Fiber reinforced shape memory polymer composites and their applications in aerospace

-

摘要: 形状记忆聚合物(SMP)是一种能够保持临时形状,并在外界刺激下自发回复到其初始形状的智能材料,具有高形状固定率、高形状回复率、转变温度可调、变形能力强、质量轻等优点,但其应用受到响应方式单一和承载能力差的限制,通过向聚合物中添加功能颗粒或增强纤维制成形状记忆聚合物复合材料(SMPC),可有效解决这一问题。首先介绍了SMP形状记忆效应的原理,然后阐述了纤维增强型SMPC有限变形过程中纤维的微屈曲行为。最后对可变形结构在航天领域的应用进行了论述。

-

关键词:

- 形状记忆聚合物复合材料 /

- 纤维 /

- 后屈曲 /

- 可变形结构 /

- 航天应用

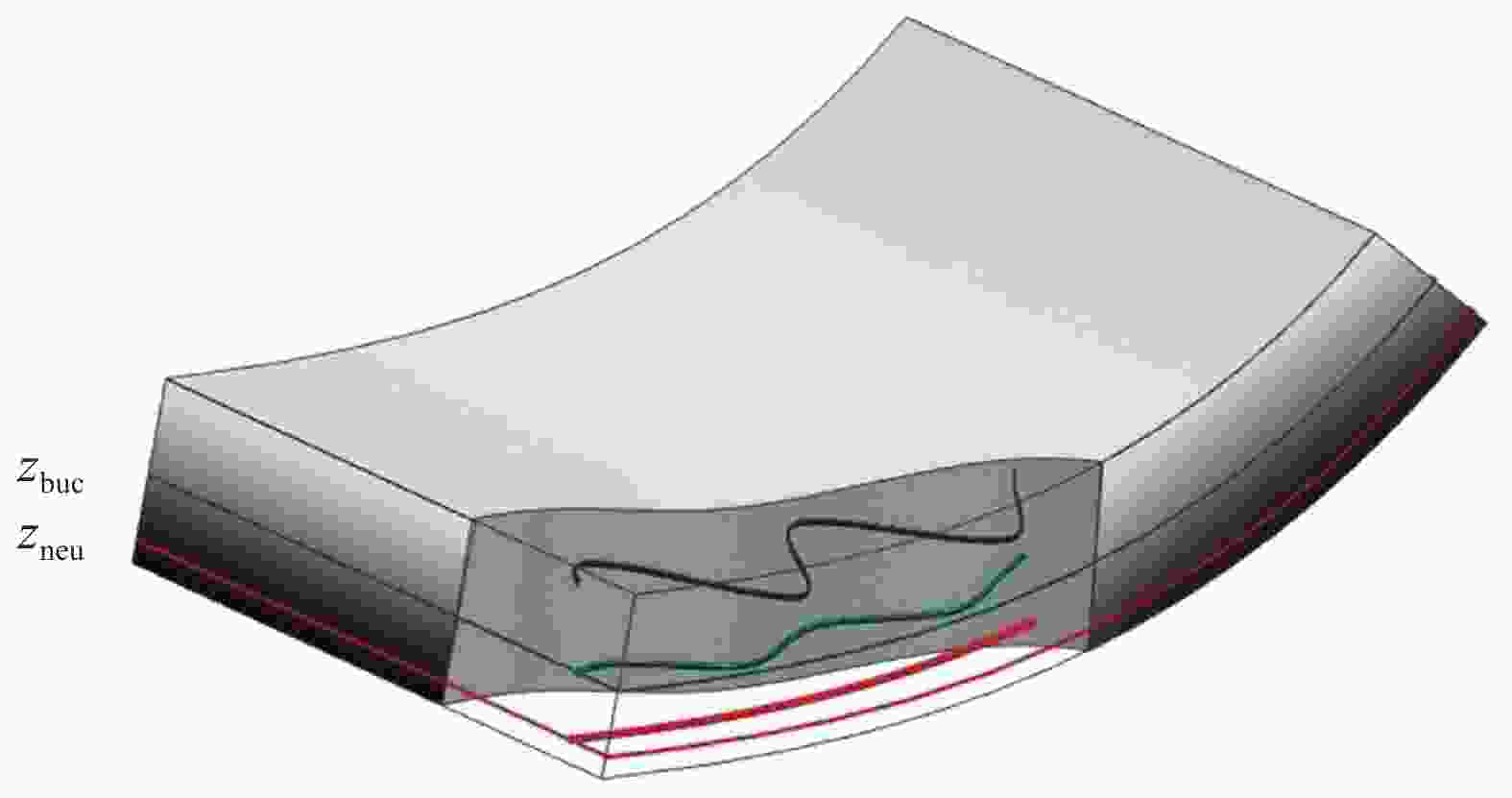

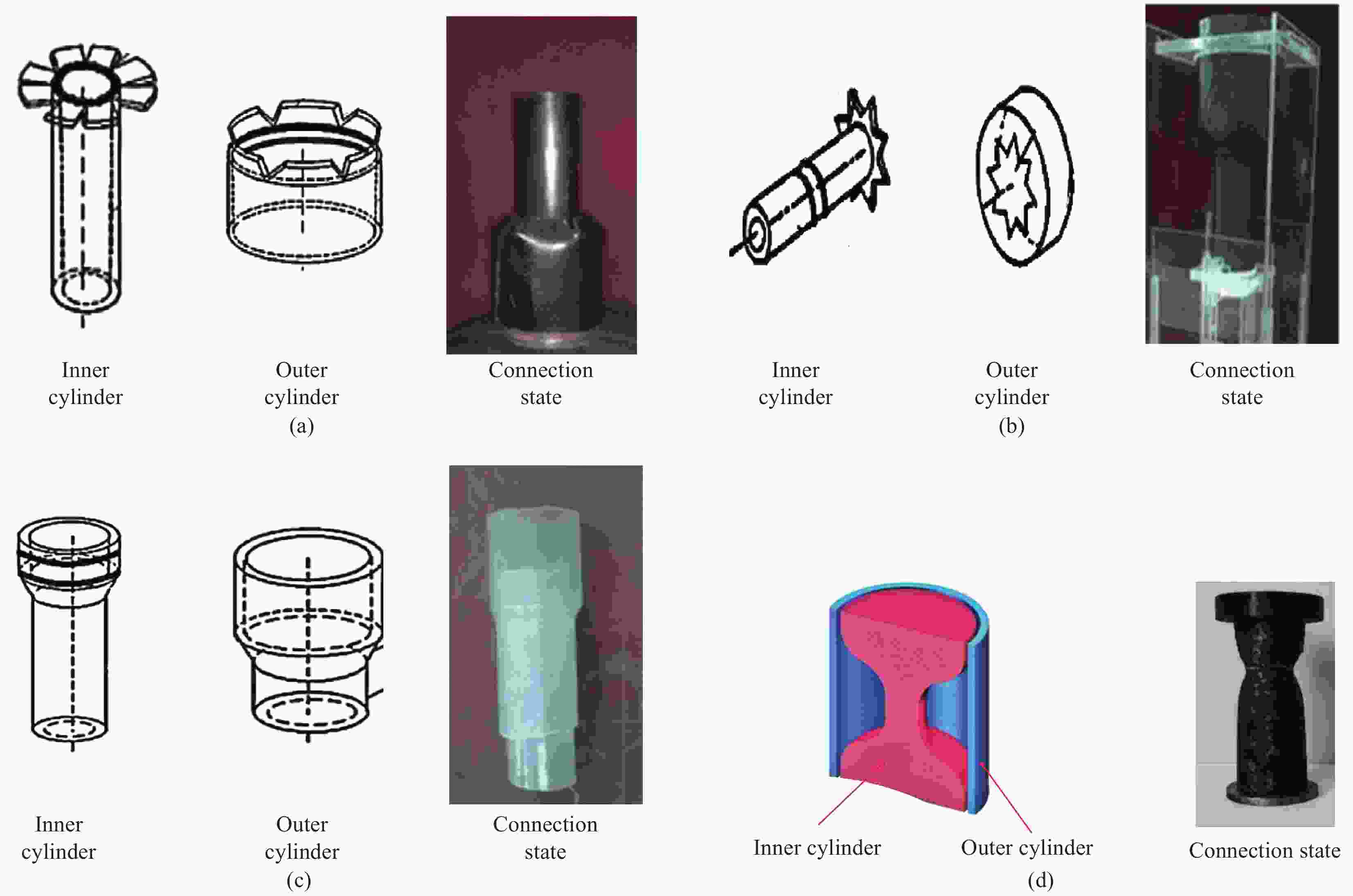

Abstract: Shape memory polymer (SMP) is a kind of smart materials that can maintain a temporary shape and recover its initial configuration under external stimuli. Its advantages of high shape fixation rate, high shape recovery rate, adjustable transition temperature, high deformation ability and light weight makes it suitable to design and fabricate deformable structures. However, its application is restricted by limited response modes and poor bearing capacity. These problems can be effectively solved by adding functional particles or enhanced fibers to the polymer matrix to obtain shape memory polymer composites (SMPC). This article first introduces the shape memory mechanism of SMP and gives its actuation methods. Then, fiber microbuckling behavior of unidirectional fiber reinforced SMPC is discussed. Finally, applications of deformable structures in aerospace are presented. -

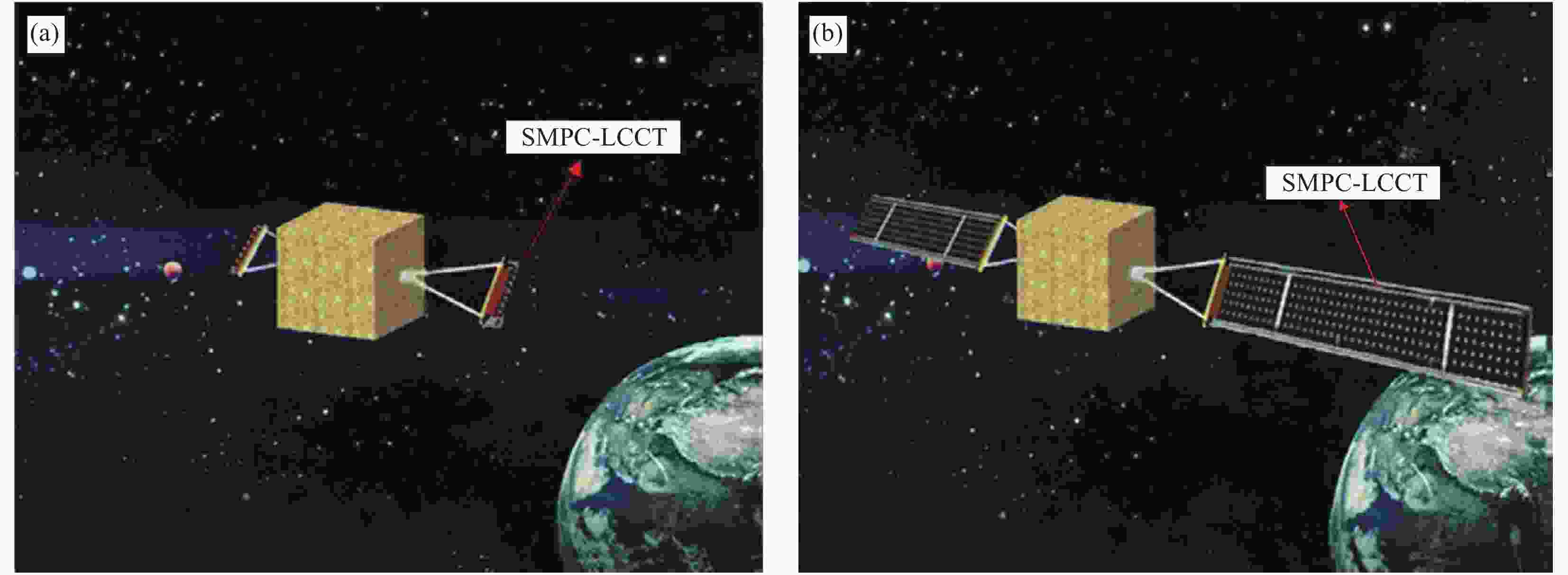

图 17 搭载SJ20同步卫星的可展开柔性太阳能电池阵列系统(SMPC-FSAS) 2020年1月5日在轨展开过程: (a), (b)解锁过程; (c)–(f)展开过程[55]

Figure 17. On-orbit releasing and deployment demonstration of SMPC-FSAS flight hardware which was performed on SJ20 Geostationary Satellite on 5 Jan., 2020: (a), (b) Unlocking process in space; (c)–(f) Deploying process in space[55]

-

[1] HARTL D J. Shape memory materials begin to take shape[J]. Aerospace America,2018,56(11):9. [2] JANI J M, LEARY M, SUBIC A, et al. A review of shape memory alloy research, applications and opportunities[J]. Materials & Design,2014,56:1078-1113. [3] ZAEEM M A, ZHANG N, MAMIVAND M. A review of computational modeling techniques in study and design of shape memory ceramics[J]. Computational Materials Science,2019,160:120-136. doi: 10.1016/j.commatsci.2018.12.062 [4] MU T, LIU L W, LAN X, et al. Shape memory polymers for composites[J]. Composites Science and Technology,2018,160:169-198. doi: 10.1016/j.compscitech.2018.03.018 [5] 李丰丰, 刘彦菊, 冷劲松. 形状记忆聚合物及其复合材料在航天领域的应用进展[J]. 宇航学报, 2020, 41(6):697-706.LI F F, LIU Y J, LENG J S. Progress of shape memory polymers and their composites in aerospace applications[J]. Journal of Astronautics,2020,41(6):697-706(in Chinese). [6] LUO X F, MATHER P T. Triple-shape polymeric composites (TSPCs)[J]. Advanced Functional Materials,2010,20(16):2649-2656. doi: 10.1002/adfm.201000052 [7] XIE T. Tunable polymer multi-shape memory effect[J]. Nature,2010,464(7286):267-270. doi: 10.1038/nature08863 [8] 黄淼铭, 董侠, 刘伟丽, 等. 双向形状记忆结晶聚合物及其复合材料的研究进展[J]. 高分子学报, 2017(4):563-579. doi: 10.11777/j.issn1000-3304.2017.16229HUANG M M, DONG X, LIU W L, et al. Recent progress in two-way shape memory crystalline polymer and its composites[J]. Acta Polymerica Sinica,2017(4):563-579(in Chinese). doi: 10.11777/j.issn1000-3304.2017.16229 [9] LI G, WANG S W, LIU Z T, et al. 2D-to-3D shape transformation of room-temperature-programmable shape-memory polymers through selective suppression of strain relaxation[J]. ACS Applied Materials & Interfaces,2018,10(46):40189-40197. [10] SU X B, PENG X Q. A 3D finite strain viscoelastic constitutive model for thermally induced shape memory polymers based on energy decomposition[J]. International Journal of Plasticity,2018,110:166-182. [11] WESTBROOK K K, KAO P H, CASTRO F, et al. A 3D finite deformation constitutive model for amorphous shape memory polymers: A multi-branch modeling approach for nonequilibrium relaxation processes[J]. Mechanics of Materials,2011,43(12):853-869. doi: 10.1016/j.mechmat.2011.09.004 [12] LENG J, XIN L, LIU Y, et al. Shape-memory polymers and their composites: Stimulus methods and applications[J]. Progress in Materials Science,2011,56(7):1077-1135. [13] YU K, GE Q, QI H J. Reduced time as a unified parameter determining fixity and free recovery of shape memory polymers[J]. Nature Communications,2014,5:3066. [14] GALL K, DUNN M L, LIU Y, et al. Shape memory polymer nanocomposites[J]. Acta Materialia,2002,50(20):5115-5126. [15] LENG J S, HUANG W M, LAN X, et al. Significantly reducing electrical resistivity by forming conductive Ni chains in a polyurethane shape-memory polymer/carbon-black composite[J]. Applied Physics Letters,2008,92(20):204101. [16] LIU Y Y, GUO Y F, ZHAO J, et al. Carbon fiber reinforced shape memory epoxy composites with superior mechanical performances[J]. Composites Science and Technology,2019,177:49-56. [17] PARK M, KIM Y, HWANG J O, et al. Shape recovery characteristics of shape memory epoxy composites reinforced with chopped carbon fibers[J]. Carbon Letters,2019,29(3):219-224. [18] LAN X, LIU L W, LIU Y J, et al. Post microbuckling mechanics of fibre-reinforced shape-memory polymers undergoing flexure deformation[J]. Mechanical of Materials,2014,72:46-60. [19] TALREJA R. Assessment of the fundamentals of failure theories for composite materials[J]. Composistes Science and Technology,2014,105:190-201. [20] ZHUANG L Q, TALREJA R. Effects of voids on postbuckling delamination growth in unidirectional composites[J]. International Jouranl of Solids and Structures,2014,51(5):936-944. [21] CAMPBELL D, MAJI A. Deployment accuracy and mechanics of elastic memory composites[C]//44th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference. Norfolk: AIAA, 2013. [22] AGORAS M, LOPEZ-PAMIES O, CASTANEDA P P. A general hyperelastic model for incompressible fiber-reinforced elastomers[J]. Journal of the Mechanics and Physics of Solids,2009,57(2):268-286. [23] LOPEZ-PAMIES O, IDIART M I. Fiber-reinforced hyperelastic solids: A realizable homogenization constitutive theory[J]. Journal of Engineering Mathematics,2010,68(1):57-83. [24] JIMENEZ F L. On the isotropy of randomly generated representative volume elements for fiber-reinforced elastomers[J]. Composite Part B: Engineering,2016,87:33-39. [25] MICHAILIDIS P A, TRIANTAFYLLIDIS N, SHAW J A, et al. Superelasticity and stability of a shape memory alloy hexagonal honeycomb under in-plane compression[J]. International Journal of Solids and Structures,2009,46(13):2724-2738. [26] MICHEL J C, LOPEZ-PAMIES O, CASTANEDA P P, et al. Microscopic and macroscopic instabilities in finitely strained fiber-reinforced elastomers[J]. Journal of the Mechanics and Physics of Solids,2010,58(11):1776-1803. [27] LIGNON E, LE TALLEC P, TRIANTAGYLLIDIS N. Onset of failure in a fiber reinforced elastomer under constrained bending[J]. International Journal of Solids and Structures,2013,50(2):279-287. [28] LE TALLEC P, BOUSSETTA R, LIGNON E. An enriched model of fiber-reinforced thin flexible structures with inplane buckling capabilities[J]. International Journal of Numerical Methods in Engineering,2012,91(8):872-895. [29] HEINRICH C, ALDRIDGE M, WINEMAN A S, et al. The influence of the representative volume element (RVE) size on the homogenized response of cured fiber composites[J]. Modelling and Simulation in Materials Science and Engineering,2012,20(7):075007. [30] JIANG H Q, SUN Y G, ROGERS J A, et al. Post-buckling analysis for the precisely controlled buckling of thin film encapsulated by elastomeric substrates[J]. International Journal of Solids and Structures,2008,45(7-8):2014-2023. doi: 10.1016/j.ijsolstr.2007.11.007 [31] TIMOSHENKO S P, GERE J M. Theory of elastic stability[M]. 2nd Edtion. New York: Dover Publications, 1962. [32] ROSEN B W. Mechanics of composite strengthening in fiber composite materials[M]. Ohio: American Society for Metals, 1965: 37-75 [33] 熊志远. 形状记忆聚合物复合材料折叠变形机理的研究[D]. 北京: 北京交通大学, 2010.XIONG Z Y. A study on packaging deformation of elastic memory composites[D]. Beijing: Beijing Jiaotong University, 2010(in Chinese). [34] FRANCIS W H, LAKE M S, SCHULTZ M R, et al. Elastic memory composite microbuckling mechanics: Closed-form model with empirical correlation[C]//48th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference. Hawaii: AIAA, 2007. [35] 兰鑫. 形状记忆聚合物复合材料及其力学基础研究[D]. 哈尔滨: 哈尔滨工业大学, 2010.LAN X. Shape memory polymer composite and its study of mechanical foundations[D]. Harbin: Harbin Institute of Technology, 2010(in Chinese). [36] ZHANG J, DUI G, LIANG X. Revisiting the micro-buckling of carbon fibers in elastic memory composite plates under pure bending[J]. International Journal of Mechanical Sciences,2018,136:339-348. [37] ZHANG J M, DUI G S, WANG X Q. Post-micro-buckling of carbon fibers in functionally graded plates under pure bending[J]. European Journal of Mechanics A: Solid,2019,75:419-425. doi: 10.1016/j.euromechsol.2019.02.007 [38] JIMENEZ F L. Mechanics of thin carbon fiber composites with a silicone matrix[D]. California: California Institute of Technology, 2011. [39] LI F F, LIU Y J, LENG J S. Progress of shape memory polymers and their composites in aerospace applications[J]. Smart Materials and Structures,2019,28(10):103003. doi: 10.1088/1361-665X/ab3d5f [40] LIU Y J, DU H Y, LIU L W, et al. Shape memory polymers and their composites in aerospace applications: A review[J]. Smart Materials and Structures,2014,23(2):023001. doi: 10.1088/0964-1726/23/2/023001 [41] BARRETT R, FRANCIS W, ABRAHAMSON E, et al. Qualification of elastic memory composite hinges for spaceflight applications[C]//47th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics & Materials Conference. Newport: AIAA, 2006. [42] LAN X, LIU Y J, LV H B, et al. Fiber reinforced shape-memory polymer composite and its application in a deployable hinge[J]. Smart Materials & Structures,2009,18(2):024002. [43] 王亚飞. 形状记忆复合材料的力学性能表征及其在空间可展开结构中的应用[D]. 哈尔滨: 哈尔滨工业大学, 2016.WANG Y F. The mechanical properties characterization of shape memory composite materials and its application in the spatical developable structures[D]. Harbin: Harbin Institute of Technology, 2016(in Chinese). [44] LIU T Z, LIU L W, YU M, et al. Integrative hinge based on shape memory polymer composites: Material, design, properties and application[J]. Composites Structures,2018,206:164-176. doi: 10.1016/j.compstruct.2018.08.041 [45] WEI H Q, LIU L W, ZHANG Z C, et al. Design and analysis of smart release devices based on shape memory polymer composites[J]. Composite Structures,2015,133:642-651. doi: 10.1016/j.compstruct.2015.07.107 [46] ZHAO H X, LAN X, LIU L W, et al. Design and analysis of shockless smart releasing device based on shape memory polymer composites[J]. Composite Structures,2019,223:110958. doi: 10.1016/j.compstruct.2019.110958 [47] ZHANG D, LIU L, LENG J, et al. Ultra-light release device integrated with screen-printed heaters for CubeSat’s deployable solar arrays[J]. Composite Structures,2020,232:111561. doi: 10.1016/j.compstruct.2019.111561 [48] KELLER P, LAKE M, FRANCIS W, et al. Development of a deployable boom for microsatellites using elastic memory composite material[C]//45th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics & Materials Conference. California: AIAA, 2004. [49] ZHANG R, GUO X, LIU Y, et al. Theoretical analysis and experiments of a space deployable truss structure[J]. Composite Structures,2014,112(5):226-230. [50] LI F, LIU L, XIN L, et al. Modal analyses of deployable truss structures based on shape memory polymer composites[J]. International Journal of Applied Mechanics,2016,8(7):1640009. doi: 10.1142/S1758825116400093 [51] LI F, LIU L, DU L, et al. Mechanical analysis of a tip-loaded deployable truss based on shape memory polymer composite[J]. Composites Structures,2020,242:112196. doi: 10.1016/j.compstruct.2020.112196 [52] LI F, LIU L, XIN L, et al. Preliminary design and analysis of a cubic deployable support structure based on shape memory polymer composite[J]. International Journal of Smart & Nano Materials,2016,7(2):106-118. [53] LI F F, LIU L W, LAN X, et al. Ground and geostationary orbital qualification of a sunlight-stimulated substrate based on shape memory polymer composite[J]. Smart Materials & Structures,2019,28(7):075023. [54] LIU Z X, LI Q F, BIAN W F, et al. Preliminary test and analysis of an ultralight lenticular tube based on shape memory polymer composites[J]. Composite Structures,2019,223:110936. doi: 10.1016/j.compstruct.2019.110936 [55] LAN X, LIU L, ZHANG F, et al. World’s first spaceflight on-orbit demonstration of a flexible solar array system based on shape memory polymer composites[J]. Science China Technological Sciences,2020,63:1436-1451. doi: 10.1007/s11431-020-1681-0 -

下载:

下载: