Research progress of composite conductive fiber in wearable intelligent textiles

-

摘要: 智能可穿戴领域是一个集多学科多门类的交叉研究领域,近年来备受各界学者关注。导电纤维作为智能可穿戴设备的枢纽,因其优异的力学性能、突出的电学和光学等功能特性,在智能可穿戴领域具有广阔的应用前景,并成为研究热点。针对目前研究学者对于可应用在柔性智能可穿戴纺织品中导电纤维的研究进展情况,系统地综述了导电纤维(包括金属导电纤维、导电聚合物纤维、碳系导电纤维)的导电机制、制备方法等。并详细阐述了近三年来研究人员运用不同电极材料制备的复合导电纤维的研究进展和未来的应用发展方向,最后总结并展望了此类柔性导电纤维的发展前景。以期望能够对未来可穿戴智能织物设备和小型化的柔性智能电子产品的科研创新研发有所助益。Abstract: Intelligent wearable field is a cross-research field with multiple disciplines and categories, and it has attracted the scholars’ attention from all domains in recent years. As the hub of intelligent wearable devices, the conductive fibers have a broad application prospect in this field because of their excellent mechanical properties and outstanding electrical and optical functional properties. In view of the research progress of conductive fibers which can be used in flexible smart wearable textiles, the conductive mechanism and preparation methods of conductive fibers including metal conductive fibers, conductive polymer fibers, carbon conductive fibers were systematically reviewed. Then the research progress and future application direction of composite conductive fibers prepared by different electrode materials in the past three years were described in details. Finally, the development prospect of this kind of flexible conductive fiber was summarized and prospected. It is expected to be helpful to the research and development of wearable intelligent fabric equipment and miniaturized flexible intelligent electronic products in the future.

-

图 1 在人体不同部位具有各类功能的柔性可穿戴智能纺织品的结构示意图和应用: ((a)~(h))可用于心率监测、柔性电子键盘、动作识别、触觉传感阵列、压力监测、智能鞋底等; ((i)~(r))可用于能量收集、风向传感器、电子皮肤、脉搏监测、智能义肢、运动跟踪、计步器/计度仪、睡眠监测、下降监测等[11]

Figure 1. Diagram shows structure and application characterization of smart flexible wearable textiles with various functions in different parts of human body: ((a)–(h)) Used for heart rate monitoring, flexible digital keyboard, gesture identification, tactile sensing array, pressure detecting, smart sole, etc.; ((i)–(r)) Used for energy harvesting, wind sensors, electronic skin, pulse monitoring, intelligent prosthetic, motion tracking, pedometer/speedmeter, sleeping monitoring, fall down monitoring, etc.[11]

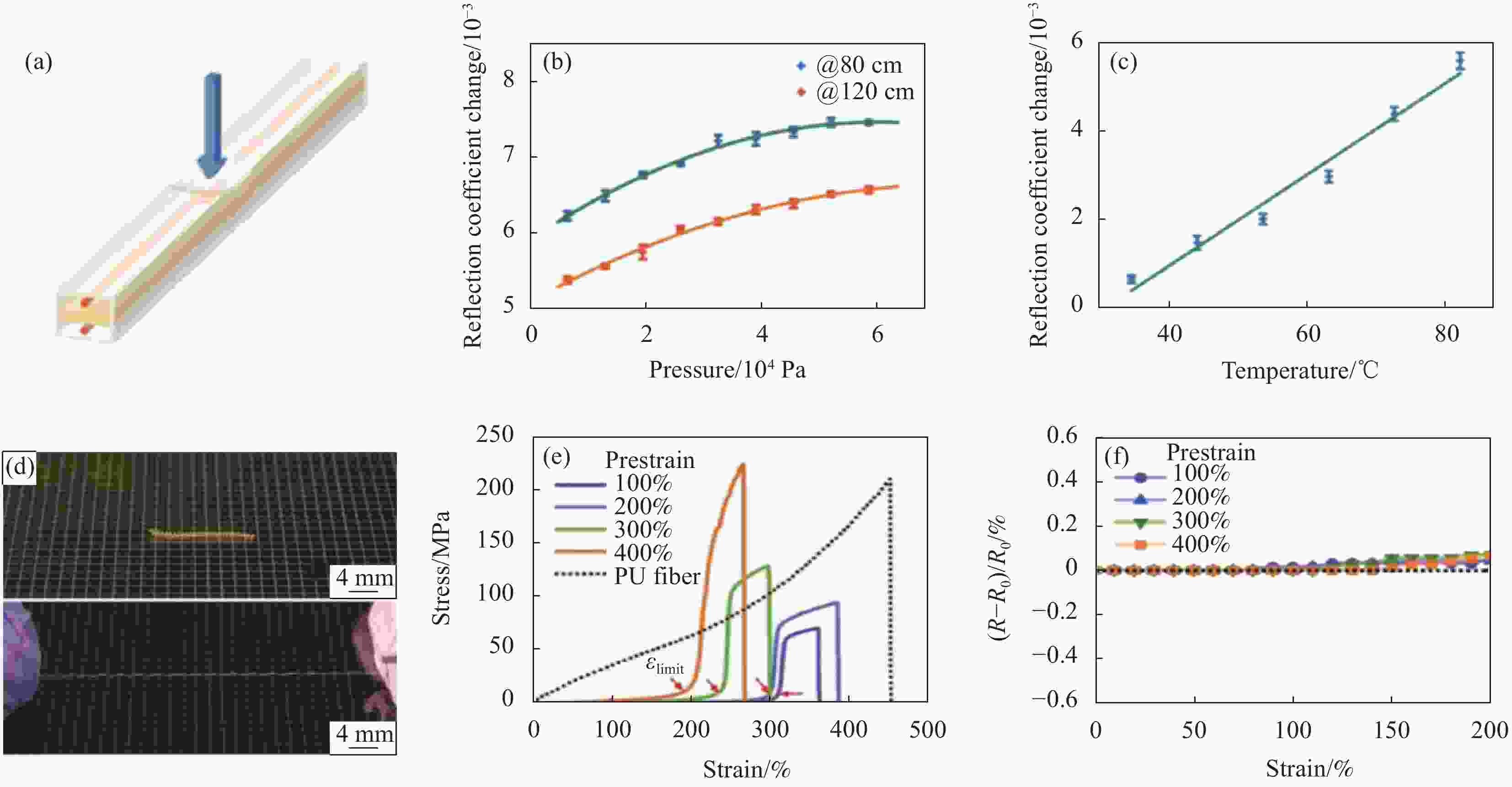

图 2 用于压力传感的复合纤维在压力下发生变形(a)、沿纤维两点测量在压力下反射系数的变化(b)、反射系数随温度的变化关系(c)[28];一根16 mm长的复合导电螺旋纤维分别处于松弛状态和拉伸至65 mm后的状态(d)、在100%、200%、300%和400%预应力下的聚氨酯(PU)纤维和3D螺旋纤维的应力-应变曲线(极限应变εlimit在图中被标出) (e)、在100%、200%、300%和400%预应变的不同拉伸应变下的三维螺旋纤维的电阻变化(f)[29]

Figure 2. Illustration of fiber deformation under pressure (a), Reflection coefficient change under pressure measured at two points along fiber (b), Reflection coefficient change versus temperature relationship (c)[28]; A 16 mm long conductive helical fiber in its relaxed state and after being stretched to 65 mm (d), Stress-strain curves of polyurethane (PU) fiber and 3D helical fibers with 100%, 200%, 300%, and 400% prestrains (limiting strains εlimit are marked) (e), Change in electrical resistance of 3D helical fibers with 100%, 200%, 300%, and 400% prestrains at different stretching strains (f)[29]

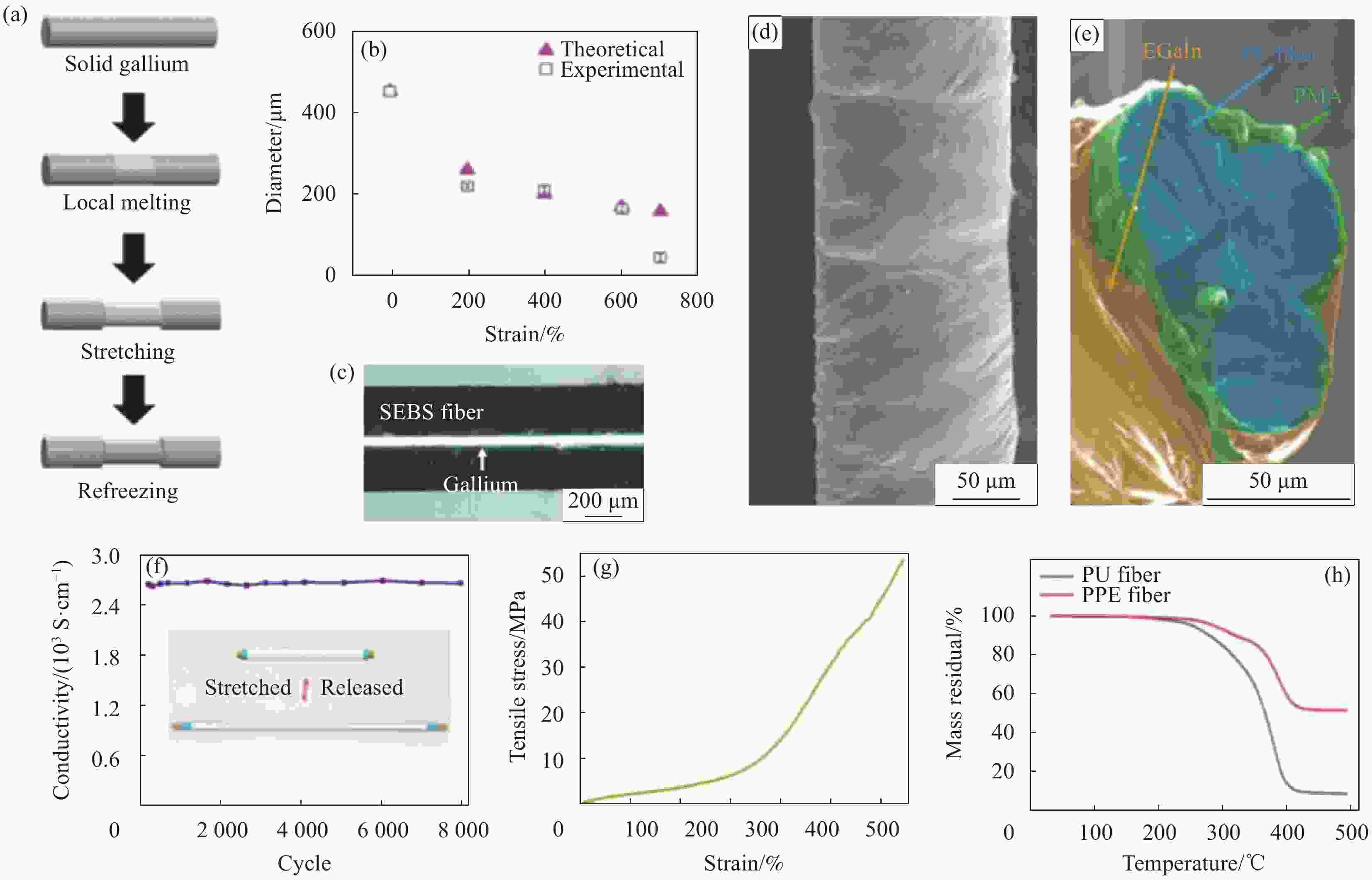

图 3 通过液态金属的局部相位处理和随后的纤维拉伸来制备薄横截面金属线(a)、取决于金属芯相的不同刚度聚合物纤维的拉伸应力-应变(b)、中空的氢化苯乙烯-丁二烯嵌段共聚物(SEBS)纤维和液态Ga填充纤维的的横截面金属线的光学显微镜图像(c)[30]; PPE纤维的纵向形态(d)、PPE纤维的截面(图像着色)(e)、在40%应变条件下PPE纤维在循环拉伸负载和卸载下的电导率(f)、PPE纤维的应力-应变曲线(g)、PU纤维和PPE纤维从室温到500℃的热重曲线(h)[31]

Figure 3. Schematic illustration showing preparation of thin crosssectional metallic wires via local phase manipulation of liquid metal and subsequent stretching of fiber (a), Tensile stress-strain plots of polymeric fibers with variable stiffness depending on phase of metallic core (b), Optical microscope image of thinnest cross-sectional metallic wire of an empty poly[styrene-b-(ethylene-co-butylene)-b-styrene] (SEBS) fiber and liquid Ga filled fiber (c)[30]; Scanning electron microscopy of longitudinal morphology of PPE fibers (d), Cross section of PPE fiber (image was colored) (e), Conductivity of PPE fiber under cyclic tensile loading and unloading under 40% strain (f), Stress-strain curve of PPE fiber (g), Thermogravimetric curve of PU fiber and PPE fiber ranged from room temperature to 500℃ (h)[31]

PPE—PU@PMA@EGaIn

图 4 聚二甲基硅氧烷(PDMS)包覆的螺旋纤维的横截面的SEM图像和EDS映射图像(a)、纤维的循环拉伸次数与电阻间的关系(b)、螺旋纤维应用于由微型光电元件组成的皮肤可贴式血氧计的示意图及无线嵌入式系统(c)[32]; 应变范围为0%~60%、60%~150%、150%~200%时应变系数的线性拟合度(d)、在不同的应变拉伸/释放循环下的ΔR/R0、(f)“DHU”、“Silver”和“MXene”时的ΔR/R0变化曲线(e)[33]; PU/AgNW纤维应变传感器的结构示意图(g)、PU/AgNW-7纤维应变传感器相对电阻变化与应变的关(h)、PU/AgNW纤维应变传感器的反应时间(i)[34]

Figure 4. Cross-sectional SEM image and EDS mapping images of PDMS-coated helical fiber (a), Relationship between number of cyclic stretching and resistance for fiber (b), Schematic illustration of skin-mountable oximeter consisting of micro optoelectronic components and a wirelessly embedded system(c)[32]; With strain range of 0%–60%, 60%–150%, 150%–200%, linear fitting degree of GF (d), Corresponding ΔR/R0 values under different strain stretching cycles (e), ΔR/R0 values with “DHU”, “Silver” and “MXene” (f)[33]; Schematic illustration of conductive networks of PU/AgNW fiber strain sensor (g), Plots of relative resistance change vs. strain for PU/AgNW-7 fiber strain sensors (h), Response time of PU/AgNW fiber strain sensor (i)[34]

图 5 原理图介绍了如何应用预应变扣策略在热塑性弹性体(TPE)通道中获得折叠导电聚合物带(a)、在增量循环加载/卸载过程中,不同的聚硼硅氧烷(PBP)重量分数的PEDOT/PSS/PBP薄膜的拉伸应力与应变曲线(b)、不同PBP重量分数下的自支撑PEDOT/PSS/PBP纤维的电导率(c)[37]; 一个置于硅基延伸器上的用S-Silk与10% SWCNT复合材料制备的3D打印机器人手指(d)、三种材料的应力-应变曲线(e),灰色虚线曲线下的区域代表S-Silk的韧性、在达到12.5wt%饱和之前,S-Silk复合材料的电导率和韧性随着SWCNT重量百分比的增加而增加,最大的导电性和韧性分别为1077 S/cm和420 MJ/m3 ((f)、(g))[38]; 聚丙烯酰胺/聚丙烯酸-1.1% Fe3+/NaCl (PAAm/PAA-1.1% Fe3+/NaCl)水凝胶被分为两段和完全自修复后的图片(h)、破损和自修复条件下的PAAm/PAA-1.1%Fe3+/NaCl水凝胶基离子皮肤在不同应变下的相对电阻的变化(i)、在原始和自修复条件下的PAAm/PAA-1.1% Fe3+/NaCl水凝胶基离子皮肤在不同压力下的相对电阻的变化(j)[39]

Figure 5. Schematic presenting how prestrain-then-buckling strategy was applied to obtain a folded conductive polymer ribbon in a TPE channel (a), Tensile stress versus strain curve of PEDOT/PSS/PBP films with different PBP fractions during incremental cyclic loading/unloading (b), Electrical conductivity of self-standing PEDOT/PSS/PBP fibers at different PBP fractions (c)[37]; Photograph of a 3D-printed robotic finger with an S-silk composite@10% SWCNT electro-tendon held in place by a silicone-based extensor (d), Stress-strain curves of natural spider silk (S-silk), spider silk with PEDOT:PSS@0% SWCNT (S-silk composite@0% SWCNT), spider silk with PEDOT:PSS@10% SWCNT (S-silk composite@10% SWCNT) (e), Area under gray dotted curve represents toughness of S-silk. Toughness is defined as the energy needed to break the silk, conductivity and toughness of the S-silk composite increased with increasing weight percent of SWCNT, before experiencing saturation at 12.5wt% ((f), (g)). The maximum conductivity and toughness achieved were 1077 S/cm and 420 MJ/m3, respectively[38]; Digital photographs of the PAAm/PAA-1.1% Fe3+/NaCl hydrogel being cut into two pieces (h), Relative resistance changes of the original, damaged, and healed PAAm/PAA-1.1% Fe3+/NaCl hydrogel based ionic skins as a function of strain of the hydrogels (i), Relative resistance changes of the original and healed PAAm/PAA-1.1% Fe3+/NaCl ionic skins as a function of pressure (j)[39]

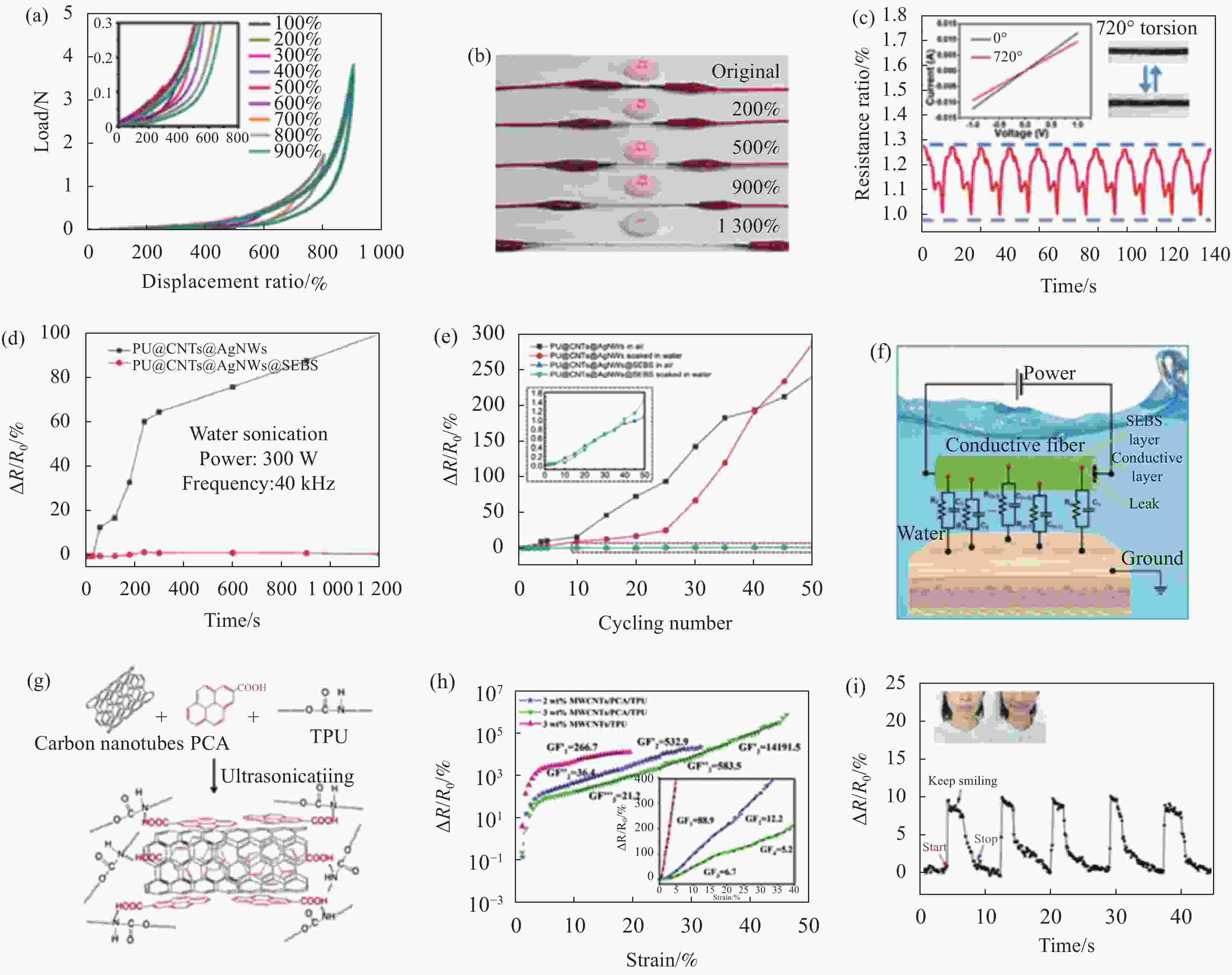

图 6 不同应变下的负载-不负载曲线,表明碳纳米管/PU螺旋纱即使在900%拉伸下也具有良好的可回收性能(a)、通过在拉伸过程中的LED灯显示出螺旋CNTs/PU纱具有良好导电性(b)、在720°扭转周期中的碳纳米管/PU螺旋线的电阻变化曲线,嵌图是与扭转变形相对应的电流-电压曲线(c)[46]; 各种情况下SEBS层对可拉伸导电纤维(CSCF)的材料绝缘作用,监测水超声后SEBS的有无对芯鞘纤维的电阻变化(d)、在水和空气中50%应变下纤维的循环使用 在水浸泡后,在水和空气中交替测试有和没有SEBS的芯鞘纤维的电阻变化,嵌图是矩形区域的放大图(e)、SEBS层对CSCF的导电绝缘效应 用在水中的贴近皮肤的CSCF电路模型[47](f); 聚合物与纳米管增强界面相互作用的示意图(g)、改性和控制样品纤维应变传感器的相对电阻变化随拉伸应变的变化,应变系数GF由曲线计算(h)、纳米复合涂层纤维传感器记录微笑时的相对电阻变化(i)[48]

Figure 6. Loading-unloading curves during different strains, showing a good recoverable property of CNTs/PU helical yarn even at 900% stretching (a), Resistance variation curves of CNTs/PU helical yarn during 720° torsion cycles. Insets are the current-voltage curves corresponding to the stretching, bending, and torsion deformation (b), Good conductivity of helical CNTs/PU yarn demonstrated by LED light during stretch proces (c)[46]; Materials-insulation effect of SEBS layer on CSCF under various circumstances. Monitoring resistance change of core-sheath fibers with and without SEBS after water sonication (d), Cyclic use of fibers at 50% strain in water and air. Resistance change of core-sheath fibers with and without SEBS alternatively tested in water and in air after water soaking. Inset is zoom-in plots of the rectangular region (e), Conductivity-insulation effect of SEBS layer on CSCF. Circuit model of CSCF next to skin used in water (f)[47]; A schematic diagram of enhanced interfacial interaction between polymer and nanotube (g), Relative resistance change of the modified and control sample fiber strain sensors as a function of tensile strain, GF is calculated from the curve (h), Recording of human motions(smiling) using the nanocomposite-coated fiber sensor (i)[48]

图 7 在扫描速率50 mV·s–1 (嵌图)通过2000次循环后导电纤维的电容保持能力(a)、对比其它工作的能量和功率损耗(b)[52]; PGFs的传感特性,无孔/无纳米颗粒、多孔/无纳米颗粒、多孔/纳米颗粒和TPU/石墨烯控制(绿色)的应变系数(c) 、PGFs的检测极限达到0.01%(信噪比:26 dB)(d)、两点触摸的电阻反射(e)[53]; 在5%的阶跃应变下,G@MPPU10光纤拉伸和释放的响应时间(f)、频率为2Hz下的G@MPPU10光纤(5 cm)在3000 s以上从0%应变到10%应变的稳定性,嵌图显示在3个连续输入的响应信号(g)、在正常状态下和放置热水瓶(60℃)后前臂皮肤温度,嵌图是测试的光学图像,及把热水瓶放在前臂的红外图像(h)[54]

Figure 7. Capacitance retention ability of conductive fiber across 2 000 cycles at scan rate of 50 mV·s–1 (Inset) (a), Ragone plot of device in comparsion to other state-of-art devices in literature (b)[52]; Sensing properties of PGFs. Gauge factors for pore-less/nanoball-free, porous/nanoball-free, porous/nanoball (red), and TPU/graphene control (c), Testing limit of PGFs reaches 0.01% (SNR: 26 dB) (d), Resistance reflection of two-point touch (e)[53]; Response time of G@MPPU10 fiber stretched and released at a step strain of 5% (f), Stability of a G@MPPU10 fiber (5 cm) from 0% strain to 10% strain over 3000 s under a frequency of 2 Hz. The inset shows the response signal at 3 consecutive input (g), Forearm skin temperature at normal state and after putting of a thermos (60℃), insets are the optical image of testing, and the IR image when putting the thermos on the forearm (h)[54]

图 8 核壳压电纤维的组成及其结构(a)、可以紧密黏附于人体皮肤上(b)[55]; 在10 000次拉伸/释放循环中,施加应变为50%的PDMS包覆的GNS/Au/GNS/PU纱的相对电阻变化,嵌图为详细的相对电阻变化第2 000和2 020次拉伸/释放周期与第1、5 000和10 000次拉伸/释放周期之间的曲线(c)、使用基于铝纺织绷带的应变传感器进行人体运动监测,行走的相对阻力变化(d)[58]。

Figure 8. Schematic illustration of a single unit of electronic skins (a), Optical photograph of an electronic skin conformably attached on the back of hand (b)[55]; Relative resistance change of PDMS-wrapped GNS/Au/GNS/PU yarn during 10 000 stretching/releasing cycles with an applied strain of 50%; Inset figure records the detailed relative resistance change curves between the 2 000th and 2 020th stretching/releasing cycles and those of the 1st, 5 000th and 10 000th stretching/releasing cycles (c), Human motion monitoring by using the strain sensor based medical textile bandage. Relative resistance changes of walking (d)[58]

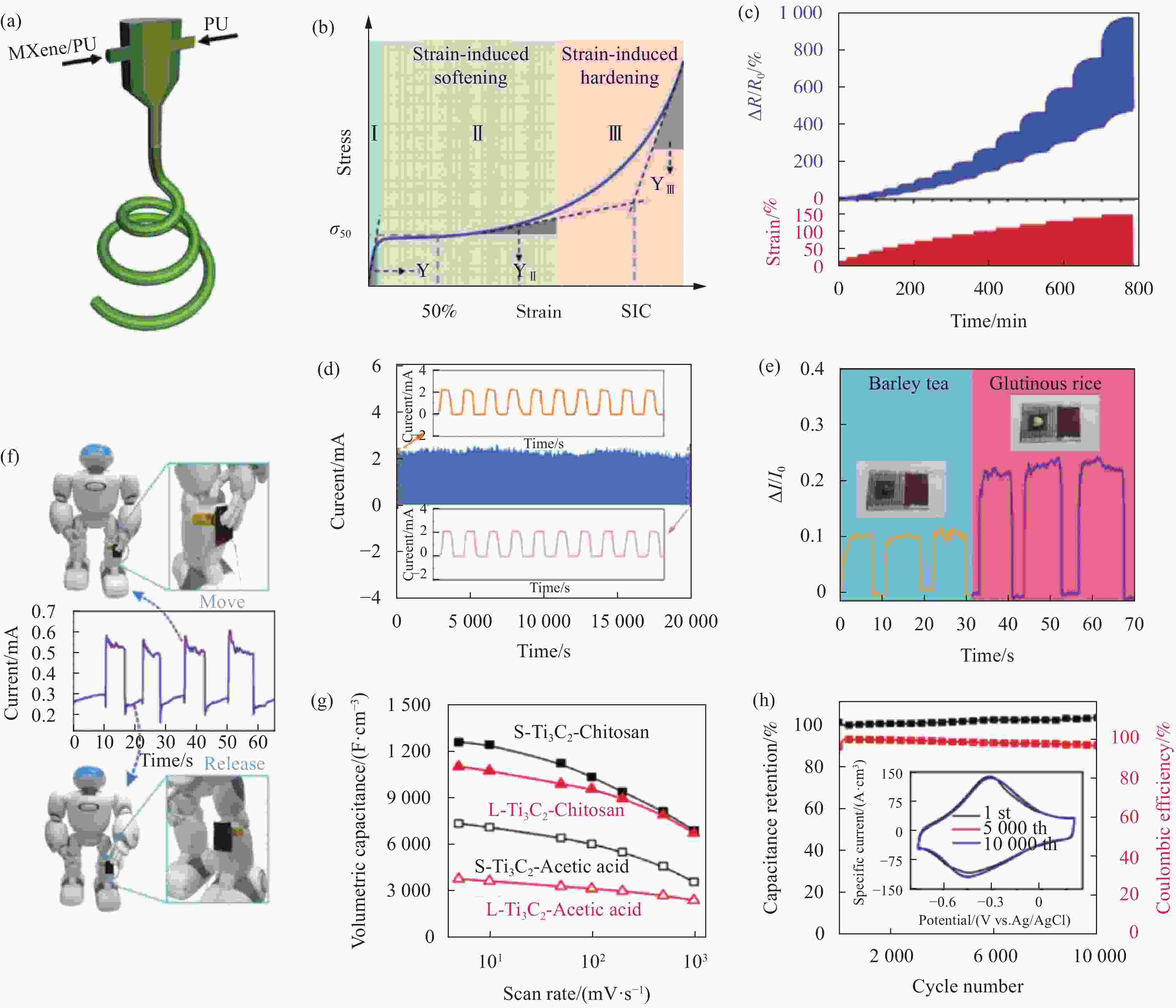

图 9 用MXene/PU护套和PU芯实现纤维的同轴纤维纺丝方法的示意图(a)、MXene/PU纤维在不同阶段应力-应变曲线的示意图(b)、MXene/PU同轴纤维在各种施加应变下的循环拉伸释放变形下的机电性能(c)[60]; 压力循环测试表现出优异的循环稳定性(d)、大麦茶(4.4 Pa)和米粒(8.6 Pa)小物体测试(e)、检测机器人运动行为(f)[61]; 不同扫描速率下液晶相MXene纤维体积电容的变化(g)、壳聚糖浴中S-Ti3C2纤维的循环稳定性(扫描速率为100 mV s−1) (h)[62]

Figure 9. Schematic illustration of coaxial fiber spinning approach used to achieve fibers with MXene/PU sheath and PU core (a), Schematic illustration of various stages of stress-strain curves for MXene/PU fibers (b), Electromechanical properties of MXene/PU coaxial fiber under cyclic stretching-releasing deformation at various applied strains (c)[60]; Excellent cycle stability performance of device after 10 000 pressure cycling test under 3.36 kPa (d), Tiny object pressure provided by a grain of barley tea (4.4 Pa) and glutinous rice (8.6 Pa) (e), Photograph of pressure sensor assembled on a robot (Inset: Enlarged view of the sensing position) and detection of its response to the motion behavior (f)[61]; Changes in volumetric capacitance of LC MXene fibers at different scan rates (g), Cyclic stability of S-Ti3C2 fibers spun in a chitosan bath over 10 000 cycles (at a scan rate of 100 mV s−1) (h)[62]

-

[1] OUYANG H, TIAN J, SUN G, et al. Self-powered pulse sensor for antidiastole of cardiovascular disease[J]. Advanced Materials,2017,29 (40):e1703456. [2] LIU Y, PHARR M, SALVATORE G A. Lab-on-skin: A review of flexible and stretchable electronics for wearable health monitoring[J]. ACS Nano,2017,11 (10):9614-9635. [3] WANG C, XIA K, WANG H, et al. Advanced carbon for flexible and wearable electronics[J]. Advanced Materials,2019,31(9):e1801072. [4] CAO M S, WANG X X, ZHANG M, et al. Electromagnetic response and energy conversion for functions and devices in low-dimensional materials[J]. Advanced Functional Materials,2019,29(25):1807398. [5] 王希晰, 曹茂盛. 特色研究报告: 低维电磁功能材料研究进展[J]. 表面技术, 2020, 49(2):18-28.WANG X X, CAO M S. Low-dimensional electromagnetic functional materials[J]. Surface Technology,2020,49(2):18-28(in Chinese). [6] 莫崧鹰, 何继超. 崭新电子纺织品技术的发展[J]. 纺织导报, 2019(5):34-41.MO S Y, HE J C. Technological development of advanced electronic textiles[J]. China Textile Leader,2019(5):34-41(in Chinese). [7] ZOU Y, TAN P, SHI B, et al. A bionic stretchable nanogenerator for underwater sensing and energy harvesting[J]. Nature Communications,2019,10(1):2695. [8] LI J, LIU Q, HO D, et al. Three-dimensional graphene structure for healable flexible electronics based on Diels-Alder chemistry[J]. ACS Applied Materials & Interfaces,2018,10 (11):9727-9735. [9] WANG C, HU K, LI W, et al. Wearable wire-shaped symmetric supercapacitors based on activated carbon-coated graphite fibers[J]. ACS Applied Materials & Interfaces,2018,10(40):34302-34310. [10] MA T, GAO H L, CONG H P, et al. A bioinspired interface design for improving the strength and electrical conductivity of graphene-based fibers[J]. Advanced Materials,2018,30(15):e1706435. [11] LEE J, LLERENA ZAMBRANO B, WOO J, et al. Recent advances in 1 d stretchable electrodes and devices for textile and wearable electronics: Materials, fabrications, and applications[J]. Advanced Materials,2020,32 (5):e1902532. [12] GONG S, LAI D T H, SU B, et al. Highly stretchy black gold E-skin nanopatches as highly sensitive wearable biomedical sensors[J]. Advanced Electronic Materials,2015,1 (4):1400063. [13] DONG K, PENG X, WANG Z L. Fiber/fabric-based piezoelectric and triboelectric nanogenerators for flexible/stretchable and wearable electronics and artificial intelligence[J]. Advanced Materials,2020,32(5):e1902549. [14] 吴颖欣, 胡铖烨, 周筱雅, 等. 柔性可穿戴氨纶/聚苯胺/聚氨酯复合材料的应变传感性能[J]. 纺织学报, 2020, 41(4):21-25.WU Y X, HU Y Y, ZHOU X Y, et al. Strain sensing property of flexible wearable spandex/polyaniline/polyurethane composites[J]. Journal of Textile Research,2020,41(4):21-25(in Chinese). [15] 吴佳奇, 李刚, 杨小平, 等. 耐高温碳纤维/双马来酰亚胺树脂复合材料制备及性能[J]. 复合材料学报, 2020, 37(7):1505-1512.WU J Q, LI G, YANG X P, et al. Preparation and properties of carbon fiber/bismaleimide resin composites with high heat resistance[J]. Acta Materiae Compositae Sinica,2020,37(7):1505-1512(in Chinese). [16] CAO M S, SONG W L, HOU Z L, et al. The effects of temperature and frequency on the dielectric properties, electromagnetic interference shielding and microwave-absorption of short carbon fiber/silica composites[J]. Carbon,2010,48(3):788-796. [17] WEN B, CAO M S, HOU Z L, et al. Temperature dependent microwave attenuation behavior for carbon-nanotube/silica composites[J]. Carbon,2013:65 124-139. [18] BERGER C, SONG Z M, LI X B, et al. Electronic confinement and coherence in patterned epitaxial graphene[J]. Science,2006,312 (5777):1191-1196. [19] LI Y H, ZHOU B, ZHENG G Q, et al. Continuously prepared highly conductive and stretchable SWNT/MWNT synergistically composited electrospun thermoplastic polyurethane yarns for wearable sensing[J]. Journal of Materials Chemistry C,2018,6(9):2258-2269. [20] 王明序, 许子傲, 葛明桥, 高强. 浅色导电纤维的发展及其最新应用[J]. 丝绸, 2020, 57(1):37-42.WANG M X, XU Z A, GE M Q, et al. Development of light-colored conductive fibers and their latest applications[J]. Journal of Silk,2020,57(1):37-42(in Chinese). [21] LIAO X, DULLE M, SLIVA J, et al. A. High strength in combination with high toughness in robust and sustainable polymeric materials[J]. Science,2019,366 (6471):1376-1379. [22] ZHANG S, LIU H, YANG S, et al. Ultrasensitive and highly compressible piezoresistive sensor based on polyurethane sponge coated with a cracked cellulose nanofibril/silver nanowire layer[J]. ACS Applied Materials & Interfaces,2019,11 (11):10922-10932. [23] LIU H, LI Q, ZHANG S, et al. Electrically conductive polymer composites for smart flexible strain sensors: A critical review[J]. Journal of Materials Chemistry C,2018,6 (45):12121-12141. [24] XIE X, ZHAO M Q, ANASORI B, et al. Porous heterostructured MXene/carbon nanotube composite paper with high volumetric capacity for sodium-based energy storage devices[J]. Nano Energy,2016,26:513-523. [25] SOUNDIRARAJU B, GEORGE B K. Two-dimensional titanium nitride (Ti2N) Mxene: Synthesis, characterization, and potential application as surface-enhanced raman scattering substrate[J]. ACS Nano,2017,11(9):8892-8900. [26] RAJAVEL K, KE T, YANG K, et al. Condition optimization for exfoliation of two dimensional titanium carbide (Ti3C2Tx)[J]. Nanotechnology,2018,29 (9):095605. doi: 10.1088/1361-6528/aaa687 [27] LEVITT A, ZHANG J, DION G, et al. Mxene-based fibers, yarns, and fabrics for wearable energy storage devices[J]. Advanced Functional Materials,2020,30(47):2000739. doi: 10.1002/adfm.202000739 [28] YU L, PARKER S, XUAN H, et al. Flexible multi-material fibers for distributed pressure and temperature sensing[J]. Advanced Functional Materials,2020,30(9):1908915. doi: 10.1002/adfm.201908915 [29] YANG Z, ZHAI Z, SONG Z, et al. Conductive and elastic 3D helical fibers for use in washable and wearable electronics[J]. Advanced Materials,2020,32(10):e1907495. doi: 10.1002/adma.201907495 [30] PARK S, BAUGH N, SHAH H K, et al. Ultrastretchable elastic shape memory fibers with electrical conductivity[J]. Advanced Science,2019,6(21):1901579. doi: 10.1002/advs.201901579 [31] CHEN G, WANG H, GUO R, et al. Superelastic egain composite fibers sustaining 500% tensile strain with superior electrical conductivity for wearable electronics[J]. ACS Applied Materials & Interfaces,2020,12 (5):6112-6118. [32] WOO J, LEE H, YI C, et al. Ultrastretchable helical conductive fibers using percolated Ag nanoparticle networks encapsulated by elastic polymers with high durability in omnidirectional deformations for wearable electronics[J]. Advanced Functional Materials,2020,30(29):1910026. [33] LI H, DU Z. Preparation of a highly sensitive and stretchable strain sensor of MXene/silver nanocomposite-based yarn and wearable applications[J]. ACS Applied Materials & Interfaces,2019,11(49):45930-45938. [34] ZHU G J, REN P G, GUO H, et al. Highly sensitive and stretchable polyurethane fiber strain sensors with embedded silver nanowires[J]. ACS Applied Materials & Interfaces,2019,11 (26):23649-23658. [35] LU Y, BISWAS M C, GUO Z, et al. Recent developments in bio-monitoring via advanced polymer nanocomposite-based wearable strain sensors[J]. Biosensors and Bioelectronics,2019,123:167-177. [36] FARRAJ Y, GROUCHKO M, MAGDASSI S. Self-reduction of a copper complex mod ink for inkjet printing conductive patterns on plastics[J]. Chemical Communications,2015,51 (9):1587-1590. doi: 10.1039/C4CC08749F [37] ZHOU J, TIAN G, JIN G, et al. Buckled conductive polymer ribbons in elastomer channels as stretchable fiber conductor[J]. Advanced Functional Materials,2019,30(5):1907316. [38] PAN L, WANG F, CHENG Y, et al. A supertough electro-tendon based on spider silk composites[J]. Nature Communications,2020,11:1332. doi: 10.1038/s41467-020-14988-5 [39] ZHAO X, CHEN F, LI Y, et al. Bioinspired ultra-stretchable and anti-freezing conductive hydrogel fibers with ordered and reversible polymer chain alignment[J]. Nature Communications,2018,9:3579. doi: 10.1038/s41467-018-05904-z [40] LEPAK-KUC S, MILOWSKA K Z, BONCEL S, et al. Highly conductive doped hybrid carbon nanotube–graphene wires[J]. ACS Applied Materials & Interfaces,2019,11 (36):33207-33220. [41] QIAO Y, WANG Y, TIAN H, et al. Multilayer graphene epidermal electronic skin[J]. ACS Nano,2018,12 (9):8839-8846. doi: 10.1021/acsnano.8b02162 [42] CAI Y, SHEN J, GE G, et al. Stretchable Ti3C2Tx MXene/carbon nanotube composite based strain sensor with ultrahigh sensitivity and tunable sensing range[J]. ACS Nano,2018,12(1):56-62. doi: 10.1021/acsnano.7b06251 [43] MA L, YANG W, WANG Y, et al. Multi-dimensional strain sensor based on carbon nanotube film with aligned conductive networks[J]. Composites Science and Technology,2018,165:190-197. [44] ZHU L, ZHOU X, LIU Y, et al. Highly sensitive, ultrastretchable strain sensors prepared by pumping hybrid fillers of carbon nanotubes/cellulose nanocrystal into electrospun polyurethane membranes[J]. ACS Applied Materials & Interfaces,2019,11 (13):12968-12977. [45] 刘素芹, 王松, 戴高鹏, 等. 复合碳纳米管增强纳米Ag2CO3的可见光催化活性和稳定性[J]. 物理化学学报, 2014, 30(11):2121-2126. doi: 10.3866/PKU.WHXB201409191LIU S Q, WANG S, DAI G P, et al. Enhanced visible-light photocatalytic activity and stability of nano-sized Ag2CO3 combined with carbon nanotubes[J]. Acta Physico-Chimica Sinica,2014,30(11):2121-2126(in Chinese). doi: 10.3866/PKU.WHXB201409191 [46] GAO Y, GUO F, CAO P, et al. Winding-locked carbon nanotubes/polymer nanofibers helical yarn for ultrastretchable conductor and strain sensor[J]. ACS Nano,2020,14(3):3442-3450. doi: 10.1021/acsnano.9b09533 [47] ZHANG Y, ZHANG W, YE G, et al. Core-sheath stretchable conductive fibers for safe underwater wearable electronics[J]. Advanced Materials Technologies,2019,5(1):1900880. [48] CHEN Q, LI Y, XIANG D, et al. Enhanced strain sensing performance of polymer/carbon nanotube-coated spandex fibers via noncovalent interactions[J]. Macromolecular Materials and Engineering,2019,305 (2):1900525. [49] 李绍娟, 甘胜, 沐浩然, 等. 石墨烯光电子器件的应用研究进展[J]. 新型炭材料, 2014, 29(5):329-356.LI S J, GAN S, MU H R, et al. Research progress in graphene use in photonic and optoelectronic devices[J]. New Carbon Materials,2014,29(5):329-356(in Chinese). [50] 匡达, 胡文彬. 石墨烯复合材料的研究进展[J]. 无机材料学报, 2013, 28(3):235-246. doi: 10.3724/SP.J.1077.2013.12345KUANG D, HU W B. Research progress of graphene composites[J]. Journal of Inorganic Materials,2013,28(3):235-246(in Chinese). doi: 10.3724/SP.J.1077.2013.12345 [51] ZHANG J, CAO Y, QIAO M, et al. Human motion monitoring in sports using wearable graphene-coated fiber sensors[J]. Sensors and Actuators A: Physical,2018,274:132-140. [52] MARRIAM I, WANG X, TEBYETEKERWA M, et al. A bottom-up approach to design wearable and stretchable smart fibers with organic vapor sensing behaviors and energy storage properties[J]. Journal of Materials Chemistry A,2018,6 (28):13633-13643. doi: 10.1039/C8TA03262A [53] HUANG T, HE P, WANG R, et al. Porous fibers composed of polymer nanoball decorated graphene for wearable and highly sensitive strain sensors[J]. Advanced Functional Materials,2019,29 (45):1903732. doi: 10.1002/adfm.201903732 [54] HU X, TIAN M, XU T, et al. Multiscale disordered porous fibers for self-sensing and self-cooling integrated smart sportswear[J]. ACS Nano,2020,14 (1):559-567. doi: 10.1021/acsnano.9b06899 [55] ZHU M, LOU M, ABDALLA I, et al. Highly shape adaptive fiber based electronic skin for sensitive joint motion monitoring and tactile sensing[J]. Nano Energy,2020,69:104429. doi: 10.1016/j.nanoen.2019.104429 [56] ZHAO S, GUO L, LI J, et al. Binary synergistic sensitivity strengthening of bioinspired hierarchical architectures based on fragmentized reduced graphene oxide sponge and silver nanoparticles for strain sensors and beyond[J]. Small,2017,13 (28):1700944. doi: 10.1002/smll.201700944 [57] REN J, WANG C, ZHANG X, et al. Environmentally-friendly conductive cotton fabric as flexible strain sensor based on hot press reduced graphene oxide[J]. Carbon,2017,111:622-630. [58] LI X, KOH K H, FARHAN M, et al. An ultraflexible polyurethane yarn-based wearable strain sensor with a polydimethylsiloxane infiltrated multilayer sheath for smart textiles[J]. Nanoscale,2020,12 (6):4110-4118. doi: 10.1039/C9NR09306K [59] 董兰静, 张强, 蔡璋文, 等. 压力作用下Cr2AC相(A=Si、Ge)的第一性原理研究[J]. 硅酸盐通报, 2019, 38(5):1343-1348, 1355.DONG L J, ZHANG Q, CAI Z W, et al. First principles study on Cr2AC phases (A = Si, Ge) under pressure[J]. Bulletin of the Chinese Ceramic Society,2019,38(5):1343-1348, 1355(in Chinese). [60] SEYEDIN S, UZUN S, LEVITT A, et al. MXene composite and coaxial fibers with high stretchability and conductivity for wearable strain sensing textiles[J]. Advanced Functional Materials,2020,30(12):1910504. doi: 10.1002/adfm.201910504 [61] CHENG Y, MA Y, LI L, et al. Bioinspired microspines for a high-performance spray Ti3C2Tx mxene-based piezoresistive sensor[J]. ACS Nano,2020,14(2):2145-2155. doi: 10.1021/acsnano.9b08952 [62] ZHANG J, UZUN S, SEYEDIN S, et al. Additive-free MXene liquid crystals and fibers[J]. ACS Central Science,2020,6 (2):254-265. doi: 10.1021/acscentsci.9b01217 [63] SHI J D, LIU S, ZHANG L S, et al. Smart textile-integrated microelectronic systems for wearable applications[J]. Advanced Materials,2020,32(5):1901958. -

下载:

下载: