| [1] |

EVANS K E. Auxetic polymers: A new range of materials[J]. Endeavour,1991,15(4):170-174. doi: 10.1016/0160-9327(91)90123-S

|

| [2] |

YANG S, QI C, WANG D, et al. A comparative study of ballistic resistance of sandwich panels with aluminum foam and auxetic honeycomb cores[J]. Advances in Mechanical Engineering,2015,5:589216.

|

| [3] |

CHOI J B, LAKES R S. Fracture toughness of re-entrant foam materials with a negative Poisson's ratio: Experiment and analysis[J]. International Journal of Fracture,1996,80(1):73-83. doi: 10.1007/BF00036481

|

| [4] |

CARNEIRO V H, MEIRELES J, PUGA H. Auxetic materials-A review[J]. Materials Science Poland,2013,31(4):561-571. doi: 10.2478/s13536-013-0140-6

|

| [5] |

ALDERSON A, ALDERSON K L, CHIRIMA G, et al. The in-plane linear elastic constants and out-of-plane bending of 3-coordinated ligament and cylinder-ligament honeycombs[J]. Composites Science and Technology,2010,70(7):1034-1041. doi: 10.1016/j.compscitech.2009.07.010

|

| [6] |

LAKES R. Foam structures with a negative Poisson’s ratio[J]. Science,1987,235:384-387.

|

| [7] |

王鲁, 姜秉元. 负泊松比复合材料裂纹尖端应力场[J]. 复合材料学报, 1996, 13(3):112-117.WANG Lu, JIANG Bingyuan. Neartip stress fields for crack in composite with negative Poisson’s ratio[J]. Acta Materiae Compositae Sinica,1996,13(3):112-117(in Chinese).

|

| [8] |

IMBALZANO G, TRAN P, NGO T D, etal. A numerical study of auxetic composite panels under blast loadings[J]. Composite Structures,2016,135:339-352. doi: 10.1016/j.compstruct.2015.09.038

|

| [9] |

张伟, 侯文彬, 胡平. 新型负泊松比多孔吸能盒平台区力学性能[J]. 复合材料学报, 2015, 32(2):534-541.ZHANG Wei, HOU Wenbin, HU Ping. Mechanical properties of new negative Poisson’s ratio crush box with cellular structure in plateau stage[J]. Acta Materiae Compositae Sinica,2015,32(2):534-541(in Chinese).

|

| [10] |

YANG L, HARRYSSON O, WEST H, et al. Mechanical properties of 3D re-entrant honeycomb auxetic structures realized via additive manufacturing[J]. International Journal of Solids and Structures,2015,69-70:475-490. doi: 10.1016/j.ijsolstr.2015.05.005

|

| [11] |

苏继龙, 吴金东, 刘远力. 蜂窝结构力学超材料弹性及抗冲击性能的研究进展[J]. 材料工程, 2019, 47(8):49-58.SU Jilong, WU Jindong, LIU Yuanli. Progress in elastic property and impact resistance of honeycomb structure mechanical metamaterial[J]. Journal of Materials Engineering,2019,47(8):49-58(in Chinese).

|

| [12] |

任鑫, 张相玉, 谢亿民. 负泊松比材料和结构的研究进展[J]. 力学学报, 2019, 51(3):656-687.REN Xin, ZHANG Xiangyu, XIE Yimin. Research progress in auxetic materials and structures[J]. Chinese Journal of Theoretical and Applied Mechanics,2019,51(3):656-687(in Chinese).

|

| [13] |

GRIMA J N, MANICARO E, ATTARD D. Auxetic behaviour from connected different-sized squares and rectangles[J]. Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences,2011,467(2126):439-458. doi: 10.1098/rspa.2010.0171

|

| [14] |

LUO C, HAN C Z, ZHANG X Y, et al. Design, manufacturing and applications of auxetic tubular structures: A review[J]. Thin-Walled Structures,2021,163:107682. doi: 10.1016/j.tws.2021.107682

|

| [15] |

ALI M N, REHMAN I U. An Auxetic structure configured as oesophageal stent with potential to be used for palliative treatment of oesophageal cancer: development and in vitro mechanical analysis[J]. Journal of Materials: Science Materials in Medicine,2011,22(11):2573-2581. doi: 10.1007/s10856-011-4436-y

|

| [16] |

MIGLIAVACCA F, PETRINI L, MASSAROTTI P, et al. Stainless and shape memory alloy coronary stents: A computational study on the interaction with the vascular wall[J]. Biomechanics and Modeling in Mechanobiology,2004,2(4):205-217.

|

| [17] |

KURIBAYASHI K, TSUCHIYA K, YOU Z, et al. Self-deployable origami stent grafts as a biomedical application of Ni-rich TiNi shape memory alloy foil[J]. Materials Science and Engineering: A,2006,419(1-2):131-137. doi: 10.1016/j.msea.2005.12.016

|

| [18] |

GRIMA J N, MIZZI L, AZZOPARDI K M, et al. Auxetic perforated mechanical metamaterials with randomly oriented cuts[J]. Advanced Materials,2016,28(2):385-389. doi: 10.1002/adma.201503653

|

| [19] |

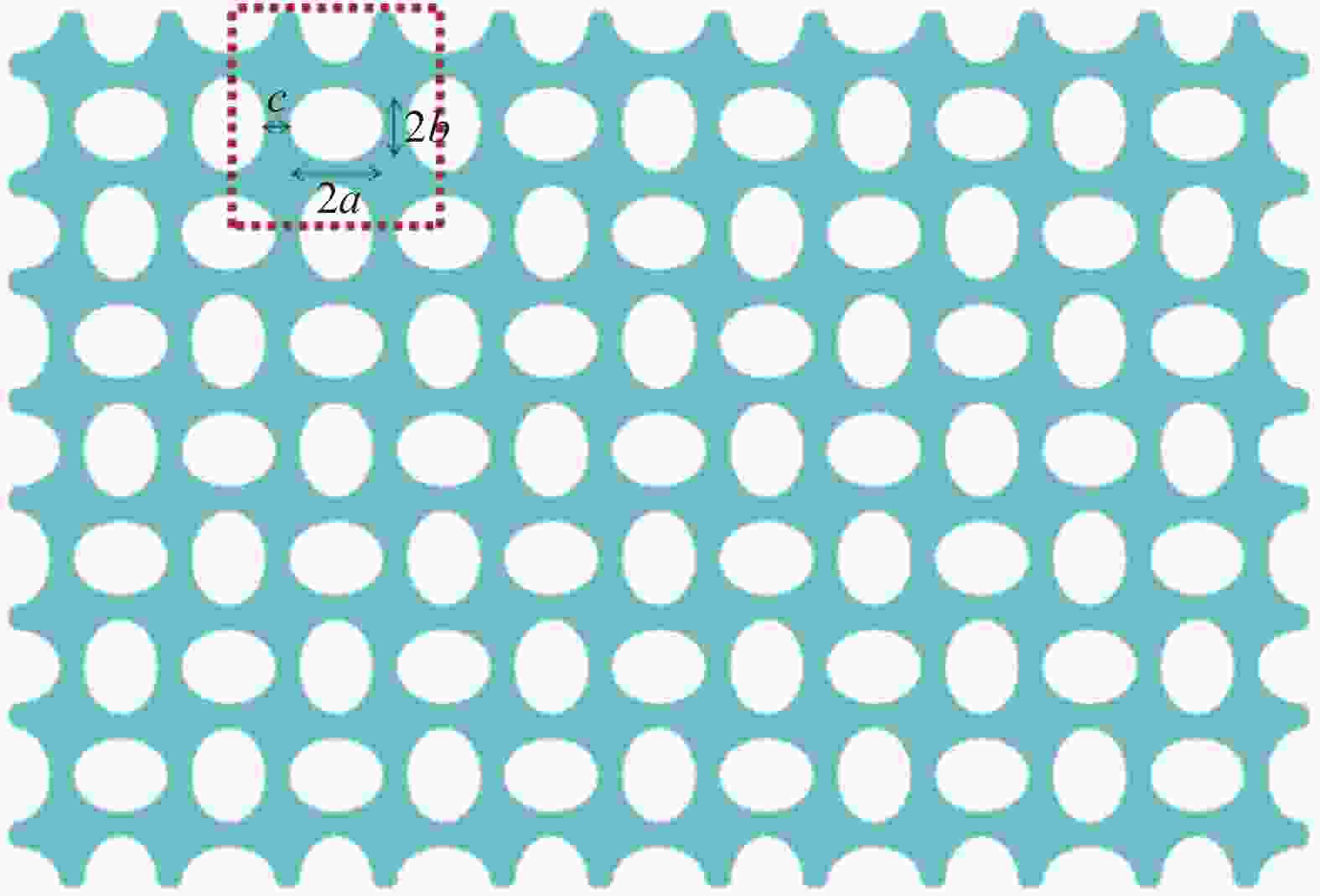

REN X, LIU F C, ZHANG X Y, et al. Numerical investigation of tubular structures generated by cutting method and pattern scale factor (PSF) method[J]. Pigment & Resin Technology, 2019, 50(5): 419-425.

|

| [20] |

REN X, SHEN J H, GHAEDIZADEH A, et al. A simple auxetic tubular structure with tuneable mechanical properties[J]. Smart Materials and Structures,2016,25(6):65012. doi: 10.1088/0964-1726/25/6/065012

|

| [21] |

GAO Q, ZHAO X, WANG C Z, et al. Multi-objective crashworthiness optimization for an auxetic cylindrical structure under axial impact loading[J]. Materials & Design,2018,143:120-130.

|

| [22] |

LEE W, JEONG Y, YOO J, et al. Effect of auxetic structures on crash behavior of cylindrical tube[J]. Composite Structures,2019,208:836-846. doi: 10.1016/j.compstruct.2018.10.068

|

| [23] |

KARNESSIS N, BURRIESCI G. Uniaxial and buckling mechanical response of auxetic cellular tubes[J]. Smart Materials and Structures,2013,22(8):84008. doi: 10.1088/0964-1726/22/8/084008

|

| [24] |

REN X, SHEN J H, PHUONG T, et al. Auxetic nail: Design and experimental study[J]. Composite Structures,2018,184:288-298. doi: 10.1016/j.compstruct.2017.10.013

|

| [25] |

ZHANG X Y, WANG X Y, REN X, et al. A novel type of tubular structure with auxeticity both in radial direction and wall thickness[J]. Thin-Walled Structures,2021,163:107758. doi: 10.1016/j.tws.2021.107758

|

| [26] |

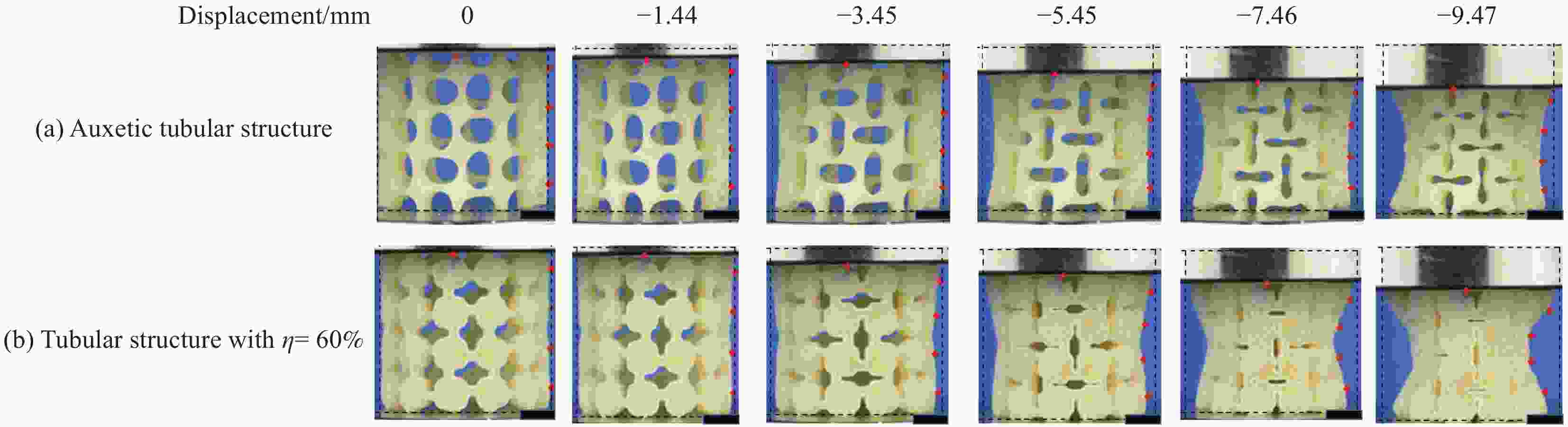

HUR J M, SEO D S, KIM K, et al. Harnessing distinct deformation modes of auxetic patterns for stiffness design of tubular structures[J]. Materials & Design,2021,198:109376.

|

| [27] |

CHEN Q, PUGNO N M. In-plane elastic buckling of hierarchical honeycomb materials[J]. European Journal of Mechanics-A/Solids,2012,34:120-129. doi: 10.1016/j.euromechsol.2011.12.003

|

| [28] |

秦浩星, 杨德庆. 任意负泊松比超材料结构设计的功能基元拓扑优化法[J]. 复合材料学报, 2018, 35(4):1014-1023.QIN Haoxing, YANG Deqing. Functional element topology optimal method of metamaterial design with arbitrary negative Poisson’s ratio[J]. Acta Materiae Compositae Sinica,2018,35(4):1014-1023(in Chinese).

|

| [29] |

LI D, MA J, DONG L, et al. Stiff square structure with a negative Poisson's ratio[J]. Materials Letters,2017,188:149-151. doi: 10.1016/j.matlet.2016.11.036

|

| [30] |

LU Z X, LI X, YANG Z Y, et al. Novel structure with negative Poisson’s ratio and enhanced Young’s modulus[J]. Composite Structures,2016,138:243-252. doi: 10.1016/j.compstruct.2015.11.036

|

| [31] |

LOGAKANNAN K P, RAMACHANDRAN V, RENGASWAMY J, et al. Quasi-static and dynamic compression behaviors of a novel auxetic structure[J]. Composite Structures,2020,254:112853. doi: 10.1016/j.compstruct.2020.112853

|

| [32] |

REN X, SHEN J H, GHAEDIZADEH A, et al. Experiments and parametric studies on 3D metallic auxetic metamaterials with tuneable mechanical properties[J]. Smart Materials and Structures,2015,24(9):95016. doi: 10.1088/0964-1726/24/9/095016

|

| [33] |

ZHANGX Y, REN X. A simple methodology to generate metamaterials and structures with negative Poisson’s ratio[J]. Physica Status Solidi (B),2020,257(10):2000439. doi: 10.1002/pssb.202000439

|

| [34] |

REN X, SHEN J H, TRAN P, et al. Design and characterisation of a tuneable 3D buckling-induced auxetic metamaterial[J]. Materials& Design,2018,139:336-342.

|

| [35] |

GRIMA J N, ZAMMIT V, GATT R. Auxetic behaviour from rotating semirigid units[J]. Physica Status Solidi (B),2007,244(3):866-882. doi: 10.1002/pssb.200572706

|

| [36] |

LI Q M, MAGKIRIADIS I, HARRIGAN J J. Compressive strain at the onset of densification of cellular solids[J]. Journal of Cellular Plastics,2006,42:371-392. doi: 10.1177/0021955X06063519

|

| [37] |

SHEN J H, XIE Y M, HUANG X D, et al. Mechanical properties of luffa sponge[J]. Journal of the Mechanical Behavior of Biomedical Materials,2012,15:141-152. doi: 10.1016/j.jmbbm.2012.07.004

|

下载:

下载: