Low-velocity impact behavior and numerical simulation of carbon fiber-glass fiber hybrid reinforced epoxy composites

-

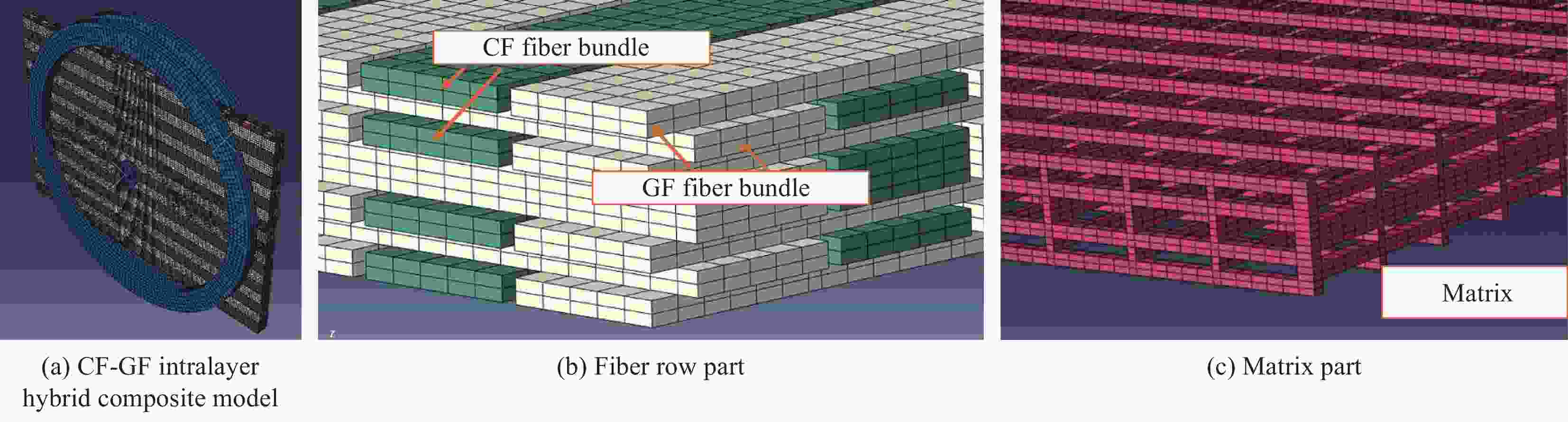

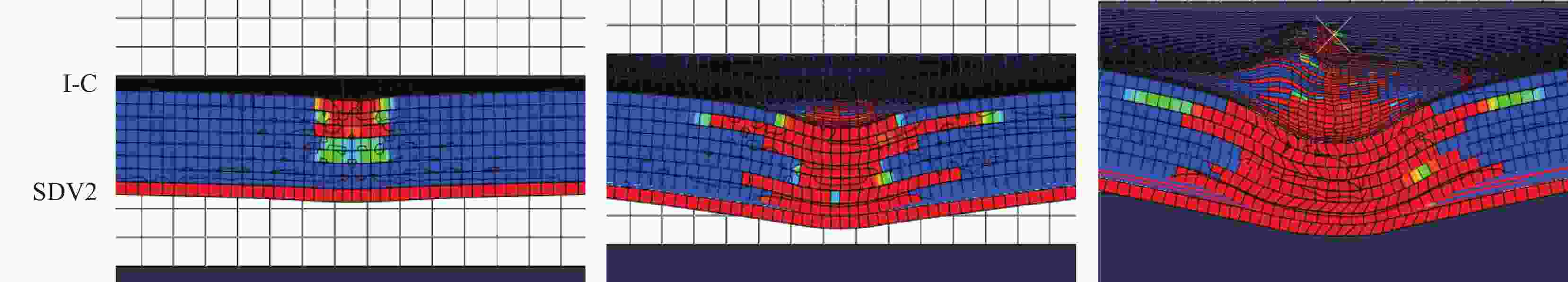

摘要: 本文基于实验和数值模拟方法研究了碳纤维-玻璃纤维混杂增强环氧树脂复合材料低速冲击性能。采用商业有限元软件ABAQUS建立了层间/层内两类混杂复合材料低速冲击模型,采用基于应变形式的Hashin失效准则模拟面内损伤;零厚度Cohesive内聚力单元预测层间分层;编写VUMAT子程序定义渐进失效过程,并结合C扫和Micro-CT扫描,分析了复合材料内部微观损伤形貌及损伤分布情况。结果表明,层间混杂结构复合材料的抗冲击性能更优,其中铺层形式为I-C的混杂复合材料抗冲击性能最佳,冲击面为玻璃纤维时混杂结构复合材料对冲击响应区别不明显,CN-1层内混杂结构复合材料抗冲击性能优于CN-2层内混杂结构复合材料。低速冲击损伤主要为冲击处纤维断裂、基体破坏及界面分层,混杂结构可有效降低冲击破坏,层间混杂结构中玻璃纤维层损伤较大,层内混杂结构损伤受混杂界面影响,碳纤维束对临近的玻璃纤维束具有保护作用。Abstract: The low velocity impact behavior of carbon fiber-glass fiber hybrid composites were investigated based on experimental and numerical simulation. Two finite element models of interlayer and intralayer hybrid composites under low velocity impact were established in ABAQUS software. The strain-based Hashin failure criteria was adopted to predict the intralaminar damage and zero thickness Cohesive elements were used to simulate the delamination. The progress damage process were carried out by user-defined subroutine VUMAT. Internal microscopic damage state and damage distribution condition were obtained by means of C-scan and Micro-CT technique. The results show that the interlayer hybrid structure composites provide better impact-resistant properties, while the I-C hybrid structure composites present the best impact behavior. The difference of impact response of hybrid structure composites is not obvious when the impact-side face is glass fiber. The impact property of CN-1 intralayer hybrid structure composites is better than that in CN-2 intralayer hybrid structure composites. The damage induced by low velocity impact includes the fiber broken near impact point, matrix damage and delamination. Hybrid structure can reduce impact damage effectively. The glass fiber layers in interlayer hybrid structure experienced severe damage and the hybrid interface have influence on the damage of intralayer laminates. The carbon fiber bundles provide protection effect on neighbor glass fiber bundle.

-

表 1 碳纤维-玻璃纤维(CF-GF)单向经编织物(NCF)规格

Table 1. Specifications of carbon fiber-glass fiber (CF-GF) non-crimp fabric (NCF)

Fabric type Areal density/(g·m−2) Mass ratio of CF to GF CF GF CF 728.3 0 1∶0 GF 0 944.9 0∶1 CF-GF 364.2 472.4 1∶1 CF-CF-GF-GF 364.2 472.4 1∶1 表 2 CF-GF混杂复合材料层合板铺层结构

Table 2. Stacking configurations of CF-GF hybrid composite laminates

Hybrid structure Stacking sequence Nomenclature Non-hybrid (CFCFCFCF)2s C (GFGFGFGF)2s G Interply-hybrid (CFGFCFGF)2s I-C (GFCFGFCF)2s I-G Sandwich-hybrid (CFCFGFGF)2s S-C (GFGFCFCF)2s S-G Intralayer-hybrid (CF-GF) fabric CN-1 (CF-CF-GF-GF) fabric CN-2 表 3 用于数值模拟的CF/2511-1A/BS环氧树脂复合材料和GF/2511-1A/BS环氧树脂复合材料弹性参数

Table 3. Elastic parameters of CF/2511-1A/BS epoxy composites and GF/2511-1A/BS epoxy composites used in numerical simulation

Material E11/GPa E22=E33/GPa G12=G13/GPa G23/GPa $ {\mu }_{12} $ $ {\mu }_{13} $ $ {\mu }_{23} $ ${G}_{{\rm{f}}}$/(kJ·m−2) ${G}_{{\rm{m}}}$/(kJ·m−2) CF/epoxy 110 8.3 4.6 3.4 0.303 0.303 0.38 80 1 GF/epoxy 40 8.4 4.3 3.2 0.315 0.315 0.39 65 1 Notes: E11, E22, E33—Elastic modulus (direction 11, 22, 33); G12, G13, G23—Shear modulus (direction 12, 13, 23); $ {\mu }_{12} $, $ {\mu }_{13} $, $ {\mu }_{23} $—Poisson’s ratio (direction 12, 13 and 23). 表 4 用于数值模拟的CF/2511-1A/BS环氧树脂复合材料和GF/2511-1A/BS环氧树脂复合材料的强度参数

Table 4. Strength parameters of CF/2511-1A/BS epoxy composites and GF/2511-1A/BS epoxy composites used in numerical simulation

MPa Material XT XC YT=ZT YC=ZC S12=S13 S23 CF/epoxy 1600 640 48 150 80 60 GF/epoxy 860 550 48 140 65 60 表 5 CF/2511-1A/BS环氧树脂复合材料和GF/2511-1A/BS环氧树脂复合材料的层间界面参数

Table 5. Material properties of interface cohesive elements for CF/2511-1A/BS epoxy composites and GF/2511-1A/BS epoxy composites

ρ/(kg·m−3) kN/(GPa·mm−1) kS=kT/(GPa·mm−1) N/MPa S=T/MPa $ G_{\rm{n}}^{\rm{C}}$/(J·m−2) $ G_{\rm{S}}^{\rm{C}}$/(J·m−2) η 1200 15 1.2 30 60 0.28 0.8 1.5 表 6 CF-GF层内混杂增强环氧树脂复合材料模型中CF、GF和2511-1A/BS环氧树脂的材料参数

Table 6. Material paramenters of CF, GF and 2511-1A/BS epoxy for CF-GF intralayer hybrid reinforced epoxy composite model

Material E11/GPa E22=E33/GPa G12=G13/GPa G23/GPa $ {\mu }_{12} $ $ {\mu }_{13} $ $ {\mu }_{23} $ $ \rho $/(kg·m−3) CF 234 20 9.2 7.4 0.3 0.3 0.34 1.77 GF 78.7 7 4.0 2.5 0.3 0.3 0.4 2.54 2511-1A/BS epoxy 3.1 — — — 0.3 — — 1.13 表 7 CF-GF层内混杂增强环氧树脂复合材料模型中CF和GF纤维束的力学性能

Table 7. Mechanical properties of CF and GF fiber bundle for CF-GF intralayer hybrid reinforced epoxy composite model

Material E11/GPa E22=E33/GPa G12=G13/GPa G23/GPa μ12 μ13 μ23 CF fiber bundle 153 8.70 3.60 3.20 0.3 0.3 0.36 GF fiber bundle 52 5.27 2.48 1.88 0.3 0.3 0.40 -

[1] SUN G Y, YU H, WANG Z, et al. Energy absorption mechanics and design optimization of CFRP/aluminium hybrid structures for transverse loading[J]. International Journal of Mechanical Sciences,2019,150:767-783. doi: 10.1016/j.ijmecsci.2018.10.043 [2] CHEN D D, SUN G, MENG M, et al. Flexural performance and cost efficiency of carbon/basalt/glass hybrid FRP composite laminates[J]. Thin-Walled Structures,2019,142:516-531. doi: 10.1016/j.tws.2019.03.056 [3] KALANTARI M, DONG C S, DAVIES I J. Multi-objective analysis for optimal and robust design of unidirectional glass/carbon fibre reinforced hybrid epoxy composites under flexural loading[J]. Composites Part B: Engineering,2016,84:130-139. [4] JESTHI D K, MANDAL P, ROUT A K, et al. Enhancement of mechanical and specific wear properties of glass/carbon fiber reinforced polymer hybrid composite[J]. Procedia Manufacturing,2018,20:536-541. doi: 10.1016/j.promfg.2018.02.080 [5] SUBADRA S P, GRISKEVICIUS P, YOUSEF S. Low velocity impact and pseudo-ductile behaviour of carbon/glass/epoxy and carbon/glass/PMMA hybrid composite laminates for aircraft application at service temperature[J]. Polymer Testing,2020,89:106711. [6] SWOLFS Y, GEBOES Y, GORBATIKH L, et al. The importance of translaminar fracture toughness for the penetration impact behaviour of woven carbon/glass hybrid composites[J]. Composites Part A: Applied Science and Manufacturing,2017,103:1-8. doi: 10.1016/j.compositesa.2017.09.009 [7] HUNG P, LAU K, HUI D, et al. Impact response of hybrid carbon/glass fibre reinforced polymer composites designed for engineering applications[J]. Composites Part B: Engineering,2018,133:86-90. doi: 10.1016/j.compositesb.2017.09.026 [8] MANIKANDAN P, CHAI G B. A similitude approach towards the understanding of low velocity impact characteristics of bi-layered hybrid composite structures[J]. Composites Structures,2015,131:183-192. doi: 10.1016/j.compstruct.2015.04.055 [9] SARASINI F, TIRILLÒ J, VALENTE M, et al. Effect of basalt fiber hybridization on the impact behavior under low impact velocity of glass/basalt woven fabric/epoxy resin composites[J]. Composites Part A: Applied Science and Manufacturing,2013,47:109-123. [10] LIU P F, LIAO B B, JIA L Y, et al. Finite element analysis of dynamic progressive failure of carbon fiber composite laminates under low velocity impact[J]. Composite Structures,2016,149:408-422. [11] HOU Y L, TIE Y, LI C, et al. Low-velocity impact behaviors of repaired CFRP laminates: Effect of impact location and external patch configurations[J]. Composites Part B: Engineering,2019,163:669-680. doi: 10.1016/j.compositesb.2018.12.153 [12] EBINA M, YOSHIMURA A, SAKAUE K, et al. High fidelity simulation of low velocity impact behavior of CFRP laminate[J]. Composites Part A: Applied Science and Manufacturing,2018,113:166-179. doi: 10.1016/j.compositesa.2018.07.022 [13] CHEN D D, LUO Q, MENG M Z, et al. Low velocity impact behavior of interlayer hybrid composite laminates with carbon/glass/basalt fibers[J]. Composites Part B: Engineering,2019,176:107191. doi: 10.1016/j.compositesb.2019.107191 [14] WU Z Y, ZHANG L C, YING Z, et al. Low-velocity impact performance of hybrid 3D carbon/glass woven orthogonal composite: Experiment and simulation[J]. Composites Part B: Engineering,2020,196:108098. doi: 10.1016/j.compositesb.2020.108098 [15] ZHOU J J, WEN P H, WANG S N. Numerical investigation on the repeated low-velocity impact behavior of composite laminates[J]. Composites Part B: Engineering,2020,185:107771. doi: 10.1016/j.compositesb.2020.107771 [16] LIAO B B, WANG P D ZHENG J Y, et al. Effect of double impact positions on the low velocity impact behaviors and damage interference mechanism for composite laminates[J]. Composites Part A: Applied Science and Manufacturing,2020,136:105964. doi: 10.1016/j.compositesa.2020.105964 [17] WANG K K, ZHAO L B, HONG, H M, et al. A strain-rate-dependent damage model for evaluating the low velocity impact induced damage of composite laminates[J]. Composite Structures,2018,201:995-1003. doi: 10.1016/j.compstruct.2018.06.046 [18] ASTM International. Standard test method for measuring the damage resistance of a fiber-reinforced polymer matrix composite to a drop-weight impact event: ASTM D7136M—05[S]. West Conshohocken: ASTM International, 2005. [19] LIU H B, FALZON B G, TAN W, et al. Experimental and numerical studies on the impact response of damage-tolerant hybrid unidirectional/woven carbon-fibre reinforced composite laminates[J]. Composites Part B: Engineering,2018,136:101-118. doi: 10.1016/j.compositesb.2017.10.016 [20] LIU Y, ZHUANG W M, WU D. Performance and damage of carbon fibre reinforced polymer tubes under low-velocity transverse impact[J]. Thin-Walled Structure,2020,151:106727. doi: 10.1016/j.tws.2020.106727 [21] TUO H L, LU Z X, MAN X P, et al. Damage and failure mechanism of thin composite laminates under low-velocity impact and compression-after-impact loading conditions[J]. Composites Part B: Engineering,2019,163:642-654. doi: 10.1016/j.compositesb.2019.01.006 [22] HAN W Q, HU K J, SHI Q H, et al. Damage evolution analysis of open-hole tensile laminated composites using a progress damage model verified by AE and DIC[J]. Composite Structures,2020,247:112452. doi: 10.1016/j.compstruct.2020.112452 [23] WANG H R, LONG S C, ZHANG X Q, et al. Study on the delamination behavior of thick composite laminates under low energy impact[J]. Composite Structures,2018,184:461-473. doi: 10.1016/j.compstruct.2017.09.083 [24] LIU S K, ZHANG J J, CHEN Z T, et al. Modeling the coupling effects of braiding structure and thermo-oxidative aging on the high-speed impact responses of 3D braided composites[J]. Thin-Walled Structures,2020,150:106705. doi: 10.1016/j.tws.2020.106705 [25] CAO W J, ZHANG J J, SUN B Z, et al. X-ray tomography and numerical study on low-velocity impact damages of three-dimensional angle-interlock woven composites[J]. Composite Structures,2019,230:111525. doi: 10.1016/j.compstruct.2019.111525 [26] SRIDHARAN S, PANKOW M. Performance evaluation of two progressive damage models for composite laminates under various speed impact loading[J]. International Journal of Impact Engineering,2020,143:103615. doi: 10.1016/j.ijimpeng.2020.103615 [27] ZHANG C, RAO Y F, LI W. Low-velocity impact behavior of intralayer hybrid composites based on carbon and glass non-crimp fabric[J]. Composite Structures,2020,234:111713. doi: 10.1016/j.compstruct.2019.111713 [28] ZHANG C, RAO Y F, LI Z, et al. Low-velocity impact behavior of interlayer/intralayer hybrid composites based on carbon and glass non-crimp fabric[J]. Materials,2018,11(12):2472. doi: 10.3390/ma11122472 -

下载:

下载: