In-plane permeability characterization of fiber fabric based on digital image technology

-

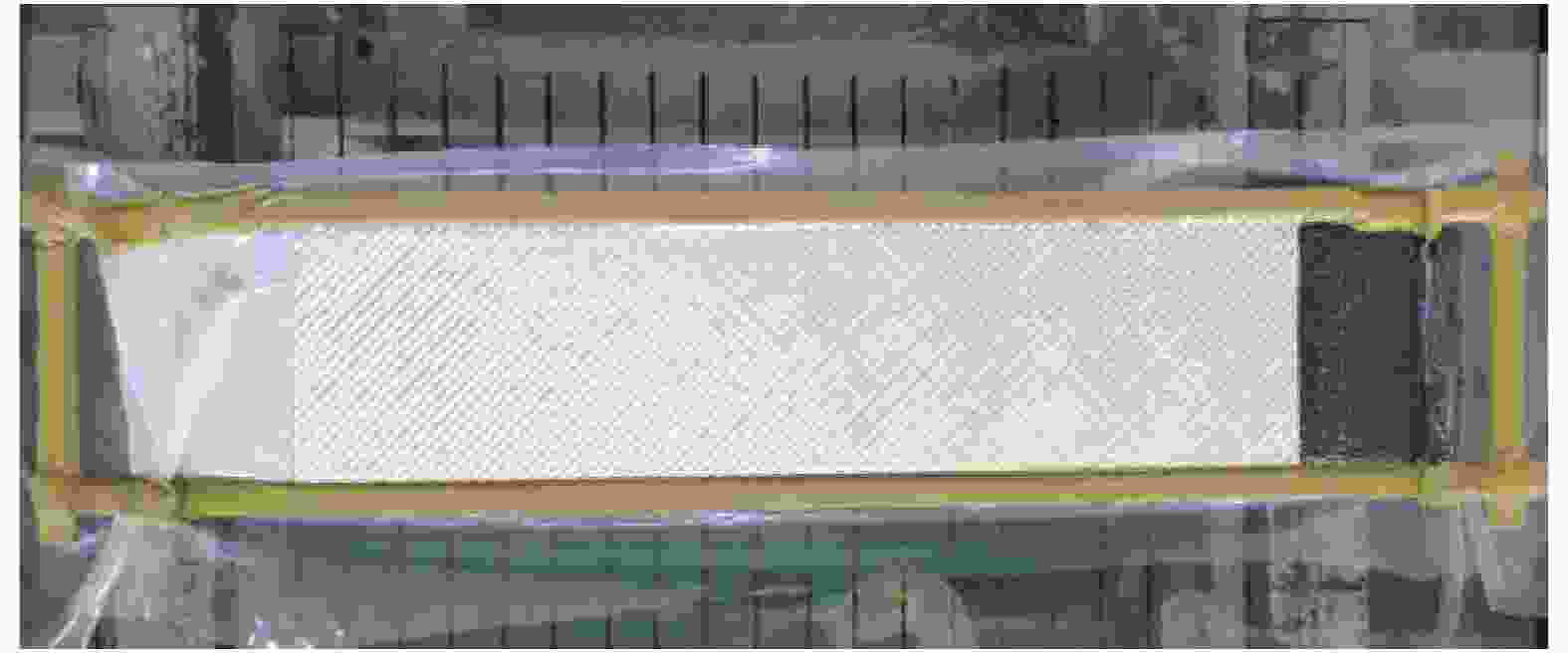

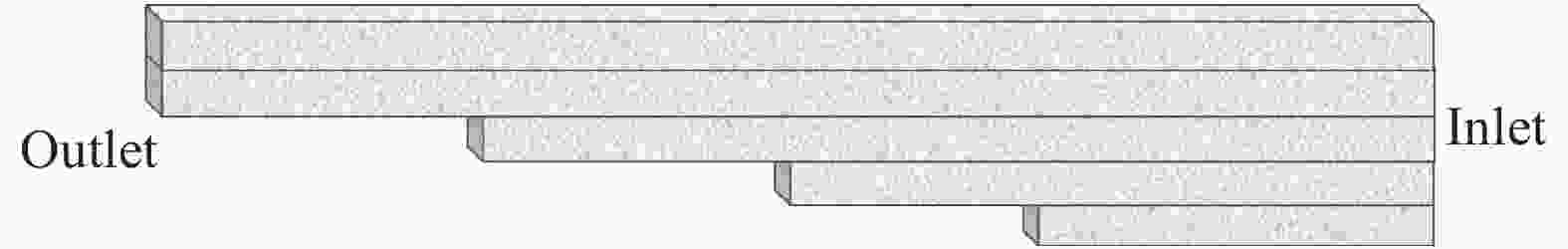

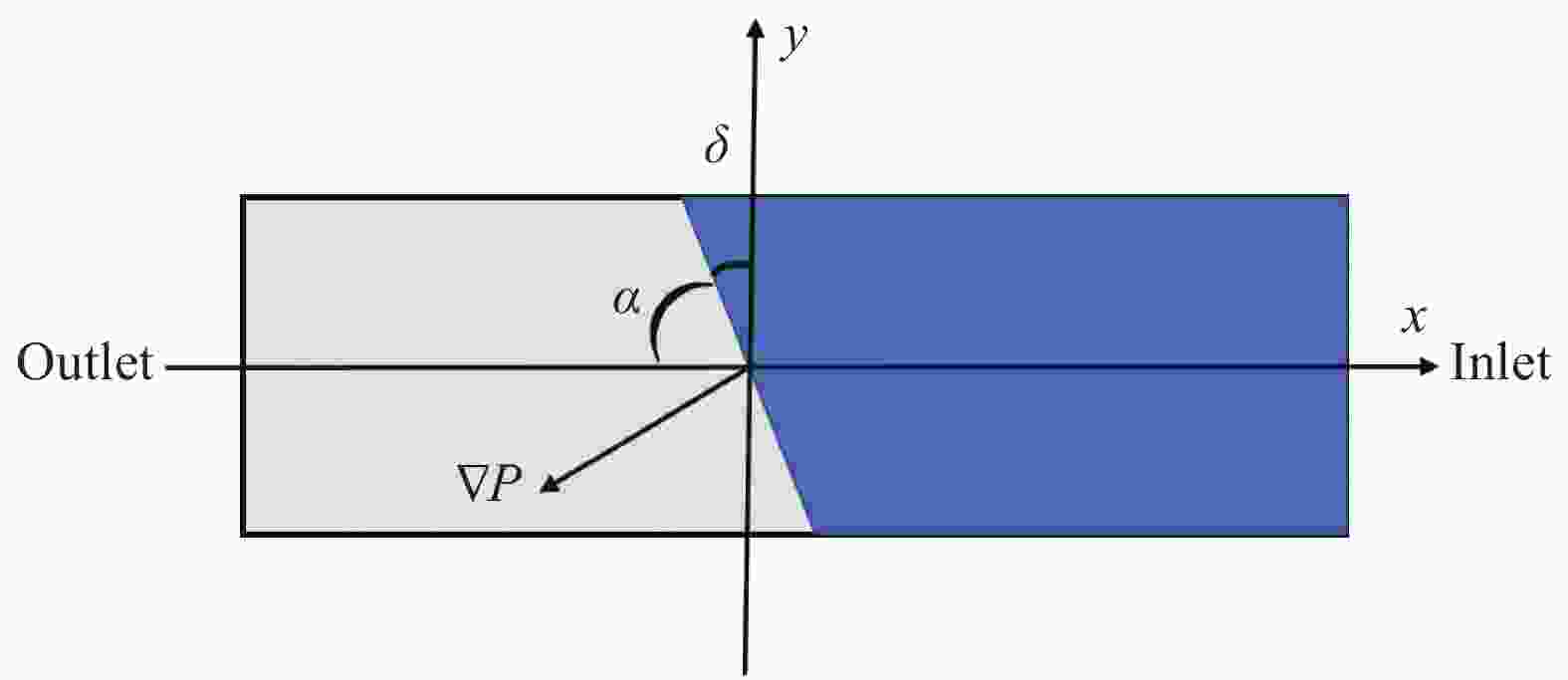

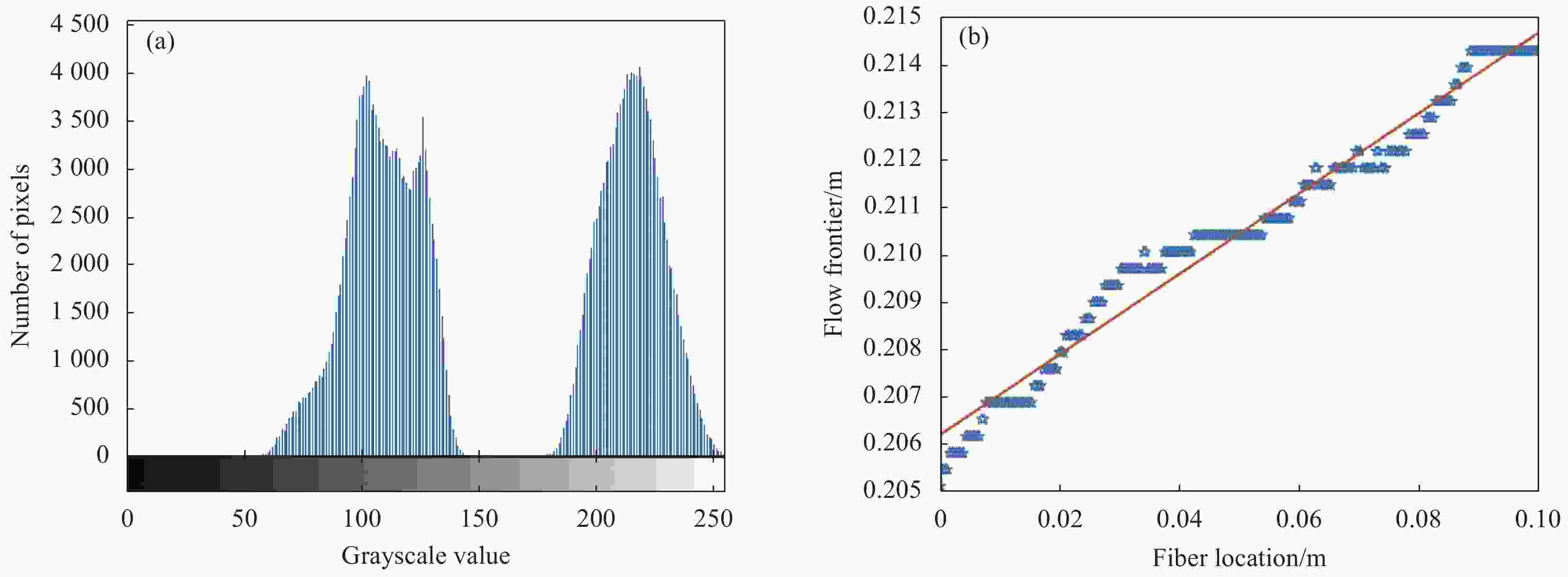

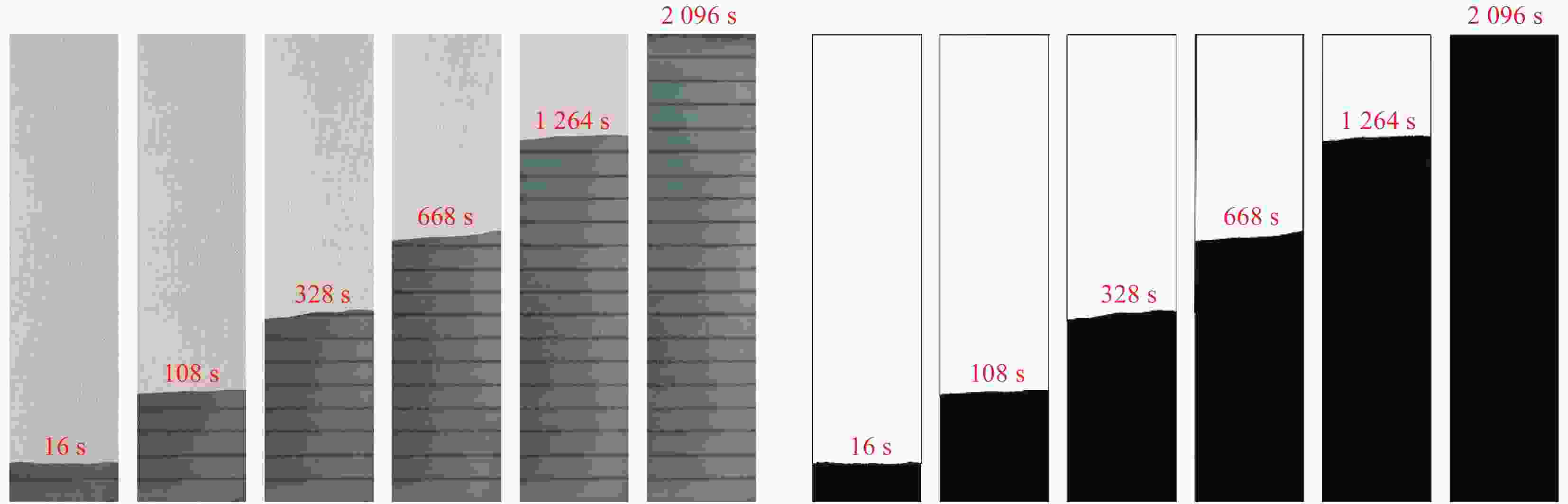

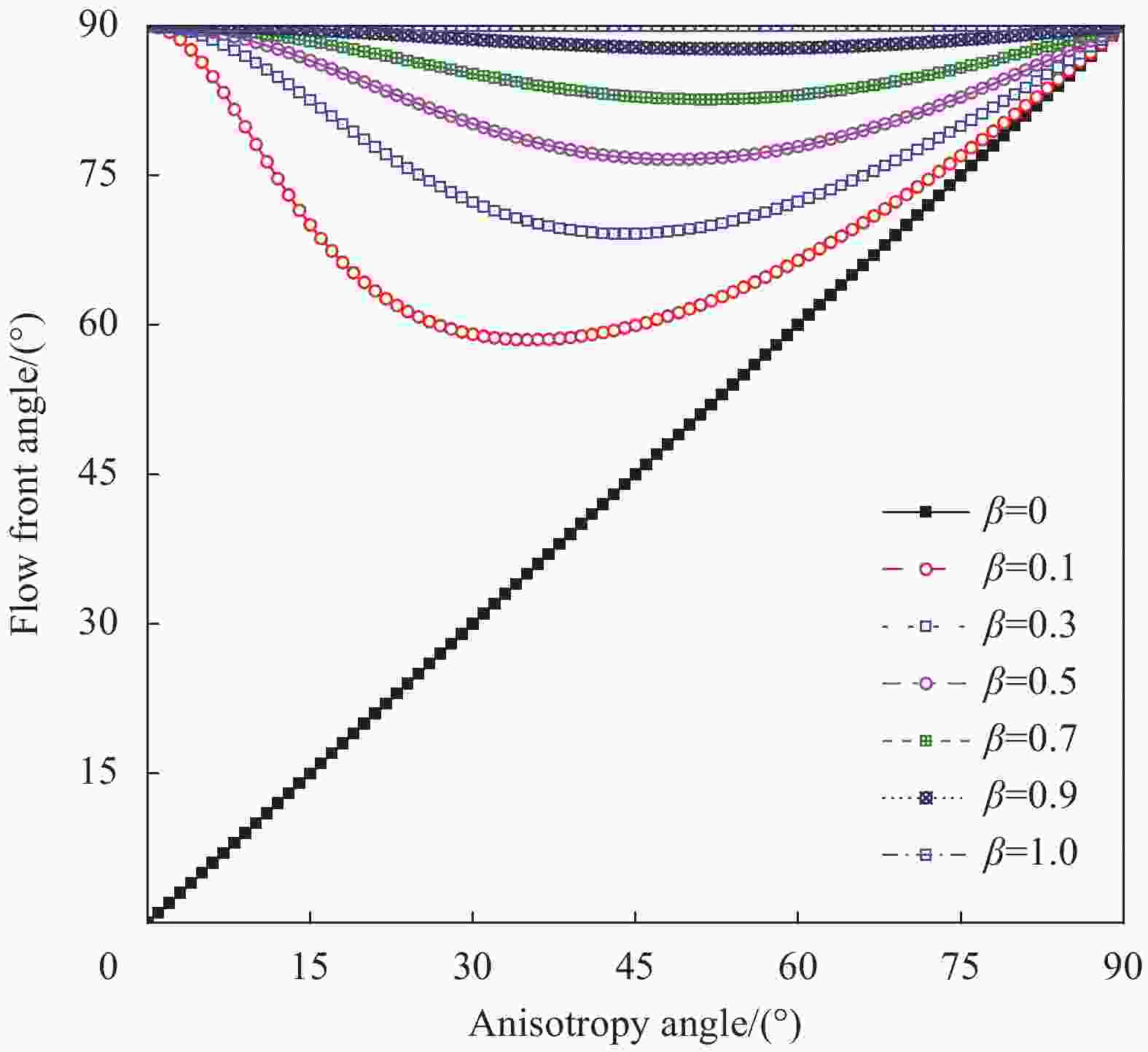

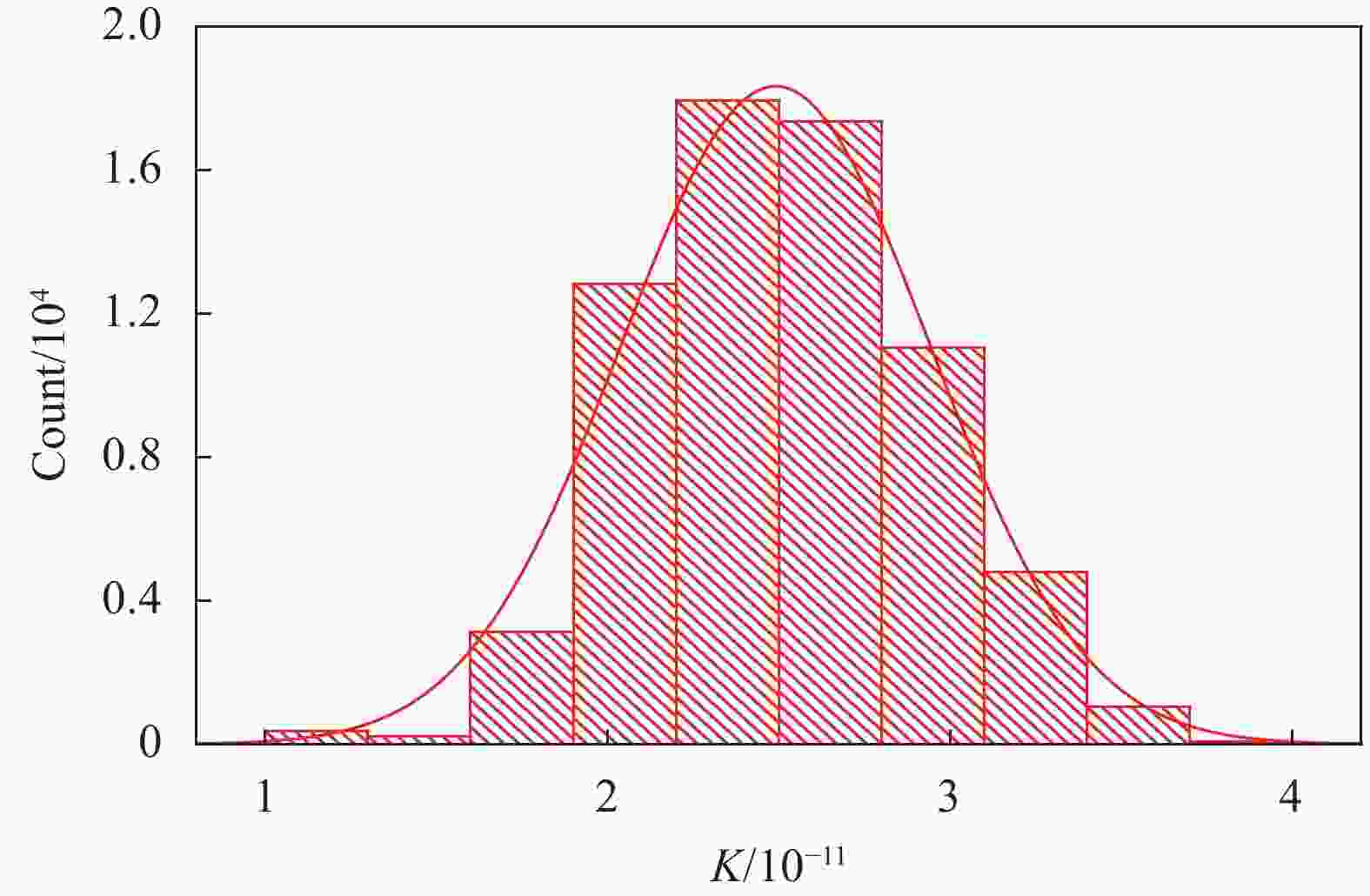

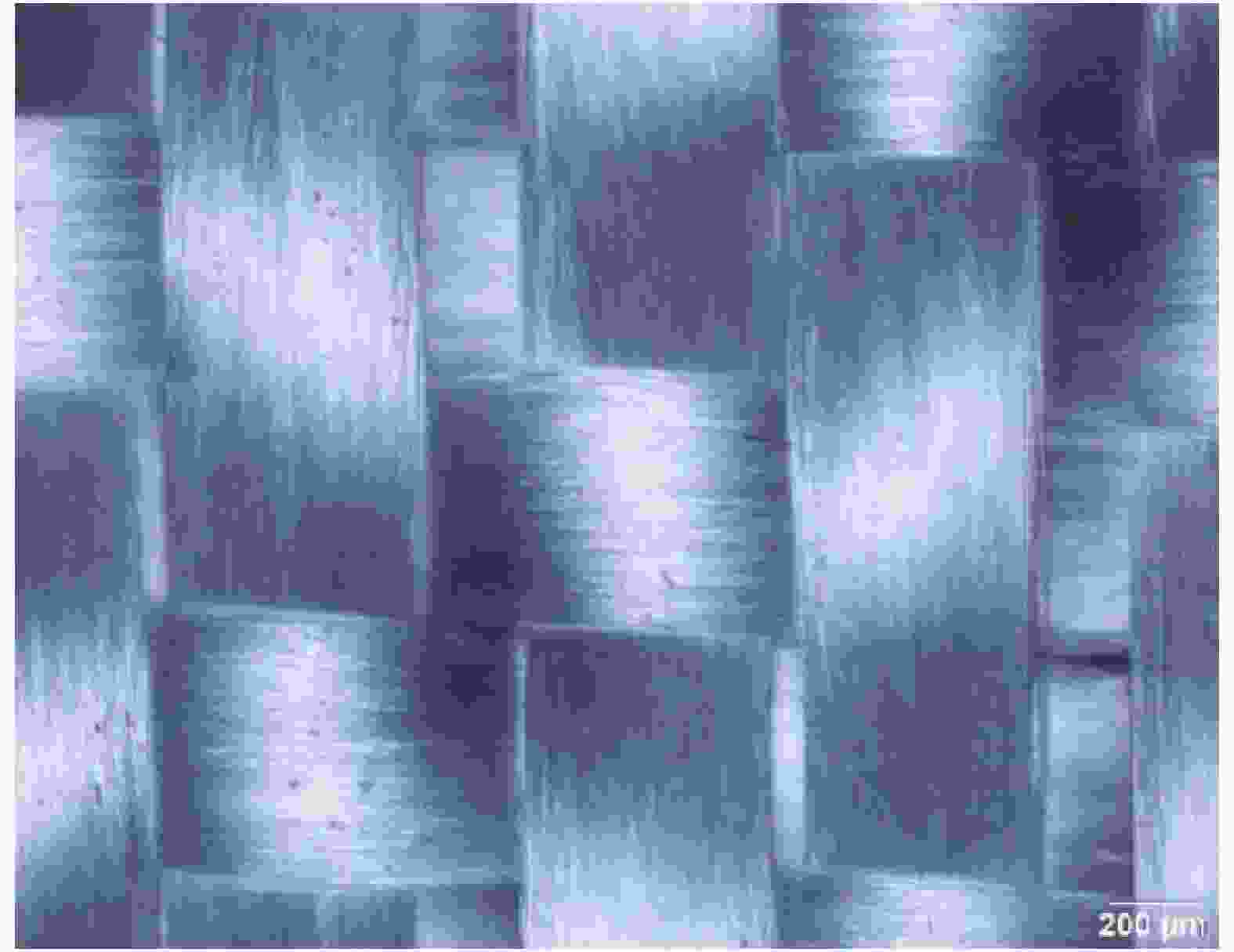

摘要: 材料渗透率的表征受其结构空间离散性和求解方式准确性的严重影响。基于数字图像技术,评估了纤维织物渗透率的空间分布,并探讨了阶梯铺层对灌注工艺的影响。首先,从恒压单向注射实验的视频流中动态提取了流动前沿的流速分布和流动前沿角,通过织物渗透率与结构的关系仅一次实验便可求得纤维织物的面内局部渗透率分布;其次,利用正态分布函数拟合,建立了基于数字图像技术的纤维织物面内主方向渗透率张量的求解方法,并利用该方法研究了编织形式对渗透率的影响;最后,研究了阶梯铺层和恒定铺层对灌注过程的影响。结果表明:建立的基于数字图像技术的渗透率表征方法可以通过一次实验同时获取面内主方向上的渗透率及其空间离散型;在恒定铺层下缎纹织物渗透率随着纤维层数增大而增大,从厚铺层向薄铺层的灌注方式可以达到最优的灌注时间。Abstract: The spatial discretization of the structure and the method’s accuracy have profoundly affected the characterization of material permeability. The spatial distribution of fabrics’ permeability was evaluated based on digital image technology, and the effect of step layup sequence on the infusion process was discussed. Firstly, the flow velocity distribution and the flow front angle of the flow front were dynamically extracted from the video stream of the constant pressure unidirectional injection experiments. The in-plane local permeability distribution of the fiber fabric can be obtained through only an experiment by the relationship between fabric permeability and structure. Secondly, solving method of the permeability tensor in the main direction of the fiber fabric based on digital image technology was established by fitting the normal distribution function and was used to study the influence of the weaving form on the permeability. Finally, the step layup sequence and constant layup sequence on the infusion process were studied. The results show that the in-plane permeability characterization method established based on digital image technology could simultaneously obtain the permeability in the main direction of the plane and its spatial discretization through only one experiment. The permeability of satin fabric increases with the increase of the number of fiber layers. The infusion method from thicker region to the thin region can achieve the optimal infusion time.

-

Key words:

- vacuum infusion /

- fiber fabric /

- permeability /

- flow front /

- digital image technology

-

表 1 实验材料的相关参数

Table 1. Related parameters of experimental materials

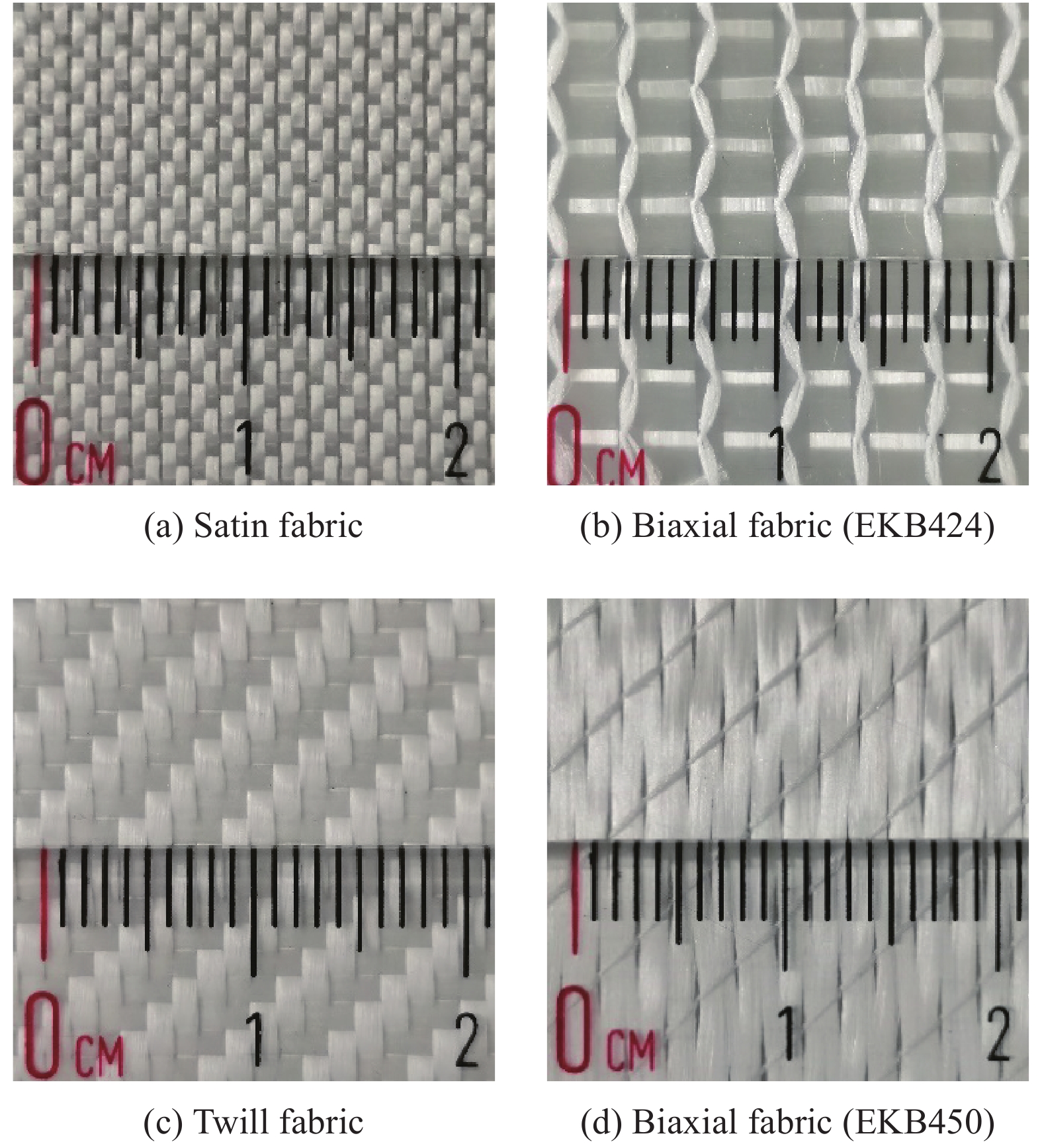

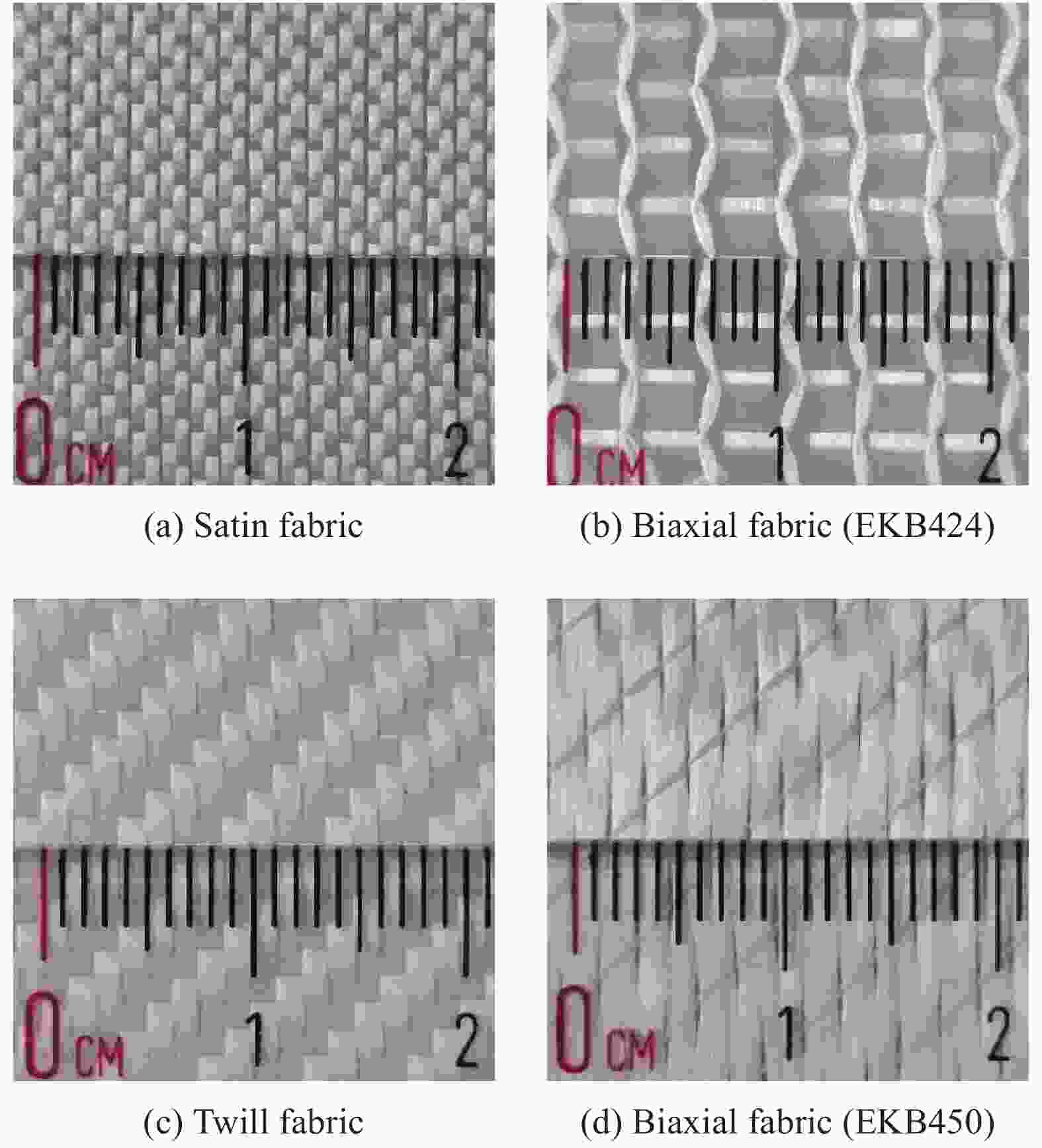

Material Type Areal weight/(g·m−2) Density/(kg·m−3) Vinyl resin ATLAC 430 LV − 1100 Satin fabric − 220 2550 Twill fabric 2/2 Twill 327 2550 Biaxial fabric EKB450 455 2550 Biaxial fabric EKB424 424 2550 表 2 纤维织物的面内渗透率结果

Table 2. In-plane permeability results of fiber fabric

Textile α/(°) K45°/10−11 m2 K1/10−11 m2 K2/10−11 m2 β SF 86 2.386 2.565 2.230 0.869 Twill 78 0.521 0.662 0.430 0.649 EKB450 74 0.990 1.387 0.769 0.554 EKB424 58 9.544 25.442 5.874 0.231 Notes: K45°—Permeability of the fabric in 45° direction; K1—Permeability of the fabric in the fastest direction; K2—Permeability of fabric in the slowest direction; β—Degree of anisotropy. 表 3 SF在均一铺层与阶梯铺层下渗透率对比

Table 3. Comparison of permeability of SF under uniform ply and step ply

Textile Number of

layersThickness/

mmAverage layer

thickness/mmVf/% KU/(10−11 m2) σ/(10−11 m2) KS/(10−11 m2) σ/(10−11 m2) SF 2 0.331 0.1655 52.13 2.490 0.451 4.363 0.829 3 0.525 0.1750 49.30 2.613 0.424 3.586 0.663 4 0.723 0.1808 47.73 2.691 0.487 2.998 0.874 5 0.922 0.1844 46.79 2.773 0.513 2.775 0.730 Notes: Vf—Fiber volume fraction; KU—Permeability under uniform ply; KS—Permeability under step ply; σ—Standard deviation. -

[1] 武卫莉, 陈丰雨. 真空辅助树脂灌注法制备风电叶片树脂的渗透及缺陷[J]. 复合材料学报, 2019, 36(12):2779-2785.WU Weili, CHEN Fengyu. Resin permeation and defects of wind turbine blades prepared by vacuum assisted resin infusion method[J]. Acta Materiae Compositae Sinica,2019,36(12):2779-2785(in Chinese). [2] 赵安安, 王林文, 王浩军, 等. 复合材料液体成型技术的航空应用[J]. 工程塑料应用, 2018, 46(4):145-150.ZHAO Anan, WANG Linwen, WANG Haojun, et al. Application of liquid composite molding technology on aeronautics[J]. Engineering Plastics Applications,2018,46(4):145-150(in Chinese). [3] KONSTANTOPOULOS S, HUEBER C, ANTONIADIS I, et al. Liquid composite molding reproducibility in real-world production of fiber reinforced polymeric composites: A review of challenges and solutions[J]. Advanced Manufacturing: Polymer & Composites Science,2019,5(3):85-99. [4] 杨旭静, 王跃飞, 韦凯, 等. 基于孔隙控制的车身结构树脂传递模塑成型工艺设计[J]. 复合材料学报, 2017, 34(5):970-977.YANG Xujing, WANG Yuefei, WEI Kai, et al. Design of resin transfer molding process for vehicle body structure based on porosity control[J]. Acta Materiae Compositae Sinica,2017,34(5):970-977(in Chinese). [5] SIRTAUTAS J, PICKETT A K, GEORGE A. Materials characterisation and analysis for flow simulation of liquid resin infusion[J]. Applied Composite Materials,2014,22(3):1-19. [6] NAIK N K, SIRISHA M, INANI A. Permeability characterization of polymer matrix composites by RTM/VARTM[J]. Progress in Aerospace Sciences, 2014, 65: 22-40. [7] MAY D, AKTAS A, ADVANI S G, et al. In-plane permeability characterization of engineering textiles based on radial flow experiments: A benchmark exercise[J]. Composites Part A: Applied Science and Manufacturing,2019,121:100-114. doi: 10.1016/j.compositesa.2019.03.006 [8] RUIZ E, VERNET N, ADVANI S. Experimental determination of the permeability of engineering textiles: Benchmark II[J]. Composites Part A: Applied Science and Manufacturing,2014,61:172-184. doi: 10.1016/j.compositesa.2014.02.010 [9] DEMARIA C, RUIZ E, TROCHU F. In-plane anisotropic permeability characterization of deformed woven fabrics by unidirectional injection. Part I: Experimental results[J]. Polymer Composites,2007,28(6):797-811. doi: 10.1002/pc.20107 [10] FAUSTER E, BERG D C, MAY D, et al. Robust evaluation of flow front data for in-plane permeability characterization by radial flow experiments[J]. Advanced Manufacturing: Polymer & Composites Science,2018,4(1):24-40. [11] 张嘉阳, 刘刚, 李龙, 等. 国产CCF300碳纤维单向织物液体成型工艺性及其复合材料力学性能[J]. 复合材料学报, 2016, 33(1):17-26.ZHANG Jiayang, LIU Gang, LI Long, et al. Processability of domestic CCF300 carbon fiber unidirectional fabrics for liquid molding and mechanical properties of their compo-sites[J]. Acta Materiae Compositae Sinica,2016,33(1):17-26(in Chinese). [12] FERLAND P, GUITTARD D, TROCHU F. Concurrent methods for permeability measurement in resin transfer molding[J]. Polymer Composites, 1996, 17(1): 149-158. [13] PIERCE R S, FALZON B G, THOMPSON M C. Permeability characterization of sheared carbon fiber textile preform[J]. Polymer Composites,2018,39(7):2287-2298. doi: 10.1002/pc.24206 [14] COSSON B. Optical measurement of local permeability of flax fiber fabrics before liquid composite molding[J]. Journal of Composite Materials,2018,52(24):3289-3297. doi: 10.1177/0021998318764579 [15] 耿奕, 蒋金华, 陈南梁. 经编四轴向玻璃纤维织物的渗透行为和渗透率[J]. 纺织学报, 2017, 38(10):49-56.GENG Yi, JIANG Jinhua, CHEN Nanliang. Permeation behavior and permeability of warp-knitted quadri-axial glass fiber fabric[J]. Journal of Textile Research,2017,38(10):49-56(in Chinese). [16] 方良超. 嵌套效应对织物压缩性及渗透性的影响研究[D]. 西安: 西北工业大学, 2016.FANG Liangchao. Effect of nesting on compaction and permeability properties of fabrics[D]. Xi’an: Northwestern Polytechnical University, 2016(in Chinese). [17] PEARCE N, SUMMERSCALES J. The compressibility of a reinforcement fabric[J]. Composites Manufacturing,1995,6(1):15-21. doi: 10.1016/0956-7143(95)93709-S [18] 周莉莉. 实时监测技术在LCM工艺上的应用研究[D]. 上海: 东华大学, 2009.ZHOU Lili. Application of real-time sensing and monitoring in LCM process[D]. Shanghai: Donghua University, 2009(in Chinese). [19] 武红玉. 阈值分割算法在图像处理中的应用[J]. 科技信息, 2012(27):201-202.WU Hongyu. Application of threshold segmentation algorithm in image processing[J]. Science and Technology Information,2012(27):201-202(in Chinese). [20] 孔凡胜, 王竹林, 高伟伟. 某型检测系统图像信息噪声处理研究[J]. 计算机与数字工程, 2014, 42(8):1484-1487.KONG Fansheng, WANG Zhulin, GAO Weiwei. Noise information processing of some detection system[J]. Computer and Digital Engineering,2014,42(8):1484-1487(in Chinese). [21] FRATTA C D, KOUTSOUKIS G, KLUNKER F, et al. Characterization of anisotropic permeability from flow front angle measurements[J]. Polymer Composites,2016,37(7):2037-2052. doi: 10.1002/pc.23382 [22] BARIS C, DAMIANO S, MURAT S E, et al. In-plane permeability distribution mapping of isotropic mats using flow front detection[J]. 2018, 113: 275-286. -

下载:

下载: