Construction and enhanced thermal properties of hollow glass beads/ aromatic thermosetting polyester composite foam

-

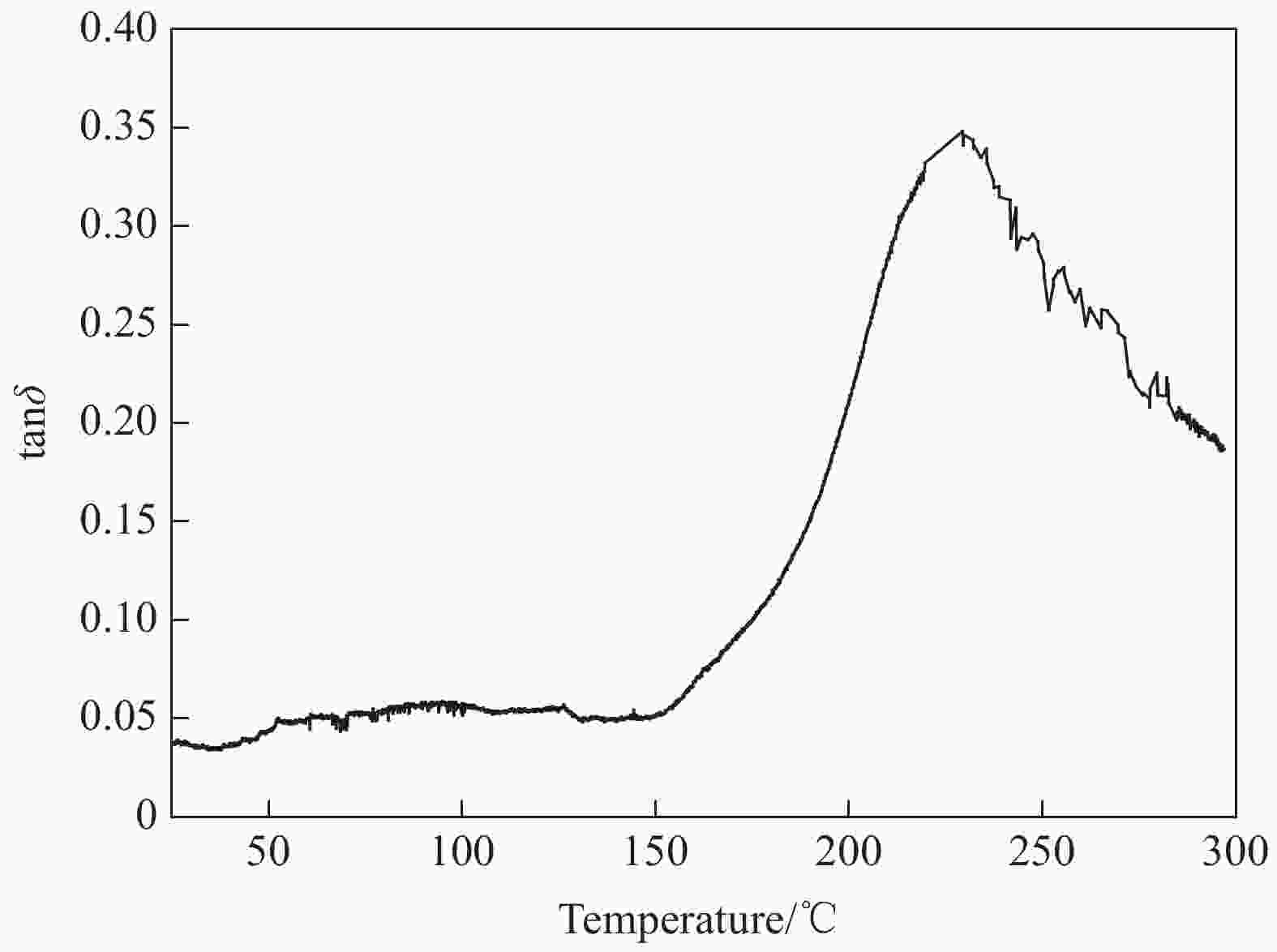

摘要: 本研究将空心玻璃微珠(HGB)引入到全芳香族热固性共聚酯(ATPE)发泡体系中制备了HGB/ATPE复合泡沫,并研究了HGB的含量和泡沫性能对于复合泡沫体系的影响。当玻璃微珠改性后,HGB/ATPE复合泡沫的比强度为26.2 MPa/(g·cm−3);HGB的加入也使复合体系热性能和阻燃性能有较大提高,HGB/ATPE复合泡沫的热分解温度、玻璃化转变温度及热变形温度分别为494.18℃、230.47℃和191.00℃,极限氧指数可达到35%~37%。Abstract: In this study, hollow glass beads (HGB) were introduced into an aromatic thermosetting polyester (ATPE) based foam to prepare HGB/ATPE composite foam, and effect of content of HGB and foaming conditions on the properties of HGB/ATPE composite foam were investigated. After modification, the specific strength of the HGB/ATPE composite foam can reach 26.2 MPa/(g·cm−3), respectively. Moreover, the addition of HGB also greatly improves thermal properties and flame resistance performance of the HGB/ATPE composite foam. The thermal decomposition temperature, glass transition temperature and heat distortion temperature of the HGB/ATPE composite foam are 494.18℃, 230.47℃ and 191.00℃, respectively, and the limiting oxygen index can reach 35%–37%.

-

表 1 对苯二酚二乙酸酯(HQDA)和4-乙酰氧基苯甲酸(ABA)的原料配比

Table 1. Proportion of raw materials of synthesizing hydroquinone diacetate (HQDA) and 4-acetoxybenzoic acid (ABA)

HQDA ABA AA/mL 252 192 HQ/g 132 — HBA/g — 132 Catalyst/g 4.8 (4-MBSA) 7.64 (SH) Oil bath temperature/℃ 100 110 Stirring time/min 30 20 Notes: AA—Acetic anhydride; HQ—Hydroquinone; HBA—p-Hydroxybenzonic acid; SH—NaOH; 4-MBSA—4-Methylbenzenesulfonic acid. 表 2 不同固化温度下HGB/ATPE复合泡沫的热变形温度

Table 2. Thermal deformation temperature of HGB/ATPE composite foams under different curing temperatures

Curing temperature/℃ Critical

temperature /℃Strength retention under criticaltemperature/% 230 210 79.0 240 180 76.3 250 165 75.8 260 160 75.9 270 150 70.3 Note: The strength of the sample will drop rapidly when it reaches a certain temperature, which is called critical temperature. 表 3 HGB/ATPE泡沫高温下的压缩性能

Table 3. Compression properties of HGB/ATPE foam at high temperature

-

[1] 李彬. 碳纳米聚氨酯泡沫吸能特性研究及其应用[D]. 长春: 吉林大学, 2017.LI Bin. Study on energy absorption characteristics of carbon nano polyurethane foam and application in autobody[D]. Changchun: Jiling University, 2017(in Chinese). [2] 王富鑫. 酚醛泡沫塑料应用及制备[J]. 热固性树脂, 2002, 17(4):36-38. doi: 10.3969/j.issn.1002-7432.2002.04.011WANG Fuxin. Manufacture and application of foamed phenolic resin[J]. Thermosetting Resin,2002,17(4):36-38(in Chinese). doi: 10.3969/j.issn.1002-7432.2002.04.011 [3] LIU Z, ZHAN J, FARD M, et al. Acoustic properties of a porous polycarbonate material produced by additive manufacturing[J]. Materials Letters,2016,181:296-299. doi: 10.1016/j.matlet.2016.06.045 [4] 马明明. 聚酰亚胺泡沫塑料的制备与性能表征[D]. 青岛: 青岛科技大学, 2011.MA Mingming. The synthesis and properties characterization of polyimide foams[D]. Qingdao: Qingdao University of Science & Technology, 2011 (in Chinese). [5] TANG H Y, CHEN L. Preparation and characterization of polymethacrylimide foam[J]. Advanced Materials Research,2010,160-162:1309-1313. doi: 10.4028/www.scientific.net/AMR.160-162.1309 [6] FRICH D, GORANOV K, SCHNEGGENBURGER L, et al. Novel high-temperature aromatic copolyester thermosets: Synthesis, characterization, and physical properties[J]. Macromolecules,1996,29(24):7734-7739. [7] HUANG Y Q, MCCORMICK J J, ECONOMY J. Adhesion of an aromatic thermosetting copolyester with copper foils[J]. Polymers for Advanced Technologies,2005,16(1):1-5. [8] WANG W Q, MEYER J, ZENG Q X, et al. Adhesion characteristics of aromatic thermosetting copolyester and glass fiber laminates with copper foils for improved circuit boards[J]. Polymers for Advanced Technologies,2016,27(12):1577-1585. [9] ZHANG J, DEMAS N G, POLYCARPOU A A, et al. A new family of low wear, low coefficient of friction polymer blend based on polytetrafluoroethylene and an aromatic thermosetting polyester[J]. Polymers for Advanced Technologies,2008,19(8):1105-1112. doi: 10.1002/pat.1086 [10] ZHANG J, POLYCARPOU A A, ECONOMY J. An improved tribological polymer-coating system for metal surfaces[J]. Tribology Letters,2010,38(3):355-365. doi: 10.1007/s11249-010-9615-3 [11] 胡培. 飞机夹层结构的设计和泡沫芯材的选择[J]. 航空制造技术, 2010(17):94-96. doi: 10.3969/j.issn.1671-833X.2010.17.022HU Pei. Design of sandwich structure and selection of foam core material for aircraft[J]. Aeronautical Manufacturing Technology,2010(17):94-96(in Chinese). doi: 10.3969/j.issn.1671-833X.2010.17.022 [12] 陈一民, 何斌. PMI高性能泡沫夹层材料的应用及国内研制现状[C]//第十六届全国复合材料学术年会. 长沙: 中国航空学会, 2010: 360-363.CHEN Yimin, HE Bin. The research and application of PMI foam in china[C]//16th National Conference on Composite Materials. Changsha: Chinese Society of Aeronautics and Astronautics, 2010: 360-363 (in Chinese). [13] HARTE A M, MCNAMARA J F, RODDY I D. A multilevel approach to the optimization of a composite light rail vehicle bodyshell[J]. Composite Structures,2004,63(3-4):447-453. [14] CHU H. Application of polyimide foam materials in aerospace vehicles[J]. Aerospace Materials & Technology,2006,36(3):1-3. [15] 吕方, 朱光明, 胡巧青, 等. 玻璃微珠填充改性聚合物研究进展[J]. 玻璃钢/复合材料, 2008(3):53-56.LV Fang, ZHU Guangming, HU Qiaoqing, et al. Advances of glass bead filled polymer composites[J]. Fiber Reinforced Plastics/Composites,2008(3):53-56(in Chinese). [16] 窦艳鹏, 孙淑芹, 吴湘锋. 高性能空心玻璃微珠的制备及其表面改性进展[J]. 中国粉体工程, 2012(1):7-13.DOU Yanpeng, SUN Shuqin, WU Xiangfeng. Progress in preparation and surface treatment of hollow glass beads with high performance[J]. China Powder Industry,2012(1):7-13(in Chinese). [17] 杨庆泉. 环氧树脂/氰酸酯树脂固化反应机理及环氧树脂/玻璃布/玻璃微珠体系力学性能研究[D]. 北京: 北京化工大学, 2003.YANG Qingquan. A study on mechanism of the co-reaction of epoxy and cyanate and the mechanical properties of epoxy/glass cloth/hollow glass-bead blend[D]. Beijing: Beijing University of Chemical Technology, 2003(in Chinese). [18] 周秋明, 王建华, 田春蓉, 等. 空心玻璃微珠复合聚氨酯泡沫的模塑成型收缩率[J]. 塑料工业, 2002, 30(5):23-24. doi: 10.3321/j.issn:1005-5770.2002.05.009ZHOU Qiuming, WANG Jianhua, TIAN Chunrong, et al. Analysis of mechanical properties of UHMWPE composite filled with different filler[J]. China Plastics Industry,2002,30(5):23-24(in Chinese). doi: 10.3321/j.issn:1005-5770.2002.05.009 [19] 孙佳慧. 球壳结构轻质树脂基复合材料的制备及性能研究[D]. 哈尔滨: 哈尔滨工程大学, 2016.SUN Jiahui. Study on the preparation and properties of spherical shell structure lightweight resin-based composite materials[D]. Harbin: Harbin Engineering University, 2016(in Chinese). [20] 中国国家标准化管理委员会. 硬质泡沫塑料压缩性能的测定: GB/T 8813—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of of the People’s Republic of China. Rigid cellular plastics: Determination of compression properties: GB/T 8813—2008[S]. Beijing: China Standards Press, 2008(in Chinese). [21] 中国国家标准化管理委员会. 塑料负荷变形温度的测定 第2部分: 塑料、硬橡胶和长纤维增强复合材料: GB/T 1634.2—2004[S]. 北京: 中国标准出版社, 2004.Standardization Administration of of the People’s Republic of China. Plastics: Determination of temperature of deflection under load Part 2: Plastics, ebonite and long-fiber-reinforced composites: GB/T 1634.2—2004[S]. Beijing: China Standards Press, 2004(in Chinese). [22] 中国国家标准化管理委员会. 塑料用氧指数法测定燃烧行为 第2部分: 室温实验: GB/T 2406.2—2009[S]. 北京: 中国标准出版社, 2010.Standardization Administration of of the People’s Republic of China. Plastics: Determination of burning behavior by oxygen index Part 2: Ambient-temperature test: GB/T 2406.2—2009[S]. Beijing: China Standards Press, 2010(in Chinese). [23] 中国国家标准化管理委员会. 硬质泡沫塑料燃烧性能试验方法: 垂直燃烧法: GB/T 8333—2008[S]. 北京: 中国标准出版社, 2008.Standardization Administration of of the People’s Republic of China. Test method for flammability of rigid cellular plastic: Vertical burning method: GB/T 8333—2008[S]. Beijing: China Standards Press, 2008(in Chinese). [24] GUO M X. Design of aromatic thermosetting polyester composites for thermally stable devices[D]. Illinois: University of Illinois at Urbana-Champaign, 2014. [25] 马立, 刘芃, 胡培. PMI泡沫材料在航天器结构中应用的可行性研究[J]. 航天器环境工程, 2010, 27(2):164-168. doi: 10.3969/j.issn.1673-1379.2010.02.008MA Li, LIU Peng, HU Pei. Feasibility study of application of PMI foam in spacecraft structure[J]. Spacecraft Environment Engineering,2010,27(2):164-168(in Chinese). doi: 10.3969/j.issn.1673-1379.2010.02.008 [26] 张翠, 张广成, 陈挺, 等. AN/MAA/AM三元共聚物的合成及性能研究[J]. 热固性树脂, 2006, 21(4):9-13. doi: 10.3969/j.issn.1002-7432.2006.04.003ZHANG Cui, ZHANG Guangcheng, CHEN Ting, et al. Synthesis and properties of AN/MAA/AM terpolymer[J]. Thermosetting Resin,2006,21(4):9-13(in Chinese). doi: 10.3969/j.issn.1002-7432.2006.04.003 [27] 廖前程. 硬质交联聚氯乙烯发泡板材研究制备[D]. 北京: 北京化工大学, 2010.LIAO Qiancheng. The preparation of rigid cross-linked foamed polyvinyl chloride sheet[D]. Beijing: Beijing University of Chemical Technology, 2010(in Chinese). -

下载:

下载: