Detection on debonding damage of fiber reinforced polymer composite strengthened concrete structure based on laser ultrasonic second harmonic generation technology

-

摘要: 纤维增强树脂(FRP)复合材料加固混凝土结构的早期剥离损伤往往趋向于闭合状态,传统线性超声技术对这种剥离损伤不敏感。本文提出了基于连续激光激发窄带超声波技术结合非线性超声二次谐波法检测FRP复合材料加固混凝土剥离损伤的方法,该方法通过强度调制激光技术在加固结构的表面激励窄带超声表面波,在超声波的扰动下,依据弹簧模型的接触非线性理论,结构中的剥离分层损伤在界面处将产生开合效应,利用声学非线性二次谐波响应检测定位出剥离损伤位置。基于仿真和实验研究结果,验证了该方法对FRP复合材料加固混凝土结构早期剥离损伤检测具备可行性,实现FRP复合材料加固混凝土结构的非接触式、高灵敏度损伤检测。

-

关键词:

- 激光超声 /

- 二次谐波 /

- 纤维增强树脂(FRP)复合材料加固混凝土结构 /

- 剥离损伤 /

- 有限元分析

Abstract: The early debonding damage of fiber reinforced polymer (FRP) composite strengthened concrete structure tends to be closed state, which can not be detected and located by traditional linear ultrasonic technology. Based on the continuous laser excited narrow-band ultrasonic technology combined with the nonlinear ultrasonic second harmonic method, a method of detecting the debonding damage of FRP composite strengthened concrete was proposed. This method uses intensity modulated laser technology to excite narrow-band ultrasonic surface wave on the surface of the reinforced structure. Under the ultrasonic disturbance, according to the contact nonlinear theory of the spring model, the debonding damage in the structure is in the boundary. The opening and closing effect will be produced on the surface, and the location of peel damage will be detected by acoustic nonlinear second harmonic response. Based on the results of simulation and experiment, the feasibility of this method for early debonding damage detection of FRP composite strengthened concrete structure was verified, and the non-contact and high sensitivity damage detection of FRP composite strengthened concrete structure was realized. -

表 1 粗骨料代表粒径级配及颗粒数

Table 1. Representative particle size grading and particle numbers of coarse aggregate

Aggregate diameter d0/mm Probability of d0

P (d<d0)Representative particle size/mm P(di)–P(di–1) Single particle area/mm2 Number of representative particle 5 0.333 — — — — 10 0.471 7.5 0.137 44.2 93 15 0.572 12.5 0.102 122.7 25 20 0.649 17.5 0.076 240.4 10 25 0.695 22.5 0.046 397.4 4 表 2 材料的热物理性能

Table 2. Thermophysical properties of materials

Material Density/

(kg·m−1)Specific heat

capacity/

(J(K·kg)−1)Coefficient of

heat conduction/

(W(K·m)−1)Concrete 2500 900 1.8 FRP 1800 850 3.0 表 3 FRP复合材料板物理参数

Table 3. Physical properties of FRP composite plate

Elasticity modulus E11/GPa Elasticity modulus E22, E33/GPa Poisson’s ratio ν12, ν13 Poisson’s ratio ν23 135 8.5 0.3 0.34 Shear modulus G11/GPa Shear modulus G22, G33/GPa Density $\rho $/ (kg·m−3) Coefficient of thermal expansion α/℃−1 4.47 3.35 1560 10−5 表 4 骨料和砂浆力学参数

Table 4. Mechanical parameters of aggregate and mortar

Material Elasticity modulus/GPa Poisson’s ratio Strength (Compressive/tensile)/MPa Ultimate compressive strain Aggregate 30 0.22 25/2.5 0.0033 Mortar 50 0.15 80/8.0 0.0016 表 5 FRP复合材料板剥离损伤的相对非线性系数量化指标

Table 5. Quantitative index of relative nonlinear coefficient of debonding damage of FRP composite plate

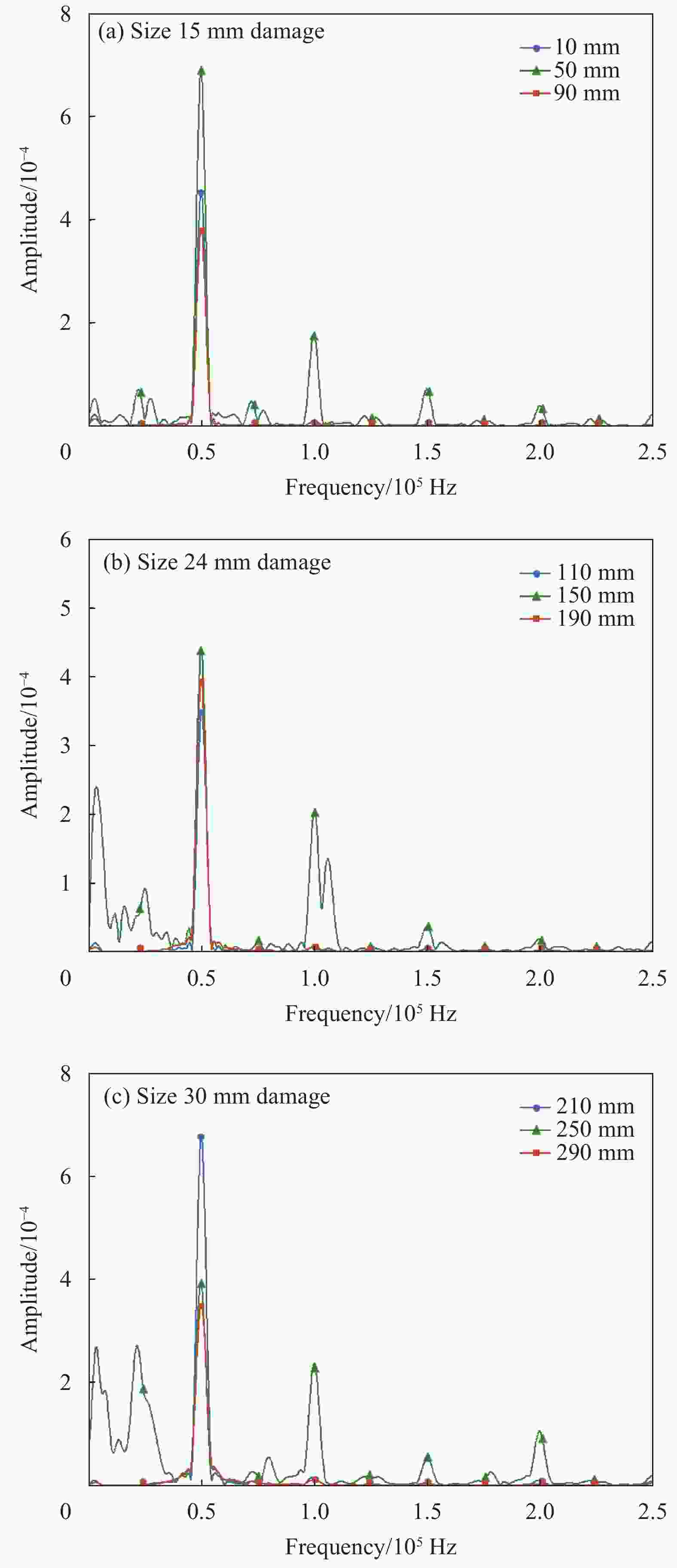

0.5 mm FRP Size 15 mm damage Size 24 mm damage Size 30 mm damage Ru Rd Ru Rd Ru Rd x/cm 35.5 51.5 132 146.5 229.5 249.5 $\beta '$/cm−1 0.50 2.80 0.56 5.26 0.46 8.30 $\beta {'_{\rm{d}}}/\beta {'_{\rm{u}}}$ 5.58 9.32 18.25 1.0 mm FRP Size 15 mm damage Size 24 mm damage Size 30 mm damage Ru Rd Ru Rd Ru Rd x/cm 24.0 47.0 131.5 150.0 227.0 252.5 $\beta '$/cm−1 17.53 27.26 2.43 92.42 4.29 65.49 $\beta {'_{\rm{d}}}/\beta {'_{\rm{u}}}$ 1.56 38.02 15.28 Notes: β′—Relative nonlinear coefficient; β′d/β′u—Damage quantification index; Ru—Undamaged area; Rd—Damaged area. 表 6 实验检测剥离损伤的相对非线性系数量化指标

Table 6. Quantitative index of relative nonlinear coefficient of debonding damage by experiment

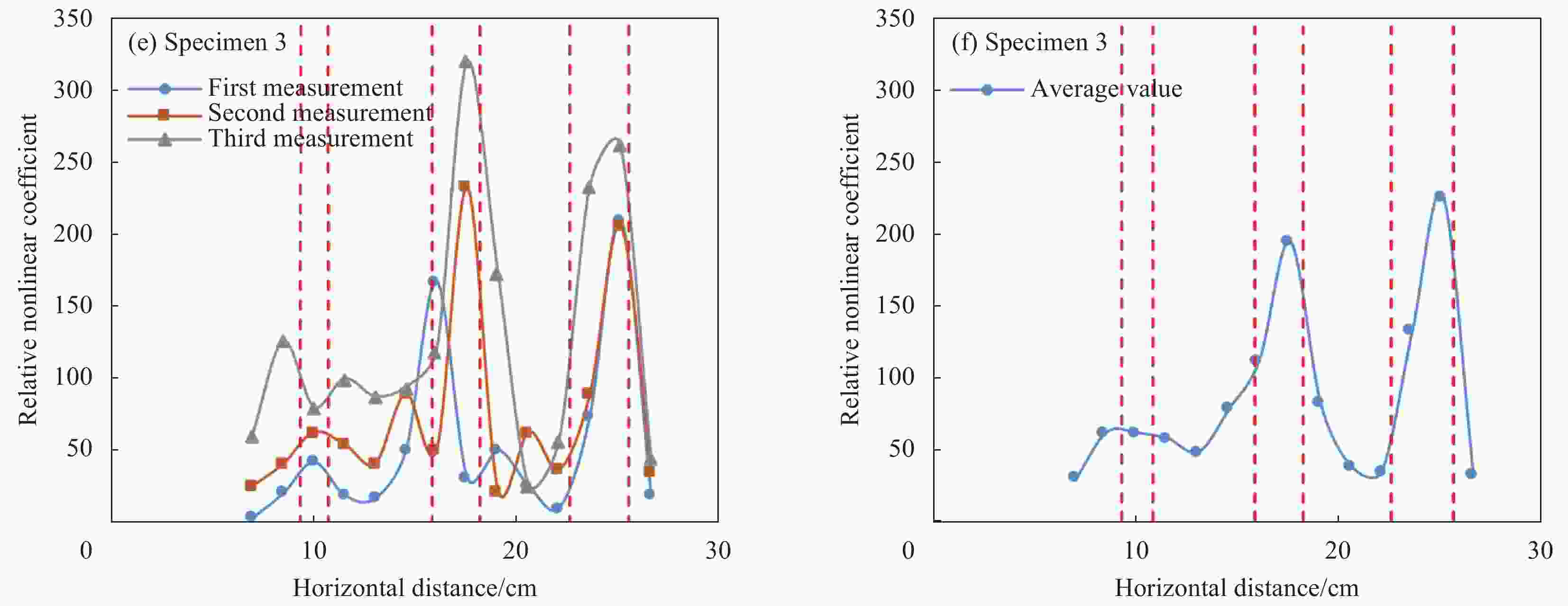

Specimen 1 Size 15 mm damage Size 24 mm damage Size 30 mm damage Ru Rd Ru Rd Ru Rd x/cm 8.5 10.0 14.5 16.0 22.0 25.0 $\beta '$/cm−1 24.22 60.65 15.17 51.34 32.25 88.55 $\beta {'_{\rm{d}}}/\beta {'_{\rm{u}}}$ 2.50 3.38 2.75 Specimen 2 Size 15 mm damage Size 24 mm damage Size 30 mm damage Ru Rd Ru Rd Ru Rd x/cm 8.5 10.0 14.5 16.0 22.0 23.5 $\beta '$/cm−1 43.50 216.27 143.31 99.00 107.44 179.91 $\beta {'_{\rm{d}}}/\beta {'_{\rm{u}}}$ 4.97 0.69 1.67 Specimen 3 Size 15 mm damage Size 24 mm damage Size 30 mm damage Ru Rd Ru Rd Ru Rd x/cm 8.5 10.0 14.5 17.5 22.0 25.0 $\beta '$/cm−1 62.74 62.20 78.32 193.91 35.57 225.18 $\beta {'_{\rm{d}}}/\beta {'_{\rm{u}}}$ 0.99 2.48 6.33 -

[1] ANTONOPOULOS C P, TRIANTAFILLOU T C. Experimental investigation of FRP-strengthened RC beam-column joints[J]. Journal of Composites for Construction,2003,7(1):39-49. doi: 10.1061/(ASCE)1090-0268(2003)7:1(39) [2] EL-GHANDOUR A. Experimental and analytical investigation of CFRP flexural and shear strengthening efficiencies of RC beams[J]. Construction & Building Materials,2011,25(3):1419-1429. [3] KELLER T. Recent all-composite and hybrid fibre-reinforced polymer bridges and buildings[J]. Progress in Structural Engineering and Materials,2001,3(2):132-140. doi: 10.1002/pse.66 [4] 李炳奇, 周月霞. 纤维复合材料加固混凝土结构的研究进展[J]. 水利与建筑工程学报, 2016, 14(1):85-90. doi: 10.3969/j.issn.1672-1144.2016.01.016LI Bingqi, ZHOU Yuexia. Research process of the concrete structure strengthened with fiber composite polymer[J]. Journal of Water Resources and Architectural Engineering,2016,14(1):85-90(in Chinese). doi: 10.3969/j.issn.1672-1144.2016.01.016 [5] SMITH S T, TENG J G. FRP-strengthened RC beams Ⅰ: Review of debonding strength models[J]. Engineering Structures,2002,24(4):385-395. doi: 10.1016/S0141-0296(01)00105-5 [6] MUKHOPADHYAYA P, SWAMY N. Interface shear stress: A new design criterion for plate debonding[J]. Journal of Composites for Construction,2001,5(1):35-43. doi: 10.1061/(ASCE)1090-0268(2001)5:1(35) [7] SEBASTIAN W M. Significance of midspan debonding failure in FRP-plated concrete beams[J]. Journal of Structural Engineering,2001,127(7):792-798. doi: 10.1061/(ASCE)0733-9445(2001)127:7(792) [8] CHEN G M, CHEN J F, TENG J G. Behaviour of FRP-to-concrete interfaces between two adjacent cracks: A numerical investigation on the effect of bondline damage[J]. Construction and Building Materials,2012,28(1):584-591. doi: 10.1016/j.conbuildmat.2011.08.074 [9] TENG J G, SMITH S T, YAO J, et al. Intermediate crack-induced debonding in RC beams and slabs[J]. Construction and Building Materials,2003,17(6-7):447-462. doi: 10.1016/S0950-0618(03)00043-6 [10] BUYUKOZTURK O, GUNES O, KARACA E. Progress on understanding debonding problems in reinforced concrete and steel members strengthened using FRP composites[J]. Construction and Building Materials,2004,18(1):9-19. doi: 10.1016/S0950-0618(03)00094-1 [11] 刘怀喜, 张恒, 马润香. 复合材料无损检测方法[J]. 无损检测, 2003, 25(12):631-634. doi: 10.3969/j.issn.1000-6656.2003.12.010LIU Huaixi, ZHANG Heng, MA Runxiang. Nondestructive testing techniques for composite materials[J]. Nondestructive Testing,2003,25(12):631-634(in Chinese). doi: 10.3969/j.issn.1000-6656.2003.12.010 [12] 李士伟, 林维正, 李少波, 等. 混凝土损伤的超声检测试验研究[J]. 无损检测, 2004, 26(3):127-141. doi: 10.3969/j.issn.1000-6656.2004.03.006LI Shiwei, LIN Weizheng, LI Shaobo, et al. Test research on ultrasonic testing of concrete damage[J]. Nondestructive Testing,2004,26(3):127-141(in Chinese). doi: 10.3969/j.issn.1000-6656.2004.03.006 [13] NAGY P B. Fatigue damage assessment by nonlinear ultrasonic materials characterization[J]. Ultrasonics,1998,36(1):375-381. [14] 张晓春, 陈立军. 固体中激光超声的机理及应用研究[J]. 传感器与微系统, 1999, 18(4):15-16. doi: 10.3969/j.issn.1000-9787.1999.04.007ZHANG Xiaochun, CHEN Lijun. Study on principle and application of laser-generated ultrasonic in solid[J]. Transducer and Microsystem Technologies,1999,18(4):15-16(in Chinese). doi: 10.3969/j.issn.1000-9787.1999.04.007 [15] MCCANN D M, FORDE M C. Review of NDT methods in the assessment of concrete and masonry structures[J]. NDT & E International,2001,34(2):71-84. [16] 田玉滨, 莫青城, 杜文淼, 等. 基于非线性超声技术损伤钢筋混凝土无损检测的适用性研究[J]. 西安建筑科技大学学报: 自然科学版, 2017, 49(2):192-199.TIAN Yubin, MO Qingcheng, DU Wenmiao, et al. Research of applicability of non-destructive testing for damaged reinforced concrete basd on nonlinear ultrasonic technology[J]. Journal of Xi’an University of Architecture & Technology (Natural Science Edition),2017,49(2):192-199(in Chinese). [17] DELRUE S, ABEELE K V B. Three-dimensional finite element simulation of closed delaminations in composite materials[J]. Ultrasonics,2012,52(2):315-324. doi: 10.1016/j.ultras.2011.09.001 [18] 周正干, 刘斯明. 非线性无损检测技术的研究、应用和发展[J]. 机械工程学报, 2011, 47(8):2-11. doi: 10.3901/JME.2011.08.002ZHOU Zhenggan, LIU Siming. Nonlinear ultrasonic techniques used in nondestructive testing: A review[J]. Journal of Mechanical Engineering,2011,47(8):2-11(in Chinese). doi: 10.3901/JME.2011.08.002 [19] DAVIES S J, EDWARDS C, TAYLOR G S, et al. Laser-generated ultrasound: Its properties, mechanisms and multifarious applications[J]. Journal of Physics D: Applied Physics,1993,26(3):329-348. doi: 10.1088/0022-3727/26/3/001 [20] WOODWARD C B, STAUFFER J D. Nonlinear ultrasonic testing with resonant and pulse velocity parameters for early damage in concrete[J]. ACI Materials Journal,2005,102(2):118-121. [21] ROE S E, WOODWARD C, CRAMER M J. Nonlinear ultrasonic testing on a laboratory concrete bridge deck[J]. AIP Conference Proceedings, 2007, 894(1): 1429-1434. [22] LEŚNICKI K J, KIM J Y, KURTIS K E, et al. Characterization of ASR damage in concrete using nonlinear impact resonance acoustic spectroscopy technique[J]. NDT & E International,2011,44(8):721-727. [23] KIM G, IN C W, KIM J Y, et al. Air-coupled detection of nonlinear rayleigh surface waves in concrete: Application to microcracking detection[J]. NDT & E International,2014,67(8):64-70. [24] DONSKOY D, SUTIN A, EKIMOV A. Nonlinear acoustic interaction on contact interfaces and its use for nondestructive testing[J]. NDT & E International,2001,34(4):231-238. [25] 许颖, 刘志安, 邵长军. FRP加固结构界面损伤的声-光纤检测数值模拟及实验[J]. 复合材料学报, 2014, 31(6):1588-1596.XU Ying, LIU Zhian, SHAO Changjun. Numerical simulation and experiment for acoustic-optical fiber based detection of interfacial damage in FRP-retrofitted structures[J]. Acta Materiae Compositae Sinica,2014,31(6):1588-1596(in Chinese). -

下载:

下载: