Deformation analysis method of FRP bar/concrete tension members by considering tension stiffening effect

-

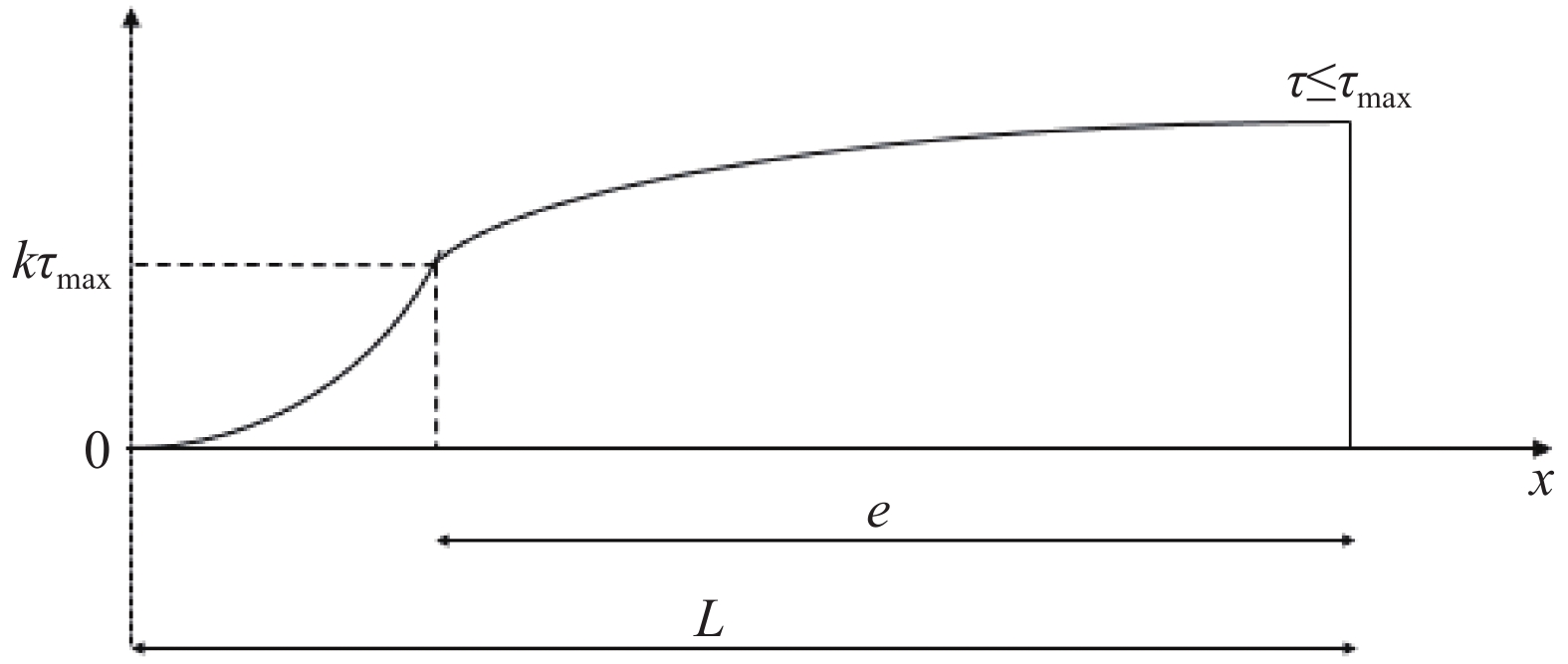

摘要: 考虑拉伸刚化效应是精确计算纤维增强树脂复合材料(FRP)筋/混凝土构件变形和裂缝的基础。提出了考虑拉伸刚化效应的FRP筋/混凝土拉伸构件变形计算的解析方法。首先,对修正Eligehausen黏结滑移模型(修正BPE模型)进行简化提出四线性黏结-滑移模型。根据该模型推导了拉伸构件在不同拉伸荷载阶段的FRP筋、混凝土应力和变形及黏结力和滑移量的分布表达式。结合混凝土开裂判别方法,提出了FRP筋/混凝土拉伸构件的全过程变形计算方法。通过与已有文献试验结果对比验证了本文方法的准确性。对影响拉伸刚化的一些参数进行了敏感性分析。结果表明,混凝土强度和配筋率对拉伸刚化效应影响不大,FRP筋弹性模量是影响拉伸刚化效应的主要因素。

-

关键词:

- 纤维增强树脂复合材料(FRP)筋 /

- 轴拉构件 /

- 拉伸刚化 /

- 黏结-滑移 /

- 配筋率

Abstract: The tension stiffening effect is the premise of accurate evaluation of the deformation and crack width of fiber reinforced polymer composite (FRP) bar/concrete members. An analytical method for determining the deformation of FRP bar/concrete tension member was proposed. A simplified four-linear model based on the modified Eligehausen model (modified BPE model) was presented. The distribution of stress, displacement of FRP bars and concrete and the distribution of bond force, slip between bars and concrete were established. By combining with the cracking criterion of concrete, an algorithm for the deformation of FRP reinforced tensive ties at different loading stages was proposed. After verification by comparing with experimental data in the literature, the effects of different parameters on the tension stiffening were analyzed. Parametric analysis results indicate that concrete strength and reinforcement ratio of FRP bars have a minor impact on the tension stiffening effect. However, the elastic modulus of FRP bars dominates the tension stiffening behavior of FRP reinforced concrete tensile elements. -

表 1 FRP筋/混凝土轴拉试件几何及材料参数

Table 1. Geometric and material parameters of FRP bars/concrete axial tensile specimens

Reference Specimen 2L/mm b/mm h/mm d/mm ${f'_{\rm{c}}}$/MPa ${f_{\rm{t}}}$/MPa ${E_{\rm{c}}}$/GPa ${f_{{\rm{fu}}}}$/MPa ${E_{\rm{p}}}$/GPa ${\delta _1}$/mm ${\delta _{\rm{f}}}$/mm [12] 13-170 1200 170 170 13.7 48.1 1.8 27.4 770 37.6 0.29 2.83 16-170 1200 170 170 16.9 46.6 2.6 34.6 1030 41.7 0.29 2.83 19-170 1200 170 170 19.1 56.2 2.1 33.3 637 40.8 0.29 2.83 [21] C30-12A-100(1) 1000 100 100 13.0 37.7 2.8 34.8 983 50.3 0.29 2.83 C85-16C-100(1) 1000 100 100 20.0 116.4 4.1 54.1 1236 63.8 1.50 10.00 [22] C50/13/100 1500 100 100 12.7 52.0 2.9 36.2 792 42.9 1.50 10.00 C50/19/150 1300 150 150 19.1 52.0 2.9 36.2 715 41.9 1.50 10.00 C90/19/150 1300 200 200 19.1 91.0 5.2 48.3 715 41.9 1.50 10.00 Notes:2L—Effective length of specimens; b, h—Width and height of cross sections, respectively; d—Perimeter of FRP bars; ${f'_{\rm{c}}}$—Compressive strength of concrete; ${f_{\rm{t}}}$—Tensile strength of concrete; ${E_{\rm{c}}}$, ${E_{\rm{p}}}$—Elastic modulus of concrete and FRP bars, respectively; ${f_{\rm{fu}}}$—Ultimate tensile strength of FRP bars; ${\delta _1}$, ${\delta _{\rm{f}}}$—Maximum slip in hardening stage and softening stage, respectively. 表 2 BPE模型黏结-滑移参数

Table 2. Bond-slip parameters for BPE model

Parameter Rough surface and medium strength concrete Smooth surface and medium strength concrete Rough surface and low strength concrete Rough surface and high strength concrete α 0.25 0.16 0.39 0.12 ${ {\delta } }_{ {{1} } }$/mm 0.29 0.42 0.61 0.24 ${ {\delta } }_{ {{2} } }/$mm 0.76 2.54 1.18 0.37 ${ {\delta } }_{ {{3} } }$/mm 2.83 4.23 3.74 3.79 ${ {\tau } }_{ {{\rm{max}}} }$/MPa 0.93 0.50 0.78 3.13 Notes: $\alpha $—A constant which controls initial nonlinear curvature; ${\delta _1}$, ${\delta _2}$, ${\delta _3}$— Maximum slip at nonlinear ascent stage, constant maximum bond stress stage and linear descent stage, respectively; ${\tau _{\max }}$— Maximum bond stress. -

[1] BENMOKRANE B, EL-SALAKAWY E, EL-RAGABY A, et al. Designing and testing of concrete bridge decks reinforced with glass FRP bars[J]. Journal of Bridge Engineering,2006,11(2):217-229. doi: 10.1061/(ASCE)1084-0702(2006)11:2(217) [2] GANGARAO H V, TALY N, VIJAY P V. Reinforced concrete design with FRP composites[M]. Florida: CRC Press, 2006. [3] TORRES L, LÓPEZ-ALMANSA F, BOZZO L M. Tension-stiffening model for cracked flexural concrete members[J]. Journal of Structural Engineering,2004,130(8):1242-1251. doi: 10.1061/(ASCE)0733-9445(2004)130:8(1242) [4] DAI J G, UEDA T, SATO Y, et al. Modeling of tension stiffening behavior in FRP-strengthened RC members based on rigid body spring networks[J]. Computer-Aided Civil and Infrastructure Engineering,2012,27(6):406-418. doi: 10.1111/j.1467-8667.2011.00741.x [5] STRAMANDINOLI R S B, LA ROVERE H L. An efficient tension-stiffening model for nonlinear analysis of reinforced concrete members[J]. Engineering Structures,2008,30(7):2069-2080. doi: 10.1016/j.engstruct.2007.12.022 [6] BISCHOFF P H, GROSS S, OSPINA C E. The story behind proposed changes to ACI 440 deflection requirements for FRP-reinforced concrete[CD]. New York: Curran Associates, Inc., 2010. [7] NARAYANAN R S, BEEBY A W. Designers’ guide to EN 1992-1-1 and EN 1992-1-2. Eurocode 2: Design of concrete structures: General rules and rules for buildings and structural fire design[M]. Thomas Telford, 2005. [8] BISCHOFF P H, PAIXAO R. Tension stiffening and cracking of concrete reinforced with glass fiber reinforced polymer (GFRP) bars[J]. Canadian Journal of Civil Engineering,2004,31(4):579-588. doi: 10.1139/l04-025 [9] BAENA M, TORRES L, TURON A, et al. Analysis of cracking behavior and tension stiffening in FRP reinforced concrete tensile elements[J]. Composites Part B: Engineering,2013,45(1):1360-1367. doi: 10.1016/j.compositesb.2012.07.026 [10] MIGLIETTA P C, GRASSELLI G, BENTZ E C. Finite/discrete element model of tension stiffening in GFRP reinforced concrete[J]. Engineering Structures,2016,111:494-504. doi: 10.1016/j.engstruct.2015.12.037 [11] GHIASSI B, SOLTANI M, RAHNAMAYE S S. Micromechanical modeling of tension stiffening in FRP-strengthened concrete elements[J]. Journal of Composite Materials,2018,52(19):2577-2596. doi: 10.1177/0021998317751248 [12] BAENA M, TURON A, TORRE L, et al. Experimental study and code predictions of fibre reinforced polymer reinforced concrete (FRP RC) tensile members[J]. Composite Structures,2011,93(10):2511-2520. doi: 10.1016/j.compstruct.2011.04.012 [13] VILANOVA I, TORRES L, BAENA M, et al. Experimental study of tension stiffening in GFRP RC tensile members under sustained load[J]. Engineering Structures,2014,79:390-400. doi: 10.1016/j.engstruct.2014.08.037 [14] LIN X S, ZHANG Y X. Evaluation of bond stress-slip models for FRP reinforcing bars in concrete[J]. Composite Structures,2014,104:131-141. [15] ELIGEHAUSEN R, POPOV E P, BERTERO V V. Local bond stress-slip relationships of deformed bars under generalized excitations: Experimental results and analytical model[R]. Berkeley: Earthquake Engineering Research Center, 1983. [16] COSENZA E, MANFREDI G, REALFONZO R. Behavior and modeling of bond of FRP rebars to concrete[J]. Journal of Composites for Construction,1997,1(2):40-51. doi: 10.1061/(ASCE)1090-0268(1997)1:2(40) [17] HARAJLI M H, HOUT M, JALKH W. Local bond stress-slip behavior of reinforcing bars embedded in plain and fiber concrete[J]. ACI Materials Journal,1995,92(4):343-354. [18] HARAJLI M, HAMAD B, KARAM K. Bond-slip response of reinforcing bars embedded in plain and fiber concrete[J]. Journal of Materials in Civil Engineering,2002,14(6):503-511. doi: 10.1061/(ASCE)0899-1561(2002)14:6(503) [19] HARAJLI M H. Bond stress-slip model for steel bars in unconfined or steel, FRC, or FRP confined concrete under cyclic loading[J]. Journal of Structural Engineering,2009,135(5):509-518. doi: 10.1061/(ASCE)0733-9445(2009)135:5(509) [20] GUPTA A K, MAESTRINI S R. Tension-stiffness model for reinforced concrete bars[J]. Journal of Structural Engineering,1990,116(3):769-790. doi: 10.1061/(ASCE)0733-9445(1990)116:3(769) [21] SOORIYAARACHCHI H, PILAKOUTAS K, BYARS E. Tension stiffening behavior of GFRP-reinforced concrete[C]//Fiber-Reinforced Polymer (FRP) Reinforcement for Concrete Structures. Kansas City: American Concrete Institute, 2005: 975-990. [22] KHARAL Z. Tension stiffening and cracking behavior of GFRP reinforced concrete[D]. Toronto: University of Toronto, 2014. [23] ROSSETTI V A, GALEOTA D, GIAMMATTEO M M. Local bond stress-slip relationships of glass fiber reinforced plastic bars embedded in concrete[J]. Materials and Structures,1995,28:340-344. doi: 10.1007/BF02473149 [24] BISCHOFF P H. Effects of shrinkage on tension stiffening and cracking in reinforced concrete[J]. Canadian Journal of Civil Engineering,2001,28(3):363-374. doi: 10.1139/l00-117 -

下载:

下载: