Design and analysis of aluminum alloy-rigid polyurethane foam-cored common bulkhead for cryogenic tanks

-

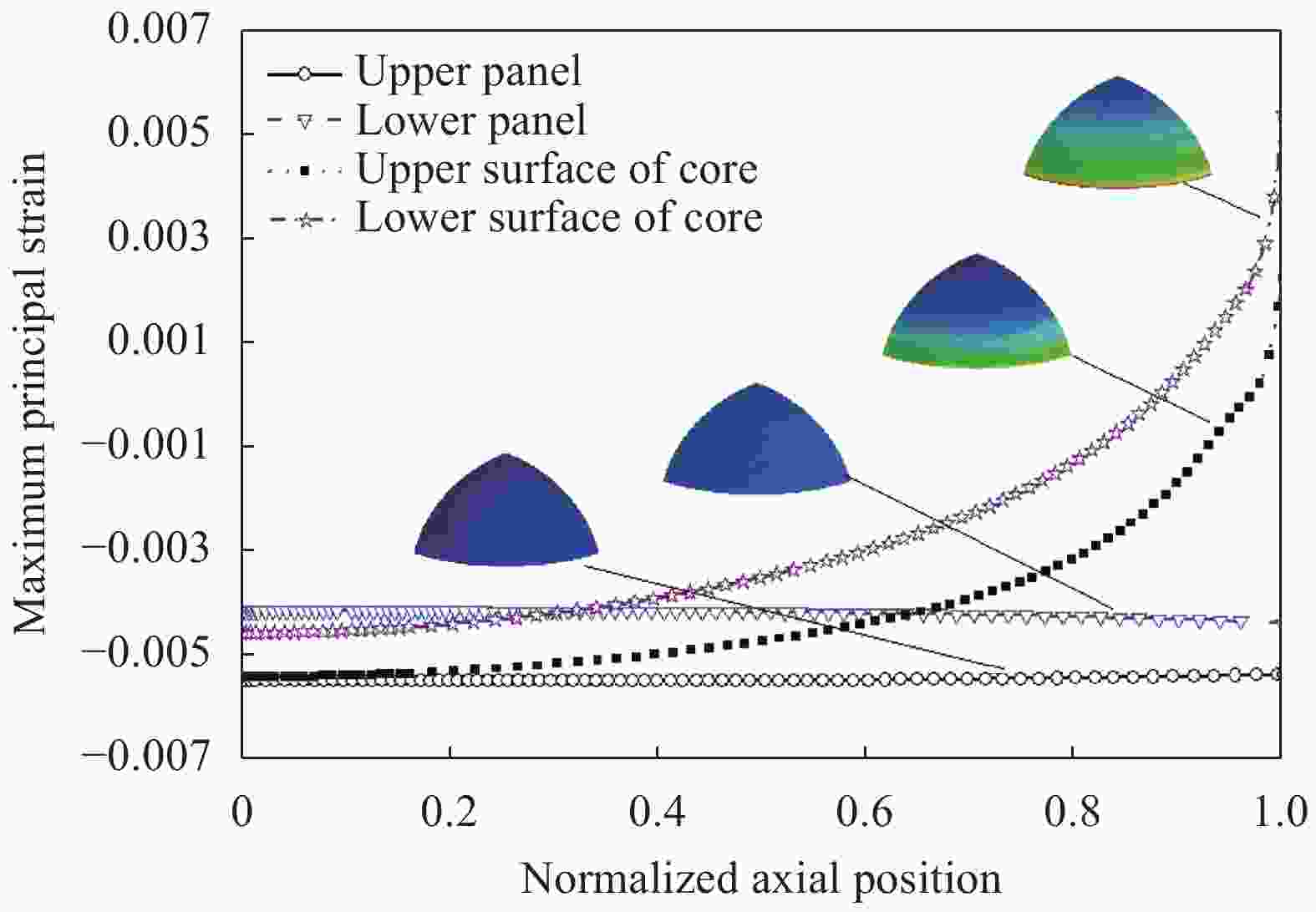

摘要: 采用铝合金面板-硬质聚氨酯泡沫夹芯的复合式夹层构型,设计了一种用于低温火箭推进剂贮箱的共底结构,其具有轻量化、易于制造、承载/隔热一体化的特点。通过数值模拟手段,对该共底的隔热效果、结构稳定性及热力耦合问题进行分析。结果表明,该共底满足低温液氢/液氧贮箱隔热要求,在0.342 MPa压差下不失稳,单箱打压低于0.5 MPa时材料不失效。此结构的设计分析可为新型低温贮箱共底的设计提供技术支持。Abstract: By using a sandwich construction that consists of aluminum alloy panels-rigid polyurethane foam, a common bulkhead was devised for cryogenic launch vehicle tanks. The common bulkhead has the characteristics of lightweight, easy to manufacture, and integrated load bearing/thermal insulation. Based on numerical simulations, thermal insulation effect, structural stability and thermal-mechanical coupling behavior of the common bulkhead were analyzed. The results show that the common bulkhead not only satisfies the thermal insulation requirements of cryogenic tanks for liquid hydrogen and oxygen, but also keeps structural stability under a differential pressure of 0.342 MPa and material safety with a pressure of 0.5 MPa. The design and analysis of this structure can provide technical support for the design of new cryogenic tanks with a common bulkhead.

-

Key words:

- common bulkhead /

- rigid polyurethane foam /

- cryogenic tank /

- numerical simulation /

- thermal insulation

-

表 1 上下金属面板尺寸参数

Table 1. Size parameters of upper and lower metal panels

ai/m bi/m Upper panel 1.6 1.589 Lower panel 1.12 1.069 Notes: ${a_{\rm{i}}}$, ${b_{\rm{i}}}$—Lengthes of semimajor axis and semiminor axis of metal panels, respectively. 表 2 贮箱共底所用各材料的热性能和力学性能

Table 2. Thermal and mechanical properties of materials for common bulkhead

ρ/(g·cm−3) E/MPa v Sc/MPa Sy/MPa λ/(10−6·℃−1) C/(J(g·℃−1)) k/(W(m·℃−1)) Al alloy 2.84 73100 0.33 483 414 20.8 0.88 154 GFRP 1.85 26000 0.28 500 — 8 1.130 0.586 RPU 0.043 32 0.3 0.33 0.32 0.022T+24.76 1.751 0.0417 PMI 0.11 180 0.29 3.55 — 50 2.0 0.0295 Notes: ρ—Density; E—Elastic modulus; v—Poisson’s ratio; Sc, Sy—Compressive strength and yield strength, respectively; λ—Thermal expansion coefficient; C—Specific heat capacity; k—Coefficient of heat conductivity; T—Temperature; GFRP—Glass fiber reinforced plastic; RPU—Rigid polyurethane; PMI—Polymethacrylimide. 表 3 共底结构前八阶屈曲临界载荷

Table 3. First eight critical buckling loads for common bulkhead structure

N=1 N=2 N=3 N=4 N=5 N=6 N=7 N=8 PCr /MPa 0.342 0.343 0.367 0.368 0.378 0.380 0.388 0.392 Note: PCr—Critical buckling load. 表 4 本文数值方法分析结果与文献[18]试验结果的对比

Table 4. Comparison between this numerical simulation results and experiment results in Ref. [18]

Load case Upper panel Lower panel Experiment

value/MPaSimulation

value/MPaRelative

error/%Experiment

value/MPaSimulation

value /MPaRelative

error/%LT filling −172.0 −185.6 7.9 178.7 180.9 1.3 LT, P1=0.4 MPa, P2=0.47 MPa −174.0 −188.1 8.1 202.6 208.2 2.8 LT, P1=0.56 MPa, P2=0.658 MPa −177.2 −184.6 4.2 203.0 227.9 12.3 LT, P1=0.4 MPa, P2=0.23 MPa −250.7 −273.0 8.9 151.6 164.0 8.2 Notes: LT—Low temperature; P1, P2—Pressure of kerosene tank and oxygen tank, respectively. -

[1] 谢福寿, 厉彦忠, 王磊, 等. 低温推进剂过冷技术研究[J]. 航空动力学报, 2017, 32(3):762-768.XIE Fushou, LI Yanzhong, WANG Lei, et al. Study on subcooled technology for cryogenic propellants[J]. Journal of Aerospace Power,2017,32(3):762-768(in Chinese). [2] 侍野, 唐一华, 刘畅, 等. 低温推进剂集成管理技术的发展与启示[J]. 宇航总体技术, 2019, 3(2):54-61.SHI Ye, TANG Yihua, LIU Chang, et al. Development and revelation of integrated vehicle fluids[J]. Astronautical Systems Engineering Technology,2019,3(2):54-61(in Chinese). [3] FREY B, WESSELS W, EBELING W D, et al. Thermal control of the cryogenic upper stage of ARIANE 5 midlife evolution[C]//42nd International Conference on Environmental Systems. California: American Institute for Aeronautics and Astronautics, 2012, 3475: 1-14. [4] KUTTER B, ZEGLER F, LUCAS S, et al. Atlas centaur extensibility to long-duration in-space applications[C]//Space 2005. California: American Institute for Aeronautics and Astronautics, 2005, 6738: 1-12. [5] 唐玉花, 狄文斌, 刘靖华. 液体运载火箭一维纵横扭一体化建模技术[J]. 宇航学报, 2017, 38(1):89-96. doi: 10.3873/j.issn.1000-1328.2017.01.012TANG Yuhua, DI Wenbin, LIU Jinghua. A one-dimension longitudinal-lateral-torsional integrated modeling technique for liquid-propellant launch vehicle[J]. Journal of Astronautics,2017,38(1):89-96(in Chinese). doi: 10.3873/j.issn.1000-1328.2017.01.012 [6] VIETZE M, MUNDT C, WEILAND S. Investigation of thermal characteristics of sandwich common bulkhead equipped launcher tank[J]. Journal of Spacecraft and Rockets,2017,54(1):67-74. doi: 10.2514/1.A33595 [7] LIU Z, LI Y Z, ZHOU G Q. Study on thermal stratification in liquid hydrogen tank under different gravity levels[J]. International Journal of Hydrogen Energy,2018,43(19):9369-9378. doi: 10.1016/j.ijhydene.2018.04.001 [8] FISCHER, WOLFGANG P P. Development of cryogenic insulations for launcher upper stages[C]//44th International Conference on Environmental Systems. Arizona: 2014, 142: 1-14. [9] 刘展, 厉彦忠, 王磊, 等. 在轨运行低温液氢箱体蒸发量计算与增压过程研究[J]. 西安交通大学学报, 2015, 49(2):135-140.LIU Zhan, LI Yanzhong, WANG Lei, et al. Evaporation calculation and pressurization process of on-orbit cryogenic liquid hydrogen storage tank[J]. Journal of Xi’an Jiaotong University,2015,49(2):135-140(in Chinese). [10] 李平岐, 何巍, 杨云飞. 液体运载火箭长细比设计研究[J]. 宇航总体技术, 2019, 3(3):16-22.LI Pingqi, HE Wei, YANG Yunfei. The research of liquid launch vehicle slenderness ratio design[J]. Astronautical Systems Engineering Technology,2019,3(3):16-22(in Chinese). [11] AEROSPACE M M. Titan 3E/Centaur D-1T systems summary, NASA-CR-141014[R]. Washington: NASA, 1973. [12] HEALD D A. Reusable centaur study, NASA-CR-120373[R]. Washington: NASA, 1974. [13] WHITEHEAD J. Mass breakdown of the Saturn V[C]//36th AIAA/ASME/SAE/ASEE Joint Propulsion Conference and Exhibit. Alabama: American Institute for Aeronautics and Astronautics, 2000, 3141: 1-11. [14] RAVET L. The ARIANE 5 launcher improvements[J]. Air & Space Europe,2000,2(2):68-72. [15] BIGGS R, An integrated airframe experiment for future responsive access to space applications[C]//50th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference. California: American Institute for Aeronautics and Astronautics, 2009, 2630: 1-12. [16] BIGGS R, MCCANDLESS M , COCHRAN R. Structural efficiency of integrated composite structures for future space launch vehicle airframe applications[C]//AIAA SPACE 2011 Conference & Exposition. California: American Institute for Aeronautics and Astronautics, 2011, 7278: 1-17. [17] SZELINSKI B, LANGE H, SACHER H, et al. Development of an innovative sandwich common bulkhead for cryogenic upper stage propellant tank[J]. Acta Astronautica,2012,81(1):200-213. doi: 10.1016/j.actaastro.2012.06.025 [18] 李茂, 韩涵, 唐杰, 等. 大温差隔热共底在运载贮箱中的应用研究[J]. 上海航天, 2016, 33(s1):43-49.LI Mao, HAN Han, TANG Jie, et al. Application of PMI foam cored sandwich bulkhead tank in launch vehicle[J]. Aerospace Shanghai,2016,33(s1):43-49(in Chinese). [19] 李照谦, 南博华, 何腾锋, 等. 新一代运载火箭贮箱大温差泡沫夹层共底研制[J]. 宇航材料工艺, 2016, 46(4):68-72. doi: 10.3969/j.issn.1007-2330.2016.04.017LI Zhaoqian, NAN Bohua, HE Tengfeng, et al. Development of large temperature difference foam sandwich co-bulkhead of cryogenic tank for new-generation launch vehicle[J]. Aerospace Materials & Technology,2016,46(4):68-72(in Chinese). doi: 10.3969/j.issn.1007-2330.2016.04.017 [20] 孙培杰, 李鹏, 张振涛, 等. 新一代运载火箭共底贮箱隔热性能试验及环境预示[J]. 上海航天, 2014, 31(5):54-59. doi: 10.3969/j.issn.1006-1630.2014.05.011SUN Peijie, LI Peng, ZHANG Zhentao, et al. Experimental and numerical investigation of heat insulation performances of coplanar tanks in new generation launch vehicle[J]. Aerospace Shanghai,2014,31(5):54-59(in Chinese). doi: 10.3969/j.issn.1006-1630.2014.05.011 [21] LI Z Q, NAN B H, HE T F, et al. Study of bonding technology and property of foam-sandwich co-bulkhead of cryogenic tank on launch vehicle[J]. Materials Science Forum, 2015, 817: 639-644. [22] 闫指江, 吴胜宝, 赵一博, 等. 应用于低温推进剂在轨贮存的组合绝热材料综述[J]. 载人航天, 2016, 22(3):28-32.YAN Zhijiang, WU Shengbao, ZHAO Yibo, et al. Review of assembled thermal insulating materials applied for on-orbit cryogenic propellant storage[J]. Manned Spaceflight,2016,22(3):28-32(in Chinese). [23] 商晋, 吕翠, 伍继浩. 聚氨酯硬质泡沫的低温应用研究现状[J]. 低温与超导, 2017, 45(10):14-19.SHANG Jin, LV Cui, WU Jihao. Cryogenic application of rigid polyurethane foam[J]. Cryogenics & Superconductivity,2017,45(10):14-19(in Chinese). [24] KAUSAR A. Polyurethane composite foams in high performance applications: a review[J]. Polymer Plastics Technology & Engineering,2018,57(4):346-369. [25] 孙小伟, 孙军坤, 俞炜, 等. LNG船货物围护系统用硬质聚氨酯绝热材料制备和性能研究[J]. 聚氨酯工业, 2018, 33(3):5-9. doi: 10.3969/j.issn.1005-1902.2018.03.002SUN Xiaowei, SUN Junkun, YU Wei, et al. Preparation and performance of the rigid polyurethane foams for cargo containment system of LNGC[J]. Polyurethane Industry,2018,33(3):5-9(in Chinese). doi: 10.3969/j.issn.1005-1902.2018.03.002 -

下载:

下载: