengthened steel plate with defects

Adhesive type Specimen number Limit

displacement/mmAverage

displacement/mmUltimate

load/kNAverage

load/kNFailure

modeHJY glue CFRP-HJY-SP(L2)-1 10.75 10.87 259.19 247.71 a CFRP-HJY-SP(L2)-2 11.10 231.14 a CFRP-HJY-SP(L2)-3 10.75 252.81 a CFRP-HJY-SP(L3)-1 7.06 7.06 252.80 240.40 a CFRP-HJY-SP(L3)-2 7.06 223.00 a+b CFRP-HJY-SP(L3)-3 7.06 245.39 a CFRP-HJY-SP(L4)-1 6.54 6.49 190.50 187.92 a+b CFRP-HJY-SP(L4)-2 6.60 183.97 a+b CFRP-HJY-SP(L4)-3 6.34 189.28 a+b SIKA30 glue CFRP-SIKA30-SP(L2)-1 18.98 18.75 238.37 240.53 a+c CFRP-SIKA30-SP(L2)-2 21.45 246.94 a+c CFRP-SIKA30-SP(L2)-3 15.83 236.28 a+c CFRP-SIKA30-SP(L3)-1 7.79 6.71 235.85 219.27 a+b CFRP-SIKA30-SP(L3)-2 5.19 197.33 a+c CFRP-SIKA30-SP(L3)-3 7.16 224.63 a+b CFRP-SIKA30-SP(L4)-1 4.54 3.27 193.51 159.98 a+c CFRP-SIKA30-SP(L4)-2 2.73 149.56 a+c CFRP-SIKA30-SP(L4)-3 2.54 136.88 a+c WSB glue CFRP-WSB-SP(L2)-1 15.26 11.33 246.51 232.53 b+c CFRP-WSB-SP(L2)-2 5.69 234.12 c+d CFRP-WSB-SP(L2)-3 13.05 216.96 c+d CFRP-WSB-SP(L3)-1 10.17 8.37 206.47 206.24 a+b+c CFRP-WSB-SP(L3)-2 8.77 211.82 a+b+c CFRP-WSB-SP(L3)-3 6.18 200.43 a+b+c CFRP-WSB-SP(L4)-1 7.09 6.85 185.69 181.52 a+b+c CFRP-WSB-SP(L4)-2 6.68 178.62 a+b+c CFRP-WSB-SP(L4)-3 6.79 180.25 a+b+c Notes: Naming rules of specimens "***-***-***-*** *" : The first line of numbers represents the composite material name; The second row of numbers represents the type of adhesive; The third line indicates the defect length; The fourth line number represents the specimen number; a—CFRP plate failure; b—Steel plate damage; c—Steel/adhesive debonding; d—CFRP board/adhesive damage. 表 3 五种CFRP厚度对应的CFRP加固带缺陷钢板极限荷载

Table 3. Ultimate load of plate with defects strengthened with CFRP corresponding to the five thickness of CFRP

Thickness/mm 0.7 1.05 1.4 1.75 2.1 Ultimate load/kN 173 221 280 323 377 Ratio 0.62 0.79 1 1.15 1.35 -

[1] 李腾, 宁志华, 吴嘉瑜. CFRP加固钢板的粘结界面剥离破坏[J]. 复合材料学报, 2021, 38(12): 4090-4105.LI Teng, NING Zhihua, WU Jiayu. CFRP reinforced steel plate bonding interface stripping damage [J]. Acta Materiae Compositae Sinica, 2021, 38(12): 4090-4105(in Chinese). [2] 张鹏, 桂金洋, 邓宇, 等. 偏心受拉作用下预应力CFRP筋-型钢混凝土构件抗裂试验[J]. 复合材料学报, 2021, 38(3):920-931.ZHANG Peng, GUI Jinyang, DENG Yu, et al. Experimental study on crack resistance of prestressed CFRP reinforced steel concrete members under eccentric tension[J]. Acta Materialia Sinica,2021,38(3):920-931(in Chinese). [3] 姜震宇, 王春江, 李向民,等. CFRP加固H型损伤钢梁的扩展有限元分析[J]. 力学季刊, 2012, 33(4):649-656. doi: 10.3969/j.issn.0254-0053.2012.04.019JIANG Zhenyu, WANG Chunjiang, LI Xiangmin, et al. Extended finite element analysis of CFRP reinforced H-type damaged steel beams[J]. Chinese Quarterly of Mechanics,2012,33(4):649-656(in Chinese). doi: 10.3969/j.issn.0254-0053.2012.04.019 [4] AP A, IH B. Steel beam strengthening with UHM CFRP strip panels[J]. Engineering Structures, 2021, 226: 111395. [5] 张依睿, 魏洋, 柏佳文, 等. 纤维增强聚合物复合材料-钢复合圆管约束混凝土轴压性能预测模型[J]. 复合材料学报, 2019, 36(10):2478-2485.ZHANG Yirui, WEI Yang, BAI Jiawen, et al. Prediction model of axial compressive performance of concrete constrained by fiber reinforced polymer composites-steel composite circular pipe[J]. Acta Materiae Compistae Sinica,2019,36(10):2478-2485(in Chinese). [6] 杨凤祥, 陈静芬, 陈善富, 等. 基于剪切非线性三维损伤本构模型的复合材料层合板失效强度预测[J]. 复合材料学报, 2020, 37(9):2207-2222.YANG Fengxiang, CHEN Jingfen, CHEN Shanfu, et al. Failure strength prediction of composite laminates based on nonlinear three-dimensional damage constitutive model[J]. Acta Materiae Compistae Sinica,2020,37(9):2207-2222(in Chinese). [7] WANG Z, XIAN G J. Effects of thermal expansion coefficients discrepancy on the CFRP and steel bonding[J]. Construction and Building Materials,2021,269:121356. [8] WANG Z Y, WANG Q Y. Fatigue strength of CFRP strengthened welded joints with corrugated steel plates[J]. Composites,2015,72:30-39. [9] FENG B, WANG X, WU Z S, et al. Performance of anchorage assemblies for CFRP cables under fatigue loads[J]. Structures, 2021, 29: 947-953. [10] YU Q Q, ZHAO X L, AL-MAHAIDI R, et al. Tests on cracked steel plates with different damage levels strengthened by CFRP laminates[J]. International Journal of Structural Stability & Dynamics,2014,14(6):1450018. [11] 杨怡, 黄炽辉, 吴作栋. 基于双剪实验的CFRP-钢板界面粘结性能研究[J]. 中山大学学报(自然科学版), 2021, 60(6): 62-70.YANG Yi, HUANG Chihui, WU Zuodong. Study on bonding performance of CFRP-steel plate interface based on double shear test[J]. Acta Scientiarum Naturalium Universitatis Sunyatseni (Natural Science Edition), 2021, 60(6): 62-70(in Chinese) [12] 黎文婧, 黄辉, 贾彬, 等. 碳纤维布-钢界面黏结性能试验研究[J]. 工业建筑, 2019, 49(3):24-28, 91.LI Wenjing, HUANG Hui, JIA Bin, et al. Experimental study on bonding properties of carbon fiber sheets-steel interface[J]. Industrial Building,2019,49(3):24-28, 91(in Chinese). [13] 姜丰, 史亚龙, 王清远. CFRP加固开孔钢板的静力力学性能研究[J]. 四川理工学院学报(自然科学版), 2018, 31(2):43-49.JIANG Feng, SHI Yalong, WANG Qingyuan. Study on static mechanical properties of CFRP reinforced open-hole steel plate[J]. Journal of Sichuan University of Science and Technology (Natural Science Edition),2018,31(2):43-49(in Chinese). [14] 张宁, 岳清瑞, 杨勇新, 等. 碳纤维布加固钢结构疲劳试验研究[J]. 工业建筑, 2004(4):19-21, 30. doi: 10.3321/j.issn:1000-8993.2004.04.005ZHANG Ning, YUE Qingrui, YANG Yongxin, et al. Fatigue test of steel structure reinforcement with carbon fiber sheets[J]. Industrial Building,2004(4):19-21, 30(in Chinese). doi: 10.3321/j.issn:1000-8993.2004.04.005 [15] 陈卓异, 彭彦泽, 李传习, 等. 高温下双搭接钢-CFRP板胶粘界面力学性能试验[J]. 复合材料学报, 2021, 38(2):449-460.CHEN Zhuoyi, PENG Yanze, LI Chuanxi, GUO Jing. Experimental study on mechanical properties of AdHESive interface between double lap steel and CFRP plate at high temperature[J]. Acta Materiae Compositae Sinica,2021,38(2):449-460(in Chinese). [16] 叶华文, KNIG Christian, UMMENHOFER Thomas, 等. 预应力CFRP板加固钢板受拉疲劳性能试验研究[J]. 西南交通大学学报, 2009, 44(6):823-829. doi: 10.3969/j.issn.0258-2724.2009.06.005YE Huawen, KNIG Christian, UMMENHOFER Thomas, et al. Experimental study on tensile fatigue behavior of steel plate strengthened by prestressed CFRP plate[J]. Journal of Southwest Jiaotong University,2009,44(6):823-829(in Chinese). doi: 10.3969/j.issn.0258-2724.2009.06.005 [17] HE J, XIAN G G, ZHANG Y X. Numerical modelling of bond behaviour between steel and CFRP laminates with a ductile adhesive[J]. International Journal of Adhesion and Adhesives,2021,104:102753. [18] 伍希志, 林彬, 程军圣, 等. 裂纹钢板的止裂孔与CFRP加固及其疲劳寿命预测[J]. 天津大学学报(自然科学与工程技术版), 2017, 50(2):154-158.WU Xizhi, LIN Bin, CHENG Junsheng, et al. Crack stopper and CFRP reinforcement of cracked steel plate and fatigue life prediction[J]. Journal of Tianjin University (Natural Science and Engineering Technology Edition),2017,50(2):154-158(in Chinese). [19] 李传习, 柯璐, 陈卓异, 等. CFRP-钢界面粘结性能试验与数值模拟[J]. 复合材料学报, 2018, 35(12):3534-3546.LI Chuanxi, KE Lu, CHEN Zhuoyi, et al. Experimental and numerical simulation of interfacial bonding properties of CFRP steel[J]. Acta Materiae Compositae Sinica,2018,35(12):3534-3546(in Chinese). [20] 中华人民共和国国家质量监督检验检疫总局. 金属材料室温拉伸试验方法: GB/T 228—2002[S]. 北京: 中国标准出版社, 2002.General Administration of Quality Supervision, Inspection and Quarantine of the People‘s Republic of China. Metallic materials-Tensile testing at ambient temperature: GB/T 228—2002[S]. Beijing: China Standars Press, 2002 [21] 刘建华, 曹东, 张晓云, 等. 树脂基复合材料T300/5405的吸湿性能及湿热环境对力学性能的影响[J]. 航空材料学报, 2010, 30(4):75-80. doi: 10.3969/j.issn.1005-5053.2010.4.015LIU Jianhua, CAO Dong, ZHANG Xiaoyun, et al. Hygrosco-pic properties of resin matrix composites T300/5405 and the effect of hot and humid environment on mechanical properties[J]. Journal of Aeronautical Materials,2010,30(4):75-80(in Chinese). doi: 10.3969/j.issn.1005-5053.2010.4.015 [22] 王云英, 刘杰, 孟江燕, 等. 纤维增强聚合物基复合材料老化研究进展[J]. 材料工程, 2011(7):85-89. doi: 10.3969/j.issn.1001-4381.2011.07.018WANG Yunying, LIU Jie, MENG Jiangyan, et al. Research progress on aging of fiber reinforced polymer matrix composites[J]. Journal of Materials Engineering,2011(7):85-89(in Chinese). doi: 10.3969/j.issn.1001-4381.2011.07.018 [23] AOKI R, HIGUCHI R, YOKOZEKI T. Fatigue simulation for progressive damage in CFRP laminates using intra-laminar and inter-laminar fatigue damage models[J]. International Journal of Fatigue,2020,143:106015. [24] NICOLO G, EDMUND T, COCKS A C F. Coupling a discrete twin model with cohesive elements to understand twin-induced fracture[J]. International Journal of Fracture,2021,227:173-192. [25] WEILLSG N, SLUYS L J. A new method for modeling cohe-sive cracks using finite elements[J]. International Journal for Numerical Methods in Engineering,2001,50(12):2667-2682. -

下载:

下载: