Axial compression behaviour of CFRP confined reactive power concrete filled steel tube stub columns

-

摘要: 为研究圆碳纤维增强树脂复合材料(CFRP)约束钢管-活性粉末混凝土(RPC)短柱的轴压性能,以CFRP粘贴层数和钢管壁厚为参数进行了12根CFRP约束钢管-RPC短柱、4根钢管-RPC短柱及4根钢管短柱的轴压力学性能试验。通过荷载-位移曲线分析了CFRP层数和钢管壁厚对试件极限荷载和变形能力的影响,探讨了提高系数、CFRP应变效率和延性系数等相关性能指标,最后通过提高系数关联套箍率提出了CFRP约束钢管-RPC短柱承载力模型。结果表明:CFRP约束能有效地增强钢管-RPC短柱的承载能力和变形能力。与CFRP约束钢管-混凝土相比,CFRP约束钢管-RPC表现出CFRP应变效率的下降,并且其延性不如CFRP约束钢管-混凝土。在钢管-RPC承载力的基础上提出了实用的CFRP约束钢管-RPC短柱轴压承载力计算模型。

-

关键词:

- CFRP约束钢管-活性粉末混凝土 /

- 荷载-位移曲线 /

- 极限荷载 /

- CFRP应变效率 /

- 延性系数

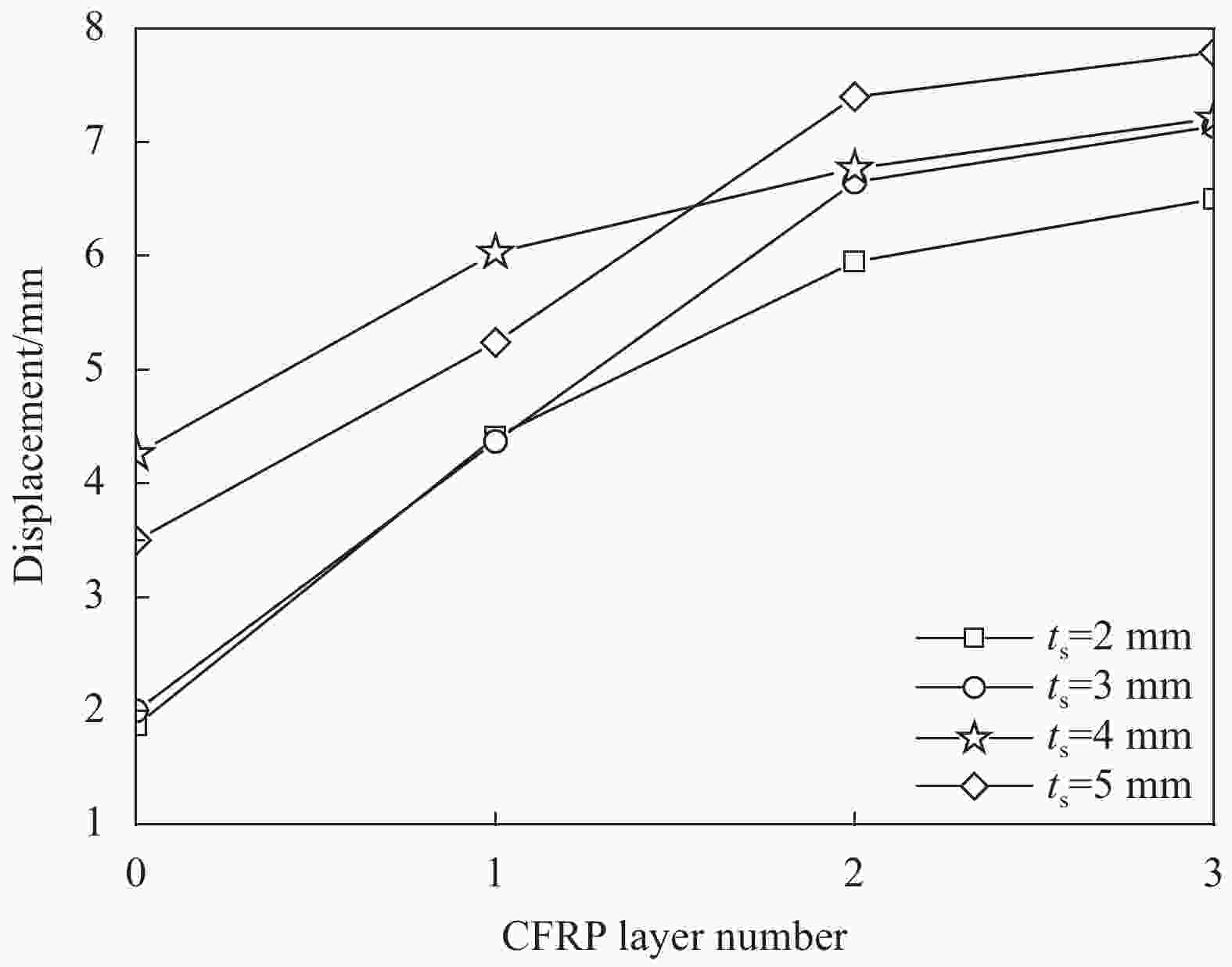

Abstract: The axial compression behaviour of circular carbon fiber reinforced polymer (CFRP) confined reactive powder concrete (RPC) filled steel tube stub columns was investigated. The mechanical tests of 12 CFRP confined steel tube-RPC stub columns, 4 steel tube-RPC stub columns and 4 steel tube stub columns were performed with the number of the CFRP layers and the steel tube thickness as parameters. The load-displacement curves were used to analyze the effects of the CFRP layer number and the steel tube thickness on the ultimate load and deformation capacity of the specimens. Subsequently, the performance indicators such as improvement coefficient, CFRP strain efficiency and ductility coefficient were discussed. Finally, a model of CFRP confined steel tube-RPC stub columns was proposed by increasing the coefficient associated confinement ratio. The experimental results indicate that the bearing capacity and deformation capacity of the CFRP confined steel tube-RPC stub columns are significantly improved by CFRP. In contrast to the CFRP confined concrete filled steel tube (CFRP confined steel tube-C), the CFRP confined steel tube-RPC exhibites a decrease in CFRP strain efficiency, and its ductility is worse than the CFRP confined steel tube-C. Based on the bearing capacity of steel tube-RPC, a practical model for calculating the bearing capacity of CFRP confined steel tube-RPC stub columns is proposed. -

表 1 试件编号及参数

Table 1. Parameters of specimens

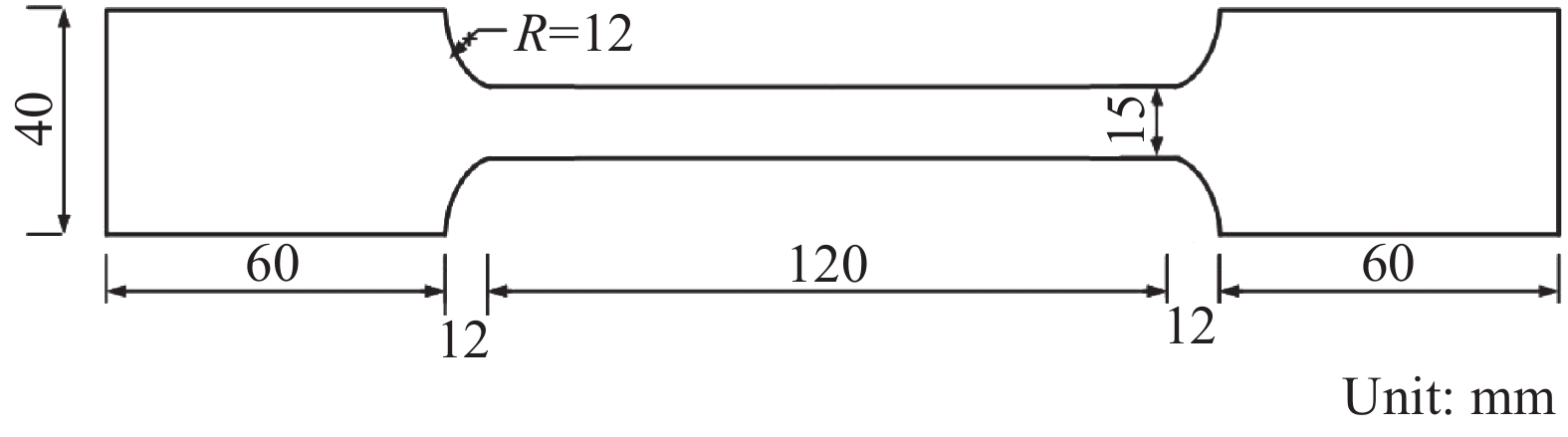

Specimen D×ts×L/mm fy/MPa Es/GPa fcu/MPa fc/MPa nf ξs ξcf kε µd rcap/% Nu/kN t2CF0 103×2×303 356 208 − − − − − − − − 328 C120t2CF0 103×2×303 356 208 127 108 0 0.272 0 − 3.75 0 1 081 C120t2CF1 103×2×303 356 208 127 108 1 0.272 0.221 0.666 2.49 14.5 1 238 C120t2CF2 103×2×303 356 208 127 108 2 0.272 0.442 0.727 2.08 20.8 1 306 C120t2CF3 103×2×303 356 208 127 108 3 0.272 0.663 0.776 1.46 32.0 1 428 t3CF0 102×3×303 310 204 − − − − − − − − 379 C120t3CF0 102×3×303 310 204 127 108 0 0.37 0 − 3.96 0 1 132 C120t3CF1 102×3×303 310 204 127 108 1 0.37 0.233 0.679 2.92 13.7 1 288 C120t3CF2 102×3×303 310 204 127 108 2 0.37 0.466 0.753 2.13 21.8 1 379 C120t3CF3 102×3×303 310 204 127 108 3 0.37 0.699 0.792 1.86 31.2 1 485 t4CF0 101×4×304 291 202 − − − − − − − − 443 C120t4CF0 101×4×304 291 202 127 108 0 0.484 0 − 4.03 0 1 221 C120t4CF1 101×4×304 291 202 127 108 1 0.484 0.246 0.738 3.11 9.7 1 340 C120t4CF2 101×4×304 291 202 127 108 2 0.484 0.492 0.781 2.56 20.7 1 474 C120t4CF3 101×4×304 291 202 127 108 3 0.484 0.738 0.805 2.19 32.8 1 621 t5CF0 102×5×306 318 207 − − − − − − − − 501 C120t5CF0 102×5×306 318 207 127 108 0 0.675 0 − 4.21 0 1 370 C120t5CF1 102×5×306 318 207 127 108 1 0.675 0.253 0.764 3.66 2.2 1 400 C120t5CF2 102×5×306 318 207 127 108 2 0.675 0.506 0.801 2.91 10.1 1 508 C120t5CF3 102×5×306 318 207 127 108 3 0.675 0.759 0.808 2.63 21.1 1 659 Notes: D—Diameter of steel tube; ts—Steel tube thickness; L—Length of a specimen; fy—Yield strength of steel; Es—Elastic modulus of steel; fcu—Cubic compressive strength of reactive powder concrete (RPC); fc—Axial compressive strength of RPC; nf—Number of carbon fiber reinforced polymer (CFRP) layers; ξs—Steel tube confinement factor; ξcf—CFRP confinement factor; kε—Strain efficiency of CFRP; µd—Ductility factor; rcap—Increase factor; Nu—Ultimate load. The letter C denotes the nominal RPC strength, the letter t is the steel tube thickness, and the letters CF denote the CFRP confined components. For example, the C120t2CF3 indicates that the strength of the specimen is 120 MPa, the thickness of the steel tube is 2 mm, and the specimen is wrapped in three CFRP layers. 表 2 CFRP约束钢管-高强混凝土预测结果与实测承载力结果比较

Table 2. Comparisons of experimental results and predicted results of CFRP confined high-strength concrete filled steel tube

Specimen D×ts×L/mm φs φcf ξsc ξcfc Nu/kN Ndf/kN Ngw/kN Nup/kN Ndf/Nu Ngw/Nu C120t2CF0 103×2×303 0.256 0 0.343 0 1 081 1 265 1 064 1 228 1.17 0.98 C120t2CF1 103×2×303 0.256 0.208 0.343 0.279 1 238 1 577 1 395 1 387 1.27 1.13 C120t2CF2 103×2×303 0.256 0.417 0.343 0.558 1 306 1 890 1 725 1 547 1.45 1.32 C120t2CF3 103×2×303 0.256 0.625 0.343 0.837 1 428 2 202 2 056 1 707 1.54 1.44 C120t3CF0 102×3×303 0.349 0 0.467 0 1 132 1 320 1 139 1 179 1.17 1.01 C120t3CF1 102×3×303 0.349 0.219 0.467 0.294 1 288 1 629 1 466 1 298 1.26 1.14 C120t3CF2 102×3×303 0.349 0.439 0.467 0.588 1 379 1 939 1 794 1 417 1.41 1.3 C120t3CF3 102×3×303 0.349 0.658 0.467 0.882 1 485 2 248 2 121 1 536 1.51 1.43 C120t4CF0 101×4×304 0.456 0 0.611 0 1 221 1 381 1 219 1 259 1.13 1 C120t4CF1 101×4×304 0.456 0.232 0.611 0.31 1 340 1 687 1 544 1 362 1.26 1.15 C120t4CF2 101×4×304 0.456 0.463 0.611 0.621 1 474 1 994 1 868 1 464 1.35 1.27 C120t4CF3 101×4×304 0.456 0.695 0.611 0.931 1 621 2 300 2 192 1 567 1.42 1.35 C120t5CF0 102×5×306 0.636 0 0.852 0 1 370 1 585 1 440 1 400 1.16 1.05 C120t5CF1 102×5×306 0.636 0.239 0.852 0.32 1 400 1 894 1 767 1 484 1.35 1.26 C120t5CF2 102×5×306 0.636 0.478 0.852 0.64 1 508 2 203 2 095 1 568 1.46 1.39 C120t5CF3 102×5×306 0.636 0.717 0.852 0.96 1 659 2 512 2 422 1 652 1.51 1.46 Notes: φs—Steel tube confinement factor of equation (6); φcf—CFRP confinement factor of equation (6); ξsc—Steel tube confinement factor of equation (7); ξcfc—CFRP confinement factor of equation (7); Ndf—Ultimate load of equation (6); Ngw—Ultimate load of equation (7). -

[1] 郑文忠, 吕雪源. 活性粉末混凝土研究进展[J]. 建筑结构学报, 2015, 36(10):44-58.ZHENG Wenzhong, LV Xueyuan. Research development of reactive powder concrete[J]. Journal of Building Structures,2015,36(10):44-58(in Chinese). [2] TAI Y S. Uniaxial compression tests at various loading rates for reactive powder concrete[J]. Theoretical and Applied Fracture Mechanics,2009,52(1):14-21. doi: 10.1016/j.tafmec.2009.06.001 [3] YAZICI H, YARDIMCI M Y, AYDIN S, et al. Mechanical properties of reactive powder concrete containing mineral admixtures under different curing regimes[J]. Construction & Building Materials,2009,23(3):1223-1231. [4] HIREMATH P N, YARAGAL S C. Influence of mixing method speed and duration on the fresh and hardened properties of reactive powder concrete[J]. Construction & Building Materials,2017,141(Complete):271-288. [5] YI N H, KIM J J, CHO Y G, et al. Blast-resistant characteristics of ultra-high strength concrete and reactive powder concrete[J]. Construction & Building Materials,2012,28(1):694-707. [6] TAI Y S, PAN H H, KUNG Y N. Mechanical properties of steel fiber reinforced reactive powder concrete following exposure to high temperature reaching 800℃[J]. Nuclear. Engineering & Design,2011,241(7):2416-2424. [7] YAN K, XU C, ZHANG X. Compressive behavior of steel fiber-reinforced reactive powder concrete at elevated temperatures[J]. Science of Advanced Materials,2016,8(7):1454-1463. doi: 10.1166/sam.2016.2758 [8] 戎芹, 曾宇声, 侯晓萌, 等. 圆钢管RPC轴压短柱有限元分析与承载力计算[J]. 哈尔滨工业大学学报, 2018, 50(12):61-66. doi: 10.11918/j.issn.0367-6234.201807186RONG Qin, ZENG Yusheng, HOU Xiaomeng, et al. Finite element analysis and bearing capacity calculation for RPC-filled circular steel tube columns under axial compression[J]. Journal of Harbin Institute of Technology,2018,50(12):61-66(in Chinese). doi: 10.11918/j.issn.0367-6234.201807186 [9] 闫志刚, 张武奇, 安明喆. 圆钢管RPC短柱轴心受压极限承载力分析[J]. 北京工业大学报, 2011, 37(3):361-367.YAN Zhigang, ZHANG Wuqi, AN Mingzhe. Analysis of ultimate loading capacity for circular RPC filled steel tube stub columns under axial compression[J]. Journal of Beijing University of Technology,2011,37(3):361-367(in Chinese). [10] 林震宇, 吴炎海, 沈祖炎. 圆钢管活性粉末混凝土轴压力学性能研究[J]. 建筑结构学报, 2005, 26(4):52-57. doi: 10.3321/j.issn:1000-6869.2005.04.008LIN Zhenyu, WU Yanhai, SHEN Zuyan. Research on behavior of RPC filled circular steel tube column subjected to axial compression[J]. Journal of Building Structures,2005, 26(4):52-57(in Chinese). doi: 10.3321/j.issn:1000-6869.2005.04.008 [11] 吴炎海, 林震宇. 钢管活性粉末混凝土轴压短柱受力性能试验研究[J]. 中国公路学报, 2005, 18(1):61-66.WU Yanhai, LIN Zhenyu. Experimental study on the mechanical behavior of activated powder concrete filled steel tube axial compression short column[J]. China Journal of Highway and Transport,2005, 18(1):61-66(in Chinese). [12] LU Y, LI N, LI S. Behavior of FRP-confined concrete-filled steel tube columns[J]. Polymers,2014,6(5):1333-1349. doi: 10.3390/polym6051333 [13] 王庆利. CFRP-钢管混凝土[M]. 北京: 科学出版社, 2017: 2-3.WANG Qingli. CFRP confined concrete filled steel tube[M]. Beijing: Science Press, 2017: 2-3(in Chinese). [14] PHAM T M, HADI M N S. Confinement model for FRP confined normal-and high-strength concrete circular columns[J]. Construction and Building Materials,2014,69(30):83-90. [15] 欧阳利军, 许峰, 陆洲导. 玄武岩纤维布增强树脂基复合材料约束高温损伤混凝土轴压力学性能[J]. 复合材料学报, 2018, 35(8):2002-2013.OUYANG Lijun, XU Feng, LU Zhoudao. Axial compressive behavior of basalt fiber reinforced polymer-confined damaged concrete after exposed to elevated temperatures[J]. Acta Materiae Compositae Sinica,2018,35(8):2002-2013(in Chinese). [16] DING Faxing, LU Deren, BAI Yu, et al. Behaviour of CFRP-confined concrete-filled circular steel tube stub columns under axial loading[J]. Thin-Walled Structures,2018,125:107-118. doi: 10.1016/j.tws.2018.01.015 [17] 翟存林, 魏洋, 李国芬, 曹兴. FRP—钢复合管混凝土桥墩设计与应用研究[J]. 公路, 2012(01):83-87. doi: 10.3969/j.issn.0451-0712.2012.01.017ZHAI Cunlin, WEI Yang, LI Guofen, et al. Research on design and application of FRP steel composite pipe concrete pier[J]. Highway,2012(01):83-87(in Chinese). doi: 10.3969/j.issn.0451-0712.2012.01.017 [18] 中国国家标准化管理委员会. 金属材料-室温拉伸试验方法: GB/T 228—2010[S]. 北京: 中国标准出版社, 2010.Standardization Administration of China. Metallic materials-tensile testing at ambient temperatures: GB/T 228—2010[S]. Beijing: Standards Press of China, 2010(in Chinese). [19] 建设部建筑物鉴定与加固规范管理委员会. 粘贴碳纤维复合材料加固混凝土工程施工与验收暂行规定: 建规固[2002]006[S]. 北京: 中国标准出版社, 2002.Building Appraisal and Reinforcement Specification Management Committee of the Ministry of Construction. Interim provisions on construction and acceptance of concrete engineering reinforced with carbon fiber composite materials: Construction regulations [2002] 006[S]. Beijing: Standards Press of China, 2002(in Chinese). [20] 中国国家标准化管理委员会. 活性粉末混凝土技术标准: GB/T 31387—2015[S]. 北京: 中国标准出版社, 2015.Standardization Administration of China. Reactive powder concrete: GB/T 31387—2015[S]. Beijing: Standards Press of China, 2015(in Chinese). [21] 谭彬. 活性粉末混凝土受压应力应变全曲线的研究[D]. 长沙: 湖南大学, 2007.TAN B. Research on stress-strain curves of reactive powder concrete under uniaxial compression[D]. Changsha: Hunan University, 2007(in Chinese). [22] HU Y M, YU T, TENG J G. FRP-confined circular concrete-filled thin steel tubes under axial compression[J]. Journal of Composites for Construction,2011,15(5):850-860. doi: 10.1061/(ASCE)CC.1943-5614.0000217 [23] CHEN M, HOU X. Comparative study on the axial compression and bearing capacity of reactive powder concrete-filled circular steel tube[J]. Advances in Materials Science & Engineering,2018,2018:1-11. [24] TANG H, CHEN J, FAN L, et al. Experimental investigation of FRP-confined concrete-filled stainless steel tube stub columns under axial compression[J]. Thin-Walled Structures,2020,146:106483. doi: 10.1016/j.tws.2019.106483 [25] 张依睿, 魏洋, 柏佳文, 等. FRP-钢复合圆管约束混凝土轴压性能预测模型[J]. 复合材料学报, 2020(5):1-8.ZHANG Yirui, WEI Yang, BAI Jiawen, et al. Models for predicting axial compression behavior of FRP-steel compo-site circular tube confined concrete[J]. Acta Materiae Compositae Sinica,2020(5):1-8(in Chinese). [26] 顾威, 赵颖华, 尚东伟. CFRP-钢管混凝土轴压短柱承载力分析[J]. 工程力学, 2006, 23(1):149-153. doi: 10.3969/j.issn.1000-4750.2006.01.027GU Wei, ZHAO Yinghua, SHANG Dongwei, et al. Analysis of the bearing capacity of CFRP concrete filled steel tubular short columns[J]. Engineering Mechanics,2006, 23(1):149-153(in Chinese). doi: 10.3969/j.issn.1000-4750.2006.01.027 [27] 顾维平, 蔡绍怀, 冯文林. 钢管高强度混凝土的性能与极限强度[J]. 建筑科学, 1991(1):23-27.GU Weiping, CAI Shaohuai, FENG Wenlin. Performance and ultimate strength of high-strength concrete filled steel tube[J]. Building Science,1991(1):23-27(in Chinese). [28] LAM L, TENG J G. Design-oriented stress-strain model for FRP-confined concrete[J]. Construction and Building Materials,2003,17(6):471-489. [29] PESSIKI S, HARRIES K A, KESTNER J T, et al. Axial behavior of reinforced concrete columns confined with FRP jackets[J]. Journal of Composites for Construction,2001,5(4):237-245. doi: 10.1061/(ASCE)1090-0268(2001)5:4(237) [30] CHE Y, WANG Q L, SHAO Y B. Compressive performances of the concrete filled circular CFRP-steel tube (C-CFRP-CFST)[J]. International Journal of Advanced Steel Construction,2012,8(4):311-338. -

下载:

下载: