Mechanical properties of carbon fiber reinforced epoxy composite pyramid lattice sandwich prosthetic foot structure under vertical load

-

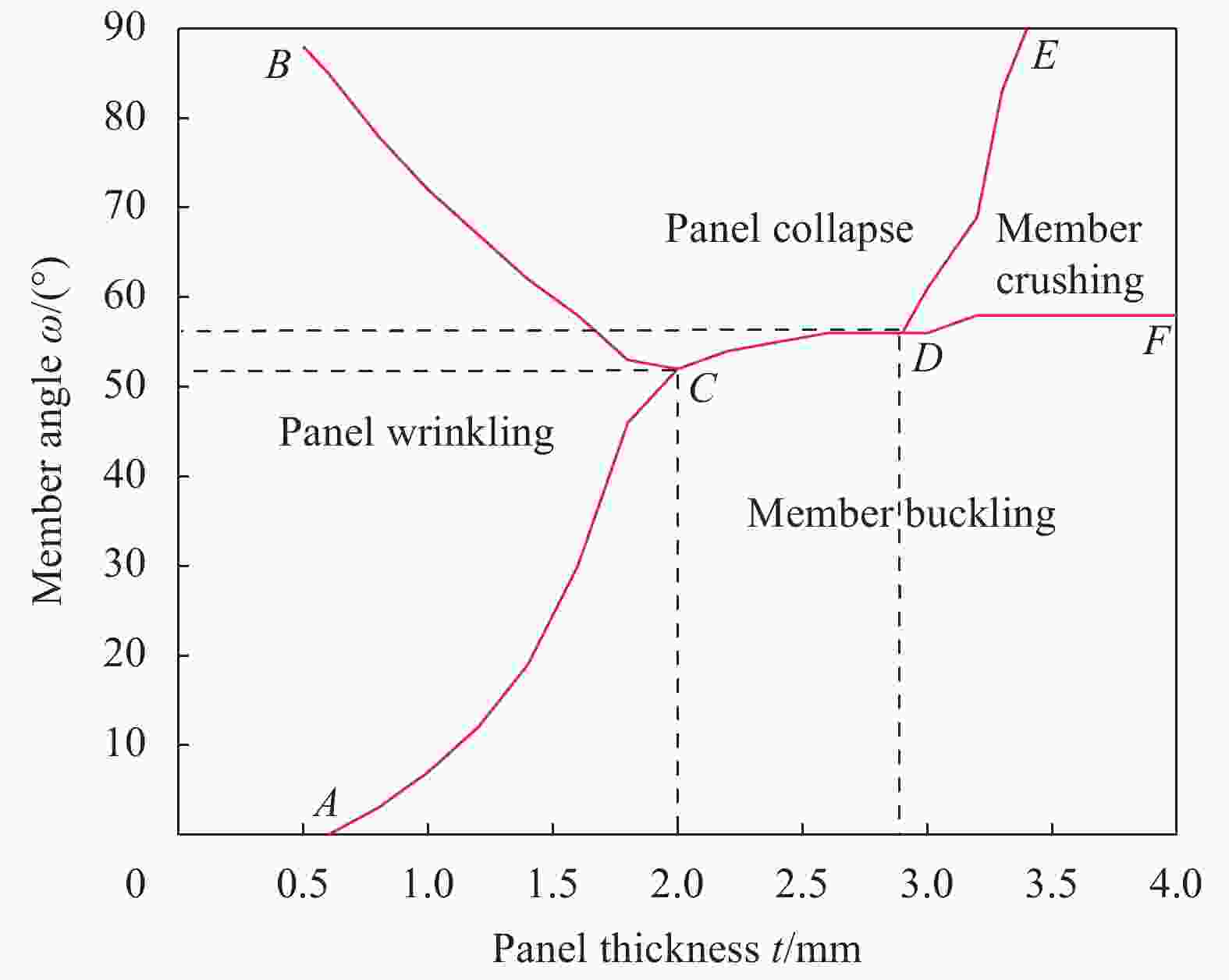

摘要: 对碳纤维增强树脂复合材料金字塔点阵夹芯假脚结构在竖向载荷下的力学性能进行研究。制备了三种不同相对密度的假脚,并进行了竖向载荷压缩试验。结果表明,相对密度对结构力学性能的影响显著,载荷-位移曲线呈非线性,峰值载荷和刚度值随相对密度的增加而增大,三种相对密度的破坏模式均为节点的失效和面板的皱曲,结构具有一定的能量吸收能力。建立了金字塔点阵夹芯假脚结构的理论强度预报模型,给出了结构在竖向载荷作用下的挠度响应,获得了四种失效模式和临界破坏载荷。对比了理论计算与试验的峰值载荷、破坏模式和挠度,得到较好的一致性。给出假脚结构参数(面板厚度、杆件角度和杆件直径)对破坏模式和破坏临界载荷的影响,并绘制了结构失效机制图。

-

关键词:

- 碳纤维增强环氧树脂复合材料 /

- 点阵夹芯结构 /

- 力学性能 /

- 破坏模式 /

- 强度

Abstract: The mechanical properties of the carbon fiber reinforced epoxy composite pyramid lattice sandwich prosthetic foot structure under vertical load were studied. Three kinds of prosthetic feet with different relative densities were prepared and subjected to vertical load compression test. The results show that the relative density has a significant effect on the mechanical properties of the structure. The load-displacement curve is nonlinear. The peak load and stiffness values increase with the increase of the relative density. The three failure modes of relative density are node failure and panel wrinkling. Curves and structures have a certain energy absorption capacity. The theoretical strength prediction model of the pyramid lattice sandwich prosthetic foot structure was established, and the deflection response of the structure under the vertical load was given. Four failure modes and critical failure loads were obtained. Comparing the peak load, failure mode and deflection of theoretical calculation and experiment, a good consistency is obtained. The effect of the structural parameters of the prosthetic foot (thickness of the panel, angle of the rod and diameter of the rod) on the failure mode and the critical load of the failure were given, and the structural failure mechanism diagram was drawn. -

表 1 碳纤维增强环氧树脂复合材料的基本力学性能参数

Table 1. Basic mechanical performance parameters of carbon fiber reinforced epoxy composite

Property Symbol Value Longitudinal stiffness/GPa E11 123 Transverse stiffness/GPa E22 8.4 Out-of-plane stiffness/GPa E33 8.4 Poisson’s ratio V12, V13, V23 0.32, 0.32, 0.3 Shear modulus/GPa G12, G13, G23 5.5, 3.0, 3.0 Longitudinal tensile strength/MPa XT 2100 Longitudinal compressive strength/MPa XC 800 Transverse tensile strength/MPa YT 25 Transverse compressive strength/MPa YC 120 Out-of-plane tensile strength/MPa ZT 50 Density/(kg.m−3) $\rho $ 1560 表 2 碳纤维增强环氧树脂复合材料金字塔点阵夹芯结构竖向载荷下的试件

Table 2. Test pieces under vertical load of carbon fiber reinforced epoxy composite pyramid lattice sandwich structure

No. Lay order Panel thickness t/mm Relative density/% A1 [0°/90°]5 1.0 11.12 B1 [0°/90°]6 1.2 12.71 C1 [0°/90°]7 1.4 14.24 表 3 碳纤维增强环氧树脂复合材料金字塔点阵夹芯假脚结构的理论和试验峰值载荷和破坏模式的对比

Table 3. Theoretical and experimental comparison of peak load and failure mode of carbon fiber reinforced epoxy composite pyramidal lattice sandwich prosthetic foot structure

RD/% Failure load /N Deflection /mm Failure mode TE TH RE/% TE TH RE/% TE TH 11.12 801 913 13.98 13.4 10.8 24.10 PW PW 12.71 1406 1582 12.52 15.1 14.4 4.90 PW PW 14.24 2200 2518 14.45 14.6 14.7 0.70 PW PW Notes: RD—Relative density; TE—Test; TH—Theoretical; RE—Relative error; PW—Panel wrinkling. -

[1] TALEBITOOTI R, ZARASTVAND M R. The effect of nature of porous material on diffuse field acoustic transmission of the sandwich aerospace composite doubly curved shell[J]. Aerospace Science and Technology, 2018, 78: 157-170. [2] JOHNSON A, KILCHERT S, FISCHER S, et al. Design and performance of novel aircraftstructures with folded composite cores[M]//BEAUMONT P W R, SOUTIS C, HODZIC A. Structural integrity and durability of advanced composites. Woodhead Publishing, 2015: 793-827. [3] GEORGE T, DESHPANDE V S, WADLEY H N G. Mechanical response of carbon fiber composite sandwich panels with pyramidal truss cores[J]. Composites Part A: Applied Science and Manufacturing,2013,47:31-40. doi: 10.1016/j.compositesa.2012.11.011 [4] FINNEGAN K, KOOISTRA G, WADLEY H N G, et al. The compressive response of carbon fiber composite pyramidal truss sandwich cores[J]. International Journal of Materials Research,2007,98(12):1264-1272. doi: 10.3139/146.101594 [5] LI X, XIONG J, MA L, et al. Effect of vacuum thermal cycling on the compression and shear performance of composite sandwich structures containing pyramidal truss cores[J]. Composites Science & Technology,2018,158:67-78. [6] ZHAO Z, WEN S, LI F. Vibration analysis of multi-span lattice sandwich beams using the assumed mode method[J]. Composite Structures,2018,185:716-727. [7] LIU J Y, XIANG L L, KAN T. The effect of temperature on the bending properties and failure mechanism of composite truss core sandwich structures[J]. Composites Part A: Applied Science and Manufacturing,2015,79:146-154. doi: 10.1016/j.compositesa.2015.09.017 [8] SONG Y, CHOI S, KIM S, et al. Performance test for laminated-type prosthetic foot with composite plates[J]. International Journal of Precision Engineering and Manufacturing, 2019, 20(10): 1777-1786. [9] LEE J Y, LEE D Y, PARK J W, et al. Carbon/epoxy composite foot structure for biped robots[J]. Composite Structures,2016,140:344-350. doi: 10.1016/j.compstruct.2016.01.022 [10] 王双情, 崔海坡, 张阿龙. 碳纤维复合材料假脚冲击与压缩强度试验[J]. 机械工程学报, 2016, 52(22):55-60. doi: 10.3901/JME.2016.22.055WANG Shuangqing, CUI Haipo, ZHANG Along. Impact and compressive strength experiment of carbon fiber composites prosthetic foot[J]. Journal of Mechanical Engineering,2016,52(22):55-60(in Chinese). doi: 10.3901/JME.2016.22.055 [11] BENCE R, DAVID P, RITA K. Functionality and load-bearing analysis of 3D-printed prosthetic feet[J]. Materials Today,2018,5(13):26566-26571. [12] WU Q Q, MA L, WU L Z, et al. A novel strengthening method for carbon fiber composite lattice truss structures[J]. Composite Structures,2016,153:585-592. [13] LI X D, WU L Z, MA L, et al. Effect of temperature on the compressive behavior of carbon fiber composite pyramidal truss cores sandwich panels with reinforced frames[J]. Theoretical and Applied Mechanics Letters,2016,6(2):76-80. doi: 10.1016/j.taml.2016.02.002 [14] SUN Y, GUO L C, WANG T S, et al. Bending behavior of composite sandwich structures with graded corrugated truss cores[J]. Composite Structures,2018,185:446-454. doi: 10.1016/j.compstruct.2017.11.043 [15] FU T, CHEN Z B, YU H Y, et al. Thermal buckling and sound radiation behavior of truss core sandwich panel resting on elastic foundation[J]. International Journal of Mechanical Sciences,2019,161-162:105055. [16] 王兵, 吴林志, 杜善义, 等. 碳纤维增强金字塔点阵夹芯结构的抗压缩性能[J]. 复合材料学报, 2010, 27(1):133-138.WANG Bing, WU Linzhi, DU Shanyi, et al. Compression resistance of carbon fiber reinforced pyramid lattice sandwich structure[J]. Acta Materiae Compositae Sinica,2010,27(1):133-138(in Chinese). [17] 唐玉玲, 姜智, 周振功, 等. 碳纤维增强环氧树脂复合材料螺栓连接结构在拉伸载荷下损伤过程的声发射分析[J]. 复合材料学报, 2019, 36(8):1854-1863.TANG Yuling, JIANG Zhi, ZHOU Zhengong, et al. Acoustic emission analysis of carbon fiber reinforced polymer bolted jointed damage process under tensile load[J]. Acta Materiae Compositae Sinica,2019,36(8):1854-1863(in Chinese). [18] 娄佳. 复合材料点阵夹芯结构的弯曲、屈曲和振动特性研究[D]. 哈尔滨: 哈尔滨工业大学, 2013.LOU Jia. Bending, buckling and vibration properties of composite lattice sandwich structures[D]. Harbin: Harbin Institute of Technology, 2013(in Chinese). [19] 陈人哲. 平面曲梁挠度方程式及其在纺织零件计算中的应用举例[J]. 东华大学学报:自然科学版, 1957(3):29-48.CHEN Renzhe. Deflection equation of plane curved beam and its application example in calculation of spinning machine parts[J]. Journal of Donghua University :Natural Science,1957(3):29-48(in Chinese). -

下载:

下载: