| [1] |

ZHENG Q, LEE J, SHEN X, et al. Graphene-based wearable piezoresistive physical sensors[J]. Materials Today,2020,36:158-179. doi: 10.1016/j.mattod.2019.12.004

|

| [2] |

FU Y, LI Y, LIU Y, et al. High-performance structural flexible strain sensors based on graphene-coated glass fabric/silicone composite[J]. ACS Applied Materials & Interfaces,2018,10(41):35503-35509.

|

| [3] |

WU S, PENG S, YU Y, et al. Strategies for designing stretchable strain sensors and conductors[J]. Advanced Materials Technologies,2019,5(2):1900908.

|

| [4] |

TUNG T T, NINE M J, KREBSZ M, et al. Recent advances in sensing applications of graphene assemblies and their composites[J]. Advanced Functional Materials,2017,27(46):1702891. doi: 10.1002/adfm.201702891

|

| [5] |

LI J, FANG L, SUN B, et al. Review-recent progress in flexible and stretchable piezoresistive sensors and their applications[J]. Journal of the Electrochemical Society,2020,167(3):37561. doi: 10.1149/1945-7111/ab6828

|

| [6] |

LI X, KOH K H, FARHAN M, et al. An ultraflexible polyurethane yarn-based wearable strain sensor with a polydimethylsiloxane infiltrated multilayer sheath for smart textiles[J]. Nanoscale,2020,12(6):4110-4118. doi: 10.1039/C9NR09306K

|

| [7] |

SON W, KIM K, LEE S, et al. Ecoflex-passivated graphene-yarn composite for a highly conductive and stretchable strain sensor[J]. Journal of Nanoscience and Nanotechnology,2019,19(10):6690-6695. doi: 10.1166/jnn.2019.17097

|

| [8] |

WANG Z, LI P, SONG R, et al. High conductive graphene assembled films with porous micro-structure for freestanding and ultra-low power strain sensors[J]. Science Bulletin,2020,65(16):1363-1370. doi: 10.1016/j.scib.2020.05.002

|

| [9] |

XIE L, ZI X, MENG Q, et al. Detection of physiological signals based on graphene using a simple and low-cost method[J]. Sensors,2019,19(7):1656. doi: 10.3390/s19071656

|

| [10] |

WANG S, NING H, HU N, et al. Environmentally-friendly and multifunctional graphene-silk fabric strain sensor for human-motion detection[J]. Advanced materials interfaces,2019,7(1):1901507.

|

| [11] |

TAO L, WANG D, TIAN H, et al. Self-adapted and tunable graphene strain sensors for detecting both subtle and large human motions[J]. Nanoscale,2017,9(24):8266-8273. doi: 10.1039/C7NR01862B

|

| [12] |

WANG W, YANG T, ZHU H, et al. Bio-inspired mechanics of highly sensitive stretchable graphene strain sensors[J]. Applied Physics Letters,2015,106(17):171903. doi: 10.1063/1.4919105

|

| [13] |

HEMPEL M, NEZICH D, KONG J, et al. A novel class of strain gauges based on layered percolative films of 2D materials[J]. Nano Letters,2012,12(11):5714-5718. doi: 10.1021/nl302959a

|

| [14] |

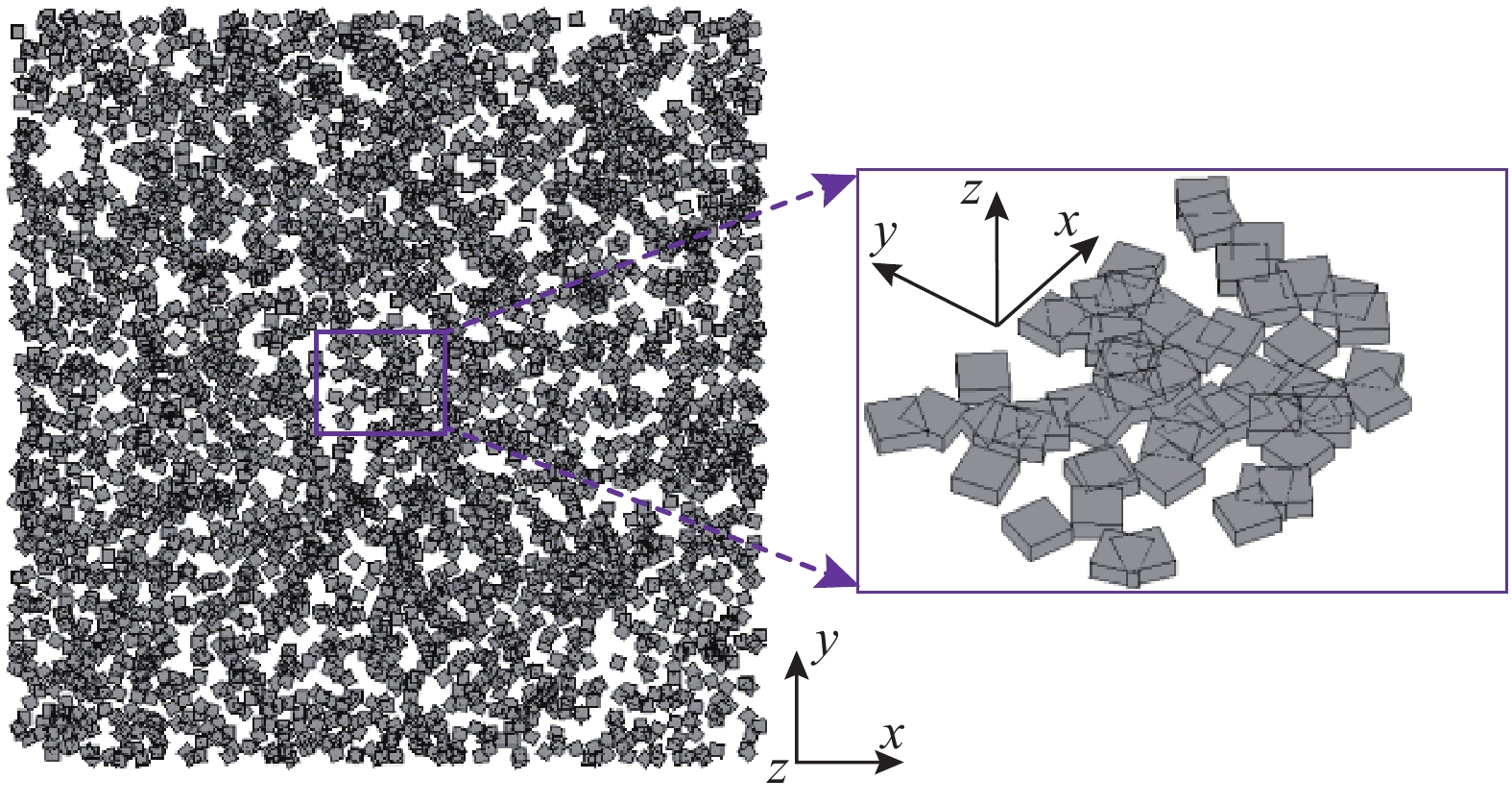

LI Z, YANG Q S. Sensing mechanism of flexible and stretchable composites based on stacked graphene[J]. Materials & Design,2020,187:108384.

|

| [15] |

李正, 杨庆生, 尚军军, 等. 面内随机堆叠石墨烯复合材料压阻传感机理与压阻性能[J]. 力学学报, 2020, 52(6):1700-1708.LI Z, YANG Q S, SHANG J J, et al. Piezoresistive sensing mechanism and piezoresistive performance of in-plane random stacked graphene composites[J]. Chinese Journal of Theoretical and Applied Mechanics,2020,52(6):1700-1708(in Chinese).

|

| [16] |

杨庆生. 复合材料力学[M]. 北京: 科学出版社, 2020: 261.YANG Q S. Mechanics of composite materials[M]. Beijing: Science Press, 2020: 261(in Chinese).

|

| [17] |

HAN F, MALOTH T, LUBINEAU G, et al. Computational investigation of the morphology, efficiency, and properties of silver nano wires networks in transparent conductive film[J]. Scientific Reports,2018,8(1):17494.

|

| [18] |

HTWE Y Z N, MARIATTI M, CHIN S Y. Fabrication of graphene by electrochemical intercalation method and performance of graphene/PVA composites as stretchable strain sensor[J]. Arabian Journal for Science and Engineering,2020,45(9):7677-7689. doi: 10.1007/s13369-020-04807-w

|

| [19] |

LI H, MIRIHANAGE W, SMITH A D, et al. Strain based electrical resistance behaviour of graphene-coated elastomeric yarns[J]. Materials Letters,2020,273:127948. doi: 10.1016/j.matlet.2020.127948

|

| [20] |

HOD O, MEYER E, ZHENG Q, et al. Structural super-lubricity and ultralow friction across the length scales[J]. Nature,2018,563(7732):485-492. doi: 10.1038/s41586-018-0704-z

|

| [21] |

LI X, YANG T, YANG Y, et al. Large-area ultrathin graphene films by single-step marangoni self-assembly for highly sensitive strain sensing application[J]. Advanced Functional Materials,2016,26(9):1322-1329. doi: 10.1002/adfm.201504717

|

| [22] |

MONTAZERIAN H, RASHIDI A, DALILI A, et al. Graphene-coated spandex sensors embedded into silicone sheath for composites health monitoring and wearable applications[J]. Small,2019,15(17):1804991. doi: 10.1002/smll.201804991

|

下载:

下载: