Mechanical properties of carbon fiber reinforced epoxy composite-aluminium alloy stub column

-

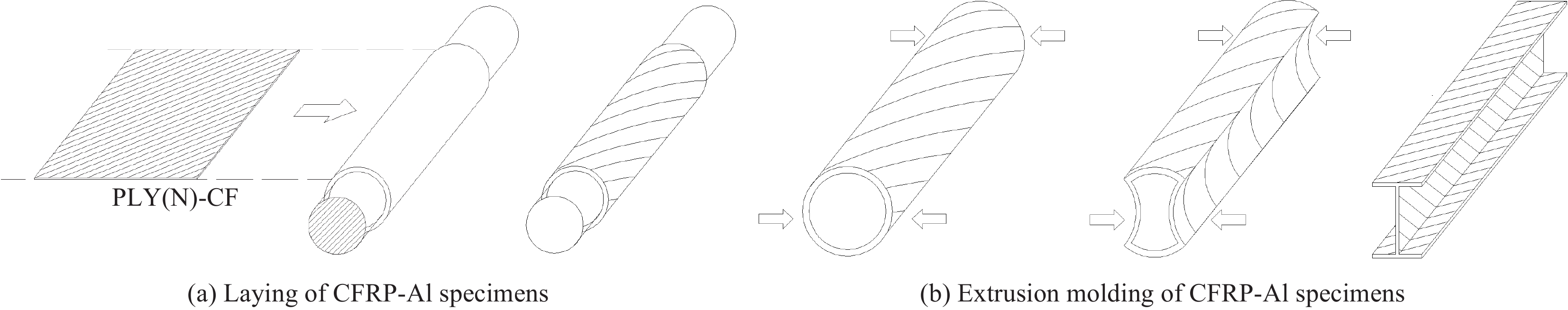

摘要: 碳纤维增强环氧树脂复合材料-铝合金 (CFRP-Al)短柱轻质高强,具有良好延性,在大跨空间结构中具有广阔的应用前景,然而国内外对其受力性能的研究目前几乎处于空白状态。为此,本文对CFRP-Al短柱进行了理论分析、试验研究和数值模拟。推导得到了CFRP-Al短柱的等效工程弹性常数;进行了6根短柱轴压试验,得到了其轴压承载力和破坏模式;根据弹性力学推导得到了试件的荷载-压缩变形曲线,理论曲线与试验曲线吻合良好;建立了两种有限元模型—逐层精细化模型和整体等效简化模型,并将两种数值模型结果与试验结果对比,结果表明,两种数值模型均能很好地模拟CFRP-Al短柱的轴压性能。Abstract: Carbon fiber reinforced epoxy composite-aluminium alloy (CFRP-Al) stub column has the characteristics of lightweight, high strength and good ductility, showing a promising application prospect in long-span space structures. However, the research on its mechanical properties is basically in a blank state at home and abroad. For this reason, the theoretical analysis, experimental and numerical researches on CFRP-Al stub column were carried out in this paper. The equivalent elastic constants of CFRP-Al stub column were derived. The axial compression tests of six stub columns were completed and the axial bearing capacity and the failure mode of the short columns were obtained. The load-displacement curves calculated by the theory of elasticity show a good agreement with the test curves. Two numerical models, the layer-by-layer refinement model and the overall equivalent simplified model, were established using ABAQUS. The results of the two numerical models were compared with the experimental results. The comparison shows that both numerical models can well simulate the axial compression performance of CFRP-Al stub columns.

-

表 1 CFRP-Al短柱编号及规格

Table 1. Number and specification of CFRP-Al short column

Number Height/mm Section(measured nominal size) 60-A 60 90×37.5×35.5×5.8×6.7 60-B 60 90×37.5×35.8×5.5×6.5 70-A 70 90×37.5×35.5×6.0×6.7 70-B 70 90×37.5×35.8×5.6×6.5 80-A 80 90×37.5×35.5×5.7×6.8 80-B 80 90×37.5×35.8×5.6×6.5 Notes: H-section specification H×B1×B2×tw×tf—Hight of the section, the width of the upper flange, the width of the lower flange, the thickness of the flange and the thickness of the web correspondingly. 表 2 CFRP-Al铺层属性及相关参数

Table 2. Layer properties and related parameters of CFRP-Al

Order Material Angle/(°) Thickness/mm Order Material Angle/(°) Thickness/mm 1 CFRP 41.08 0.09 48 EP 0 0.08 2 EP 0 0.08 49 CFRP −23.59 0.09 3 Al 0 0.02 50 EP 0 0.08 4 EP 0 0.08 51 Al 0 0.02 5 CFRP 27.95 0.09 52 EP 0 0.08 6 EP 0 0.08 53 CFRP −26.45 0.09 7 Al 0 0.02 54 EP 0 0.08 8 EP 0 0.08 55 Al 0 0.02 9 CFRP 26.45 0.09 56 EP 0 0.08 10 EP 0 0.08 57 CFRP −27.95 0.09 11 Al 0 0.02 58 EP 0 0.08 12 EP 0 0.08 59 Al 0 0.02 13 CFRP 23.59 0.09 60 EP 0 0.08 14 EP 0 0.08 61 CFRP −41.08 0.09 15 Al 0 0.02 62 EP 0 0.08 16 EP 0 0.08 63 Al 0 0.02 17 CFRP 41.08 0.09 64 EP 0 0.08 18 EP 0 0.08 65 CFRP −23.59 0.09 19 Al 0 0.02 66 EP 0 0.08 20 EP 0 0.08 67 Al 0 0.02 21 CFRP 27.95 0.09 68 EP 0 0.08 22 EP 0 0.08 69 CFRP −26.45 0.09 23 Al 0 0.02 70 EP 0 0.08 24 EP 0 0.08 71 Al 0 0.02 25 CFRP 26.45 0.09 72 EP 0 0.08 26 EP 0 0.08 73 CFRP −27.95 0.09 27 Al 0 0.02 74 EP 0 0.08 28 EP 0 0.08 75 Al 0 0.02 29 CFRP 23.59 0.09 76 EP 0 0.08 30 EP 0 0.08 77 CFRP −41.08 0.09 31 Al 0 0.02 78 EP 0 0.08 32 EP 0 0.08 79 Al 0 0.02 33 CFRP 41.08 0.09 80 EP 0 0.08 34 EP 0 0.08 81 CFRP −23.59 0.09 35 Al 0 0.02 82 EP 0 0.08 36 EP 0 0.08 83 Al 0 0.02 37 CFRP 27.95 0.09 84 EP 0 0.08 38 EP 0 0.08 85 CFRP −26.45 0.09 39 Al 0 0.02 86 EP 0 0.08 40 EP 0 0.08 87 Al 0 0.02 41 CFRP 26.45 0.09 88 EP 0 0.08 42 EP 0 0.08 89 CFRP −27.95 0.09 43 Al 0 0.02 90 EP 0 0.08 44 EP 0 0.08 91 Al 0 0.02 45 CFRP 23.59 0.09 92 EP 0 0.08 46 EP 0 0.08 93 CFRP −41.08 0.09 47 Al 0 0.5 表 3 CFRP-Al复合材料叠层短柱试验结果

Table 3. Test results of CFRP-Al composite stub column

Number A/mm2 FT/kN σT/MPa dp/mm du/mm Data validity ρ/(g·cm−3) 60-A 951.56 175.20 184.12 2.19 2.27 Valid 1.31 60-B 880.13 186.50 211.90 2.03 2.31 Valid 1.40 70-A 952.28 192.80 208.37 2.23 2.28 Valid 1.31 70-B 926.53 183.64 198.20 1.93 2.01 Valid 1.35 80-A 939.81 171.90 182.92 1.55 6.18 Valid 1.33 80-B 915.66 156.35 170.75 7.53 9.73 Invalid 1.36 Average 930.06 182.01 197.10 1.99 — — 1.34 Notes:A—Nominal section area of the specimen; FT and σT—Peak load and peak stress of tests, respectively; dp and du—Peak displacement and ultimate displacement, respectively; ρ—Density of the specimen. 表 4 材料力学性能

Table 4. Mechanical properties

Material E1/GPa E2/GPa $\nu $ G12/GPa f /MPa f0.1/MPa f0.2/MPa CFRP T800H/HT-280 157 9.1 0.38 4.8 2386 — — Aluminum alloy 1070 65.7 65.7 0.3 252.69 — 50 55 Epoxy resin 2 — 0.38 — 100 — — Notes:E1 and E2—Axial modulus of elasticity and transverse modulus of elasticity, respectively; $\nu $—Poisson’s ratio; G12—Shear modulus; f—Tensile strength; f0.1 and f0.2—Stress corresponding to 0.1% and 0.2% residual strain, respectively. 表 5 CFRP-Al试件极限承载力对比

Table 5. Comparison of ultimate bearing capacity of CFRP-Al specimens

Number FT/kN FFE/kN er/% 60-A 175.20 185.65 5.96 60-B 186.50 185.65 −0.46 70-A 192.80 181.89 −5.66 70-B 183.64 181.89 −0.95 80-A 171.90 179.14 4.21 80-B 156.35 179.14 14.58 Notes:FT and FFE —Ultimate bearing capacity of tests and refined finite element models, respectively; er—Relative error between test results and numerical results. -

[1] BELLINI C, DI COCCO V, IACOVIELLO F, et al. Performance evaluation of CFRP/Al fibre metal laminates with different structural characteristics[J]. Composite Structures,2019,225(10):111117. [2] LIU D F, TANG Y J, CONG W L. A review of mechanical drilling for composite laminates[J]. Composite Structures,2012,94(4):1265-1279. doi: 10.1016/j.compstruct.2011.11.024 [3] CHAI G B, MANIKANDAN P. Low velocity impact response of fibre-metal laminates-A review[J]. Composite Structures,2014,107:363-381. doi: 10.1016/j.compstruct.2013.08.003 [4] GENG D, LIU Y, SHAO Z, et al. Delamination formation, evaluation and suppression during drilling of composite laminates: A review[J]. Composite Structures,2019,216(5):168-186. [5] BOTELHO E C, SILVA R A, PARDINI L C, et al. A review on the development and properties of continuous fiber/epoxy/aluminum hybrid composites for aircraft structures[J]. Materials Research,2006,9(3):247-256. doi: 10.1590/S1516-14392006000300002 [6] ZHAO X L, ZHANG L. State-of-the-art review on FRP strengthened steel structures[J]. Engineering Structures,2007,29(8):1808-1823. doi: 10.1016/j.engstruct.2006.10.006 [7] FENG P, LOUGHERY, et al. Mechanical behavior and design of FRP structural members at high and low service temperatures[J]. Journal of Composites for Construction,2016,20(5):04016021. [8] JIA J, CHEN J, ZHOU H, et al. Comparative investigation on the wear and transfer behaviors of carbon fiber reinforced polymer composites under dry sliding and water lubrication[J]. Composites Science & Technology,2005,65(7):1139-1147. [9] WANG J, GU M. Wear properties and mechanisms of nylon and carbon-fiber-reinforced nylon in dry and wet conditions[J]. Journal of Applied Polymer Science,2004,93(2):789-795. doi: 10.1002/app.20483 [10] JACOB G C, STARBUCK J M, FELLERS J F, et al. Crashworthiness of various random chopped carbon fiber reinforced epoxy composite materials and their strain rate dependence[J]. Journal of Applied Polymer Science,2006,101(3):1477-1486. doi: 10.1002/app.24224 [11] BANK L C. Flexural and shear moduli of full-section fiber reinforced plastic (FRP) pultruded beams[J]. Journal of Testing and Evaluation,1989,6(2):40-45. [12] HERAKOVICH C T, MIRZADEH F. Properties of pultruded graphite/epoxy[J]. Journal of Reinforced Plastic and Composites,1991,10:2-28. doi: 10.1177/073168449101000101 [13] BARBERO E J, SONTI S S. Material characterization of pultruded laminates and shapes[J]. Journal of Reinforced Plastic and Composites,1996,15:701-717. doi: 10.1177/073168449601500705 [14] ZUREICK A, SCOTT D. Short-term behavior and design of fiber-reinforced polymeric slender members underaxial compression[J]. Journal of Composites for Construction, ASCE,1997,1(4):140-149. doi: 10.1061/(ASCE)1090-0268(1997)1:4(140) [15] GUADES E, ARAVINTHAN T, ISLAM M M. Characterisation of the mechanical properties of pultruded fibre-reinforced polymer tube[J]. Material and Design,2014,63:305-315. doi: 10.1016/j.matdes.2014.06.018 [16] 杨婷慧. 铝镁叠层复合材料力学性能计算与轧制复合工艺[D]. 南京: 南京理工大学, 2010.YANG Tinghui. Calculation of mechanical properties and rolling composite process of aluminum magnesium laminated composite[D]. Nanjing: Nanjing University of Technology, 2010(in Chinese). [17] 金明江. 叠层阻尼功能复合材料的制备和性能研究[D]. 镇江: 江苏大学, 2005.JIN Mingjiang. Preparation and properties of laminated damping functional composites[D]. Zhenjiang: Jiangsu University, 2005(in Chinese). [18] 隋国鑫. 周本镰. 郑宗光, 等. 维尼纶增强铝合金叠层板(VIRALL)一种新型超混杂复合材料[J]. 材料科学进展, 1993, 17(4):365-367.SUI Guoxin, ZHOU Benlian, ZHENG Zongguang, et al. Vigny fiber reinforced aluminum alloy laminated plate (VIRALL), a new type of super hybrid composite[J]. Progress in Materials Science,1993,17(4):365-367(in Chinese). [19] CORTES P, CANTWELL W J. The prediction of tensile failure in titanium-based thermoplastic fiber-metal laminates[J]. Composites Science and Technology,2006,66(13):2306-2316. doi: 10.1016/j.compscitech.2005.11.031 [20] 解江, 张雪晗, 宋山山, 等. CFRP薄壁C型柱轴向压缩破坏机制及吸能特性[J]. 复合材料学报, 2018, 35(12):3261-3270.XIE Jiang, ZHANG Xuehan, SONG Shanshan, et al. Failure mechanism and energy-absorbing characteristics of CFRP thin-walled C-channels subject to axial compression[J]. Acta Materiae Compositae Sinica,2018,35(12):3261-3270(in Chinese). [21] 李峰, 刘加顺, 张恒铭. 复合材料圆柱壳的轴压屈曲失效试验[J]. 复合材料学报, 2016, 33(7):1469-1477.LI Feng, LIU Jiashun, ZHANG Hengming. Experiments on the buckling behavior of composite cylindrical shells subject to axial compression[J]. Acta Materiae Compositae Sinica,2016,33(7):1469-1477(in Chinese). [22] 李伟东, 张金栋, 刘刚, 等. 国产T800碳纤维/双马来酰亚胺复合材料的界面及力学性能[J]. 复合材料学报, 2016, 33(7):1484-1491.LI Weidong, ZHANG Jindong, LIU Gang, et al. Interfacial and mechanical properties of domestic T800 carbon fiber/bismaleimide composites[J]. Acta Materiae Compo-sitae Sinica,2016,33(7):1484-1491(in Chinese). [23] 沈观林, 胡更开. 复合材料力学[M]. 北京: 清华大学出版社, 2006.SHEN Guanlin, HU Gengkai. Composite mechanics[M]. Beijing: Tsinghua University Press, 2006(in Chinese). [24] 石亦平, 周玉蓉. ABAQUS有限元分析实例详解[M]. 北京: 机械工业出版社, 2006.SHI Yiping, ZHOU Yurong. Detailed explanation of ABAQUS finite element analysis examples[M]. Beijing: China Machine Press, 2006(in Chinese). -

下载:

下载: