Mechanical properties of reinforced composite pipe wound with steel strip under complex loads

-

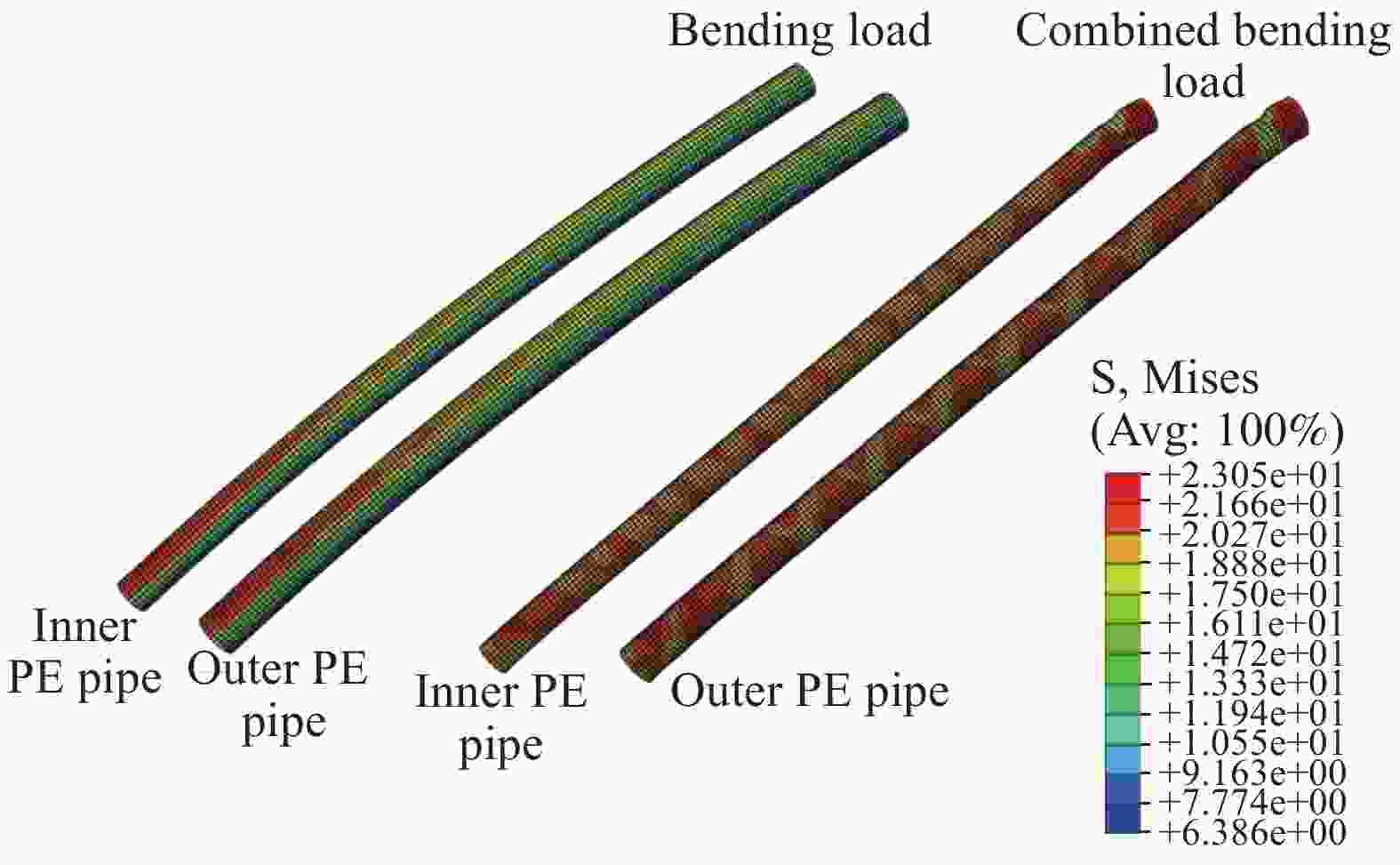

摘要: 为研究海洋油气输送用钢带缠绕增强复合管在复杂载荷下的力学响应特性,考虑非线性接触,建立钢带缠绕增强复合管数值计算模型,研究由内外压、弯曲及拉伸载荷组合作用下钢带缠绕增强复合管的变形及承载性能。结果表明,压差(外压大于内压,≤2 MPa)越大钢带缠绕增强复合管的柔性越高。与纯弯曲相比,拉伸载荷和压差的附加联合作用使钢带缠绕增强复合管柔性降低;与纯拉伸相比,弯曲载荷和压差的附加联合作用则使钢带缠绕增强复合管抗拉承载能力降低。与单一载荷相比,复杂载荷下内、外聚乙烯(PE)管的高应力区位置及内层钢带对称应力分布的路径发生改变。钢带螺旋角度及摩擦系数越大,钢带缠绕增强复合管柔性越低;增大摩擦系数,钢带缠绕增强复合管承载能力提高。组合弯曲载荷下随着钢带螺旋角增大,钢带缠绕增强复合管屈曲时的临界弯矩呈非单调变化,存在极大值。研究结果可为钢带缠绕增强复合管的设计、制造及安全评价提供理论依据。Abstract: In order to study the mechanical characteristics of reinforced composite pipe wound with steel strip for marine oil and gas transportation under complex loads, a numerical calculation model that considers non-linear contact was established. The model was studied to reflect the deformation and load-bearing properties of the composite pipe wound with steel strip under the combination of internal and external pressure, bending and tensile loads. The results show that the greater the pressure difference (the external pressure is greater than the internal one and ≤2 MPa), the more flexible the reinforced composite pipe wound with steel strip. Compared with pure bending, the additional combined effect of tensile load and pressure difference reduces the flexibility of reinforced composite pipe wound with steel strip. Compared with pure stretching, the additional combined effect of bending load and differential pressure reduces the tensile load carrying capacity of the reinforced composite pipe wound with steel strip. Compared with a single load, the location of the high stress area of the inner and outer polyethylene (PE) pipes and the symmetrical stress distribution path of the inner strip change under the complex loads. The greater the spiral angle and friction coefficient of the strip, the lower the flexibility of reinforced composite pipe wound with steel strip. The greater the friction coefficient, the higher the bearing capacity of reinforced composite pipe wound with steel strip. With the increase of the spiral angle under the combined bending load, the critical bending moment during buckling is non-monotonic and has a maximum value. The results can provide theoretical basis for the design, manufacture, and safety evaluation of reinforced composite pipe wound with steel strip.

-

表 1 钢带缠绕增强复合管的几何模型及材料参数

Table 1. Geometric and material parameters of reinforced composite pipe wound with steel strip

Model Inner ring radius/mm Thickness/mm Helix angle/(°) Width/mm E/GPa μ Yield strength/MPa Inner PE pipe 25.0 6.0 — — 1.04 0.40 20 Inner steel strip 31.0 0.5 54.7 52 199.00 0.26 850 Outer steel strip 31.5 0.5 −54.7 52 199.00 0.26 850 Protective layer 32.0 1.0 — — 1.04 0.40 20 Outer PE pipe 33.0 4.0 — — 1.04 0.40 20 Notes: E—Elastic modulus; μ—Poisson’s ratio. -

[1] 原帅. 径向压力作用下非粘接柔性管极限承载力研究[D]. 杭州: 浙江大学, 2017.YUAN Shuai. Ultimate capacity study for unbonded flexible pipes under pressures[D]. Hangzhou: Zhejiang University, 2017(in Chinese). [2] 何琦, 汪鹏. 深海能源开发现状和前景研究[J]. 海洋开发与管理, 2017, 34(12):66-71.HE Qi, WANG Peng. Current situation and prospect of deep sea energy development[J]. Ocean Development and Management,2017,34(12):66-71(in Chinese). [3] 孙巍. 深海石油工程装备技术发展现状及展望[J]. 中外能源, 2012, 17(9):9-14.SUN Wei. Deep-sea petroleum engineering equipment and technology today and prospects[J]. Sino-Global Energy,2012,17(9):9-14(in Chinese). [4] 杨旭, 孙丽萍, 艾尚茂. 深水无粘结柔性管抗拉伸层屈曲问题研究进展[J]. 海洋工程, 2013, 31(1):95-102.YANG Xu, SUN Liping, AI Shangmao. Recent research of deepwater unbonded flexible pipe tensile armor layer’s buckling behaviors[J]. The Ocean Engineering,2013,31(1):95-102(in Chinese). [5] 方娜, 陈国明, 朱红卫, 等. 海底管道泄漏事故统计分析[J]. 油气储运, 2014, 33(1):99-103.FANG Na, CHEN Guoming, ZHU Hongwei, et al. Statistical analysis of leakage accidents of submarine pipeline[J]. Oil & Gas Storage and Transportation,2014,33(1):99-103(in Chinese). [6] BAI Y, LIU T, CHENG P, et al. Buckling stability of steel strip reinforced thermoplastic pipe subjected to external pressure[J]. Composite Structures,2016,152:528-537. doi: 10.1016/j.compstruct.2016.05.051 [7] BAI Y, HAN P H, LIU T, et al. Mechanical responses of metallic strip flexible pipe subjected to combined bending and external pressure[J]. Ships and Offshore Structures,2018,13(3):320-329. [8] BAI Y, LIU T, RUAN W D, et al. Mechanical behavior of metallic strip flexible pipe subjected to tension[J]. Composite Structures,2017,170:1-10. [9] JIANG K, LIU T, YUAN S, et al. Mechanical behaviors of metallic strip flexible pipe under axisymmetric loads[C]//ASME 2018 37th International Conference on Ocean, Offshore and Arctic Engineering. Madrid: ASME, 2018. [10] BAI Y, CHEN W, XIONG H C, et al. Analysis of steel strip reinforced thermoplastic pipe under internal pressure[J]. Ships and Offshore Structures,2016,11(7):766-773. doi: 10.1080/17445302.2015.1063470 [11] LIU T, LEIRA B J, FU P, et al. Reliability-base safety factor for metallic strip flexible pipe subjected to external pressure[J]. Ocean Engineering,2018,148:48-52. [12] 姜豪, 杨和振. 组合载荷作用下深海非粘结柔性管力学性能对比分析[J]. 海洋工程, 2014, 32(5):93-99.JIANG Hao, YANG Hezhen. Machanical analysis of deepwater unbonded flexible riser under combined loads[J]. The Ocean Engineering,2014,32(5):93-99(in Chinese). [13] GONG S F, HU Q, BAO S, et al. Asymmetric buckling of offshore pipelines under combined tension, bending external pressure[J]. Ships and Offshore Structures,2015,10(2):162-175. doi: 10.1080/17445302.2014.918310 [14] SERTÃ O, FUMIS R, CONNAIRE A, at al. Predictions of armour wire buckling for a flexible pipe under compression, bending and external pressure loading[C]//ASME 2012 31st International Conference on Ocean, Offshore and Arctic Engineering. Rio de Janeiro: ASME, 2012: 361-365. [15] FE´RET J J, BOURNAL C L. Calculataion of stress and slip in structural layers of unbonded flexible pipes[J]. Journal of Offshore Mechanics and Arctic Engineering,1987,109(3):263-269. doi: 10.1115/1.3257019 [16] BATHTUI A. Development of a constitutive model to simulate unbonded flexible riser pipe elements[D]. London: Brunel University, 2008. [17] RAMOS R, PESCE C P. A consistent analytical model to predict the structural behavior of flexible risers subjected to combined loads[J]. Journal of Offshore Mechanics and Arctic Engineering,2004,126(2):141-146. doi: 10.1115/1.1710869 [18] RAMOS R, KAWANO A. Local structural analysis of flexible pipes subjected to traction, torsion and pressure loads[J]. Marine Structures,2015,42:95-114. [19] MERINO H E M, DE SOUSA J R M, MAGLUTA C, et al. A study on the extensional-torsional response of a damaged flexible pipe[C]//ASME 2012 31st International Conference on Ocean, Offshore and Arctic Engineering. Rio de Janeiro: ASME, 2012: 385-393. [20] GONG S F, WANG X P, ZHANG T, et al. Buckle propagation of sandwich pipes under external pressure[J]. Engineering Structures,2018,175:339-354. doi: 10.1016/j.engstruct.2018.08.033 [21] XUE J H. A non-linear finite-element analysis of buckle propagation in subsea corroded pipelines[J]. Finite Elements in Analysis & Design,2006,42(14-15):1211-1219. [22] XUE J H, GAN N. A comprehensive study on a propagating buckle in externally pressurized pipelines[J]. Journal of Mechanical Science and Technology,2014,28(12):4907-4919. doi: 10.1007/s12206-014-1110-6 [23] XUE J H, WANG Y, YUAN D. A shear deformation theory for bending and buckling of undersea sandwich pipes[J]. Composite Structures,2015,132:633-643. doi: 10.1016/j.compstruct.2015.06.004 [24] 刘婷. 钢带缠绕复合管力学性能及可靠性分析[D]. 杭州: 浙江大学, 2018.LIU Ting. Mechanical behaviors and reliability analysis of steel strip reinforced flexible pipes[D]. Hangzhou: Zhejiang University, 2018(in Chinese). -

下载:

下载: