Influence of basalt fiber on the anti-carbonation performance of recycled aggregate concrete

-

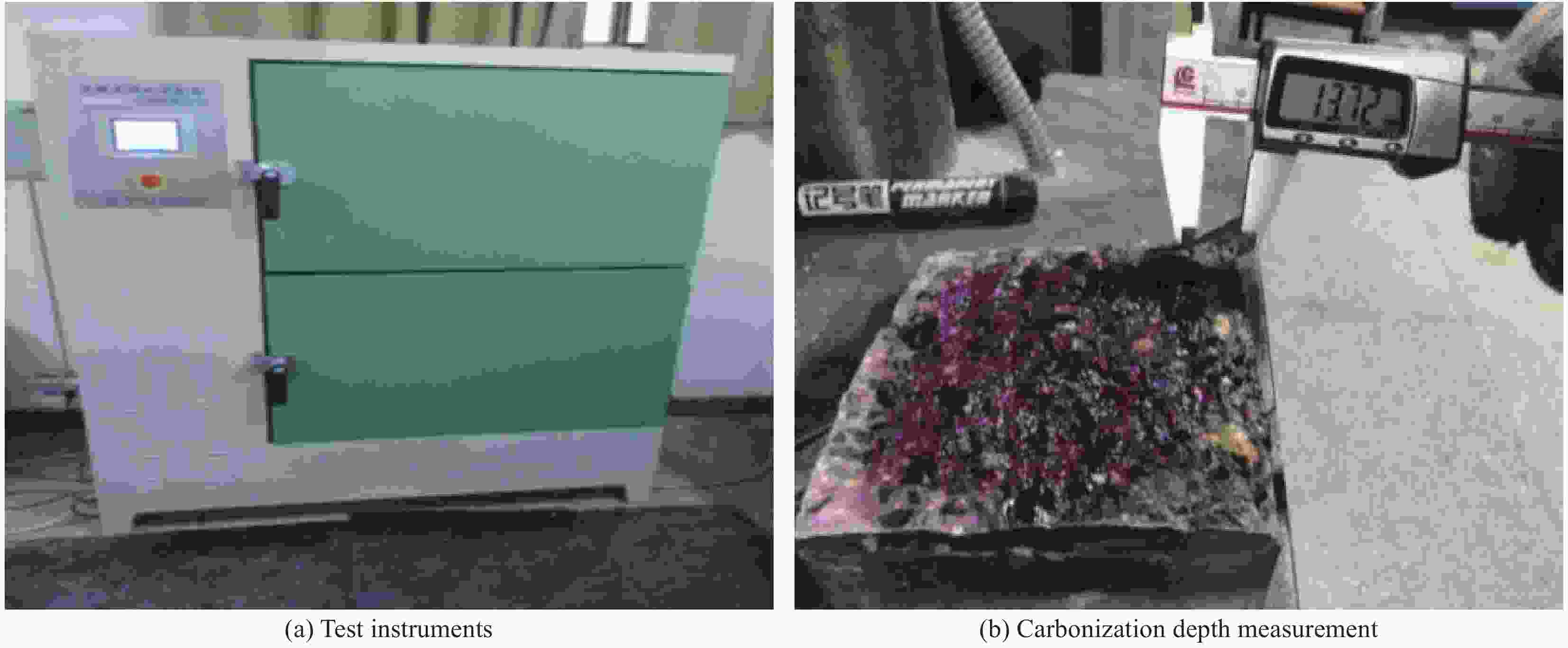

摘要: 采用快速碳化的方法研究了玄武岩纤维(BF)掺量和再生粗骨料(RCA)取代率对再生混凝土(RAC)抗碳化性能的影响,实测了3天、7天、14天、28天的碳化深度,对随碳化天数的增加,碳化深度与BF掺量、RCA取代率之间的关系进行了分析。结果表明,RAC的碳化与天然混凝土(NAC)类似,其碳化深度均随碳化天数的增加而增加,随着RCA取代率的增加,RAC的碳化深度先降后增,当RCA的质量取代率为50%时,RAC的抗碳化性能最佳,掺入BF可以有效地提高RAC的抗碳化性能,随着BF掺量的增加,RAC的抗碳化性能先增后减,最佳掺量为2 kg/m3。另外,采用扫描电子显微镜对BF/RAC的微观结构进行观测,结合扩散理论,揭示了碳化损伤机制。利用试验数据进行拟合,建立了BF/RAC的碳化深度模型。研究成果对今后开展BF/RAC抗碳化性能的研究及工程应用具有一定的参考价值。Abstract: The rapid carbonization method was used to study the influence of basalt fiber (BF) content and recycled coarse aggregate (RCA) replacement ratio on the anti-carbonization performance of recycled aggregate concrete (RAC). The carbonization depth of 3 days, 7 days, 14 days and 28 days was measured, and the relationship between carbonization depth with BF content and replacement ratio of RCA was analyzed with the increase of carbonization days. The results show that the carbonization of RAC is similar to that of natural aggregate concrete (NAC). The depth of carbonization increases with the increase of carbonization days. As the replacement ratio of RCA increases, the carbonization depth of RAC first decreases and then increases, when the RCA mass replacement ratio is 50%, the carbonization resistance of RAC is the best. Incorporating BF can effectively improve the anti-carbonization performance of RAC. With the increase of BF content, the anti-carbonization performance of RAC increases first and then decreases. In this experiment, the optimal content of RAC is 2 kg/m3. In addition, using scanning electron microscope to observe the microstructure of BF/RAC, combined with diffusion theory, the carbonization damage mechanism was revealed. Using test data for fitting, a carbonization depth model of BF/RAC was established. The research results have reference value for future research and engineering applications.

-

Key words:

- recycled aggregate concrete /

- basalt fiber /

- carbonization depth /

- micro structure /

- carbonization model

-

表 1 玄武岩纤维(BF)性能指标

Table 1. Performance index of basalt fiber (BF)

One-dimensional diameter/µm Length/mm Density/(g·cm−3) Elongation at break/% Tensile strength/MPa Elastic modulus/GPa 1.3 18 2.65 2.7 3500 80 表 2 BF/再生混凝土 (RAC) 配合比 (kg/m3)

Table 2. Mixture proportion of BF/recycled aggregate concrete (RAC) (kg/m3)

Group Cement Fly ash Silica fume Sand RCA/mm NCA/mm Water-reducing

agentBF 5-10 10-20 5-10 10-20 NAC 380 40 74 655 0 0 328 655 4.9 0 2BF/NAC 380 40 74 655 0 0 328 655 4.9 2 4BF/NAC 380 40 74 655 0 0 328 655 4.9 4 6BF/NAC 380 40 74 655 0 0 328 655 4.9 6 RAC(50%RCA) 380 40 74 655 163 327 163 327 4.9 0 2BF/RAC(50%RCA) 380 40 74 655 163 327 163 327 4.9 2 4BF/RAC(50%RCA) 380 40 74 655 163 327 163 327 4.9 4 6BF/RAC(50%RCA) 380 40 74 655 163 327 163 327 4.9 6 RAC(100%RCA) 380 40 74 655 328 655 0 0 4.9 0 2BF/RAC(100%RCA) 380 40 74 655 328 655 0 0 4.9 2 4BF/RAC(100%RCA) 380 40 74 655 328 655 0 0 4.9 4 6BF/RAC(100%RCA) 380 40 74 655 328 655 0 0 4.9 6 Notes:NAC—Natural aggregate concrete; BF—Basalt fiber; RAC—Recycled aggregate concrete; RCA—Recycled coarse aggregate; NCA—Natural coarse aggregate; 2BF/NAC, 4BF/NAC, 6BF/NAC—Mixing 2, 4, 6 kg/m3 BF into NAC, respectively; RAC(50%RCA), 2BF/RAC(50%RCA), 4BF/RAC(50%RCA), 6BF/RAC(50%RCA)—Mixing 0, 2, 4, 6 kg/m3 BF into RAC with 50% replacement ratio of RCA, respectively; RAC(100%RCA), 2BF/RAC(100%RCA), 4BF/RAC(100%RCA), 6BF/RAC(100%RCA)—Mixing 0, 2, 4, 6 kg/m3 BF into RAC with 100% replacement ratio of RCA, respectively. 表 3 BF/RAC的碳化深度

Table 3. Carbonization depth of BF/RAC

Project 3 Days 7 Days 14 Days 28 Days NAC 5.82 6.70 7.47 8.73 2BF/NAC 3.95 4.12 4.32 5.30 4BF/NAC 1.83 3.43 3.82 4.77 6BF/NAC 1.53 4.85 5.53 7.43 RAC(50%RCA) 3.09 3.16 6.00 7.61 2BF/RAC(50%RCA) 2.18 3.24 5.46 6.08 4BF/RAC(50%RCA) 3.47 5.54 5.92 7.21 6BF/RAC(50%RCA) 2.71 6.53 6.70 9.79 RAC(100%RCA) 4.21 8.06 9.90 10.15 2BF/RAC(100%RCA) 5.77 7.98 8.62 9.58 4BF/RAC(100%RCA) 5.17 8.75 10.32 10.79 6BF/RAC(100%RCA) 6.36 10.85 11.21 13.05 表 4 BF/RAC碳化深度拟合参数

Table 4. BF/RAC carbonization depth fitting parameters

Project A R2 NAC 1.960 0.763 2BF/NAC 1.191 0.670 4BF/NAC 0.997 0.936 6BF/NAC 1.452 0.944 RAC(50%RCA) 1.470 0.968 2BF/RAC(50%RCA) 1.249 0.963 4BF/RAC(50%RCA) 1.557 0.884 6BF/RAC(50%RCA) 1.901 0.951 RAC(100%RCA) 2.296 0.870 2BF/RAC(100%RCA) 2.193 0.780 4BF/RAC(100%RCA) 2.458 0.851 6BF/RAC(100%RCA) 2.899 0.843 Notes:A—Carbonization ratio coefficient; R2—Coefficient of determination. 表 5 BF/RAC A值的拟合参数

Table 5. Fitting parameters of A value of BF/RAC

RCA substitution ratio a b c R2 0% 0.08 −0.55 1.96 0.998 50% 0.04 −0.13 1.45 0.833 100% 0.03 −0.10 2.29 0.981 表 6 BF/RAC碳化深度模型

Table 6. BF/RAC carbonization depth model

RCA substitution ratio Carbonization depth model of BF/RAC 0% $Y = (0.077{m^2} - 0.545m + 1.964)\sqrt x $ 50% $Y = (0.035{m^2} - 0.131m + 1.445)\sqrt x $ 100% $Y = (0.034{m^2} - 0.1m + 2.286)\sqrt x $ 表 7 RAC碳化深度模型对比

Table 7. Comparison of carbonization depth models of RAC

Specimen Time/d Actual value Calculated value Calculated value/Actual value This study Xiao’s model[30] Geng’s model[13] This study Xiao’s model[30] Geng’s model[13] NAC 3 5.82 3.37 1.31 6.50 0.58 0.23 1.12 7 6.70 5.15 2.01 8.69 0.77 0.30 1.30 14 7.47 7.28 2.84 11.01 0.97 0.38 1.47 28 8.73 10.30 4.02 13.96 1.18 0.46 1.60 RAC(50%RCA) 3 3.09 2.50 1.64 6.59 0.81 0.53 2.13 7 3.16 3.82 2.51 8.81 1.21 0.79 2.79 14 6.00 5.41 3.55 11.16 0.90 0.59 1.86 28 7.61 7.65 5.02 14.15 1.00 0.66 1.86 RAC(100%RCA) 3 4.21 3.96 1.97 6.68 0.94 0.47 1.59 7 8.06 6.05 3.01 8.93 0.75 0.37 1.11 14 9.90 8.55 4.26 11.31 0.86 0.43 1.14 28 10.15 12.10 6.02 14.34 1.19 0.59 1.41 -

[1] GÁLVEZ-MARTOS J, STYLES D, SCHOENBERGER H, et al. Construction and demolition waste best management practice in Europe[J]. Resources, Conservation and Recycling,2018,136:166-178. doi: 10.1016/j.resconrec.2018.04.016 [2] 周静海, 吴迪, 赵庭钰, 等. 废弃纤维再生混凝土受压徐变及预测模型[J]. 土木与环境工程学报(中英文), 2019, 41(6):143-151.ZHOU Jinghai, WU Di, ZHAO Tingyu, et al. Pressure and creep characteristics of waste fiber recycled concrete and estimation model[J]. Journal of Civil and Environmental Engineering,2019,41(6):143-151(in Chinese). [3] TAM V W Y, SOOMRO M, EVANGELISTA A C J, et al. A review of recycled aggregate in concrete applications (2000-2007)[J]. Construction and Building Materials,2018,172:272-292. doi: 10.1016/j.conbuildmat.2018.03.240 [4] MA Z, LIU M, TANG Q. Chloride permeability of recycled aggregate concrete under the coupling effect of freezing-thawing, elevated temperature or mechanical damage[J]. Construction and Building Materials,2020,237:117648. doi: 10.1016/j.conbuildmat.2019.117648 [5] 黄一杰, 张宜健, 肖建庄, 等. 海水海砂再生混凝土与环氧涂层钢筋黏结性能[J]. 建筑结构学报, 2020, 41(S1):390-398.HUANG Yijie, ZHANG Yijian, XIAO Jianzhuang, et al. Study on bond between seawater sea sand recycled concrete and epoxy-coated steel bars[J]. Journal of Building Structures,2020,41(S1):390-398(in Chinese). [6] 孟二从, 余亚琳, 袁军, 等. 温度对全再生混凝土三轴受压性能及破坏准则影响[J]. 应用基础与工程科学学报, 2019, 27(6):1370-1380.MENG Ercong, YU Yalin, YUAN Jun, et al. Influence of temperature on the triaxial compressive behavior and failure criterion of recycled aggregate concrete[J]. Journal of Basic Science and Engineering,2019,27(6):1370-1380(in Chinese). [7] SOARES D, DE BRITO J, FERREIRA J, et al. Use of coarse recycled aggregates from precast concrete rejects: Mecha-nical and durability performance[J]. Construction and Building Materials,2014,71:263-272. doi: 10.1016/j.conbuildmat.2014.08.034 [8] 任瑞. 型钢再生混凝土框架抗震性能及设计方法研究[D]. 西安: 西安建筑科技大学, 2014.REN Rui. Study on seismic behavior and seismic design methods of steel reinforced recycled concrete frame structure[D]. Xi’an: Xi’an University of Architecture and Technology, 2014(in Chinese). [9] REN R, Qi L, XUE J, et al. Cyclic bond property of steel reinforced recycled concrete (SRRC) composite structure[J]. Construction and Building Materials,2020,245:11845. [10] ZHU P, ZHANG X, WU J, et al. Performance degradation of the repeated recycled aggregate concrete with 70% replacement of three-generation recycled coarse aggregate[J]. Journal of Wuhan University of Technology: Materials Science,2016,31(5):989-995. doi: 10.1007/s11595-016-1480-y [11] WANG J, ZHANG J, CAO D, et al. Pore characteristics of recycled aggregate concrete and its relationship with durability under complex environmental factors[J]. Construction and Building Materials,2020,272(1):121642. [12] SILVA R V, NEVES R, DE BRITO J, et al. Carbonation behaviour of recycled aggregate concrete[J]. Cement and Concrete Composites,2015,62:22-32. doi: 10.1016/j.cemconcomp.2015.04.017 [13] 耿欧, 张鑫, 张铖铠. 再生混凝土碳化深度预测模型[J]. 中国矿业大学学报, 2015, 44(1):54-58.GENG Ou, ZHANG Xin, ZHANG Chengkai. Prediction models of the carbonization depth of recycled concrete[J]. Journal of China University of Mining & Technology,2015,44(1):54-58(in Chinese). [14] KURDA R, DE BRITO J, SILVESTRE J D. Carbonation of concrete made with high amount of fly ash and recycled concrete aggregates for utilization of CO2[J]. Journal of CO2 Utilization,2019,29:12-19. doi: 10.1016/j.jcou.2018.11.004 [15] 薛维培, 刘晓媛, 姚直书, 等. 不同损伤源对玄武岩纤维增强混凝土孔隙结构变化特征的影响[J]. 复合材料学报, 2020, 37(9):2285-2293.XUE Weipei, LIU Xiaoyuan, YAO Zhishu, et al. Effects of diff-erent damage sources on pore structure change characteristics of basalt fiber reinforced concrete[J]. Acta Materiae Compositae Sinica,2020,37(9):2285-2293(in Chinese). [16] 丁一宁, 马跃, 郝晓卫. 基于分形理论分析裂缝形态对纤维/混凝土渗透性的影响[J]. 复合材料学报, 2020, 37(11):2908-2916.DING Yining, MA Yue, HAO Xiaowei. Investigation on effect of crack geometry on permeability of fiber/concrete based on fractal theory[J]. Acta Materiae Compositae Sinica,2020,37(11):2908-2916(in Chinese). [17] 孙浩, 王培铭, 孙家瑛. 再生混凝土抗气渗性及抗碳化性能研究[J]. 建筑材料学报, 2006, 9(1):86-91. doi: 10.3969/j.issn.1007-9629.2006.01.016SUN Hao, WANG Peiming, SUN Jiaying. Study on the gas anti-permeability and carbonation resistance of recycled concrete[J]. Journal of Building Materials,2006,9(1):86-91(in Chinese). doi: 10.3969/j.issn.1007-9629.2006.01.016 [18] 王建超, 裘子铭, 陆佳韦, 等. 废弃纤维再生混凝土碳化深度预测模型研究[J]. 硅酸盐通报, 2020, 39(5):1503-1510,1516.WANG Jianchao, QIU Ziming, LU Jiawei, et al. Carbonation depth prediction model of waste fiber recycled concrete[J]. Bulletin of the Chinese Ceramic Society,2020,39(5):1503-1510,1516(in Chinese). [19] 闫春岭, 高丹盈, 胡春生, 等. 钢纤维再生粗骨料混凝土碳化试验[J]. 土木工程与管理学报, 2017, 34(2):64-72. doi: 10.3969/j.issn.2095-0985.2017.02.015YAN Chunling, GAO Danying, HU Chunsheng, et al. Carbonization test of steel fiber reinforced recycled coarse aggregate concrete[J]. Journal of Civil Engineering and Management,2017,34(2):64-72(in Chinese). doi: 10.3969/j.issn.2095-0985.2017.02.015 [20] 王艳, 牛荻涛, 苗元耀, 等. 弯曲荷载作用下钢纤维混凝土碳化性能[J]. 西安建筑科技大学学报(自然科学版), 2015, 47(1):51-55.WANG Yan, NIU Ditao, MIAO Yuanyao, et al. Carbona-tion of steel fiber reinforced concrete under flexural loading[J]. Journal of Xi’an University of Architecture & Technology,2015,47(1):51-55(in Chinese). [21] 王占海, 杨德健. 钢纤维混凝土碳化深度影响因素及预测模型研究[J]. 天津城建大学学报, 2015, 21(4):262-266. doi: 10.3969/j.issn.1006-6853.2015.04.006WANG Zhanhai, YANG Dejian. Study on influencing factors and prediction model of carbonation depth of steel fiber concrete[J]. Journal of Tianjin Chengjian University,2015,21(4):262-266(in Chinese). doi: 10.3969/j.issn.1006-6853.2015.04.006 [22] 刘玉林, 吴多, 刘思语, 等. 钢-聚丙烯纤维混凝土碳化深度预测模型算法研究[J]. 南昌工程学院学报, 2020, 39(6):54-58.LIU Yulin, WU Duo, LIU Siyu, et al. Study on prediction model algorithm of carbonation depth of steel-polypro-pylene fiber reinforced concrete[J]. Journal of Nanchang Institute of Technology,2020,39(6):54-58(in Chinese). [23] 张运华, 姚丽萍, 徐仕进, 等. 表面处理玄武岩纤维增强水泥基复合材料力学性能[J]. 复合材料学报, 2017, 34(5):1159-1166.ZHANG Yunhua, YAO Liping, XU Shijin, et al. Mechanical properties of cement matrix composites reinforced with surface treated basalt fibers[J]. Acta Materiae Compositae Sinica,2017,34(5):1159-1166(in Chinese). [24] 李为民, 许金余, 沈刘军, 等. 玄武岩纤维混凝土的动态力学性能[J]. 复合材料学报, 2008(2):135-142. doi: 10.3321/j.issn:1000-3851.2008.02.023LI Weimin, XU Jinyu, SHEN Liujun, et al. Dynamic mecha-nical properties of basalt fiber reinforced concrete using a split hopkinson pressure bar[J]. Acta Materiae Compo-sitae Sinica,2008(2):135-142(in Chinese). doi: 10.3321/j.issn:1000-3851.2008.02.023 [25] LI S, ZHANG Y, CHEN W, et al. Bending performance of unbonded prestressed basalt fiber recycled concrete beams[J]. Engineering Structures,2020,221:110937. doi: 10.1016/j.engstruct.2020.110937 [26] FANG S E, HONG H S, ZHANG P H, et al. Mechanical pro-perty tests and strength formulas of basalt fiber reinforced recycled aggregate concrete[J]. Materials (Basel),2018,11(10):2-14. [27] LI G, ZHANG L, ZHAO F. Acoustic emission characteristics and damage mechanisms investigation of basalt fiber concrete with recycled aggregate[J]. Materials,2020,13(18):2-22. [28] MENG W, LIU H, LIU G, et al. Bond-slip constitutive relation between BFRP bar and basalt fiber recycled aggregate concrete[J]. KSCE Journal of Civil Engineering,2016,20(5):1996-2006. doi: 10.1007/s12205-015-0350-z [29] 中华人民共和国住房和城乡建设部. GB/T 50082—2009 普通混凝土长期性能和耐久性能试验方法标准[S]. 北京: 中国建筑工业出版社, 2009.Ministry of Housing and Urban-Rural Development of the People's Republic of China. GB/T 50082—2009 Standard for test methods of long-term performance and durability of ordinary concrete[S]. Beijing: China Architecture & Building Press, 2009(in Chinese). [30] 肖建庄, 雷斌. 再生混凝土碳化模型与结构耐久性设计[J]. 建筑科学与工程学报, 2008(3):66-72. doi: 10.3321/j.issn:1673-2049.2008.03.013XIAO Jianzhuang, LEI Bin. Carbonation model and structural durability design for recycled concrete[J]. Journal of Architecture and Civil Engineering,2008(3):66-72(in Chinese). doi: 10.3321/j.issn:1673-2049.2008.03.013 -

下载:

下载: