| [1] |

SURAPPA M K. Aluminum matrix composite: Challenge and opportunities[J]. Sadhana,2003,28(1-2):319-334. doi: 10.1007/BF02717141

|

| [2] |

NAM T H, REQUENA G, DEGISCHER P. Thermal expansion behaviour of aluminum matrix composites with densely packed SiC particles[J]. Composites Part A: Applied Science and Manufacturing,2008,39:856-865. doi: 10.1016/j.compositesa.2008.01.011

|

| [3] |

王荣国, 武卫莉. 复合材料概论[M]. 哈尔滨: 哈尔滨工业大学出版社, 2004: 1-8.WANG R G, WU W L. Introduction of composite materials[M]. Harbin: Press of Harbin Institute of Technology, 2014: 1-8(in Chinese).

|

| [4] |

吴瑞瑞, 丁福帅, 李秋书, 等. 球磨-转喷微注法制备纳米 Al2O3颗粒/Al(7075)复合材料的组织及磨损特性[J]. 复合材料学报, 2020, 37(10):2512-2517.WU R R, DING F S, LI Q S, et al. Microstructure and wear properties of nano-Al2O3P/Al(7075) composites fabricated by ball milling-spray-stirring process[J]. Acta Materiae Compositae Sinica,2020,37(10):2512-2517(in Chinese).

|

| [5] |

雷宗坤, 赵卫星, 于成龙, 等. SiCP表面镀Ti改性对SiCP/Al2014复合材料组织及力学性能的影响[J]. 复合材料学报, 2016, 33(10):2261-2269.LEI Z K, ZHAO W X, YU C L, et al. Effects of Ticoated SiCP oN structures and mechanical properties of SiCp/Al2014 composites[J]. Acta Materiae Compositae Sinica,2016,33(10):2261-2269(in Chinese).

|

| [6] |

谢瑞, 李萍, 薛克敏, 等. 高压扭转对SiCP/Al复合材料微观组织和力学性能的影响[J]. 复合材料学报, 2017, 34(5):1016-1022.XIE R, LI P, XUE K M, et al. Influence of high pressure torsion on microstructure and mechanical properties of SiCP/Al composites[J]. Acta Materiae Compositae Sinica,2017,34(5):1016-1022(in Chinese).

|

| [7] |

孔德昊, 左孝青, 卢锴, 等. 原位合成TiB2/ZL205A复合材料的组织及流动性[J]. 复合材料学报, 2017, 34(8):1788-1793.KONG D H, ZUO X Q, LU K, et al. Microstructure and fluidity of in-situ TiB2/Zl205A composites[J]. Acta Materiae Compositae Sinica,2017,34(8):1788-1793(in Chinese).

|

| [8] |

吴瑞瑞, 李秋书, 郭璐, 等. 原位合成TiC/Al(7075)复合材料的组织及力学性能[J]. 复合材料学报, 2017, 34(6):1334-1339.WU R R, LI Q S, GUO L, et al. Microstructure and mechanical properties of TiC/Al(7075) composites fabricated by in situ reaction[J]. Acta Materiae Compositae Sinica,2017,34(6):1334-1339(in Chinese).

|

| [9] |

PALT K. Joining of aluminium metal matrix composites[J]. Materials and Manufacturing Processes,2005,20(4):717-726. doi: 10.1081/AMP-200055116

|

| [10] |

CHENG H J, YAO J F, YANG Z W, WANG Y, and XIAO B. Structure and composition of oxide film on 5083 alloy at brazing temperature[J]. Journal of Materials Science & Technology,2015,31(11):1282-1287.

|

| [11] |

WANG P, GAO Z, NIU J T. Micro-nano filler metal foil on vacuum brazing of SiCP/Al composites[J]. Applied Physics A,2016,122:592-594. doi: 10.1007/s00339-016-0110-z

|

| [12] |

CHEN S J, WEI M Q, ZHAO P F. Study on microstructure and property of aluminum matrix composites SiCP/Al6063 vacuum brazing joint with different holding time[J]. Transactions of the China Welding Institution,2015,36(10):87-90.

|

| [13] |

曹金营, 曹贺, 欧阳求保, 等. 多道次搅拌摩擦加工对 SiCP/2A14 复合材料显微组织和力学性能的影响[J]. 复合材料学报, 2020, 37(11):2861-2869.CAO J Y, CAO H, OUYANG Q B, et al. Effect of multi-pass friction stir processing on microstructure and mechanical properties of SiCP/2A14 composites[J]. Acta Materiae Compositae Sinica,2020,37(11):2861-2869(in Chinese).

|

| [14] |

SALIH O S, OU H, SUN W, et al. A review of friction stir welding of aluminium matrix composites[J]. Materials & Design,2015,86(5):61-71.

|

| [15] |

ZHANG G, WEI Z, CHEN B, et al. Abnormal transient liquid phase bondability of high-volume fraction SiC particle-reinforced A356 composite for Cu interlayer and the interlayer improvement routes[J]. Journal of Materials Engineering & Performance,2017,26:5921-5937.

|

| [16] |

ZHANG G F, SU W, SUZUMURA A. Active transient liquid phase(A-TLP) bonding of pure aluminum matrix compo-site reinforced with short alumina fiber using Al-12Si-xTi foils as active interlayer[J]. Metallurgical and Materials Transactions B,2016,47(3):1-14.

|

| [17] |

ZHANG G F, CHEN B, JIN M Z, et al. Active-transient liquid phase (A-TLP) bonding of high volume fraction SiC particle reinforced A356[J]. Matrix Composite, Materials Transactions,2015,56(2):212-217.

|

| [18] |

YARAHMADI M, SHAMANIAN M, SALIMIH R J, et al. Hosh-yarmanesh, transient liquid phase diffusion bonding of Al/Al2O3 nanostructured metal matrix composites[J]. Science and Technology of Welding and Joining,2014,19(7):603-608. doi: 10.1179/1362171814Y.0000000231

|

| [19] |

ROY P, PAL T K, MAITY J. Transient liquid phase diffusion bonding of 6061Al-15wt% SiCP composite using mixed Cu-Ag powder interlayer[J]. Journal of Materials Engineering and Performance,2016,25(8):3518-3530. doi: 10.1007/s11665-016-2165-6

|

| [20] |

WANG P, XU D X, CHENG D F, et al. Active brazing filler metal on SiC particle reinforced aluminium matrix composites[J]. Science and Technology of Welding and Joining,2015,20(5):361-370. doi: 10.1179/1362171815Y.0000000024

|

| [21] |

ELLIS M B D. Joining of aluminum based metal matrix composites[J]. International Materials Reviews,1996,41(2):41-58. doi: 10.1179/imr.1996.41.2.41

|

| [22] |

MURATOGLU M, YILMAZ O, AKSOY M. Investigation on diffusion bonding characteristics of aluminum metal matrix composites(Al/SiCP) with pure aluminum for different heat treatments[J]. Journal of Materials Processing Technology,2006,178:211-217. doi: 10.1016/j.jmatprotec.2006.03.168

|

| [23] |

WERT J A. Microstructures of friction stir weld joints between an aluminium base metal matrix composite and a monolithic aluminium alloy[J]. Scripta Materialia,2003,49:607-612. doi: 10.1016/S1359-6462(03)00215-X

|

| [24] |

FEMANDEZ G J, MURR L E. Characterization of tool wear and weld optimization in the friction-stir welding of cast aluminum 359+20% SiC metal-matrix composite[J]. Materials Characterization,2004,52:65-75. doi: 10.1016/j.matchar.2004.03.004

|

| [25] |

HUSEYIN U. Friction stir welding of SiC particulate reinforced AA2124 aluminium alloy matrix composite[J]. Materials and Design,2007,28:1440-1446. doi: 10.1016/j.matdes.2006.03.023

|

| [26] |

GALE W F, BUTTS D A. Transient liquid phase bonding[J]. Science and Technology of Welding and Joining,2004,9(4):283-300. doi: 10.1179/136217104225021724

|

| [27] |

ZHANG G F, SU W, GUO Y, et al. Development of three kinds of active ternary filler metals of Al-Si-Ti, Zn-Al-Ti and Cu-Al-Ti systems for Al metal matrix composites[J]. China Welding,2011,20(2):73-80.

|

| [28] |

张贵锋, 廖先金, 张建勋. 铝基复合材料的原位强化活性液相扩散焊方法及其所用的Al-Cu-Ti系三元活性钎料: 中国, ZL 201110356359.9[P]. 2012-06-13.ZHANG G F, LIAO X J, ZHANG J X. In situ reinforced reactive liquid phase diffusion welding method for aluminum matrix composites and its use of Al-Cu-Ti series three active solder: China, ZL 201110356359.9[P]. 2012-06-13(in Chinese).

|

| [29] |

ZHANG G F, LIAO X J, CHEN B, et al. Approach to In situ producing reinforcing phase within active-transient liquid phase bond seam for aluminum matrix composite[J]. Metallurgical and Materials Transactions A,2015,46(6):2568-2578. doi: 10.1007/s11661-015-2821-8

|

| [30] |

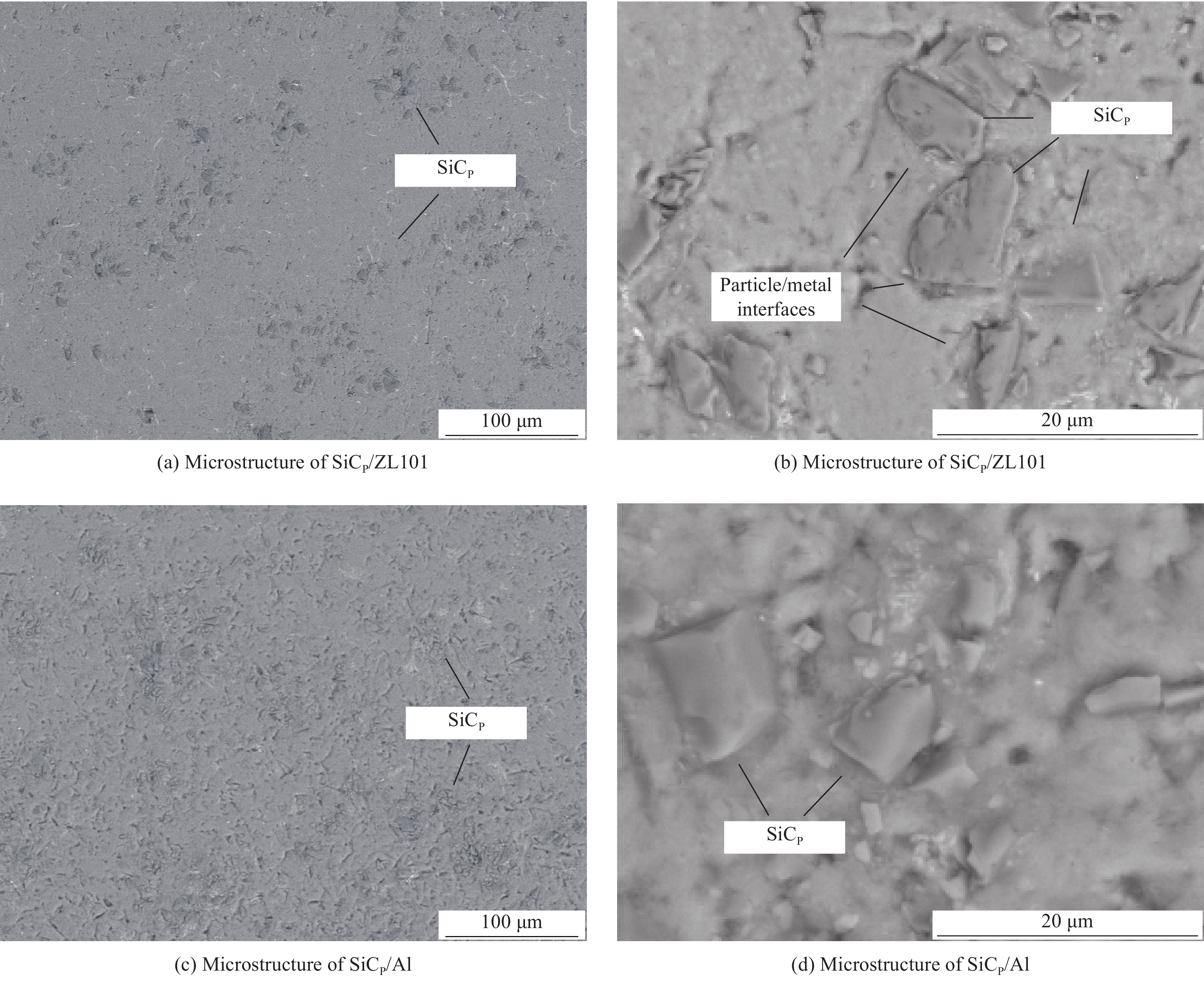

张贵锋, 廖先金, 陈博, 等. SiCP/ZL101铝基复合材料的原位强化活性液相扩散焊方法(In situ A-TLP)[J]. 焊接, 2014, 1:18-21.ZHANG G F, LIAO X J, CHEN B, et al. In situ active transient liquid phase(In situ A-TLP) bonding of SiCP/ZL101 aluminum metal matrix composite[J]. Welding & Joining,2014,1:18-21(in Chinese).

|

| [31] |

ASKEW J R, WILDE J F, KHAN T I. Transient liquid phase bonding of 2124 aluminum metal-matrix composite[J]. Materials Science and Technology,1998,14(10):920-924.

|

| [32] |

SUZUMURA A, XING Y J. Diffusion brazing of short Al2O3 fiber-reinforced aluminum composite[J]. Materials Transaction, JIM,1996,37(5):1109-1115. doi: 10.2320/matertrans1989.37.1109

|

| [33] |

LI Z, ZHOU Y, NORTH T H. Counteraction of particulate segregation during transient liquid-phase bonding of aluminium-based MMC material[J]. Journal of Materials Science,1995,30(4):1075-1082. doi: 10.1007/BF01178448

|

| [34] |

XU Z W, YAN J C, WU G H. Interface structure and strength of ultrasonic vibration liquid phase bonded joints of Al2O3P/6061Al composites[J]. Scripta Materialia,2005,53(7):835-839. doi: 10.1016/j.scriptamat.2005.06.009

|

| [35] |

刘卫红, 孙大谦, 贾树盛, 等. 铝基复合材料的Al-Cu合金中间层瞬间液相扩散连接[J]. 焊接学报, 2003, 24(5):13-16. doi: 10.3321/j.issn:0253-360X.2003.05.004LIU W H, SUN D Q, JIA S S, et al. Transient liquid phase bonding of aluminium-based metal matrix composite with Al-Cu alloy interlayer[J]. Transactions of the China Welding Institution,2003,24(5):13-16(in Chinese). doi: 10.3321/j.issn:0253-360X.2003.05.004

|

| [36] |

WEMG W P, CHUANG T H. Interfacial characteristics for brazing of aluminum matrix composites with Al-12Si filler metals[J]. Metallurgical and Materials Transactions A,1997,28(12):2673-2682. doi: 10.1007/s11661-997-0024-7

|

| [37] |

YAN J C, XU Z W, WU G H. Interface structure and mechanical performance of TLP bonded joints of Al2O3/6061Al composites using Cu/Ni composite interlayers[J]. Scripta Materialia,2004,51(2):147-150. doi: 10.1016/j.scriptamat.2004.03.036

|

| [38] |

HUANG J H, DONG Y L, WAN Y. Investigation on reactive diffusion bonding of SiCP/6063 MMC by using mixed powders as interlayers[J]. Journal of Materials Processing Technology,2007,190(1-3):312-316. doi: 10.1016/j.jmatprotec.2007.02.028

|

| [39] |

HUANG J H, WAN Y, ZHANG H, et al. TLP bonding of SiCP/2618Al composites using mixed Al-Ag-Cu system powders as interlayers[J]. Journal of Materials Science,2007,42(23):9746-9749. doi: 10.1007/s10853-007-2016-9

|

| [40] |

WENG W P, CHUANG T H. Brazing of aluminum matrix composite with Sn10Ag4Ti active filler metal[J]. Materials and Manufacturing Processes,1997,12(6):1107-1132. doi: 10.1080/10426919708935207

|

| [41] |

ZHANG X P, YE L, MAI Y W, et al. Investigation on diffusion bonding characteristics of SiC particulate reinforced aluminium metal matrix composites (Al/SiCp-MMC)[J]. Composites Part A: Applied Science and Manufacturing,1999,30(12):1415-1421. doi: 10.1016/S1359-835X(99)00040-8

|

| [42] |

ZHANG X P, QUAN G F, WEI W. Preliminary investigation on joining performance of SiCp-reinforced aluminium metal matrix composite (Al/SiCp-MMC) by vacuum brazing[J]. Composites Part A: Applied Science and Manufacturing,1999,30(6):823-827. doi: 10.1016/S1359-835X(98)00186-9

|

| [43] |

ZHANG G F, ZHANG J X, PEI Y, et al. Joining of Al2O3p/Al composites by transient liquid phase (TLP) bonding and a novel process of active-transient liquid phase (A-TLP) bonding[J]. Materials Science and Engineering A,2008,488(1-2):146-156. doi: 10.1016/j.msea.2007.11.084

|

| [44] |

ZHANG G F, SU W, ZHANG J X. Development of Al-12Si-xTi system active ternary filler metals for Al metal matrix composites[J]. Transactions of Nonferrous Metals Society of China,2012,22(3):596-603. doi: 10.1016/S1003-6326(11)61219-3

|

| [45] |

NIEMANN B J T, WILLE G W. Fluxless diffusion brazing of aluminum castings[J]. Welding Journal,1978,52:285-291.

|

| [46] |

HIDEKI S, RONG C. A combined microstructure strengthening analysis of SiCP/Al metal matrix composites[J]. Composites,1995,26:183-188. doi: 10.1016/0010-4361(95)91381-E

|

| [47] |

CAVALIERE P, CERRI E, LEO P. Effect of heat treatments on mechanical properties and fracture behavior of a thixocast A356 aluminum alloy[J]. Journal of Materials Science,2004,39:1653-1658. doi: 10.1023/B:JMSC.0000016165.99666.dd

|

| [48] |

ZHANG G F, SU W, ZHANG J X, et al. Wetting behavior of a novel Al-Si-Ti active brazing filler metal foil on aluminum matrix composite[J]. Journal of Materials Engineering & Performance,2013,22(7):1982-1994.

|

| [49] |

张启运, 庄鸿寿. 三元合金相图手册[M]. 北京: 机械工业出版社, 2011: 159.ZHANG Q Y, ZHUANG H S. Manual of ternary alloy phase diagrams[M]. Beijing: Press of Mechanical Industry, 2011: 159(in Chinese).

|

| [50] |

唐仁政, 田荣璋. 二元合金相图及中间相晶体结构[M]. 长沙, 中南大学出版社, 2009: 51.TANG R Z, TIAN R Z. Manual of binary alloy phase diagrams[M]. Changsha: Press of Central South University, 2009: 51(in Chinese).

|

下载:

下载: