Analysis of the structure and properties of a medium resistant liquid fluoroelastomer

-

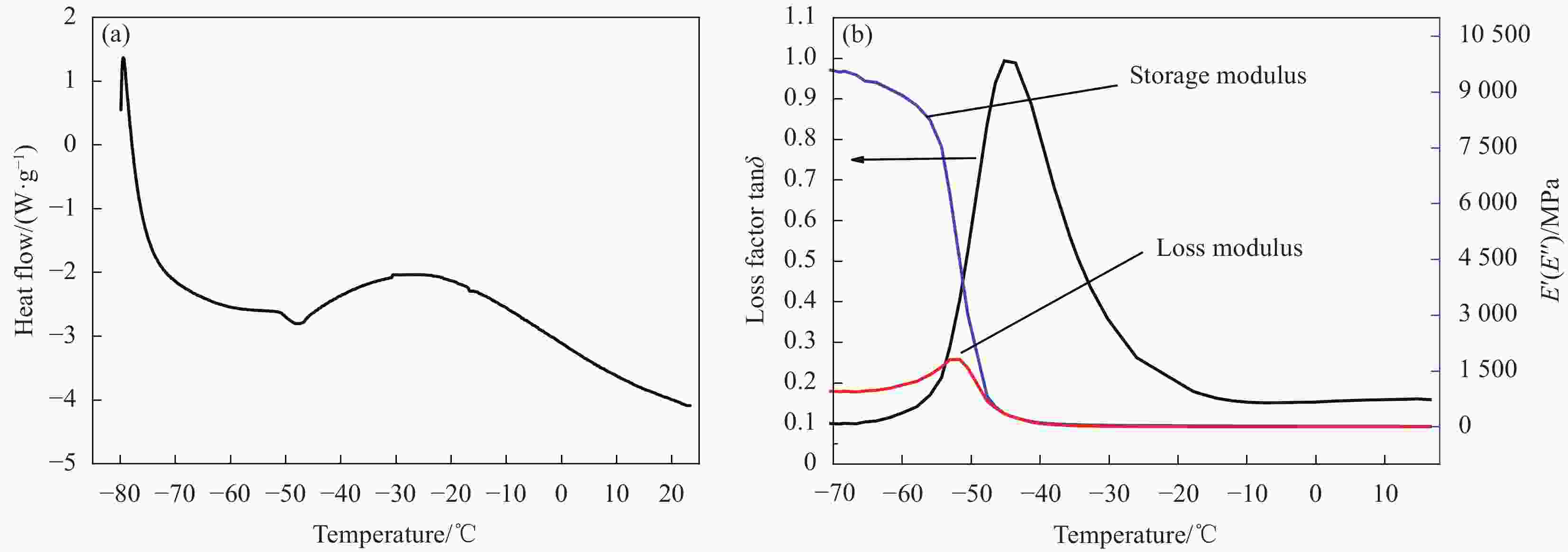

摘要: SIFEL 3705是日本信越开发的一种可耐多种化学品及强还原性介质的液体含氟弹性体材料,在国外军事、电子、石油化工等领域获得了广泛应用。掌握该材料的结构及性能特点,可以科学指导密封选材,充分发挥材料的高性能从而满足苛刻的密封工况。本文通过FTIR、核磁共振波谱仪及差示扫描量热仪(DSC)测试分析了SIFEL 3705A及3705B预混胶的化学结构及耐低温特性;针对采用两组分预混胶混合硫化后制备的含氟弹性体,开展了DSC、动态热机械分析(DMA)、力学性能、低温回弹性、高温压缩回弹性、耐高温性能、耐化学介质性能等方面的测试分析。结果表明:SIFEL 3705A和3705B预混胶中的主胶料化学结构基本一致,为分子主链含醚键C—O—C的氟橡胶;采用两组分预混胶制备的含氟弹性体玻璃化转变温度Tg达−52.5℃,在−50℃低温环境下仍具有回弹性,弹性体力学性能及耐高温性能良好,邵尔A硬度66,拉伸强度8.98 MPa,拉断伸长率289%,5wt%质量损失时的热分解温度476.8℃;经高温130℃压缩120天后恒定压缩永久变形≤20%,具有非常优异的高温回弹性能;另外,含氟弹性体具有非常优异的耐化学介质性能,在无水乙醇及液压油中的性能变化幅度很小,在强极性偏二甲肼介质中浸泡后性能变化先较快而后基本达到平衡。根据性能剖析结果可知,信越含氟弹性体SIFEL 3705可在−50℃低温环境及强腐蚀性环境中作密封材料使用。Abstract: SIFEL 3705 is a kind of liquid fluoroelastomer developed by Shinyue company, Janpan, which can resist many chemicals and strong reducing media. It has been widely used in military, electronic, petrochemical and other fields overseas. It can scientifically guide the selection of sealing materials, give full play to the high performance of the material so as to meet the harsh sealing conditions when the structure and performance characteristics of SIFEL 3705 are mastered. The chemical structure and low temperature resistance of the liquid fluoroelastomer SIFEL 3705A and 3705B premixed were analyzed by FTIR, nuclear magnetic resonance spectroscopy (NMR) and differential scanning calorimetry (DSC) analyses. For the fluoroelastomer prepared by vulcanization of two-component premix, DSC, dynamic thermo-mechanical analysis (DMA), mechanical properties, low temperature flexibility, compression set, heat resistance and chemical medium resistance were tested and analyzed. The results show that the chemical structure of the main compound in SIFEL 3705A and 3705B premix is similar, which is fluororubber with ether bond C—O—C bond in the main chain. The glass transition temperature Tg of the fluoroelastomer is −52.5℃, and it still own resilience at −50℃. The fluoroelastomer has good mechanical properties and heat resis-tance with Shore A hardness of 66, tensile strength of 8.98 MPa, elongation at break of 289%, and initial degradation (mass loss of 5wt%) temperature as 476.8℃. The constant compression set is no more than 20% after compressing at 130℃ for 120 days. Meanwhile, the fluoroelastomer has excellent resistance to chemical media. The performance changes are unconspicuous in anhydrous ethanol and synthetic oil. The properties are changed quickly and then reach equilibrium in strong polar solvent of N, N-dimethylhydrazine. The results show that SHIN-ETSU fluoroelastomer as a sealing material is applicable for harsh environment such as low temperature of −50℃ and strong corrosive solvent.

-

Key words:

- fluoroelastomer /

- SIFEL 3705 /

- FTIR /

- nuclear magnetic resonance spectroscopy /

- compression set /

- medium resistant

-

表 1 SIFEL 3705含氟弹性体的物理力学性能

Table 1. Physical properties of SIFEL 3705 fluoroelastomer

Property Value Shore A hardness 66 Tensile strength/MPa 8.98 Elongation at break/% 289 100% tensile strength/MPa 2.89 Coefficient of cold resistance under compression 0.46 (at −40℃) 0.38 (at −45℃) 0.21 (at −50℃) TR10/℃ −50 Brittle temperature/℃ −53 Note: TR10—Temperature corresponding to 10% shrinkage. 表 2 SIFEL 3705含氟弹性体的线膨胀系数

Table 2. Coefficient of linear expansion of SIFEL 3705 fluoroelastomer

Temperature range/℃ Average coefficient/10−6℃ RT~50 225 RT~100 240 RT~150 247 RT~200 255 RT~250 268 Note: RT—Room temperature. -

[1] WAKSMAN L, KISHITA H, SATO S, et al. The evolution of fluoroelastomer: SIFEL, a new class of easily processed high performance elastomer adhesive and sealant[J]. SAE 2001 World Congress,2001:849-856. [2] KOSHIKAWA H, TARUMI Y, SHIONO M. Perfluoroether elastomer for wide fluid and temperature capabilities[J]. Sealing Technology,2006(6):7-12. [3] BIGG D M, HEATER K J, SKIDMORE T L, et al. Hydrocarbon stability of perfluorinated polyether rubbers at elevated temperatures[J]. Polymer Engineering and Science,2005(45):1622-1629. [4] 荒井正俊, 黄汉生. 低温下能保持柔软性的液体氟橡胶[J]. 有机氟工业, 2001(4):31-36.ARAI M, HUANG Hansheng. Development of new temperature grade liquid fluororubber[J]. Organo-Fluorine Industry,2001(4):31-36(in Chinese). [5] 黄汉生. 新型液态氟橡胶的特性与用途[J]. 有机氟工业, 2003(1):53-56.HUANG Hansheng. Characteristics and application of new liquid fluororubber[J]. Organo-Fluorine Industry,2003(1):53-56(in Chinese). [6] FUKUSHIMA M, YAMAYA M, YAMAMOTO A, et al. Perfluoropolyether rubber composition and ion-conducting polymer electrolyte membrane: US, 7838616[P]. 2010-11-23. [7] TURRI S, LEVI M, CRISTINI M, et al. Dynamic and thermo-mechanical properties of some specialty fluoroelastomers for low Tg seal materials[J]. Journal of Polymer Research,2007,14:141-145. doi: 10.1007/s10965-006-9093-3 [8] MALTEZOS G, GARCIA E, HANRAHAN G, et al. Design and fabrication of chemically robust three-dimensional microfluidic valves[J]. Lab Chip,2007,7:1209-1211. doi: 10.1039/b705031c [9] DEVARAJU N, UNGER M A. Multilayer soft lithography of perflfluoropolyether based elastomer for microflfluidic device fabrication[J]. Lab Chip,2011,11:1962-1967. doi: 10.1039/c0lc00274g [10] FRIESEN C M, AEMEDURI B. Outstanding telechelic perfluoropolyalkylethers and applications therefrom[J]. Progress in Polymer Science,2018,81:230-280. [11] 中国国家标准化管理委员会. 硫化橡胶或热塑性橡胶压入硬度试验方法 第1部分: 邵氏硬度计法(邵尔硬度): GB/T 531.1—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of the People’s Republic of China. Rubber, vulcanized or thermoplastic-Determination of indentation hardness Part 1: Duromerer method (Shore hardness): GB/T 531.1—2008[S]. Beijing: China Standards Press, 2008(in Chinese). [12] 中国国家标准化管理委员会. 硫化橡胶或热塑性橡胶拉伸应力应变性能的测定: GB/T 528—2009[S]. 北京: 中国标准出版社, 2009.Standardization Administration of the People’s Republic of China. Rubber, vulcanized or thermoplastic-Determination of tensile stress-strain properties: GB/T 528—2009[S]. Beijing: China Standards Press, 2008(in Chinese). [13] 中国国家发展和改革委员会. 硫化橡胶 压缩耐寒系数的测定: HG/T 3866—2008[S]. 北京: 化工出版社, 2008.Development and Reform Commission of the People’s Republic of China. Vulcanized rubber-Determinaiton of coefficient of cold resistance under compression: HG/T 3866—2008[S]. Beijing: Chemical Press, 2008(in Chinese). [14] 中国国家标准化管理委员会. 硫化橡胶低温脆性的测定 单试样法: GB/T1682—1994[S]. 北京: 中国标准出版社, 1994.Standardization Administration of the People’s Republic of China. Rubber, vulcanized-Determination of low-temperature brittleness (single test piece method): GB/T1682—1994[S]. Beijing: China Standards Press, 1994(in Chinese). [15] 中国国家标准化管理委员会. 硫化橡胶恒定形变压缩永久变形的测定方法: GB/T 1683—1981[S]. 北京: 中国标准出版社, 1981.Standardization Administration of the People’s Republic of China. Vulcanized rubber-Determination of compression set at constant deformation: GB/T 1683—1981[S]: Beijing: China Standards Press, 1981(in Chinese). [16] 中国航空航天工业部. 胶粘剂平均线膨胀系数测试方法: QJ1867—90[S]. 北京: 航空航天工业部出版社, 1990.Ministry of Aeronautics and Astronautics of China. Test method for average linear expansion coefficient of adhesives: QJ1867—90[S]. Beijing: Ministry of Aerospace Industry Press, 1990(in Chinese). [17] 中国国家标准化管理委员会. 硫化橡胶 低温性能的测定 温度回缩法(TR试验): GB/T 7758—2002[S]. 北京: 中国标准出版社, 2002.Standardization Administration of the People’s Republic of China. Rubber, vulcanized-Deternination of low-tempera-ture characteristics-Temperature-retraction procedure (TR Test): GB/T 7758—2002[S]. Beijing: China Standards Press, 2002 (in Chinese). -

下载:

下载: