| [1] |

SU Y S, ZHANG D, GONG X L, et al. Mechanical behavior in bending deformation of thermoplastic composite laminates with different stacking sequences[J]. Journal of Composite Materials,2015,50(8):1037-1048.

|

| [2] |

BORIA S, SCATTINA A, BELINGARDI G. Impact behavior of a fully thermoplastic composite[J]. Composite Structures,2017,167:63-75. doi: 10.1016/j.compstruct.2017.01.083

|

| [3] |

LU K, SHANKAR K. Wrinkling behavior of a woven thermoplastic composite material[J]. Materials Science Forum,2017,893:26-30. doi: 10.4028/www.scientific.net/MSF.893.26

|

| [4] |

石峰晖, 代志双, 张宝艳. 碳纤维表面性质分析及其对复合材料界面性能的影响[J]. 航空材料学报, 2010, 30(3):43-47. doi: 10.3969/j.issn.1005-5053.2010.3.010SHI F H, DAI Z S, ZHANG B Y. Characterization of surface properties of carbon fibers and interfacial properties of carbon fiber reinforced matrix composites[J]. Journal of Aeronautical Materials,2010,30(3):43-47(in Chinese). doi: 10.3969/j.issn.1005-5053.2010.3.010

|

| [5] |

WU Z J, CUI H Y, CHEN L, et al. Interfacially reinforced unsaturated polyester carbon fiber composites with a vinyl ester-carbon nanotubes sizing agent[J]. Composites Science and Technology,2018,164:195-203. doi: 10.1016/j.compscitech.2018.05.051

|

| [6] |

DAI Z S, ZHANG B Y, SHI F H, et al. Chemical interaction between carbon fibers and surface sizing[J]. Journal of Applied Polymer Science,2012,124(3):2127-2132. doi: 10.1002/app.35226

|

| [7] |

GAMZE KARSLI N, OZKAN C, AYTAC A, et al. Effects of sizing materials on the properties of carbon fiber-reinforced polyamide 6, 6 composites[J]. Polymer Composites,2013,34(10):1583-1590. doi: 10.1002/pc.22556

|

| [8] |

鲁佳腾, 颜春, 徐海兵, 等. 热塑性碳纤维上浆剂的研究进展[J]. 玻璃钢/复合材料, 2017(6):94-99. doi: 10.3969/j.issn.1003-0999.2017.06.017LU J T, YAN C, XU H B, et al. Research progress on thermoplastic sizing agent for carbon fibers[J]. Fiber Reinforced Plastics/Composites,2017(6):94-99(in Chinese). doi: 10.3969/j.issn.1003-0999.2017.06.017

|

| [9] |

张宝艳. 先进复合材料界面技术[M]. 北京: 航空工业出版社, 2017.ZHANG B Y. Interfacial technology of advanced composites[M]. Beijing: Aviation Industry Press, 2017(in Chinese).

|

| [10] |

张凤翻. 先进热塑性树脂预浸料用原材料[J]. 高科技纤维与应用, 2014, 39(3):1-6. doi: 10.3969/j.issn.1007-9815.2014.03.001ZHANG F F. Raw materials for advanced thermoplastic resin prepreg[J]. Hi-Tech Fiber <italic>&</italic> Application,2014,39(3):1-6(in Chinese). doi: 10.3969/j.issn.1007-9815.2014.03.001

|

| [11] |

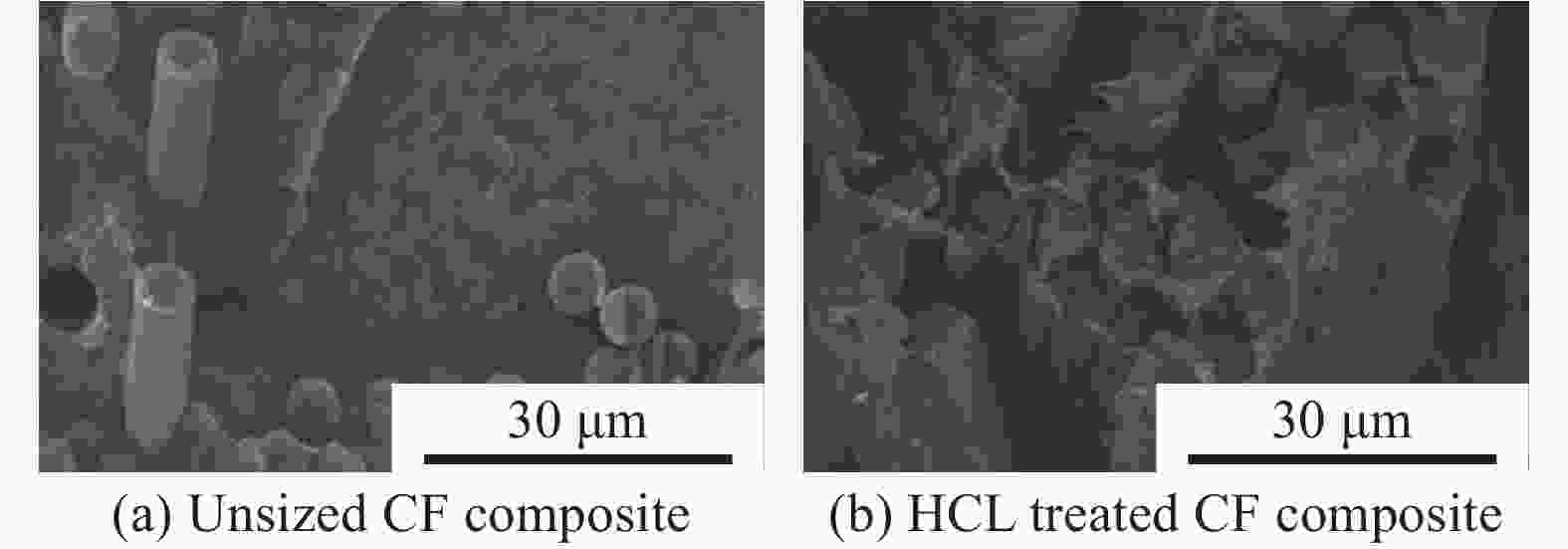

李鹏, 季春晓, 刘瑞超, 等. 国内碳纤维上浆剂技术专利分析[J]. 石油化工技术与经济, 2018, 34(1):55-61. doi: 10.3969/j.issn.1674-1099.2018.01.014LI P, JI C X, LIU R C, et al. Study on domestic patent application of carbon fibers sizing[J]. Technology <italic>&</italic> Economics in Petrochemicals,2018,34(1):55-61(in Chinese). doi: 10.3969/j.issn.1674-1099.2018.01.014

|

| [12] |

ZHAO Y Z, LIU F Y, LU J, et al. Si-Al hybrid effect of waterborne polyurethane hybrid sizing agent for carbon fiber/PA6 composites[J]. Fibers and Polymers,2017,18(8):1586-1593. doi: 10.1007/s12221-017-1257-8

|

| [13] |

王昊, 颜春, 徐海兵, 等. 碳纤维上浆剂的研究进展[J]. 热固性树脂, 2016, 31(3):65-69.WANG H, YAN C, XU H B, et al. Research progress of carbon fiber sizing agent[J]. Thermosetting Resin,2016,31(3):65-69(in Chinese).

|

| [14] |

郝瑞婷, 张学军, 田艳红. 耐热型热塑性上浆剂研究进展[J]. 化工进展, 2018, 37(S1):117-124.HAO R T, ZHANG X J, TIAN Y H. Research progress of heat-resistant thermoplastic sizing agents[J]. Chemical Industry and Engineering Progress,2018,37(S1):117-124(in Chinese).

|

| [15] |

李金亮, 高小茹. 碳纤维上浆剂的研究进展[J]. 纤维复合材料, 2015(4):37-40. doi: 10.3969/j.issn.1003-6423.2015.04.009LI J L, GAO X R. Advances in sizing agent for carbon fiber[J]. Fiber Composites,2015(4):37-40(in Chinese). doi: 10.3969/j.issn.1003-6423.2015.04.009

|

| [16] |

李松荣, 胡照会, 黄其忠. 碳纤维热塑性上浆剂研究进展[J]. 纤维复合材料, 2017(2):3-7. doi: 10.3969/j.issn.1003-6423.2017.02.001LI S R, HU Z H, HUANG Q Z. Progress in thermoplastic sizing agent for carbon fiber[J]. Fiber Composites,2017(2):3-7(in Chinese). doi: 10.3969/j.issn.1003-6423.2017.02.001

|

| [17] |

YAO T T, LIU Y T, ZHU H, et al. Controlling of resin impregnation and interfacial adhesion in carbon fiber/polycarbonate composites by a spray-coating of polymer on carbon fibers[J]. Composites Science and Technology,2019,182:107763. doi: 10.1016/j.compscitech.2019.107763

|

| [18] |

YAMAMOTO T, UEMATSU K, IRISAWA T, et al. A polymer colloidal technique for enhancing bending properties of carbon fiber-reinforced thermoplastics using nylon modifier[J]. Composites Part A: Applied Science and Manufacturing,2018,112:250-254. doi: 10.1016/j.compositesa.2018.06.011

|

| [19] |

GAMZE KARSLI N, OZKAN C, AYTAC A, et al. Characterization of poly(butylene terephthalate) composites prepared by using various types of sized carbon fibers[J]. Materials <italic>& </italic>Design,2015,87:318-323.

|

| [20] |

XU B, WANG X S, LU Y. Surface modification of polyacrylonitrile-based carbon fiber and its interaction with imide[J]. Applied Surface Science,2006,253(5):2695-2701. doi: 10.1016/j.apsusc.2006.05.044

|

| [21] |

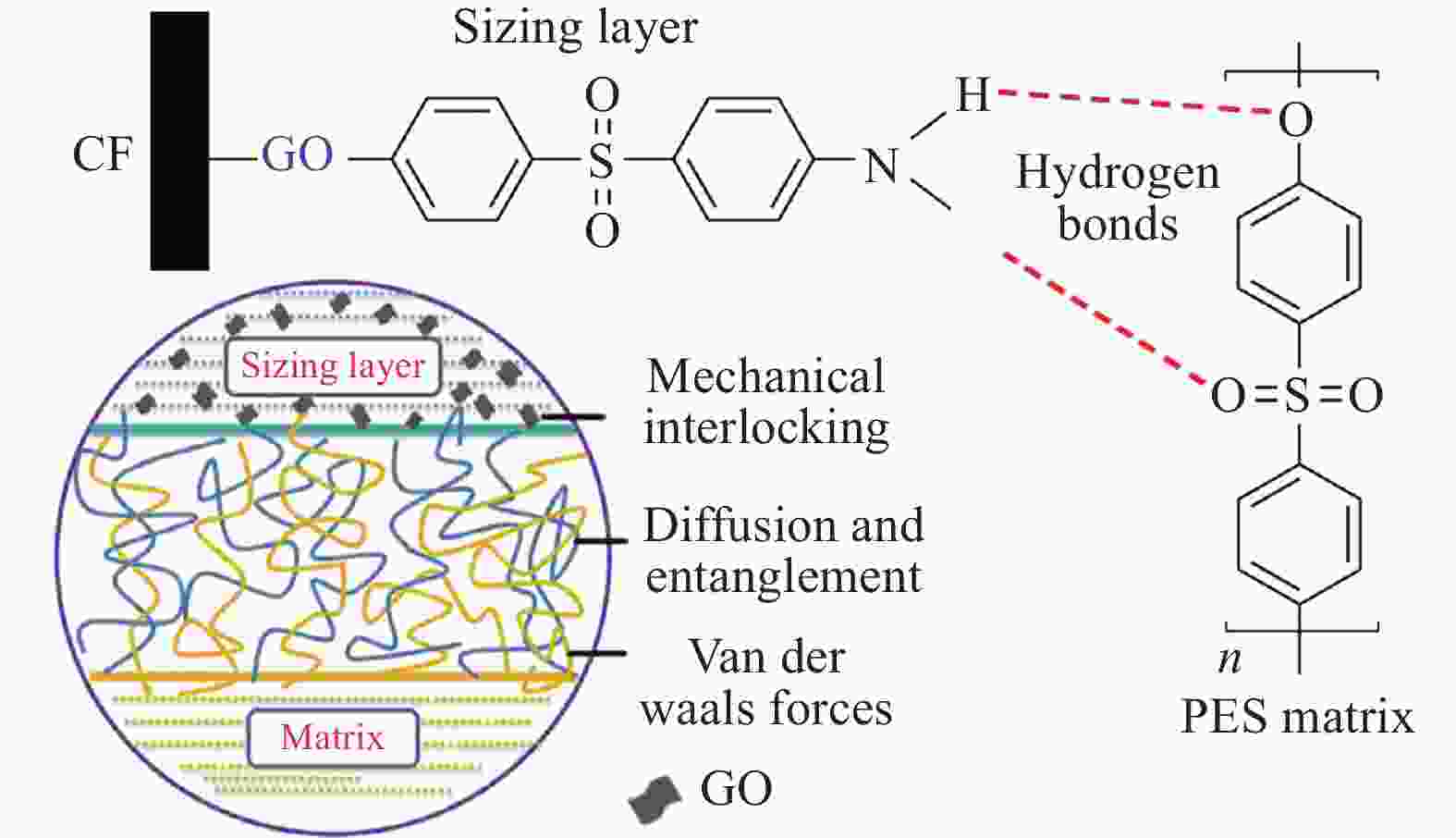

LIU L, YAN F, LI M, et al. A novel thermoplastic sizing containing graphene oxide functionalized with structural analogs of matrix for improving interfacial adhesion of CF/PES composites[J]. Composites Part A: Applied Science and Manufacturing,2018,114:418-428. doi: 10.1016/j.compositesa.2018.09.004

|

| [22] |

张学军, 郝瑞婷, 田艳红, 等. 一种碳纤维用耐热型水性上浆剂及其制备方法和应用. 中国: ZL 201810868788.6[P]. 2020-04-15.ZHANG X J, HAO R T, TIAN Y H, et al. Preparation and application of an heat resistant waterborne sizing agent for carbon fiber. China: ZL 201810868788.6[P]. 2020-04-15(in Chinese).

|

| [23] |

水兴瑶. 应用于热塑性基体的碳纤维水性上浆剂的制备及性能研究[D]. 杭州: 浙江理工大学, 2016.SHUI X Y. Preparation and properties of the waterborne sizing agent applied to thermoplastic matrix for carbon fiber[D]. Hangzhou: Zhejiang Sci-Tech University, 2016(in Chinese).

|

| [24] |

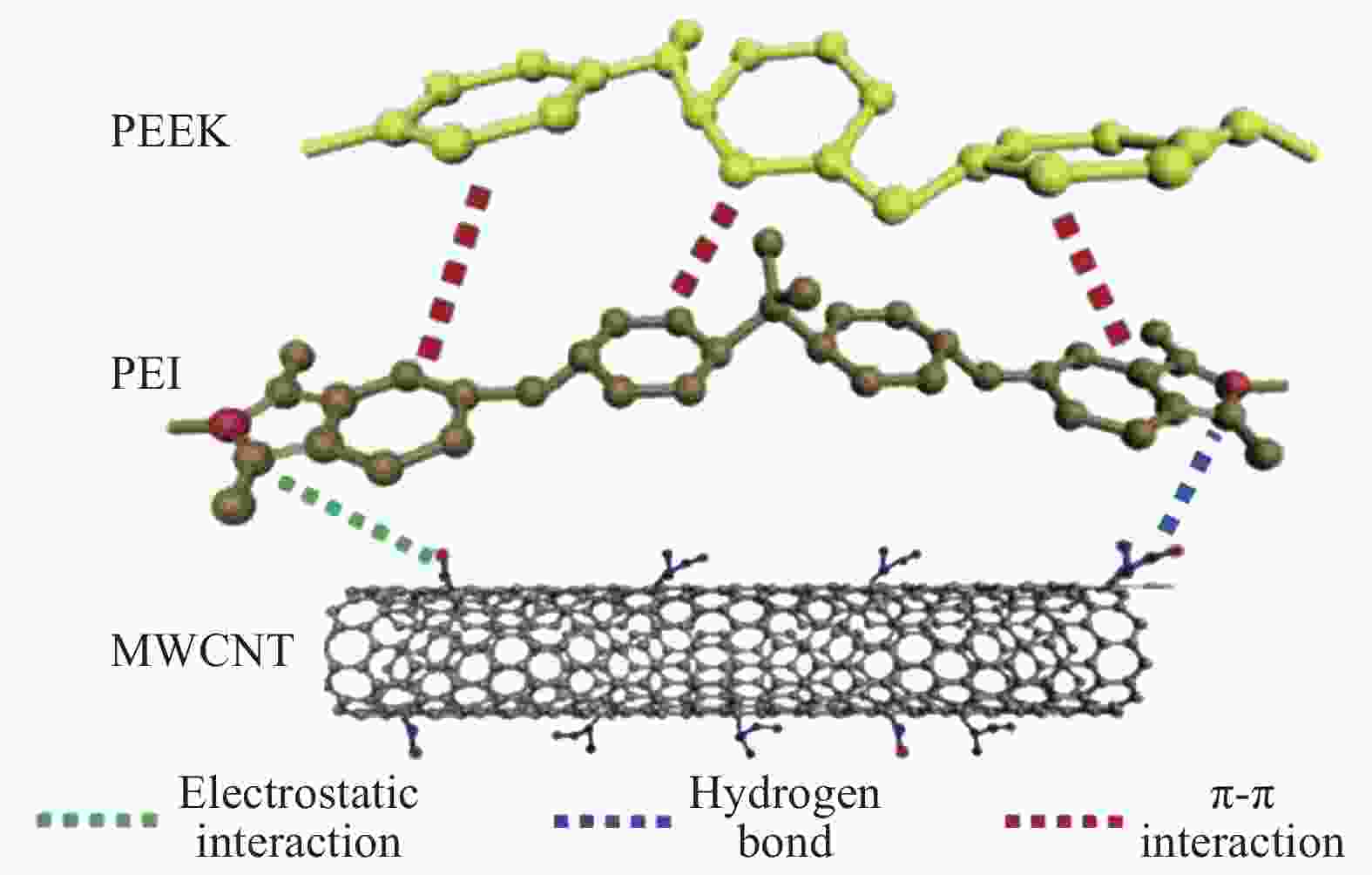

HASSAN E A M, YANG L, ELAGIB T H H, et al. Synergistic effect of hydrogen bonding and π-π stacking in interface of CF/PEEK composites[J]. Composites Part B: Engineering,2019,171:70-77. doi: 10.1016/j.compositesb.2019.04.015

|

| [25] |

RAN J, LAI X, LI H, et al. Remarkable enhancement of mechanical and tribological properties of polyamide 46/polyphenylene oxide alloy by polyurethane-coated carbon fiber[J]. High Performance Polymers,2019,31(9-10):1122-1131. doi: 10.1177/0954008319827639

|

| [26] |

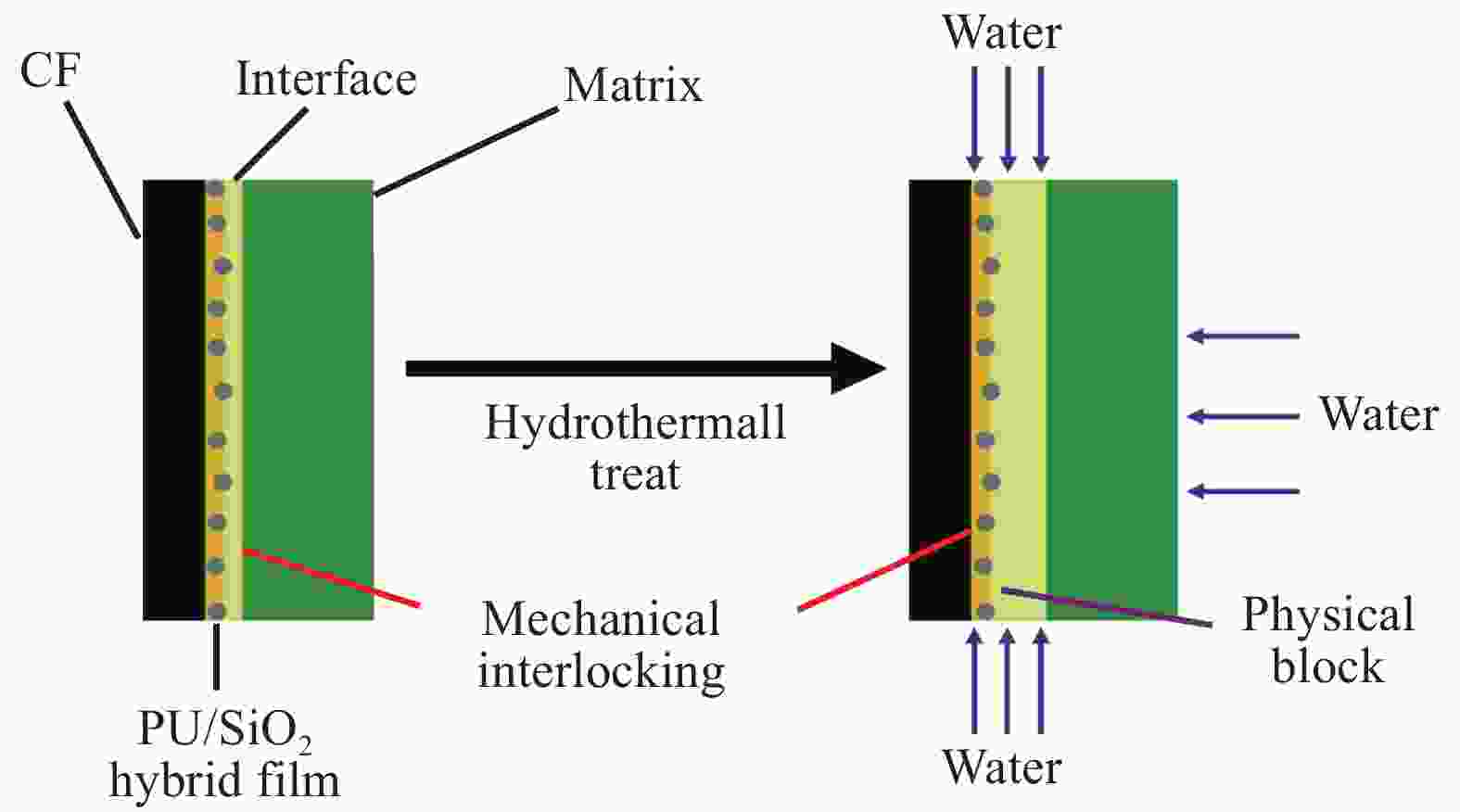

KISHI H, NAKAO N, KUWASHIRO S, et al. Carbon fiber reinforced thermoplastic composites from acrylic polymer matrices: Interfacial adhesion and physical properties[J]. Express Polymer Letters,2017,11(4):334-342. doi: 10.3144/expresspolymlett.2017.32

|

| [27] |

SAMANTA S, HE J, SELVAKUMAR S, et al. Polyamides based on the renewable monomer, 1, 13-tridecane diamine II: Synthesis and characterization of nylon 13, 6[J]. Polymer,2013,54(3):1141-1149. doi: 10.1016/j.polymer.2012.12.034

|

| [28] |

BAI Y P, HUANG L, HUANG T, et al. Synthesis and characterization of a water-soluble nylon copolyamide[J]. Polymer,2013,54(16):4171-4176. doi: 10.1016/j.polymer.2013.05.070

|

| [29] |

张显果, 孙春燕, 朱帅甫, 等. CF表面处理对尼龙66/CF复合材料性能的影响[J]. 工程塑料应用, 2014, 42(8):82-86. doi: 10.3969/j.issn.1001-3539.2014.08.019ZHANG X G, SUN C Y, ZHU S F, et al. Impact of surface modification of carbon fiber on properties of PA66/CF composites[J]. Engineering Plastics Application,2014,42(8):82-86(in Chinese). doi: 10.3969/j.issn.1001-3539.2014.08.019

|

| [30] |

SUGIURA N, MAKI N. Sizing agent for carbon fiber, method for sizing carbon fiber by said sizing agent, sized carbon fiber and knitted or woven fabric using said carbon fiber. U. S.: 7, 135, 516[P]. 2020-04-15.

|

| [31] |

CZIGÁNY T, ISHAK Z A M, KARGER-KOCSIS J. On the failure mode in dry and hygrothermally aged short fiber-reinforced injection-molded polyarylamide composites by acoustic emission[J]. Applied Composite Materials,1995,2(5):313-326. doi: 10.1007/BF00568767

|

| [32] |

LEI Y P, ZHANG J F, ZHANG T, et al. Water diffusion in carbon fiber reinforced polyamide 6 composites: Experimental, theoretical, and numerical approaches[J]. Journal of Reinforced Plastics and Composites,2019,38(12):578-587. doi: 10.1177/0731684419835034

|

| [33] |

SAKATA J, MATSUKAWA T, KAWATA H. Fiber treatment agent, carbon fibers treated with fiber treatment agent, and carbon fiber composite material containing said carbon fibers: U. S., 14/768, 5432016-2-4[P]. 2020-04-15.

|

| [34] |

MICHELMAN. Michelman introduces hydrosize® PA845-ideal for carbon fiber sizing where thermal stability is required[EB/OL]. (2012-02-16)[2020-04-15]. http://www.prweb.com/releases/2012/2/prweb9202629.htm.

|

| [35] |

MICHELMAN. Technical data sheet[EB/OL]. (2018-10-12)[2020-04-15]. https://www.michelman.co.jp/en/#coatings.

|

| [36] |

LOOS M R, YANG J, FEKE D L, et al. Enhancement of fatigue life of polyurethane composites containing carbon nanotubes[J]. Composites Part B: Engineering,2013,44(1):740-744. doi: 10.1016/j.compositesb.2012.01.038

|

| [37] |

POKHAREL P. High performance polyurethane nanocomposite films prepared from a masterbatch of graphene oxide in polyether polyol[J]. Chemical Engineering Journal,2014,253:356-365. doi: 10.1016/j.cej.2014.05.046

|

| [38] |

WANG C, WU Y C, LI Y C, et al. Flame-retardant rigid polyurethane foam with a phosphorus-nitrogen single intumescent flame retardant[J]. Polymers for Advanced Technologies,2017,29(1):668-676.

|

| [39] |

ZHANG W S, YANG C L, YAO L L, et al. Effect of polyurethane sizing agent on interface properties of carbon fiber reinforced polycarbonate composites[J]. Journal of Applied Polymer Science,2019,136(38):47982.

|

| [40] |

杨常玲, 刘立果, 吕永根, 等. 一种乳液型碳纤维用上浆剂及其制备方法和应用: 中国, ZL 201710183154.2[P]. 2020-04-15.YANG C L, LIU L G, LV Y G, et al. Preparation and application of an emulsion type sizing agent for carbon fiber: China, ZL 201710183154.2[P]. 2020-04-15(in Chinese).

|

| [41] |

ZHAO D F, HAMADA H, YANG Y Q. Influence of polyurethane dispersion as surface treatment on mechanical, thermal and dynamic mechanical properties of laminated woven carbon-fiber-reinforced polyamide 6 composites[J]. Composites Part B: Engineering,2019,160:535-545. doi: 10.1016/j.compositesb.2018.12.105

|

| [42] |

ZHANG T, SONG Y X, ZHAO Y Q, et al. Effect of hybrid sizing with nano-SiO<sub>2</sub> on the interfacial adhesion of carbon fibers/nylon 6 composites[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects,2018,553:125-133.

|

| [43] |

燕丰. 西格里新型热塑性相容碳纤维投产[J]. 橡塑技术与装备, 2014(18):65.YAN F. SGL new thermoplastic compatible carbon fiber put into production[J]. China Rubber/Plastics Technology and Equipment,2014(18):65(in Chinese).

|

| [44] |

MICHELMAN. Fibers & composites[EB/OL]. (2012-09-24)[2020-04-15]. https://www.michelman.com.cn/en/industry-expertise/fibers-composites/.

|

| [45] |

MICHELMAN. Product selection guide sizings for engineered resins[EB/OL]. (2018-05-16)[2020-04-15]. https://www.michelman.co.jp/en/#coatings.

|

| [46] |

TEIJIN. Product data sheet Tenax® filament yarn[EB/OL]. (2020-02-15)[2020-04-15].https://www.teijincar-bon.com/products/tenaxr-carbon-fiber/tenaxr-filament-yarn.

|

| [47] |

WANG L, SHEN Y D, LAI X J, et al. Effect of nanosilica content on properties of polyurethane/silica hybrid emulsion and its films[J]. Journal of Applied Polymer Science,2011,119(6):3521-3530. doi: 10.1002/app.33024

|

| [48] |

WANG S Y, ZHOU Z G, ZHANG J Z, et al. Effect of temperature on bending behavior of woven fabric-reinforced PPS-based composites[J]. Journal of Materials Science,2017,52(24):13966-13976. doi: 10.1007/s10853-017-1480-0

|

| [49] |

FLANAGAN M, GROGAN D M, GOGGINS J, et al. Permeability of carbon fibre PEEK composites for cryogenic storage tanks of future space launchers[J]. Composites Part A: Applied Science and Manufacturing,2017,101:173-184. doi: 10.1016/j.compositesa.2017.06.013

|

| [50] |

MA R, TANG T T. Current strategies to improve the bioactivity of PEEK[J]. International Journal of Molecular Sciences,2014,15(4):5426-5445. doi: 10.3390/ijms15045426

|

| [51] |

LIU W B, ZHANG S, HAO L F, et al. Properties of carbon fiber sized with poly(phthalazinone ether ketone) resin[J]. Journal of Applied Polymer Science,2012,128(6):3702-3709.

|

| [52] |

GAO X P, HUANG Z G, ZHOU H M, et al. Higher mechanical performances of CF/PEEK composite laminates via reducing interlayer porosity based on the affinity of functional s-PEEK[J]. Polymer Composites,2019,40(9):3749-3757. doi: 10.1002/pc.25236

|

| [53] |

HASSAN E A M, ELAGIB T H H, MEMON H, et al. Surface modification of carbon fibers by grafting peek-NH<sub>2</sub> for improving interfacial adhesion with polyetheretherketone[J]. Materials,2019,12(5):778. doi: 10.3390/ma12050778

|

| [54] |

HASSAN E A M, GE D, YANG L, et al. Highly boosting the interlaminar shear strength of CF/PEEK composites via introduction of PEKK onto activated CF[J]. Composites Part A: Applied Science and Manufacturing,2018,112:155-160. doi: 10.1016/j.compositesa.2018.05.029

|

| [55] |

周光远, 王红华, 张兴迪, 等. 一种碳纤维用耐温型乳液上浆剂及其制备: 中国, ZL 201710637200.1[P]. 2020-04-15.ZHOU G Y, WANG H H, ZHANG X D, et al. A heat resistant emulsion sizing agent for carbon fiber and its preparation: China, ZL 201710637200.1[P]. 2020-04-15(in Chinese).

|

| [56] |

XIE J F, YAO L, XU F J, et al. Fabrication and characterization of three-dimensional PMR polyimide composites reinforced with woven basalt fabric[J]. Composites Part B: Engineering,2014,66:268-275. doi: 10.1016/j.compositesb.2014.05.028

|

| [57] |

CHUANG S L, CHU N J, WHANG W T. Effect of polyamic acids on interfacial shear strength in carbon fiber/aromatic thermoplastics[J]. Journal of Applied Polymer Science,1990,41(1-2):373-382.

|

| [58] |

LING J Q, ZHAI W T, FENG W W, et al. Facile preparation of lightweight microcellular polyetherimide/graphene composite foams for electromagnetic interference shielding[J]. ACS Applied Materials & Interfaces,2013,5(7):2677-2684.

|

| [59] |

VISWANATHAN H, WANG Y Q, AUDI A A, et al. X-ray photoelectron spectroscopic studies of carbon fiber surfaces. 24. Interfacial interactions between polyimide resin and electrochemically oxidized PAN-based carbon fibers[J]. Chemistry of Materials,2001,13(5):1647-1655. doi: 10.1021/cm000930h

|

| [60] |

ZHOU C, CHENG J L, SUN Y. Preparation and property of epoxy based nano-SiO<sub>2</sub>/TiO<sub>2</sub>/polyimide hybrid enhanced sizing[J]. Advanced Materials Research,2011,335-336:96-100. doi: 10.4028/www.scientific.net/AMR.335-336.96

|

| [61] |

NAITO K. Tensile properties of polyimide composites incorporating carbon nanotubes-grafted and polyimide-coated carbon fibers[J]. Journal of Materials Engineering and Performance,2014,23(9):3245-3256. doi: 10.1007/s11665-014-1110-9

|

| [62] |

LIU H S, ZHAO Y, LI N, et al. Enhanced interfacial strength of carbon fiber/PEEK composites using a facile approach via PEI <italic>& </italic>ZIF-67 synergistic modification[J]. Journal of Materials Research and Technology,2019,8(6):6289-6300. doi: 10.1016/j.jmrt.2019.10.022

|

| [63] |

GIRAUD I, FRANCESCHI-MESSANT S, PEREZ E, et al. Preparation of aqueous dispersion of thermoplastic sizing agent for carbon fiber by emulsion/solvent evaporation[J]. Applied Surface Science,2013,266:94-99. doi: 10.1016/j.apsusc.2012.11.098

|

| [64] |

GIRAUD I, FRANCESCHI-MESSANT S, PEREZ E, et al. Influence of new thermoplastic sizing agents on the mechanical behavior of poly (ether ketone ketone)/carbon fiber composites[J]. Journal of Applied Polymer Science,2015,132(38):42550.

|

| [65] |

CHARY R R, HIRT D E. Coating carbon fibers with a thermoplastic polyimide using aqueous foam[J]. Polymer Composites,1994,15(4):306-311. doi: 10.1002/pc.750150409

|

| [66] |

YUAN H J, LU C X, ZHANG S C, et al. Preparation and characterization of a polyimide coating on the surface of carbon fibers[J]. New Carbon Materials,2015,30(2):115-121. doi: 10.1016/S1872-5805(15)60179-2

|

| [67] |

YUAN H J, ZHANG S C, LU C X, et al. Improved interfacial adhesion in carbon fiber/polyether sulfone composites through an organic solvent-free polyamic acid sizing[J]. Applied Surface Science,2013,279:279-284. doi: 10.1016/j.apsusc.2013.04.085

|

| [68] |

黄铄涵. Toho Tenax: 碳纤维的热塑性应用[J]. 国际纺织导报, 2015(1):42. doi: 10.3969/j.issn.1007-6867.2015.01.010HUANG S H. Toho Tenax: Application of carbon fiber for thermoplastic[J]. Melliand-China,2015(1):42(in Chinese). doi: 10.3969/j.issn.1007-6867.2015.01.010

|

| [69] |

齐磊, 刘扬涛, 高猛, 等. 碳纤维表面处理和上浆剂的研究进展[J]. 纤维复合材料, 2016, 33(1):33-35. doi: 10.3969/j.issn.1003-6423.2016.01.008QI L, LIU Y T, GAO M, et al. Development of carbon fiber surface treatment and sizing[J]. Fiber Composites,2016,33(1):33-35(in Chinese). doi: 10.3969/j.issn.1003-6423.2016.01.008

|

| [70] |

陆逢. 碳纳米管和环氧树脂改性双马来酰亚胺树脂的研究[D]. 武汉: 华中科技大学, 2015.LU F. Study on bismaleimide resin modified with carbon nanotubes and epoxy[D]. Wuhan: Huazhong University of Science and Technology, 2015(in Chinese).

|

| [71] |

张国良, 李艳华, 陈秋飞, 等. 一种碳纤维上浆剂: 中国, ZL 201210463139.0[P]. 2020-04-15.ZHANG G L, LI Y H, CHEN Q F, et al. A sizing agent for carbon fiber: China, ZL 201210463139.0[P]. 2020-04-15(in Chinese).

|

| [72] |

YI J W, LEE W, SEONG D G, et al. Effect of phenoxy-based coating resin for reinforcing pitch carbon fibers on the interlaminar shear strength of PA6 composites[J]. Composites Part A: Applied Science and Manufacturing,2016,87:212-219. doi: 10.1016/j.compositesa.2016.04.028

|

| [73] |

BOWMAN S, JIANG Q R, MEMON H, et al. Effects of styrene-acrylic sizing on the mechanical properties of carbon fiber thermoplastic towpregs and their composites[J]. Molecules,2018,23(3):547. doi: 10.3390/molecules23030547

|

| [74] |

HEXCEL. HexTow® carbon fiber selector guide[EB/OL]. (2020)[2020-04-15]. https://www.hexcel.com/Products/Carbon-Fiber/HexTow-Chopped-Carbon-Fiber?ljs=en.

|

| [75] |

LI N, ZONG L S, WU Z Q, et al. Amino-terminated nitrogen-rich layer to improve the interlaminar shear strength between carbon fiber and a thermoplastic matrix[J]. Composites Part A: Applied Science and Manufacturing,2017,101:490-499. doi: 10.1016/j.compositesa.2017.06.023

|

| [76] |

XI X F, CHEN Y S, WANG J, et al. A multiscale hydrothermal carbon layer modified carbon fiber for composite fabrication[J]. RSC Advances,2018,8(41):23339-23347. doi: 10.1039/C8RA04064H

|

| [77] |

YAMAMOTO T, YABUSHITA S, IRISAWA T, et al. Enhancement of bending strength, thermal stability and recyclability of carbon-fiber-reinforced thermoplastics by using silica colloids[J]. Composites Science and Technology,2019,181:107665. doi: 10.1016/j.compscitech.2019.05.022

|

下载:

下载: