| [1] |

WAMBUA P M, ANANDJIWALA R. A review of preforms for the composites industry[J]. Journal of Industrial Textiles,2011,40(4):310-333. doi: 10.1177/1528083709092014

|

| [2] |

BUSSETTA Philippe, CORREIA Nuno. Numerical forming of continuous fibre reinforced composite material: A review[J]. Composites Part A: Applied Science and Manufacturing,2018,113:12-31. doi: 10.1016/j.compositesa.2018.07.010

|

| [3] |

SKORDOS A A, MONROY ACEVES C, SUTCLIFFE M P F. A simplified rate dependent model of forming and wrinkling of pre-impregnated woven composites[J]. Composites Part A: Applied Science and Manufacturing,2007,38(5):1318-1330. doi: 10.1016/j.compositesa.2006.11.005

|

| [4] |

GEREKE Thomas, DÖBRICH Oliver, HÜBNER Matthias, et al. Experimental and computational composite textile reinforcement forming: A review[J]. Composites Part A: Applied Science and Manufacturing,2013,46:1-10. doi: 10.1016/j.compositesa.2012.10.004

|

| [5] |

KÄRGER Luise, BERNATH Alexander, FRITZ Florian, et al. Development and validation of a CAE chain for unidirectional fibre reinforced composite components[J]. Composite Structures,2015,132:350-358. doi: 10.1016/j.compstruct.2015.05.047

|

| [6] |

BOISSE P, COLMARS J, HAMILA N, et al. Bending and wrinkling of composite fiber preforms and prepregs. A review and new developments in the draping simulations[J]. Composites Part B: Engineering,2018,141:234-249. doi: 10.1016/j.compositesb.2017.12.061

|

| [7] |

YOKOZEKI Tomohiro, OGASAWARA Toshio, ISHIKAWA Takashi. Nonlinear behavior and compressive strength of unidirectional and multidirectional carbon fiber compo-site laminates[J]. Composites Part A: Applied Science and Manufacturing,2006,37(11):2069-2079. doi: 10.1016/j.compositesa.2005.12.004

|

| [8] |

KAWAI M, SUDA H. Effects of non-negative mean stress on the off-axis fatigue behavior of unidirectional carbon/epoxy composites at room temperature[J]. Journal of Composite Materials,2016,38(10):833-854.

|

| [9] |

BARDL Georg, NOCKE Andreas, CHERIF Chokri, et al. Automated detection of yarn orientation in 3D-draped carbon fiber fabrics and preforms from eddy current data[J]. Composites Part B: Engineering,2016,96:312-324. doi: 10.1016/j.compositesb.2016.04.040

|

| [10] |

LEE Minsik, KANG Chunggil. Determination of forming procedure by numerical analysis and investigation of mechanical properties of steel/CFRP hybrid composites with complicated shapes[J]. Composite Structures,2017,164:118-129. doi: 10.1016/j.compstruct.2016.10.021

|

| [11] |

杨雪勤, 张骁骅. 航空航天用复合材料的无损检测和自修复研究进展[J]. 纺织导报, 2018(S1):92-98.YANG Xueqin, ZHANG Xiaohua. Progress in non-destructive testing and self-healing of composite materials in the aerospace field[J]. China Textile Leader,2018(S1):92-98(in Chinese).

|

| [12] |

XIANG He, JIANG Yaming, QI Yexiong, et al. Process-induced distortions characterization of MBWK fabric reinforced composite helmet shell[J]. Materials,2020,13(13):2983. doi: 10.3390/ma13132983

|

| [13] |

马保全, 周正干. 航空航天复合材料结构非接触无损检测技术的进展及发展趋势[J]. 航空学报, 2014, 35(7):1787-1803.MA Baoquan, ZHOU Zhenggan. Progress and development trends of composite structure evaluation using noncontact nondestructive testing techniques in aviation and aerospace industries[J]. Acta Aeronautica et Astronautica Sinica,2014,35(7):1787-1803(in Chinese).

|

| [14] |

刘松平, 刘菲菲, 李乐刚, 等. 航空复合材料无损检测与评估技术研究进展回顾[J]. 航空制造技术, 2019, 62(14):14-27.LIU Songping, LIU Feifei, LI Legang, et al. Review of research progress on nondestructive testing and evaluation techniques for aero-composites[J]. Aeronautical Manufacturing Technology,2019,62(14):14-27(in Chinese).

|

| [15] |

王奕首, 卿新林. 复合材料连接结构健康监测技术研究进展[J]. 复合材料学报, 2016, 33(1):1-16.WANG Yishou, QING Xinlin. Progress on study of structural health monitoring technology for composite joints[J]. Acta Materiae Compositae Sinica,2016,33(1):1-16(in Chinese).

|

| [16] |

HENNING Frank, KÄRGER Luise, DÖRR Dominik, et al. Fast processing and continuous simulation of automotive structural composite components[J]. Composites Science and Technology,2019,171:261-279. doi: 10.1016/j.compscitech.2018.12.007

|

| [17] |

FLEISCHER Jürgen, TETI Roberto, LANZA Gisela, et al. Composite materials parts manufacturing[J]. CIRP Annals,2018,67(2):603-626. doi: 10.1016/j.cirp.2018.05.005

|

| [18] |

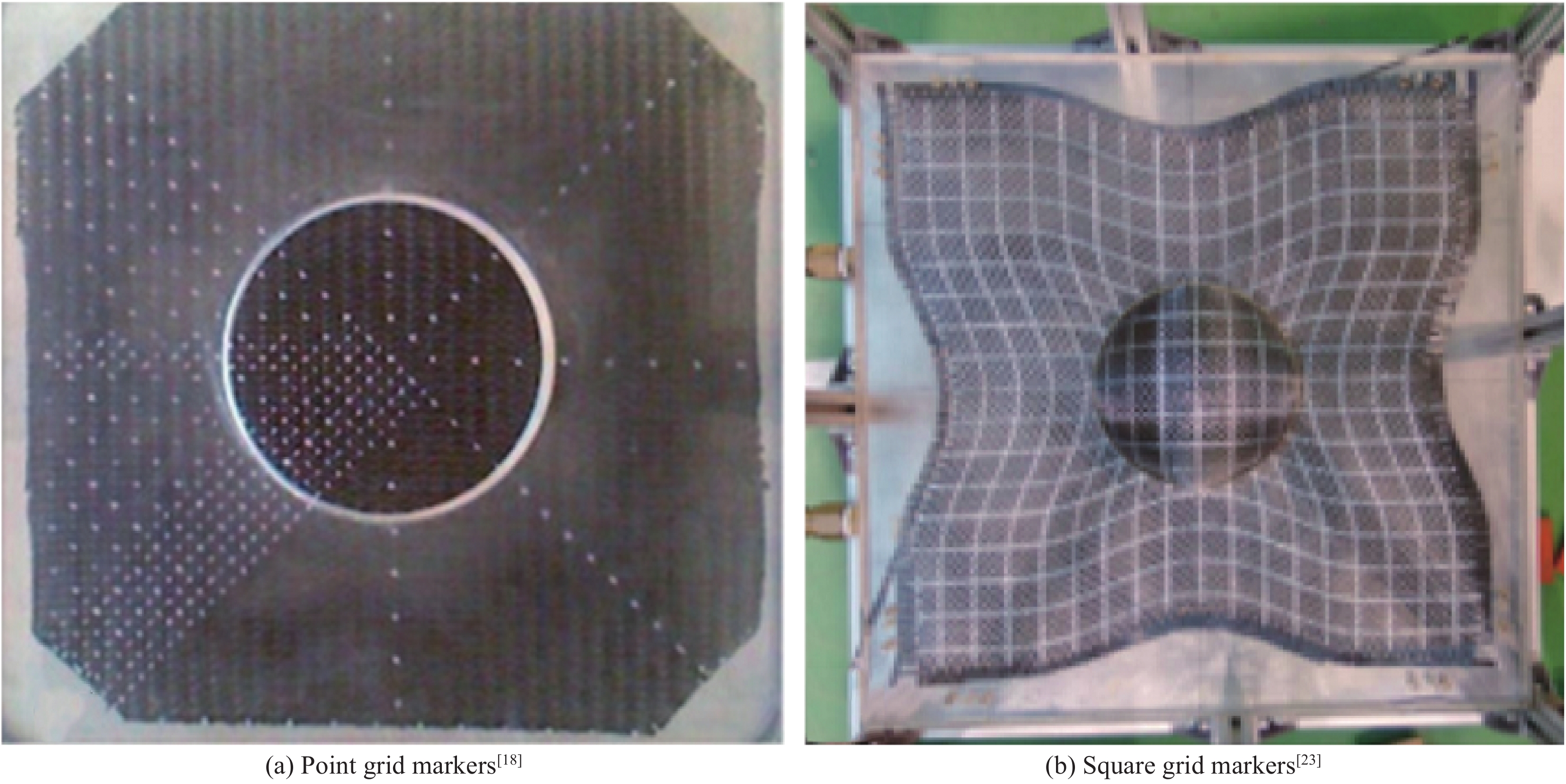

LABANIEH A R, GARNIER C, OUAGNE P, et al. Intra-ply yarn sliding defect in hemisphere preforming of a woven preform[J]. Composites Part A: Applied Science and Manufacturing,2018,107:432-446. doi: 10.1016/j.compositesa.2018.01.018

|

| [19] |

LEE Jiseok, HONG Seokjin, YU Woongryeol, et al. The effect of blank holder force on the stamp forming behavior of non-crimp fabric with a chain stitch[J]. Composites Science and Technology,2007,67(3-4):357-366. doi: 10.1016/j.compscitech.2006.09.009

|

| [20] |

MOHAMMED U, LEKAKOU C, BADER M G. Experimental studies and analysis of the draping of woven fabrics[J]. Composites Part A,2000,31(12):1409-1420. doi: 10.1016/S1359-835X(00)00080-4

|

| [21] |

WANG J, PATON R, PAGE J R. The draping of woven fabric preforms and prepregs for production of polymer compo-site components[J]. Composites Part A,1999,30(6):757-765. doi: 10.1016/S1359-835X(98)00187-0

|

| [22] |

YU Woongryeol, HARRISON Philip, LONG Andrew. Finite element forming simulation for non-crimp fabrics using a non-orthogonal constitutive equation[J]. Composites Part A: Applied Science and Manufacturing,2005,36(8):1079-1093. doi: 10.1016/j.compositesa.2005.01.007

|

| [23] |

IWATA Akira, INOUE Takuya, NAOUAR Naim, et al. Coupled meso-macro simulation of woven fabric local deformation during draping[J]. Composites Part A: Applied Science and Manufacturing,2019,118:267-280. doi: 10.1016/j.compositesa.2019.01.004

|

| [24] |

HARRISON P, GOMES R, CURADO-CORREIA N. Press forming a 0/90 cross-ply advanced thermoplastic compo-site using the double-dome benchmark geometry[J]. Composites Part A: Applied Science and Manufacturing,2013,54:56-69. doi: 10.1016/j.compositesa.2013.06.014

|

| [25] |

杜洋, 高志山. 使用高精度三坐标测量仪实现透镜定中心[J]. 光学精密工程, 2015, 23(3):639-644. doi: 10.3788/OPE.20152303.0639DU Yang, GAO Zhishan. Lens centering using high-precision three coordinate measuring machine[J]. Optics and Precision Engineering,2015,23(3):639-644(in Chinese). doi: 10.3788/OPE.20152303.0639

|

| [26] |

CHEN S, MCGREGOR O P L, HARPER L T, et al. Defect formation during preforming of a bi-axial non-crimp fabric with a pillar stitch pattern[J]. Composites Part A: Applied Science and Manufacturing,2016,91:156-167. doi: 10.1016/j.compositesa.2016.09.016

|

| [27] |

CHEN S, MCGREGOR O P L, HARPER L T, et al. Optimisation of local in-plane constraining forces in double diaphragm forming[J]. Composite Structures,2018,201:570-581. doi: 10.1016/j.compstruct.2018.06.062

|

| [28] |

LI Xiongkui, BAI Shulin. Sheet forming of the multi-layered biaxial weft knitted fabric reinforcement. Part I: On hemispherical surfaces[J]. Composites Part A: Applied Science and Manufacturing,2009,40(6-7):766-777. doi: 10.1016/j.compositesa.2009.03.007

|

| [29] |

OUAGNE P, SOULAT D, MOOTHOO J, et al. Complex shape forming of a flax woven fabric; analysis of the tow buckling and misalignment defect[J]. Composites Part A: Applied Science and Manufacturing,2013,51:1-10. doi: 10.1016/j.compositesa.2013.03.017

|

| [30] |

ALLAOUI S, BOISSE P, CHATEL S, et al. Experimental and numerical analyses of textile reinforcement forming of a tetrahedral shape[J]. Composites Part A: Applied Science and Manufacturing,2011,42(6):612-622. doi: 10.1016/j.compositesa.2011.02.001

|

| [31] |

BEL S, HAMILA N, BOISSE P, et al. Finite element model for NCF composite reinforcement preforming: Importance of inter-ply sliding[J]. Composites Part A: Applied Science and Manufacturing,2012,43(12):2269-2277. doi: 10.1016/j.compositesa.2012.08.005

|

| [32] |

KHAN M A, MABROUKI T, VIDAL-SALLÉ E, et al. Numerical and experimental analyses of woven composite reinforcement forming using a hypoelastic behaviour. Application to the double dome benchmark[J]. Journal of Materials Processing Technology,2010,210(2):378-388. doi: 10.1016/j.jmatprotec.2009.09.027

|

| [33] |

LOMOV S V, BOISSE P, DELUYCKER E, et al. Full-field strain measurements in textile deformability studies[J]. Composites Part A: Applied Science and Manufacturing,2008,39(8):1232-1244. doi: 10.1016/j.compositesa.2007.09.014

|

| [34] |

CABRERA N O, REYNOLDS C T, ALCOCK B, et al. Non-isothermal stamp forming of continuous tape reinforced all-polypropylene composite sheet[J]. Composites Part A: Applied Science and Manufacturing,2008,39(9):1455-1466. doi: 10.1016/j.compositesa.2008.05.014

|

| [35] |

VANCLOOSTER K, LOMOV S V, VERPOEST I. Experimental validation of forming simulations of fabric reinforced polymers using an unsymmetrical mould configuration[J]. Composites Part A: Applied Science and Manufacturing,2009,40(4):530-539. doi: 10.1016/j.compositesa.2009.02.005

|

| [36] |

SUN Guangyong, ZHANG Wenwu, WANG Zhen, et al. A novel specimen design to establish the forming limit diagram (FLD) for GFRP through stamping test[J]. Compo-sites Part A: Applied Science and Manufacturing,2020,130:105737. doi: 10.1016/j.compositesa.2019.105737

|

| [37] |

PAZMINO J, CARVELLI V, LOMOV S V. Formability of a non-crimp 3D orthogonal weave E-glass composite reinforcement[J]. Composites Part A: Applied Science and Manufacturing,2014,61:76-83. doi: 10.1016/j.compositesa.2014.02.004

|

| [38] |

QIAN Connie, WEARE Rachel, PASCO Corentin, et al. Numerical and experimental studies of multi-ply woven carbon fibre prepreg forming process[J]. 23rd International Conference on Material Forming (ESAFORM 2020),2020,47:93-99.

|

| [39] |

TREJO Eleazar A., GHAZIMORADI Mehdi, BUTCHER Clifford, et al. Assessing strain fields in unbalanced unidirectional non-crimp fabrics[J]. Composites Part A: Applied Science and Manufacturing,2020,130:105758. doi: 10.1016/j.compositesa.2019.105758

|

| [40] |

VANLEEUW B, CARVELLI V, BARBURSKI M, et al. Quasi-unidirectional flax composite reinforcement: Deformability and complex shape forming[J]. Composites Science and Technology,2015,110:76-86. doi: 10.1016/j.compscitech.2015.01.024

|

| [41] |

PUYSTIENS Silke, Van CRAENENBROECK Maarten, Van HEMELRIJCK Danny, et al. Implementation of bending-active elements in kinematic form-active structures-Part II: Experimental verification[J]. Composite Structures,2019,213:1-13.

|

| [42] |

SALEM M M, DE LUYCKER E, FAZZINI M, et al. Experimental, analytical and numerical investigation to prevent the tow buckling defect during fabric forming[J]. Compo-sites Part A: Applied Science and Manufacturing,2019,125:105567. doi: 10.1016/j.compositesa.2019.105567

|

| [43] |

WANG Zhen, ZHANG Wenwu, LUO Quantian, et al. A novel failure criterion based upon forming limit curve for thermoplastic composites[J]. Composites Part B: Engineering,2020:108320. doi: 10.1016/j.compositesb.2020.108320

|

| [44] |

HARRISON Philip. Modelling the forming mechanics of engineering fabrics using a mutually constrained pantographic beam and membrane mesh[J]. Composites Part A: Applied Science and Manufacturing,2016,81:145-157. doi: 10.1016/j.compositesa.2015.11.005

|

| [45] |

SCHIRMAIER F J, DÖRR D, HENNING F, et al. A macroscopic approach to simulate the forming behaviour of stitched unidirectional non-crimp fabrics (UD-NCF)[J]. Composites Part A: Applied Science and Manufacturing,2017,102:322-335. doi: 10.1016/j.compositesa.2017.08.009

|

| [46] |

XU Xianyang, YANG Hao, NEUMANN Ingo. Monotonic loads experiment for investigation of composite structure based on terrestrial laser scanner measurement[J]. Composite Structures,2018,183:563-567. doi: 10.1016/j.compstruct.2017.07.001

|

| [47] |

杨必胜, 梁福逊, 黄荣刚. 三维激光扫描点云数据处理研究进展、挑战与趋势[J]. 测绘学报, 2017, 46(10):1509-1516. doi: 10.11947/j.AGCS.2017.20170351YANG Bisheng, LIANG Fuxun, HUANG Ronggang. Progress, challenges and perspectives of 3D LiDAR point cloud processing[J]. Acta Geodaetica et Cartographica Sinica,2017,46(10):1509-1516(in Chinese). doi: 10.11947/j.AGCS.2017.20170351

|

| [48] |

CHRIST Mirko, MIENE Andrea, MÖRSCHEL Ulrich. Measurement and analysis of drapeability effects of warp-knit NCF with a standardised, automated testing device[J]. Applied Composite Materials,2017,24(4):803-820. doi: 10.1007/s10443-016-9555-7

|

| [49] |

李文羽, 程隆棣. 基于机器视觉和图像处理的织物疵点检测研究新进展[J]. 纺织学报, 2014, 35(3):158-164.LI Wenyu, CHENG Longdi. New progress of fabric defect detection based on computer vision and image processing[J]. Journal of Textile Research,2014,35(3):158-164(in Chinese).

|

| [50] |

ZAMBAL Sebastian, PALFINGER Werner, STÖGER Matthias, et al. Accurate fibre orientation measurement for carbon fibre surfaces[J]. Pattern Recognition,2015,48(11):3324-3332. doi: 10.1016/j.patcog.2014.11.009

|

| [51] |

ŞERBAN Alexandru. Automatic detection of fiber orientation on CF/PPS composite materials with 5-harness satin weave[J]. Fibers and Polymers,2016,17(11):1925-1933. doi: 10.1007/s12221-016-6049-z

|

| [52] |

GOMMER F, BROWN L P. BROOKS Richard. Quantification of mesoscale variability and geometrical reconstruction of a textile[J]. Journal of Composite Materials,2016,50(23):3255-3266. doi: 10.1177/0021998315617819

|

| [53] |

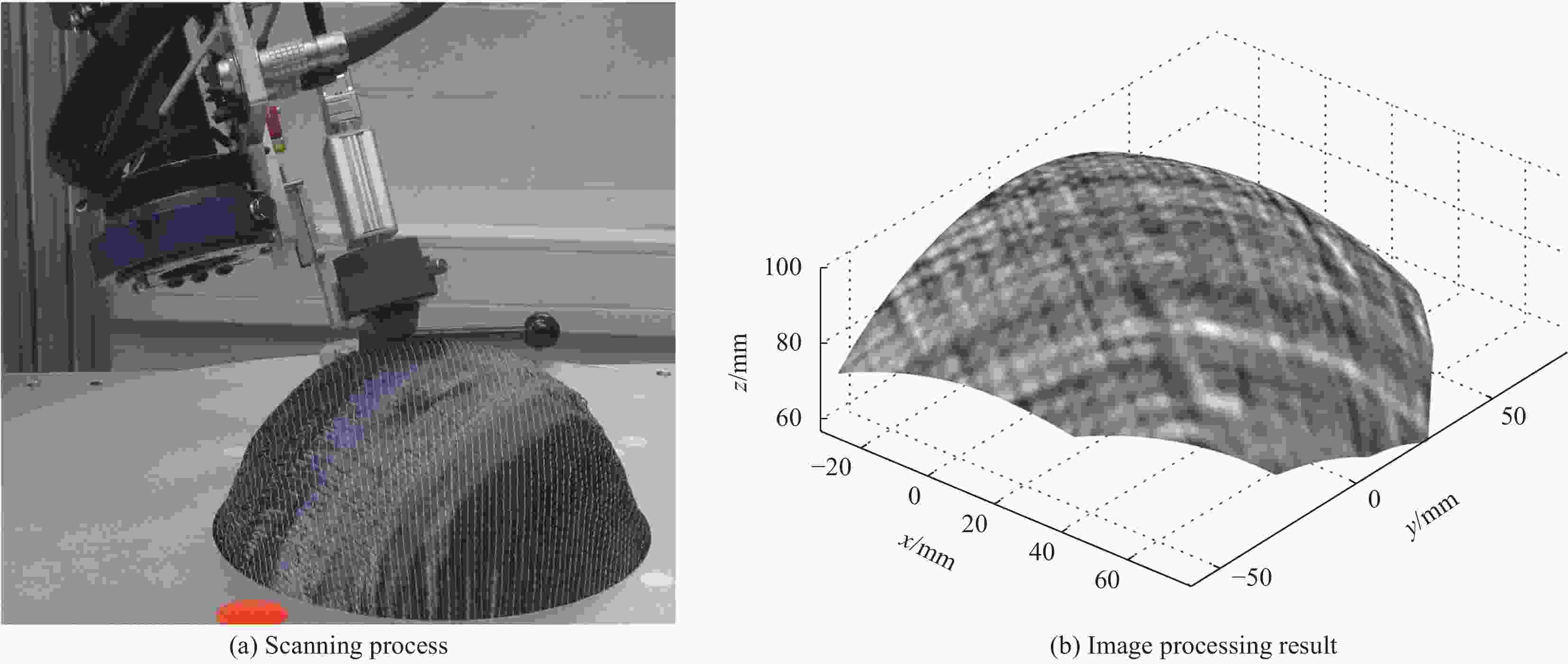

MALLACH Annegret, HÄRTEL Frank, HEIECK Frieder, et al. Experimental comparison of a macroscopic draping simulation for dry non-crimp fabric preforming on a complex geometry by means of optical measurement[J]. Journal of Composite Materials,2016,51(16):2363-2375.

|

| [54] |

田松峰, 韩强, 王美俊, 等. 复合材料风电叶片静态无损检测方法研究进展[J]. 工程塑料应用, 2016, 44(06):137-141. doi: 10.3969/j.issn.1001-3539.2016.06.040TIAN Songfeng, HAN Qiang, WANG Meijun, et al. Research progress in static non-destructive testing methods for wind turbine blades of composite[J]. Engineering Plastics Application,2016,44(06):137-141(in Chinese). doi: 10.3969/j.issn.1001-3539.2016.06.040

|

| [55] |

汪星明, 郭耀红, 朱庆友, 等. 复合材料无损检测研究进展[J]. 玻璃钢/复合材料, 2012(S1):261-265.WANG Xingming, GUO Yaohong, ZHU Qingyou, et al. Progress in research of nondestructive testing technique of composites[J]. Fiber Reinforced Plastics/Composites,2012(S1):261-265(in Chinese).

|

| [56] |

ZHANG H, ROBITAILLE F, GROSSE C U, et al. Optical excitation thermography for twill/plain weaves and stitched fabric dry carbon fibre preform inspection[J]. Composites Part A: Applied Science and Manufacturing,2018,107:282-293. doi: 10.1016/j.compositesa.2018.01.006

|

| [57] |

THOMAS S, SOMEN D. Automation in production integrated NDT using thermography[C]. 4th International Symposium on NDT in Aerospace, Germany, 2012.

|

| [58] |

THOMAS S, SOMEN D. CFRP manufacturing process chain observation by means of automated thermography[C]. 5th International Symposium on NDT in Aerospace, Singapore, 2014.

|

| [59] |

徐帅, 程军, 杨继全, 等. 各向异性碳纤维复合材料的方向性涡流检测[J]. 振动. 测试与诊断, 2019, 39(3):631-637.XU Shuai, CHENG Jun, YANG Jiquan, et al. Pile defects detection based on the change of phase angle[J]. Journal of Vibration, Measurement & Diagnosis,2019,39(3):631-637(in Chinese).

|

| [60] |

曾辉耀, 叶波, 张依仃, 等. 单向碳纤维复合材料分层缺陷垂直涡流检测有限元仿真研究[J]. 传感技术学报, 2020, 33(1):45-50.CENG Huiyao, YE Bo, ZHANG Yiding, et al. Finite element analysis of delamination in unidirectional carbon fiber reinforced polymer by vertical eddy current method[J]. Chinese Journal of Sensors and Actuators,2020,33(1):45-50(in Chinese).

|

| [61] |

周德强, 尤丽华, 张秋菊, 等. 碳纤维增强复合材料脉冲涡流无损检测仿真与实验研究[J]. 传感技术学报, 2014, 27(2):277-282. doi: 10.3969/j.issn.1004-1699.2014.02.025ZHOU Deqiang, YOU Lihua, ZHANG Qiuju, et al. Simulation and experiments on the carbon fiber reinforced plastic using pulsed eddy current testing[J]. Chinese Journal of Sensors and Actuators,2014,27(2):277-282(in Chinese). doi: 10.3969/j.issn.1004-1699.2014.02.025

|

| [62] |

周德强, 吴佳龙, 王俊, 等. 碳纤维增强复合材料冲击缺陷脉冲涡流无损检测仿真与试验研究[J]. 传感技术学报, 2015, 28(5):671-676. doi: 10.3969/j.issn.1004-1699.2015.05.011ZHOU Deqiang, WU Jialong, WANG Jun, et al. Simulation and experiment of impact damages in carbon fiber reinforced plastic using pulsed eddy current testing[J]. Chinese Journal of Sensors and Actuators,2015,28(5):671-676(in Chinese). doi: 10.3969/j.issn.1004-1699.2015.05.011

|

| [63] |

程军, 杨继全, 裘进浩, 等. 基于涡流成像的碳纤维增强树脂基复合材料细观结构可视化[J]. 复合材料学报, 2018, 35(8):2074-2083.CHENG Jun, YANG Jiquan, QIU Jinhao, et al. Visualization of meso-structure of carbon fiber reinforced polymer based on eddy current imaging[J]. Acta Materiae Compo-sitae Sinica,2018,35(8):2074-2083(in Chinese).

|

| [64] |

WU Dehui, CHENG Fang, YANG Fan, et al. Non-destructive testing for carbon-fiber-reinforced plastic (CFRP) using a novel eddy current probe[J]. Composites Part B: Engineering,2019,177:107460. doi: 10.1016/j.compositesb.2019.107460

|

| [65] |

ZENG Zhiwei, TIAN Qingze, WANG Handong, et al. Testing of delamination in multidirectional carbon fiber reinforced polymer laminates using the vertical eddy current method[J]. Composite Structures,2019,208:314-321. doi: 10.1016/j.compstruct.2018.10.027

|

| [66] |

BOULOUDENINE Abderraouf, FELIACHI Mouloud, LATRECHE Mohamed El Hadi. Development of circular arrayed eddy current sensor for detecting fibers orientation and in-plane fiber waviness in unidirectional CFRP[J]. NDT & E International,2017,92:30-37.

|

| [67] |

MACHADO M A, ANTIN K N, ROSADO L S, et al. Contactless high-speed eddy current inspection of unidirectional carbon fiber reinforced polymer[J]. Composites Part B: Engineering,2019,168:226-235. doi: 10.1016/j.compositesb.2018.12.021

|

| [68] |

BARDL Georg, NOCKE Andreas, HÜBNER Matthias, et al. Analysis of the 3D draping behavior of carbon fiber non-crimp fabrics with eddy current technique[J]. Composites Part B: Engineering,2018,132:49-60. doi: 10.1016/j.compositesb.2017.08.007

|

| [69] |

KHAN A M, BARDL G, NOCKE A, et al. Quality analysis of 2D and 3D-draped carbon preforms by eddy current scanning[J]. Composites Part B: Engineering,2019,176:107110. doi: 10.1016/j.compositesb.2019.107110

|

| [70] |

NARESH K, KHAN K A, UMER R, et al. The use of X-ray computed tomography for design and process modeling of aerospace composites: A review[J]. Materials & Design,2020,190:108553.

|

| [71] |

ALI M A, UMER R, KHAN K A, et al. Application of X-ray computed tomography for the virtual permeability prediction of fiber reinforcements for liquid composite molding processes: A review[J]. Composites Science and Technology,2019,184:107828. doi: 10.1016/j.compscitech.2019.107828

|

| [72] |

EL SAID B, GREEN S, HALLETT S R. Kinematic modelling of 3D woven fabric deformation for structural scale features[J]. Composites Part A: Applied Science and Manufacturing,2014,57:95-107. doi: 10.1016/j.compositesa.2013.11.006

|

| [73] |

LIU Chong, XIE Junbo, SUN Ying, et al. Micro-scale modeling of textile composites based on the virtual fiber embedded models[J]. Composite Structures,2019,230:111552. doi: 10.1016/j.compstruct.2019.111552

|

| [74] |

JIAO Wei, CHEN Li, XIE Junbo, et al. Effect of weaving structures on the geometry variations and mechanical properties of 3D LTL woven composites[J]. Composite Structures,2020,252:112756. doi: 10.1016/j.compstruct.2020.112756

|

| [75] |

ZHANG Yifan, GUO Qiwei, CHEN Xiaoming, et al. Effect of apertures on tensile property of warp-reinforced 2.5D woven composites notched plates[J]. Composite Structures,2020,252:112693. doi: 10.1016/j.compstruct.2020.112693

|

| [76] |

何业茂, 焦亚男, 周庆, 等. 超高分子量聚乙烯纤维/水性聚氨酯复合材料层压板抗软钢芯弹侵彻性能及其损伤机制[J/OL].复合材料学报:1-15[2021-03-03]. https://doi.org/10.13801/j.cnki.fhclxb.20200722.003.HE Yemao, JIAO Ya'nan, ZHOU Qing, et al. Ballistic performance of ultrahigh molecular weight polyethylene fiber/waterborne polyurethane composite laminate against mild-steel core projectile and its damage mechanism[J/OL]. Acta Materiae Compositae Sinica, 2020: 1-15[2021-03-03]. https://doi.org/10.13801/j.cnki.fhclxb.20200722.003(in Chinese).

|

| [77] |

KUNZE Eckart, SCHWARZ Benjamin, WEBER Tony, et al. Forming analysis of internal plies of multi-layer unidirectional textile preforms using projectional radiography[C]. 23rd International Conference on Material Forming, Germany, 2020.

|

| [78] |

韩振宇, 梅海洋, 付云忠, 等. 三维编织预成型体的织造及三维编织复合材料细观结构研究进展[J]. 材料工程, 2018, 46(11):25-36. doi: 10.11868/j.issn.1001-4381.2017.000682HAN Zhenyu, MEI Haiyang, FU Yunzhong, et al. Research progress on preform forming and microstructure of 3D braided composites[J]. Journal of Materials Engineering,2018,46(11):25-36(in Chinese). doi: 10.11868/j.issn.1001-4381.2017.000682

|

| [79] |

陈利, 焦伟, 王心淼, 等. 三维机织复合材料力学性能研究进展[J]. 材料工程, 2020, 48(8):62-72.CHEN Li, JIAO Wei, WANG Xinmiao, et al. Research progress on mechanical properties of 3D woven composites[J]. Journal of Materials Engineering,2020,48(8):62-72(in Chinese).

|

| [80] |

BILISIK Kadir. Multiaxis three-dimensional weaving for composites: A review[J]. Textile Research Journal,2012,82(7):725-743. doi: 10.1177/0040517511435013

|

| [81] |

BILISIK Kadir. Three-dimensional braiding for compo-sites: A review[J]. Textile Research Journal,2012,83(13):1414-1436.

|

| [82] |

GEREKE Thomas, CHERIF Chokri. A review of numerical models for 3D woven composite reinforcements[J]. Composite Structures,2019,209:60-66. doi: 10.1016/j.compstruct.2018.10.085

|

| [83] |

LI Mengru, WANG Peng, BOUSSU François, et al. A review on the mechanical performance of three-dimensional warp interlock woven fabrics as reinforcement in compo-sites[J]. Journal of Industrial Textiles,2020:2025532350.

|

下载:

下载: