Micromechanical model of tensile properties of poplar fiber/polyethylene composite

-

摘要: 制备了不同杨木纤维含量的杨木纤维/聚乙烯复合材料,利用Hirsch模型、Kelly-Tyson模型和Bowyer-Bader模型对杨木纤维/聚乙烯复合材料的微观力学进行建模,通过对杨木纤维/聚乙烯复合材料及塑料基体的拉伸应力-应变曲线和杨木纤维长度分布的研究,计算得到杨木纤维在聚乙烯基体中的取向系数、界面剪切强度和本征抗拉强度,解释了杨木纤维/聚乙烯复合材料拉伸性能的变化规律。此外,利用微观力学模型计算得到了亚临界纤维、超临界纤维、塑料基体对杨木纤维/聚乙烯复合材料拉伸强度的贡献比例。

-

关键词:

- 微观力学 /

- 纤维含量 /

- 拉伸性能 /

- Kelly-Tyson模型 /

- Bowyer-Bader模型

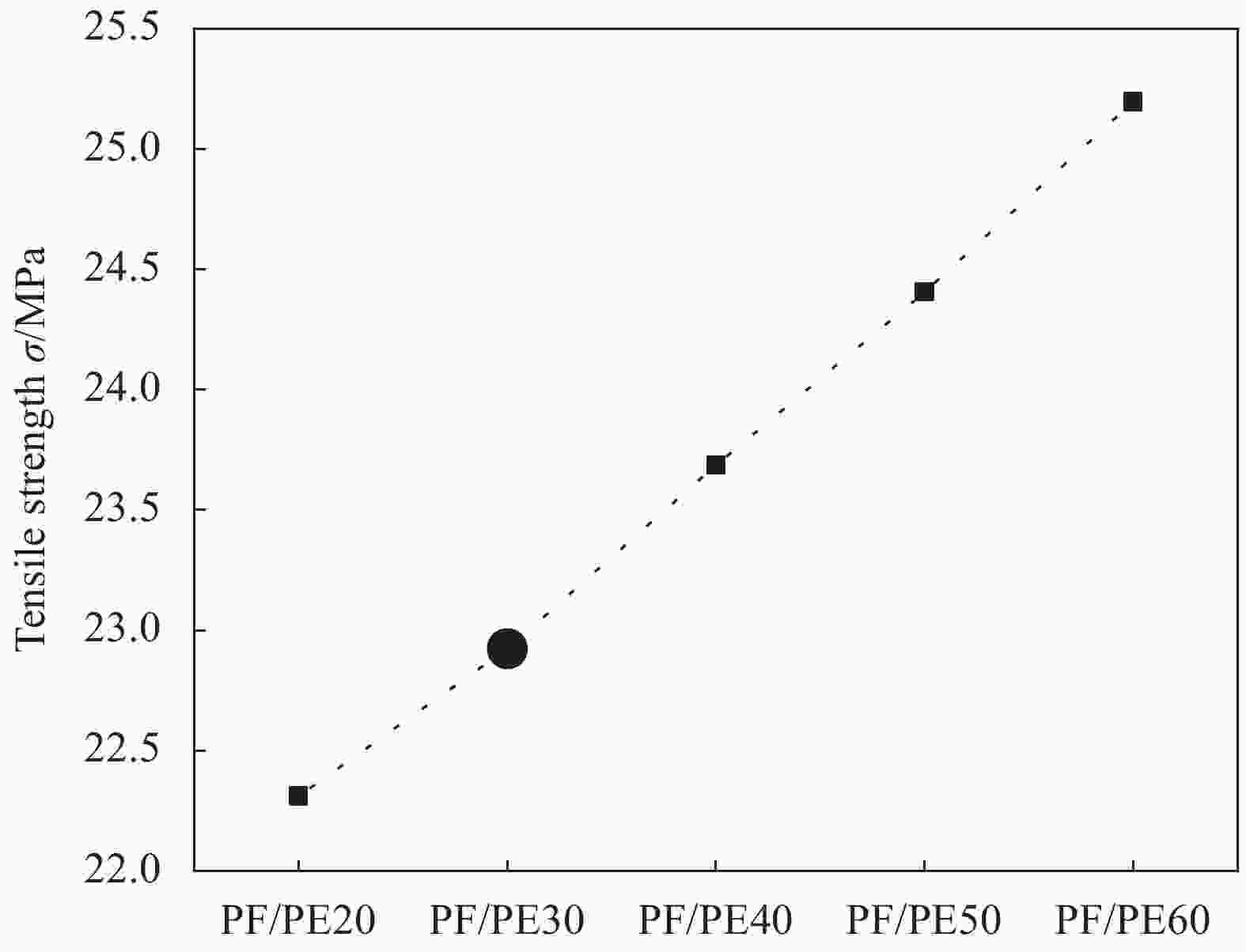

Abstract: The poplar fiber/polyethylene composites with different contents of poplar fiber were prepared. The micromechanics of poplar fiber/polyethylene composites were modeled by Hirsch model, Kelly-Tyson model and Bowyer-Bader model. By studying the tensile stress-strain curves of the poplar fiber/polyethylene composite and plastic matrix and the length distribution of poplar fiber in the composite, the orientation coefficient, interfacial shear strength and intrinsic tensile strength of poplar fiber in polyethylene matrix were calculated, and the variation law of the tensile properties of poplar fiber/polyethylene composites was explained. In addition, the contribution ratio of subcritical fiber, supercritical fiber, plastic matrix to the tensile strength of poplar/polyethylene composites was obtained by using micromechanical model calculation.-

Key words:

- micromechanics /

- fiber content /

- tensile behavior /

- Kelly-Tyson model /

- Bowyer-Bader model

-

表 1 杨木纤维/聚乙烯复合材料的配方

Table 1. Formulation of poplar fiber/ polyethylene composites

Group Poplar fiber/

wt%HDPE/

wt%MAPE/

wt%Lubricant/

wt%PF/PE0 0 100 0 0 PF/PE20 20 75 3 2 PF/PE30 30 65 3 2 PF/PE40 40 55 3 2 PF/PE50 50 45 3 2 PF/PE60 60 35 3 2 Notes: PF—Poplar fiber; PE—Polyethylene; HDPE—High-density polyethylene; MAPE—Maleic anhydride grafted polyethylene. 表 2 杨木纤维的平均长度、直径和长径比

Table 2. Average length, diameter and aspect ratio of poplar fibers

Average length/μm Average diameter/μm Average aspect ratio 290.35 (314.89) 50.00 (10.24) 5.807 Note: Figures in parentheses represent standard deviations. 表 3 杨木纤维/聚乙烯复合材料的杨木纤维体积分数(Vf)

Table 3. Volume fraction of poplar fiber in poplar fiber/polyethylene composites (Vf)

Group PF/PE0 PF/PE20 PF/PE30 PF/PE40 PF/PE50 PF/PE60 ${V_{\rm{f}}}$/vol% 0 15.4 23.8 32.8 42.2 52.3 表 4 杨木纤维/聚乙烯复合材料在应变水平1和2(

${\varepsilon _1}$ 和${\varepsilon _2}$ )时的参数Table 4. Parameters of poplar fiber/polyethylene composites at strain level 1 and 2 (

${\varepsilon _1}$ and${\varepsilon _2}$ )Sample PF/PE20 PF/PE30 PF/PE40 PF/PE50 PF/PE60 ${\varepsilon _1}$/% 0.5 0.75 0.35 0.35 0.3 ${\sigma _{{{\rm{c}}_1}}}$/MPa 10.5 15.1 11.8 13.1 13.5 ${\sigma _{{{\rm{m}}_1}}}$/MPa 5.01 7.02 3.5 3.5 3.25 ${L_{{\varepsilon _1}}}$/μm 472.7 189.1 264.7 220.6 270.1 ${\varepsilon _2}$/% 1.0 1.5 0.7 0.7 0.6 ${\sigma _{{{\rm{c}}_2}}}$/MPa 15.4 20.2 18.2 20.75 20.75 ${\sigma _{{{\rm{m}}_2}}}$/MPa 8.7 10.89 6.47 6.47 5.68 ${L_{{\varepsilon _2}}}$/μm 945.4 378.2 529.4 441.2 540.2 Notes: $\varepsilon $—Strain; ${\sigma _{{{\rm{c}}_{}}}}$—Stress of poplar fiber/polyethylene composites; ${\sigma _{{{\rm{m}}_{}}}}$—Stress of polyethylene; ${L_\varepsilon }$—Critical fiber length; Subscripts 1, 2—Two strain levels. 表 5 杨木纤维/聚乙烯复合材料参数的计算结果

Table 5. Calculation results of parameters of poplar fiber/polyethylene composites

Sample PF/PE20 PF/PE30 PF/PE40 PF/PE50 PF/PE60 $\tau $/MPa 4.13 5.07 5.19 6.11 4.56 $K$ 0.940 0.665 0.730 0.621 0.718 ${\sigma _{\rm{f}}}$/MPa 80 80 100 135 75 Notes: $\tau $—Interfacial shear strength of poplar fibers and plastics; $K$—Spatial orientation coefficient of poplar fibers; ${\sigma _{\rm{f}}}$—Intrinsic tensile strength of poplar fibers. -

[1] IBRAHIM H, MEHANNY S, DARWISH L, et al. A comparative study on the mechanical and biodegradation characteristics of starch-based composites reinforced with different lignocellulosic fibers[J]. Journal of Polymers and the Environment, 2018, 26(6): 2434-2447. [2] 王瑞, 王春红. 亚麻落麻纤维增强可降解复合材料的拉伸强度预测[J]. 复合材料学报, 2009, 26(1):43-47. doi: 10.3321/j.issn:1000-3851.2009.01.008WANG Rui, WANG Chunhong. Prediction of tensile strength of flax noil fibers reinforced biodegradable composite[J]. Acta Materiae Compositae Sinica,2009,26(1):43-47(in Chinese). doi: 10.3321/j.issn:1000-3851.2009.01.008 [3] DELGADO-AGUILAR M, REIXACH R, TARRÉS Q, et al. Bleached kraft eucalyptus fibers as reinforcement of poly(lactic acid) for the development of high-performance biocomposites[J]. Polymers, 2018, 10(7): 699. [4] PHUA Y J, PEGORETTI A, MOHD ISHAK Z A. Experimental analysis and theoretical modeling of the mechanical behavior of starch-grafted-polypropylene/kenaf fibers composites[J]. Polymer Composites, 2018, 39(9): 3289-3299. [5] 栗越, 张京发, 易顺民, 等. 改性芳纶纤维增强木粉/高密度聚乙烯复合材料的力学性能[J]. 复合材料学报, 2019, 36(3):638-645.LI Yue, ZHANG Jingfa, YI Shunmin, et al. Mechanical properties of modified aramid fiber reinforced wood flour/high density polyethylene composites[J]. Acta Materiae Compositae Sinica,2019,36(3):638-645(in Chinese). [6] 朱碧华, 何春霞, 石峰, 等. 三种壳类植物纤维/聚氯乙烯复合材料性能比较[J]. 复合材料学报, 2017, 34(2):291-297.ZHU Bihua, HE Chunxia, SHI Feng, et al. Performance comparison of three kinds of husk’s fibers/polyvinyl chloride composites[J]. Acta Materiae Compositae Sinica,2017,34(2):291-297(in Chinese). [7] 曹岩. 纤维尺寸及分布对WPCs力学性能的影响[D]. 哈尔滨: 东北林业大学, 2013.CAO Yan. Effect of fiber size and distribution on the mechanical properties of WPCs[D]. Harbin: Northeast Forestry University, 2013(in Chinese). [8] HALPIN J C, TSAI S W. Environmental factors in composite materials design: Technical Report AFML-TR[R]. United State Air Force Materials Laboratory, 1969. [9] KALAPRASAD G, JOSEPH K, THOMAS S, et al. Theoretical modelling of tensile properties of short sisal fibre-reinforced low-density polyethylene composites[J]. Journal of Materials Science, 1997, 32(16): 4261-4267. [10] HASSANZADEH-AGHDAM M K, JAMALI J. A new form of a Halpin-Tsai micromechanical model for characterizing the mechanical properties of carbon nanotube-reinforced polymer nanocomposites[J]. Bulletin of Materials Science, 2019, 42(3): 117. [11] CLIFFORD M J, WAN T. Fibre reinforced nanocomposites: Mechanical properties of PA6/clay and glass fibre/PA6/clay nanocomposites[J]. Polymer, 2010, 51(2): 535-539. [12] COX H L. The elasticity and strength of paper and other fibrous materials[J]. British Journal of Applied Physics,1952,3(3):72-79. [13] MIGNEAULT S, KOUBAA A, ERCHIQUI F, et al. Application of micromechanical models to tensile properties of wood-plastic composites[J]. Wood Science and Technology, 2011, 45(3): 521-532. [14] GUN H, KOSE G. Prediction of longitudinal modulus of aligned discontinuous fiber-reinforced composites using boundary element method[J]. Science and Engineering of Composite Materials, 2014, 21(2): 219-221. [15] KELLY A, TYSON W R. Tensile properties of fibre-reinforced metals: Copper/tungsten and copper/molybdenum[J]. Journal of the Mechanics and Physics of Solids, 1965, 13(6): 329-338. [16] LI Y, PICKERING K L, FARRELL R L. Determination of interfacial shear strength of white rot fungi treated hemp fibre reinforced polypropylene[J]. Composites Science and Technology, 2009, 69(7-8): 1165-1171. [17] SERRANO A, ESPINACH F X, JULIAN F, et al. Estimation of the interfacial shears strength, orientation factor and mean equivalent intrinsic tensile strength in old newspaper fiber/polypropylene composites[J]. Composites Part B: Engineering, 2013, 50: 232-238. [18] YAN X, YANG Y, HAMADA H. Tensile properties of glass fiber reinforced polypropylene composite and its carbon fiber hybrid composite fabricated by direct fiber feeding injection molding process[J]. Polymer Composites, 2018, 39(10): 3564-3574. [19] LAW T T, PHUA Y J, SENAWI R, et al. Experimental analysis and theoretical modeling of the mechanical behavior of short glass fiber and short carbon fiber reinforced polycarbonate hybrid composites[J]. Polymer Composites, 2016, 37(4): 1238-1248. [20] ASTM International. Standard test method for tensile properties of plastics: ASTM D638—14[S]. West Conshohocken: ASTM International, 2014. [21] VALLEJOS M E, ESPINACH F X, JULIÁN F, et al. Micromechanics of hemp strands in polypropylene composites[J]. Composites Science and Technology, 2012, 72(10): 1209-1213. [22] ESPINACH F X, JULIAN F, VERDAGUER N, et al. Analysis of tensile and flexural modulus in hemp strands/polypropylene composites[J]. Composites Part B: Engineering, 2013, 47: 339-343. [23] LÓPEZ J P, BOUFI S, MANSOURI N E E, et al. PP composites based on mechanical pulp, deinked newspaper and jute strands: A comparative study[J]. Composites Part B: Engineering, 2012, 43(8): 3453-3461. [24] YAN X, CAO S. Structure and interfacial shear strength of polypropylene-glass fiber/carbon fiber hybrid composites fabricated by direct fiber feeding injection molding[J]. Composite Structures, 2018, 185: 362-372. [25] BOWYER W H, BADER H G. On the reinforcement of thermoplastics by imperfectly aligned discontinuous fibres[J]. Materials. Science, 1972, 4(3): 1315-1321. [26] HIRSCH T. Modulus of elasticity of concrete affected by elastic moduli of cement paste matrix and aggregate[J]. American Concrete Institute. 1962, 59(1): 154-427. [27] SERRANO A, ESPINACH F X, TRESSERRAS J, et al. Macro and micromechanics analysis of short fiber composites stiffness: The case of old newspaper fibers-polypropylene composites[J]. Materials & Design, 2014, 55: 319-324. [28] OLIVER-ORTEGA H, CHAMORRO-TRENADO M À, SOLER J, et al. Macro and micromechanical preliminary assessment of the tensile strength of particulate rapeseed sawdust reinforced polypropylene copolymer biocomposites for its use as building material[J]. Construction and Building Materials, 2018, 168: 422-430. [29] ZHANG Y, ZHANG S Y, CHOI P. Effects of wood fiber content and coupling agent content on tensile properties of wood fiber polyethylene composites[J]. Holz als Roh- und Werkstoff, 2008, 66(4): 267-274. [30] EL-SHEKEIL Y A, SAPUAN S M, ABDAN K, et al. Influence of fiber content on the mechanical and thermal properties of Kenaf fiber reinforced thermoplastic polyurethane composites[J]. Materials & Design, 2012, 40: 299-303. [31] VENKATESHWARAN N, ELAYAPERUMAL A, JAGATHEESHWARAN M S. Effect of fiber length and fiber content on mechanical properties of banana fiber/epoxy composite[J]. Journal of Reinforced Plastics and Composites, 2011, 30(19): 1621-1627. [32] 宋丽贤, 张平, 姚妮娜, 等. 木粉粒径和填量对木塑复合材料力学性能影响研究[J]. 功能材料, 2013, 44(17): 2451-2454.SONG Lixian, ZHANG Ping, YAO Nina, et al. Study on effect of particle diameter and filling quantity of wood flour on mechanical properties of wood-plastics composite[J]. Journal of Functional Materials, 2013, 44(17): 2451-2454(in Chinese). -

下载:

下载: