Ultrasonic guided wave-based evaluation for mechanical properties of interlaminar toughening carbon fiber/epoxy composites with microcapsules

-

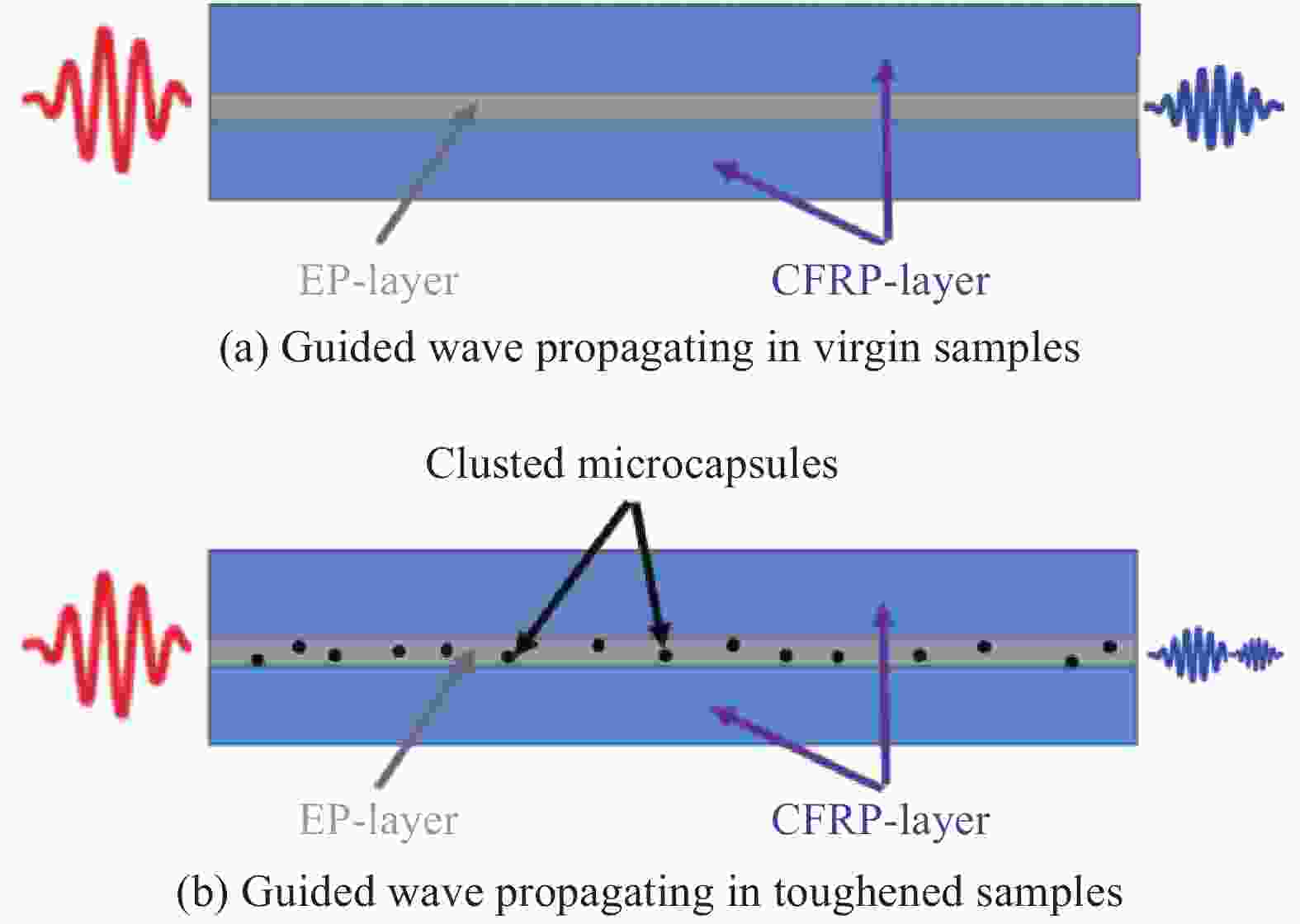

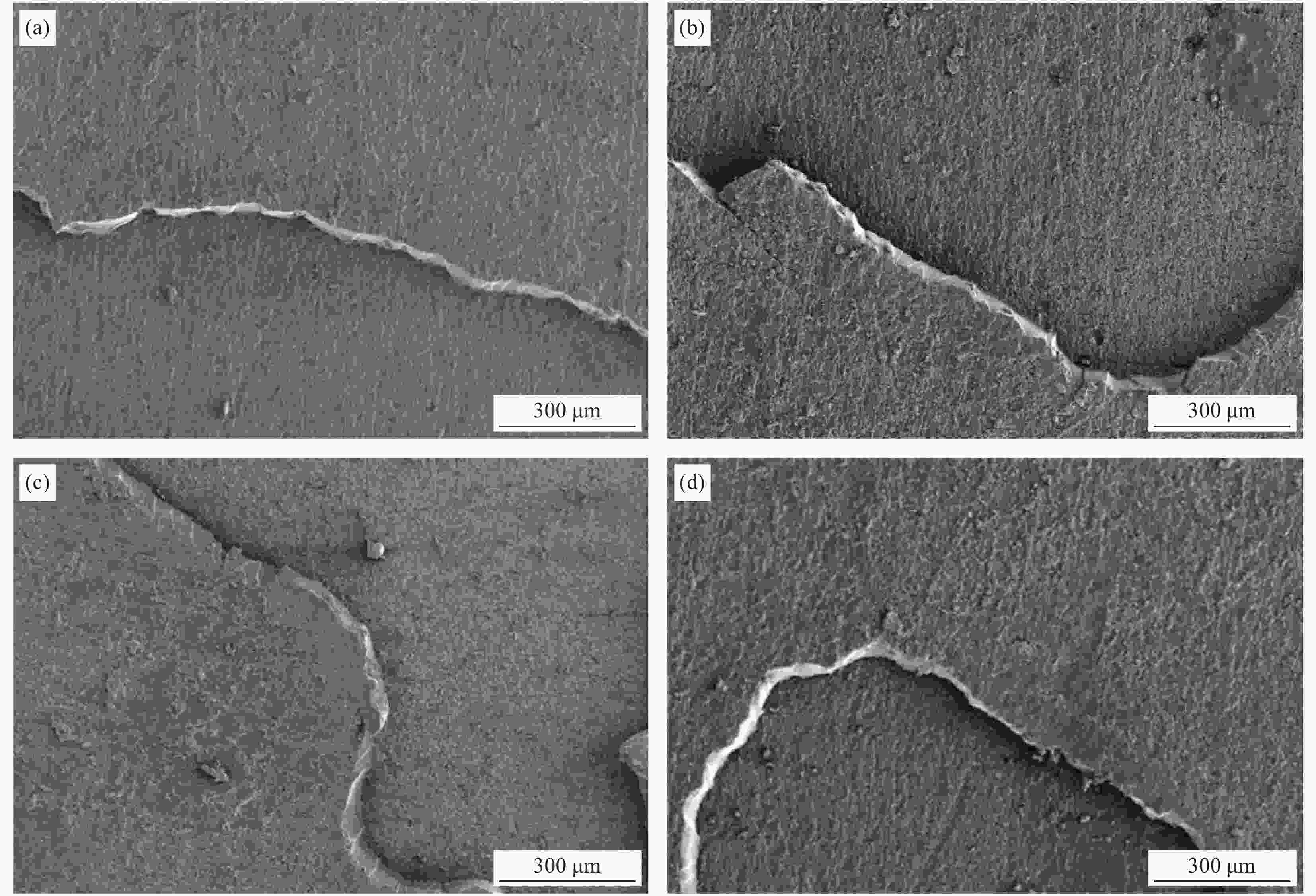

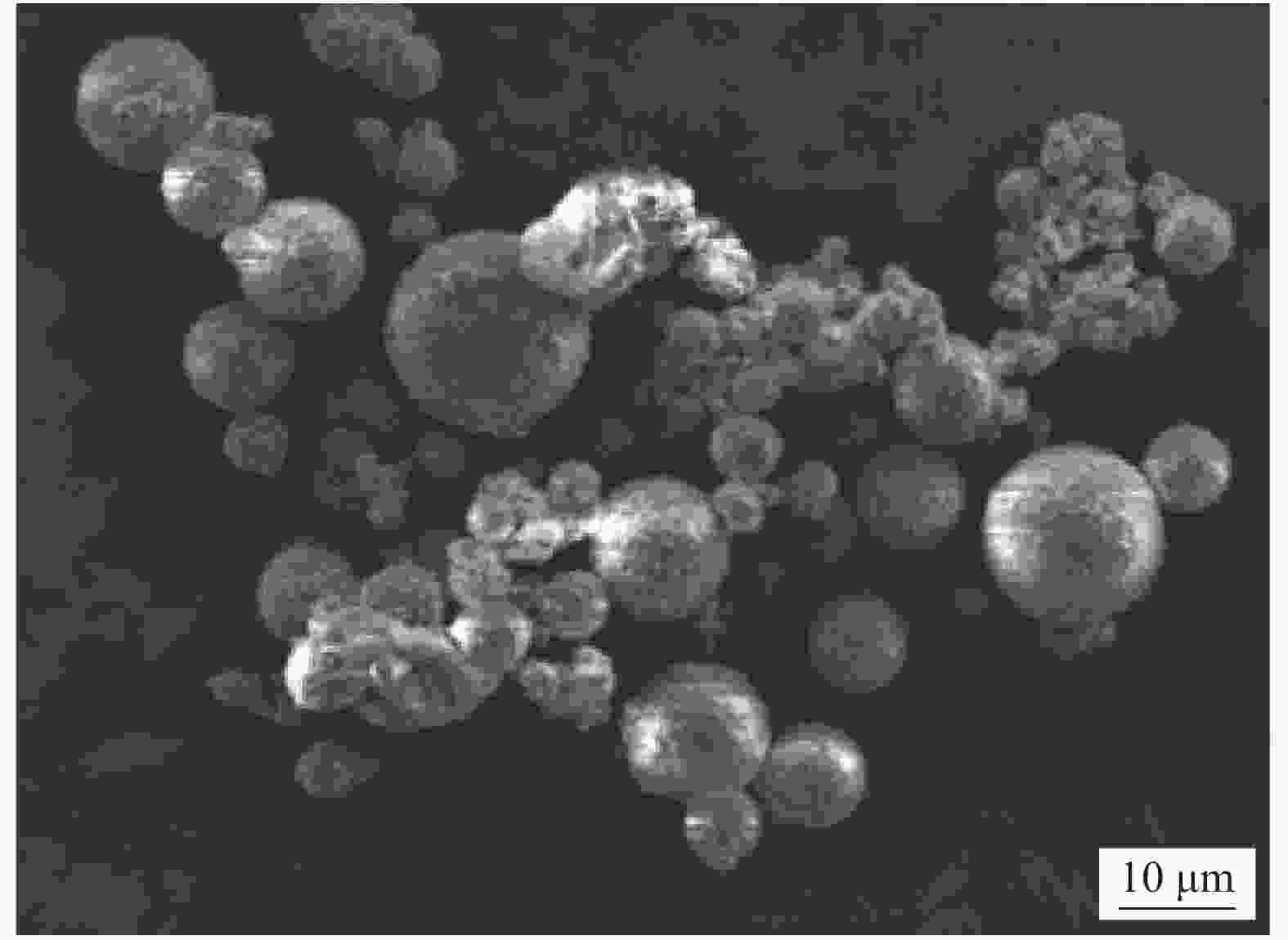

摘要: 选用微胶囊作为改性材料,采用热压机层压成型工艺制备出微胶囊层间增韧T300碳纤维/环氧树脂(CF/EP)复合材料。通过双悬臂梁(DCB)Ⅰ型层间断裂试验评估了CF/EP复合材料的增韧效果。利用超声导波技术对普通CF/EP复合材料和增韧CF/EP复合材料层间力学性能进行评价。通过SEM对CF/EP复合材料层间断面微观形貌进行观察,以揭示微胶囊的增韧机制,同时对超声导波检测结果进行辅助说明。结果表明,微胶囊以团聚形式分布在层间基体中,可以有效提高CF/EP复合材料的层间断裂韧性。微胶囊的填充改变了CF/EP复合材料层间基体特性,增加了导波传播过程中的衰减,导致响应信号峰值降低。同时,团聚的微胶囊改变了CF/EP复合材料对于中心频率125 kHz五峰波激励的振动响应,导致中心频率在信号频谱中的幅值低于普通CF/EP复合材料。Abstract: The interlaminar-toughening T300 carbon fiber/epoxy (CF/EP) composites with agglomerate microcapsules were prepared using hot-compaction laminating technology. The toughening effect was evaluated through mode Ⅰ interlaminar fracture tests conducted on double cantilever beam (DCB) CF/EP composites. The interlaminar properties of virgin and toughened CF/EP composites were evaluated by ultrasonic guided wave technology. The microstructures of interlaminar fracture surfaces of CF/EP composites were observed by SEM to reveal the toughening mechanism of microcapsules and explain the ultrasonic guided wave detection results. The results indicate that the microcapsules are distributed in the interlamination matrix resin in the form of agglomeration, which effectively improve the interlaminar fracture toughness of CF/EP composites. The filling of microcapsules changes the characteristics of the interlaminar matrix of the CF/EP composites, which increases attenuation of the propagating guided waves and causes the response signal peak to decrease. Meanwhile, the agglomerate microcapsules change the vibration response of the CF/EP composites to the excitation of the five-peak wave with a center frequency of 125 kHz, resulting in the amplitude of the center frequency in the signal spectrum being lower than that of the virgin CF/EP composites.

-

表 1 普通CF/EP复合材料和微胶囊层间增韧CF/EP复合材料中心频率125 kHz的幅值Af

Table 1. Amplitude Af of center frequency 125 kHz of virgin CF/EP composites and microcapsules interlaminar-toughening CF/EP composites

Type of sample Af of 1#/V Af of 2#/V Af of 3#/V Virgin DCB 0.7721 0.9244 0.9413 Toughened DCB 0.3548 0.1983 0.1562 -

[1] 杜善义. 先进复合材料与航空航天[J]. 复合材料学报, 2007, 24(1):1-12. doi: 10.3321/j.issn:1000-3851.2007.01.001DU S Y. Advanced composite materials and aerospace engineering[J]. Acta Materiae Compositae Sinica,2007,24(1):1-12(in Chinese). doi: 10.3321/j.issn:1000-3851.2007.01.001 [2] 董慧民, 益小苏, 安学锋, 等. 纤维增强热固性聚合物基复合材料层间增韧研究进展[J]. 复合材料学报, 2014, 31(2):273-285.DONG H M, YI X S, AN X F, et al. Development of interleaved fibre-reinforced thermoset polymer matrix composites[J]. Acta Materiae Compositae Sinica,2014,31(2):273-285(in Chinese). [3] HAO W F, GE D Y, MA Y J, et al. Experimental investigation on deformation and strength of carbon/epoxy laminated curved beams[J]. Polymer Testing,2012,31(4):520-526. doi: 10.1016/j.polymertesting.2012.02.003 [4] STEVANOVIC D. Delamination properties of a vinyl-ester/glass fibre composite toughened by particulate-modified interlayers[D]. Canberra: Australian National University, 2001. [5] ALJARRAH M T, ABDELAL N R. Improvement of the mode Ⅰ interlaminar fracture toughness of carbon fiber composite reinforced with electrospun nylon nanofiber[J]. Composites Part B: Engineering,2019,165:379-385. doi: 10.1016/j.compositesb.2019.01.065 [6] 郭壮壮, 徐武, 余音. 低温环境下测试复合材料Ⅰ型层间断裂韧性的简易方法[J]. 复合材料学报, 2019, 36(5):154-159.GUO Z Z, XU W, YU Y. A simple method for determining mode Ⅰ interlaminar fracture toughness of composite at low temperature[J]. Acta Materiae Compositae Sinica,2019,36(5):154-159(in Chinese). [7] GAO Y, LIU L, WU Z J, et al. Toughening and self-healing fiber-reinforced polymer composites using carbon nanotube modified poly(ethylene-co-methacrylic acid) sandwich membrane[J]. Composites Part A: Applied Science and Manufacturing,2019,124:105510. doi: 10.1016/j.compositesa.2019.105510 [8] 高峰, 矫桂琼, 宁荣昌, 等. 层间颗粒增韧复合材料层压板的损伤阻抗特性[J]. 复合材料学报, 2005, 22(2):116-120. doi: 10.3321/j.issn:1000-3851.2005.02.022GAO F, JIAO G Q, NING R C, et al. Damage resistance of the composite laminates with interlayer thermoplastic particles[J]. Acta Materiae Compositae Sinica,2005,22(2):116-120(in Chinese). doi: 10.3321/j.issn:1000-3851.2005.02.022 [9] 莫正才, 胡程耀, 霍冀川, 等. 苎麻短纤维层间增韧碳纤维/环氧树脂复合材料[J]. 复合材料学报, 2017, 34(6):1237-1244.MO Z C, HU C Y, HUO J C, et al. Interlayer-toughening carbon fiber/epoxy composites with short ramie fiber[J]. Acta Materiae Compositae Sinica,2017,34(6):1237-1244(in Chinese). [10] OU Y, GONZALEZ C, JOSE V J. Interlaminar toughening in structural carbon fiber/epoxy composites interleaved with carbon nanotube veils[J]. Composites Part A: Applied Science and Manufacturing,2019,124:105477. doi: 10.1016/j.compositesa.2019.105477 [11] WILLIAMS J, GRADDAGE N, RAHATEKAR S. Effects of plasma modified carbon nanotube interlaminar coating on crack propagation in glass epoxy composites[J]. Composites Part A: Applied Science & Manufacturing,2013,54:173-181. [12] 姚佳伟, 刘梦瑶, 牛一凡. PEK-C膜层间增韧碳纤维/环氧树脂复合材料的力学性能[J]. 复合材料学报, 2019, 36(5):1083-1091.YAO J W, LIU M Y, NIU Y F. Mechanical properties of PEK-C interlayer toughened carbon fiber/epoxy composites[J]. Acta Materiae Compositae Sinica,2019,36(5):1083-1091(in Chinese). [13] 孙筱辰. 纤维复合材料层合板的层间增韧及低速冲击研究[D]. 济南: 山东大学, 2015.SUN X C. Study on interlayer toughening and low-speed impact of fiber composite laminate[D]. Jinan: Shandong University, 2015(in Chinese). [14] KAYNAN O, ATESCAN Y, OZDEN-YENIGUN E, et al. Mixed mode delamination in carbon nanotube/nanofiber interlayered composites[J]. Composites Part B: Engineering,2018,154:186-194. doi: 10.1016/j.compositesb.2018.07.032 [15] GHAZALI H, YE L, ZHANG M Q. Interlaminar fracture of CF/EP composite containing a dual-component microencapsulated self-healant[J]. Composites Part A: Applied Science and Manufacturing,2016,82:226-234. doi: 10.1016/j.compositesa.2015.12.012 [16] ASTM International. Standard test method for mode Ⅰ interlaminar fracture toughness of unidirectional fiber-reinforced polymer matrix composites: ASTM D5528—13[S]. West Conshohocken: ASTM International, 2013. [17] ROSE J L. Ultrasonic electrospun nylon s in solid media[M]. New York: Cambridge University Press, 1999. [18] WANG D, YE L, TANG Y, et al. Monitoring of delamination onset and growth during mode Ⅰ and mode Ⅱ interlaminar fracture tests using guided waves[J]. Composites Science and Technology,2012,72(2):145-151. doi: 10.1016/j.compscitech.2011.10.004 [19] ZHAO G Q, WANG B, WANG T, et al. Detection and monitoring of delamination in composite laminates using ultrasonic guided wave[J]. Composite Structures,2019,225:111161. doi: 10.1016/j.compstruct.2019.111161 [20] SOLODOV I Y. Ultrasonics of non-linear contacts: Propagation, reflection and NDE-applications[J]. Ultrasonics,1998,36(1-5):383-390. doi: 10.1016/S0041-624X(97)00041-3 [21] 宋国荣, 徐煜阳, 吕炎, 等. 特殊制备材料力学性能超声无损检测与评价方法[J]. 北京工业大学学报, 2017, 43(10):1449-1456.SONG G R, XU Y Y, LV Y, et al. Ultrasonic nondestructive testing and evaluation method of special processing mechanical properties[J]. Journal of Beijing University of Technology,2017,43(10):1449-1456(in Chinese). [22] MITRA M, GOPALAKRISHNAN S. Guided wave based structural health monitoring: A review[J]. Smart Materials and Structures,2016,25(5):053001. doi: 10.1088/0964-1726/25/5/053001 [23] WILCOX P D, LOWE M J S, CAWLEY P. Mode and transducer selection for long range lamb wave inspection[J]. Journal of Intelligent Material Systems and Structures,2001,12(8):553-565. doi: 10.1177/10453890122145348 [24] MEI H, GIURGIUTIU V. Guided wave excitation and propagation in damped composite plates[J]. Structural Health Monitoring,2019,18(3):690-714. doi: 10.1177/1475921718765955 [25] SOLEIMANPOUR R, NG C T, WANG C H. Higher harmonic generation of guided waves at delamination in laminated composite beams[J]. Structural Health Monitoring,2017,16(4):400-417. doi: 10.1177/1475921716673021 [26] ESKIZEYBEK V, YAR A, AVCI A. CNT-PAN hybrid nanofibrous mat interleaved carbon/epoxy laminates with improved mode Ⅰ interlaminar fracture toughness[J]. Composites Science and Technology,2018,157:30-39. doi: 10.1016/j.compscitech.2018.01.021 -

下载:

下载: