Flexible piezoresistive sensor and heating de-icing performance based on expanded graphite/polydimethylsiloxane composite

-

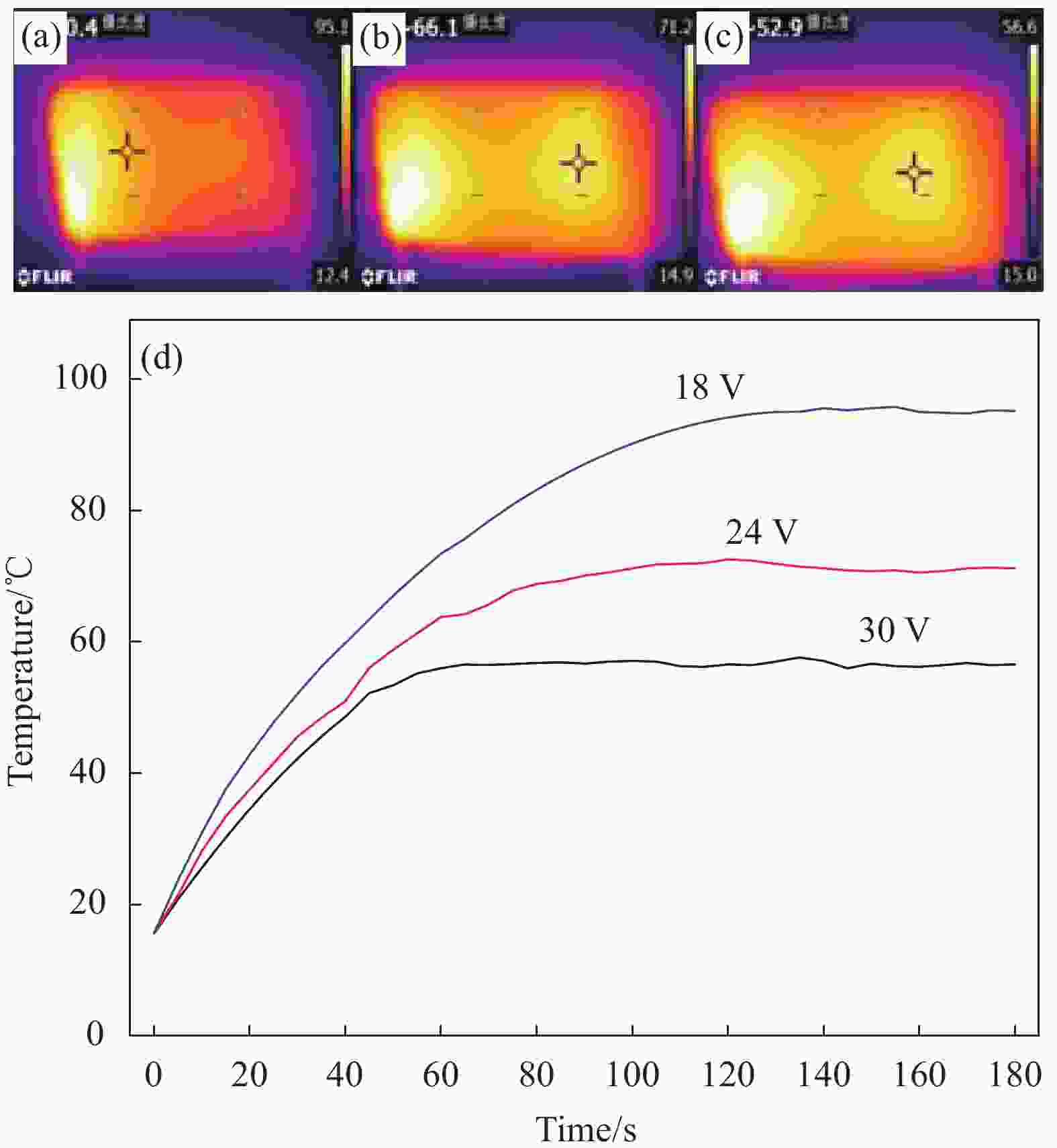

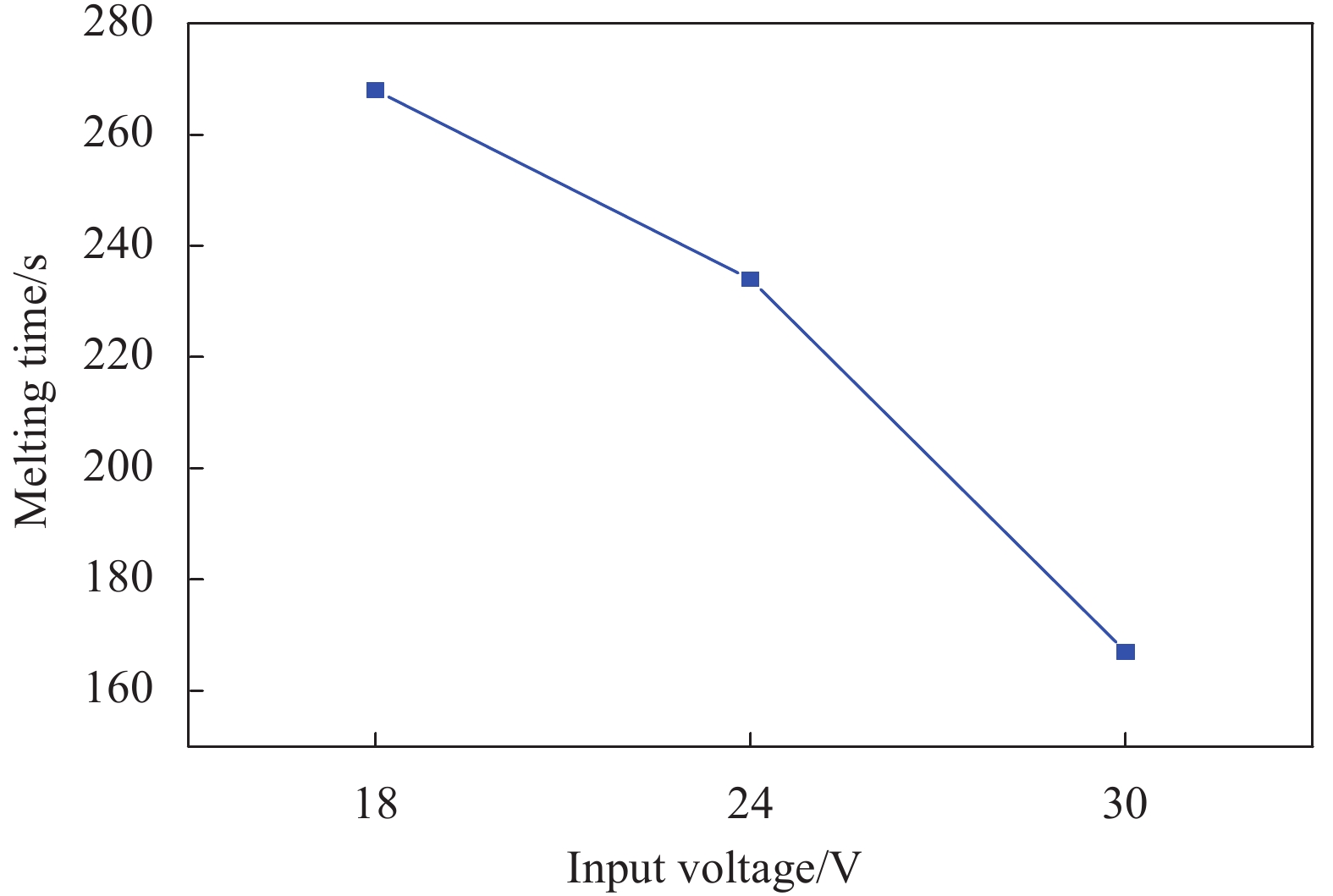

摘要: 积冰作为一种常见的自然现象,给航空、电力和道路交通等方面带来了极大安全隐患。本文利用膨胀石墨优异的导电性和聚二甲基硅氧烷良好的柔韧性与疏水性,制备具有探冰与电热除冰功能为一体的膨胀石墨/聚二甲基硅氧烷的复合材料(Expandable graphite/polydimethylsiloxane, EG/PDMS),并研究其疏水性、压阻性能和电热效应。结果表明,EG/PDMS复合材料传感器压力灵敏度最大为0.15 kPa−1,且能在10~110 kPa大范围内产生线性压阻反应;在电加热过程中,当输入电压为30 V、输入电流为0.05 A时,最高平衡温度为94.7℃,完全融化10 g冰的时间为166 s。EG/PDMS复合材料不仅可以监测其表面积冰厚度变化,还可通电加热除冰,在探冰/除冰领域具有较大的应用价值。Abstract: As a common natural phenomenon, ice accretion poses great security risks to aviation, power and road traffic. In this paper, an excellent composite of expanded graphite/polydimethylsiloxane (EG/PDMS) based ice detection and electrothermal de-icing function was designed by using the excellent conductivity of expanded graphite and the good flexibility and hydrophobicity of polydimethylsiloxane. Through experiments, the hydrophobicity, piezoresistive performance and electrothermal effect of the EG/PDMS composite material were analyzed. The sensor pressure sensitivity is up to 0.15 kPa−1, and the linear piezoresistive reaction can be generated in the range of 10~110 kPa; during the electric heating process when the input voltage is 30 V and the input current is 0.05 A, the maximum equilibrium temperature is 94.7℃, and the time to completely melt 10 g of ice is 166 s. The EG/PDMS composite material has great potential application value in the field of ice exploration/deicing. The composite material has great potential application value in the field of deicing.

-

Key words:

- expand graphite /

- polydimethylsiloxane /

- flexible pressure sensor /

- deicing /

- heating effect of current

-

表 1 膨胀石墨(EG)/聚二甲基硅氧烷(PDMS)复合材料化学组成

Table 1. Chemical composition of composite expandable graphite (EG)/polydimethylsiloxane (PDMS)

Sample EG/

gPDMS/

gSilicone

oil/gSodium lauryl

sulfate/gEG/PDMS-10 1.1 8 3 0.1 EG/PDMS-30 3.3 8 3 0.1 EG/PDMS-50 5.5 8 3 0.1 -

[1] 徐开威. 基于Modified-ELM算法的输电线路除冰机器人的障碍物识别技术[D]. 南昌: 南昌大学, 2019.XU K W. Obstacle recognition technology for robots power lines based on modified-ELM[D]. Nanchang: Nanchang University, 2019(in Chinese). [2] 蒋彦翃. 电网覆冰灾害风险评估方法及应对措施研究[D]. 武汉: 华中科技大学, 2018.JIANG Y H. Risk assessment methods and countermeasures of power grid under ice-covered disasters[D]. Wuhan: Huazhong University of Science & Technology, 2018(in Chinese). [3] PAUL S, BASHIR S, CHANG J. Design of a novel electromagnetic energy harvester with dual core for deicing device of transmission lines[C]. IEEE Transactions on Magnetics, 2018: 2873021. [4] MALEKI P, IRANPOUR B, SHAFABAKHSH G. Investigation of de-icing of roads with conductive concrete pavement containing carbon fibre-reinforced polymer (CFRP)[J]. International Journal of Pavement Engineering,2019,20(6):682-690. doi: 10.1080/10298436.2017.1326235 [5] ESPINHA MARQUES J, MARQUES J M, et al. Groundwater resources in a mediterranean mountainous region: Environmental impact of road de-icing[J]. Sustainable Water Resources Management,2019,5(1SI):305-317. [6] WAN J, WU S, XIAO Y, et al. Study on the effective compo-sition of steel slag for asphalt mixture induction heating purpose[J]. Construction and Building Materials,2018,178:542-550. doi: 10.1016/j.conbuildmat.2018.05.170 [7] 王晋, 纪双英, 益小苏, 等. 飞行器防/除冰技术研究进展[J]. 航空制造技术, 2015(S2):30-32.WANG J, JI S Y, YI X S, et al. Progress of the aircraft anti-icing/de-icing[J]. Aeronautical Manufacturing Technology,2015(S2):30-32(in Chinese). [8] 周莉, 徐浩军, 龚胜科, 等. 飞机结冰特性及防除冰技术研究[J]. 中国安全科学学报, 2010, 20(6):105-110. doi: 10.3969/j.issn.1003-3033.2010.06.018ZHOU L, XU H J, GONG S K, et al. Research of aircraft icing characteristics and anti-icing and de-icing technology[J]. China Safety Science Journal,2010,20(6):105-110(in Chinese). doi: 10.3969/j.issn.1003-3033.2010.06.018 [9] 陆煊, 崔玫, 曹洪波, 等. 船舶防冻除冰技术现状与发展[J]. 船海工程, 2016, 45(2):37-39. doi: 10.3963/j.issn.1671-7953.2016.02.011LU X, CUI M, CAO H B, et al. Present situation and development of de-icing and prevent frostbite technology of ships[J]. Ship & Ocean Engineering,2016,45(2):37-39(in Chinese). doi: 10.3963/j.issn.1671-7953.2016.02.011 [10] MARBŒUF A, BENNANI L, BUDINGER M, et al. Electromechanical resonant ice protection systems: Numerical investigation through a phase-field mixed adhesive/brittle fracture model[J]. Engineering Fracture Mechanics,2020,230:106926. doi: 10.1016/j.engfracmech.2020.106926 [11] RODZIEWICZ J, MIELCAREK A, JANCZUKOWICZ W, et al. Biofilter with innovative filling for low-temperature treatment of sewage from de-icing airport runways[J]. Separation and Purification Technology,2020,242:116761. doi: 10.1016/j.seppur.2020.116761 [12] WANG Y, XU Y, SU F. Damage accumulation model of ice detach behavior in ultrasonic de-icing technology[J]. Renewable Energy,2020,153:1396-1405. doi: 10.1016/j.renene.2020.02.069 [13] 陈龙, 刘慧, 张一术. 石墨烯涂层对直升机旋翼防除冰组件传热的影响[J]. 复合材料学报, 2021, 38(1): 239-245.CHEN L, LIU H, ZHANG Y S. Effect of graphene coating on heat transfer of anti-/deicing component for helicopter rotor[J]. Acta Materiae Compositae Sinica, 2021, 38(1): 239-245(in Chinese). [14] LIN L, WANG L, LI B, et al. Dual conductive network enabled superhydrophobic and high performance strain sensors with outstanding electro-thermal performance and extremely high gauge factors[J]. Chemical Engineering Journal,2020,385:123391. doi: 10.1016/j.cej.2019.123391 [15] REDONDO O, PROLONGO S G, CAMPO M, et al. Anti-icing and de-icing coatings based Joule's heating of graphene nanoplatelets[J]. Composites Science and Technology,2018,164:65-73. doi: 10.1016/j.compscitech.2018.05.031 [16] SABATIER J, LANUSSE P, FEYTOUT B, et al. Ice accretion detection and anti-icing/de-icing systems for wind turbine blades[M]//GUSIKHIN O, MADANI K. Lecture Notes in Electrical Engineering. Berlin: Springer, 2020: 641-663. [17] WANG F, TAY T E, SUN Y, et al. Low-voltage and -surface energy SWCNT/poly(dimethylsiloxane) (PDMS) nanocomposite film: Surface wettability for passive anti-icing and surface-skin heating for active deicing[J]. Composites Science and Technolog Y,2019,184:107872. [18] GOLOVIN K, DHYANI A, THOULESS M D, et al. Low-interfacial toughness materials for effective large-scale deicing[J]. Science,2019,364(6438):371. doi: 10.1126/science.aav1266 [19] DING L, WANG X, ZHANG W, et al. Microwave de-icing efficiency: Study on the difference between microwave frequencies and road structure materials[J]. Applied Sciences-Basel,2018,8(12):2360. [20] BANG S, LIM J, CHUN S, et al. A flexible graphene-polydimethylsiloxane nanocomposite force sensor with linear response across a wide pressure detection range[J]. Journal of Nanoscience and Nanotechnology,2019,19(3):1630-1634. doi: 10.1166/jnn.2019.16184 [21] LI H, DING G, YANG Z. A high sensitive flexible pressure sensor designed by silver nanowires embedded in polyimide (AgNW-PI)[J]. Micromachines,2019,10(3):206. [22] YANG J, LUO S, ZHOU X, et al. Flexible, tunable, and ultrasensitive capacitive pressure sensor with microconformal graphene electrodes[J]. Acs Applied Materials & Interfaces,2019,11(16):14997-15006. [23] PENG T, LIU B, GAO X, et al. Preparation, quantitative surface analysis, intercalation characteristics and industrial implications of low temperature expandable graphite[J]. Applied Surface Science,2018,444:800-810. doi: 10.1016/j.apsusc.2018.03.089 [24] MAKOTCHENKO V G, GRAYFER E D, NAZAROV A S, et al. The synthesis and properties of highly exfoliated graphites from fluorinated graphite intercalation compounds[J]. Carbon,2011,49(10):3233-3241. doi: 10.1016/j.carbon.2011.03.049 [25] 王希晰, 曹茂盛. 特色研究报告: 低维电磁功能材料研究进展[J]. 表面技术, 2020, 49(2):18-28.WANG X X, CAO M S. Low-dimensional electromagnetic functional materials[J]. Surface Technology,2020,49(2):18-28(in Chinese). [26] WANG M, GURUNATHAN R, IMASATO K, et al. A percolation model for piezoresistivity in conductor-polymer composites[J]. Advanced Theory and Simulations,2019,2:1800125. [27] KIM H S, KIM J H, KIM W Y, et al. Volume control of expanded graphite based on inductively coupled plasma and enhanced thermal conductivity of epoxy composite by formation of the filler network[J]. Carbon,2017,119:40-46. doi: 10.1016/j.carbon.2017.04.013 [28] YELLAPANTULA K, DEVARAJ H, ASSADIAN M, et al. Soft and flexible sensor array using carbon black pillars for object recognition via pressure mapping[J]. Measurement,2020,159:107781. doi: 10.1016/j.measurement.2020.107781 [29] BISWAS D K, SINCLAIR M, LE T, et al. Modeling and characterization of scaling factor of flexible spiral coils for wirelessly powered wearable sensors[J]. Sensors (Basel, Switzerland),2020,20(8):2282. [30] 田甜, 王渊, 陶明杰, 等. 石墨烯复合材料电热除冰实验研究[J]. 科学技术与工程, 2019, 19(28):390-395. doi: 10.3969/j.issn.1671-1815.2019.28.059TIAN T, WANG Y, TAO M J, et al. Experimental study on electro-thermal de-icing of graphene composites[J]. Science Technology and Engineering,2019,19(28):390-395(in Chinese). doi: 10.3969/j.issn.1671-1815.2019.28.059 -

下载:

下载: