Integration manufacturing and testing verification for RTMable carbon fiber/polyimide composite rudder

-

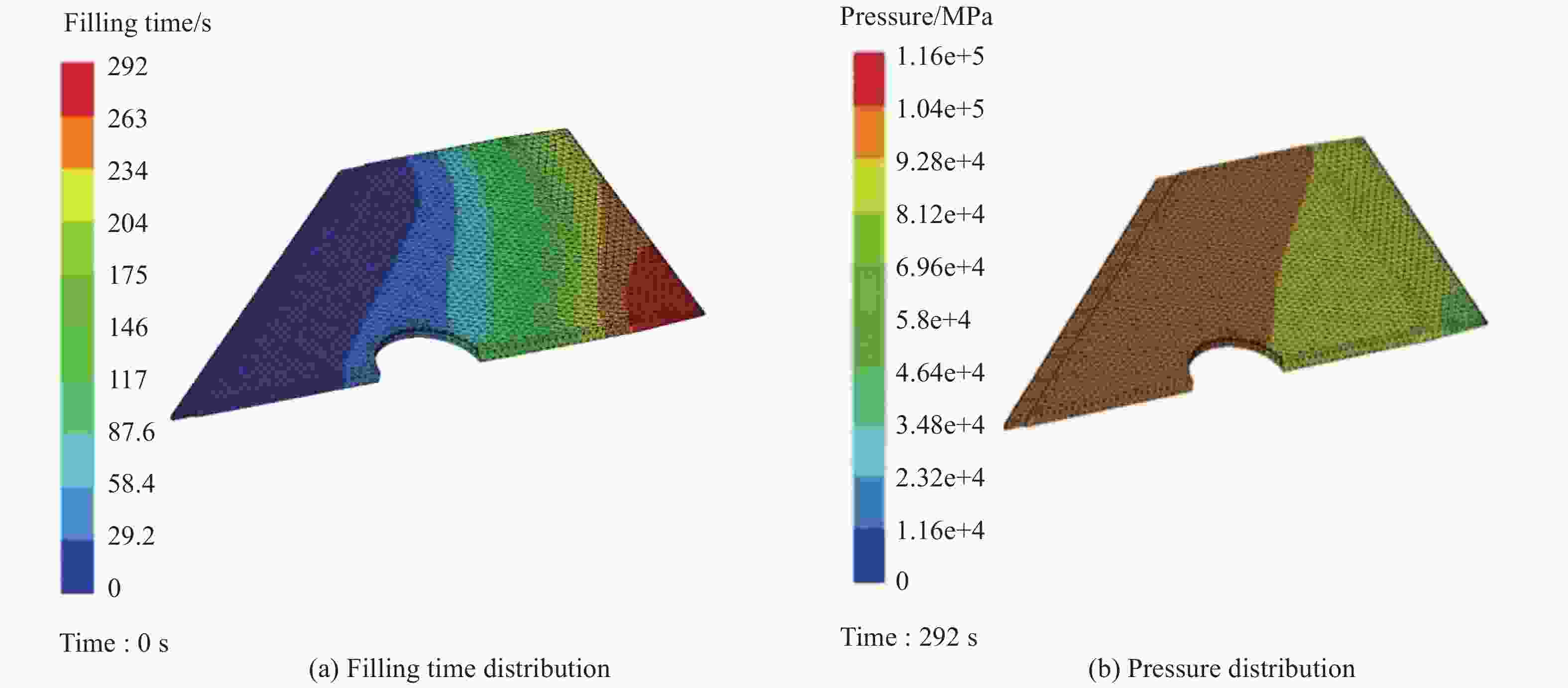

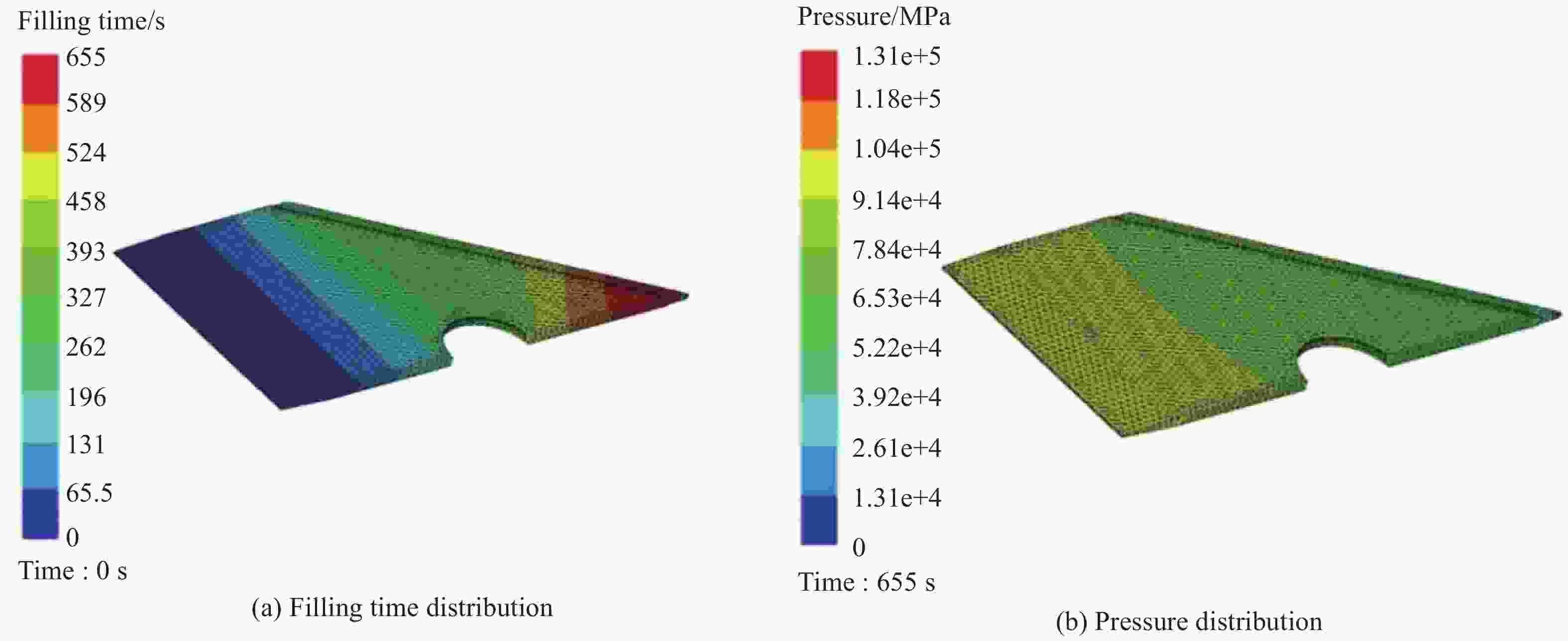

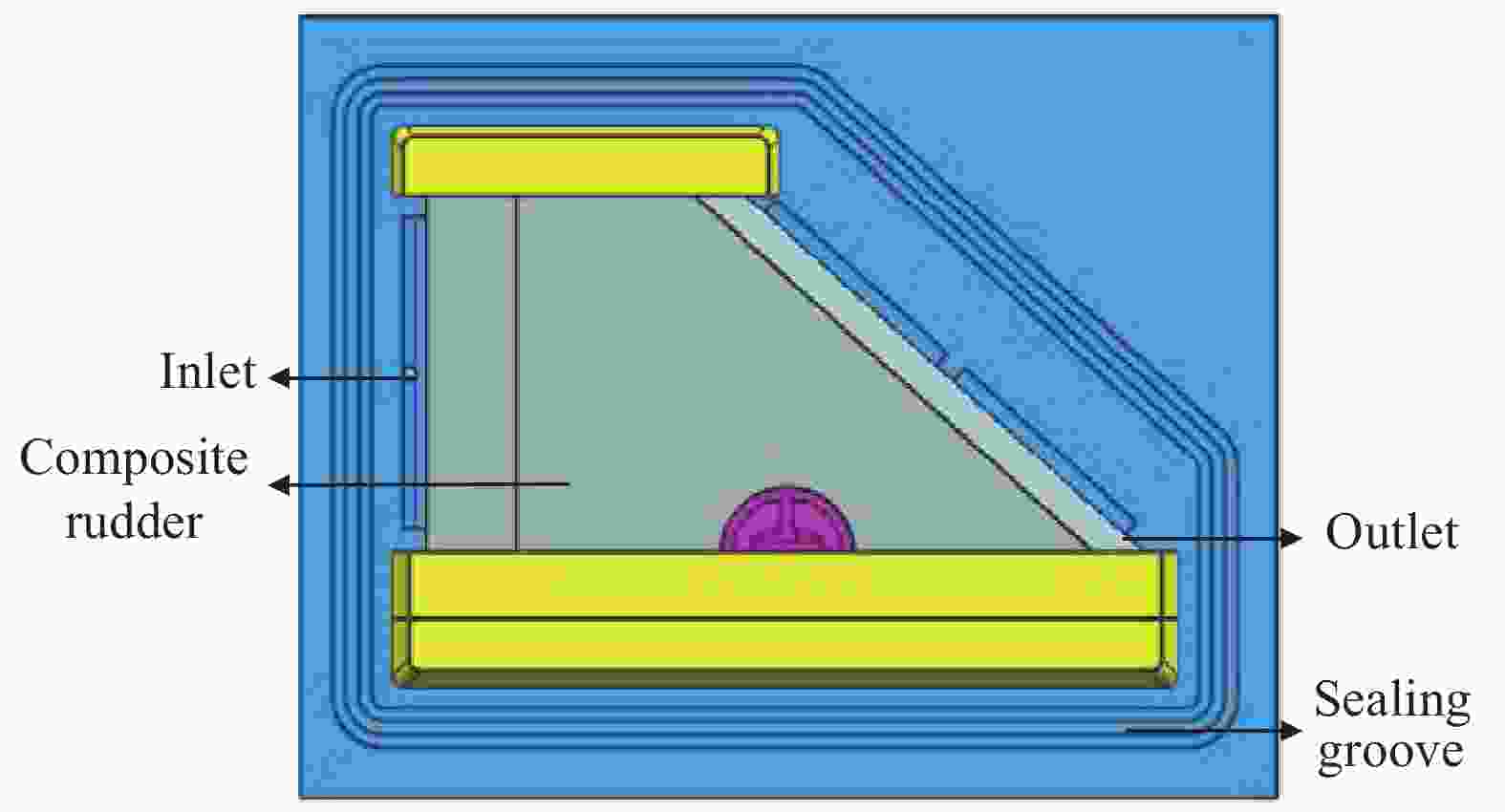

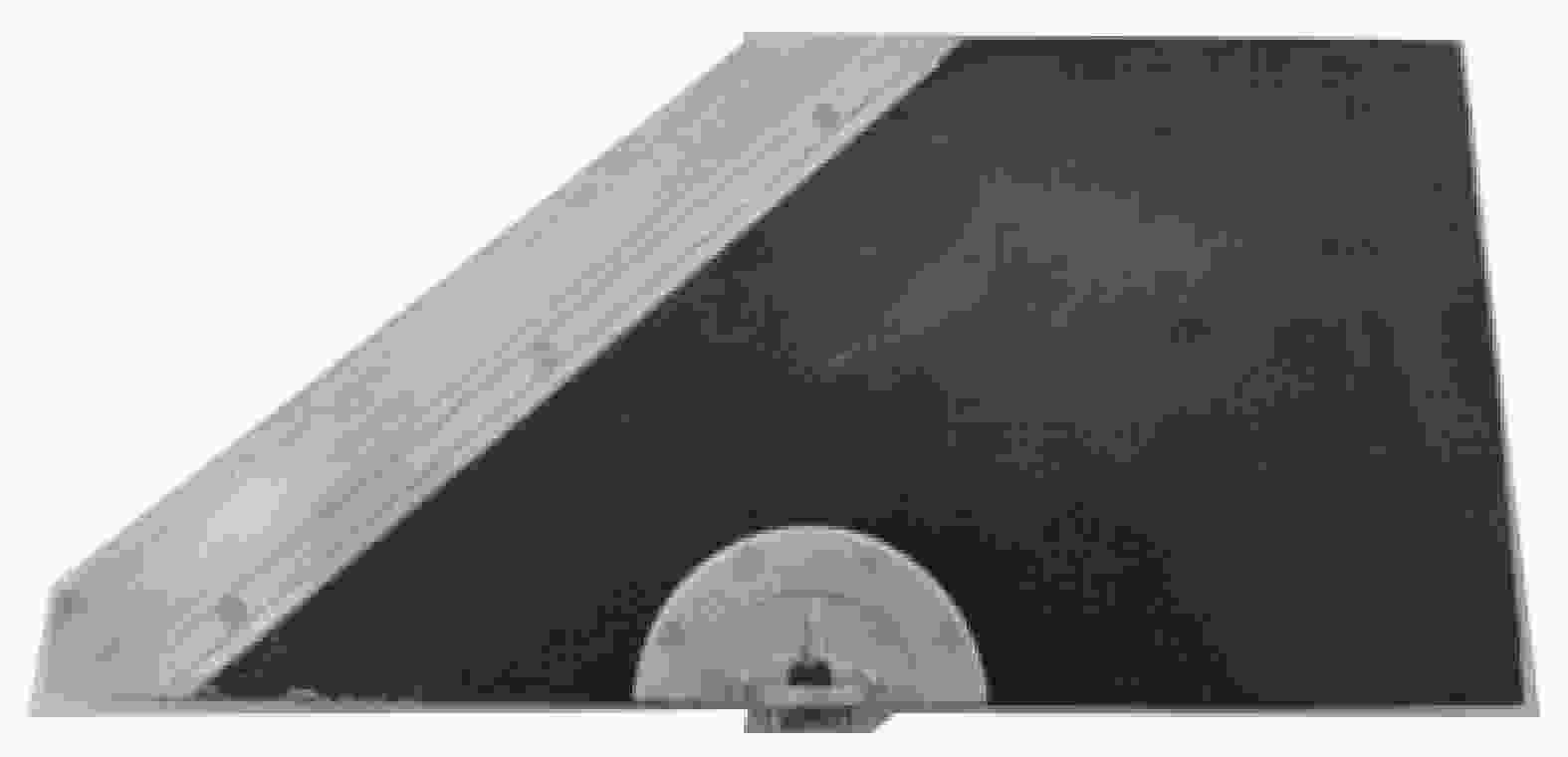

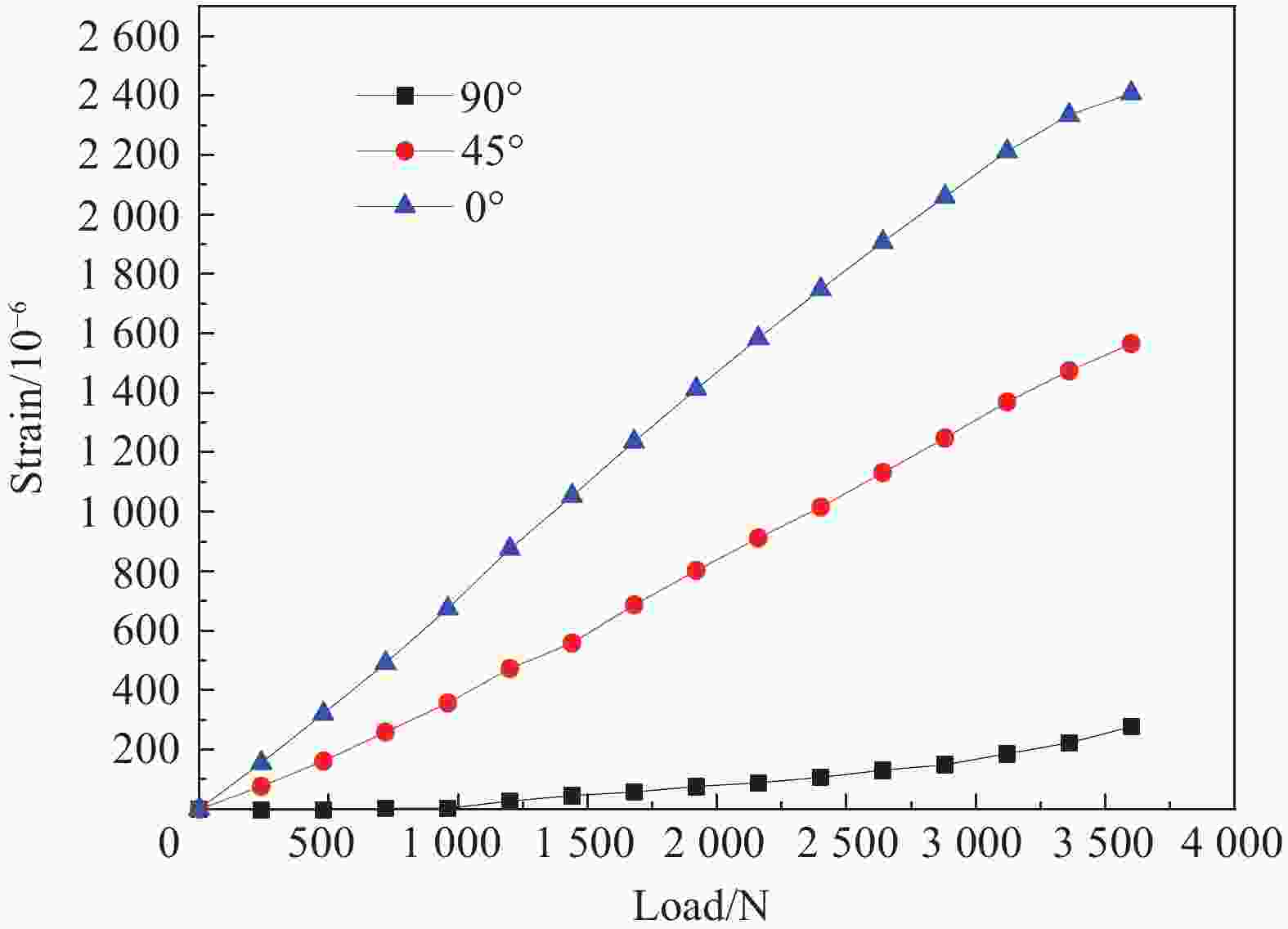

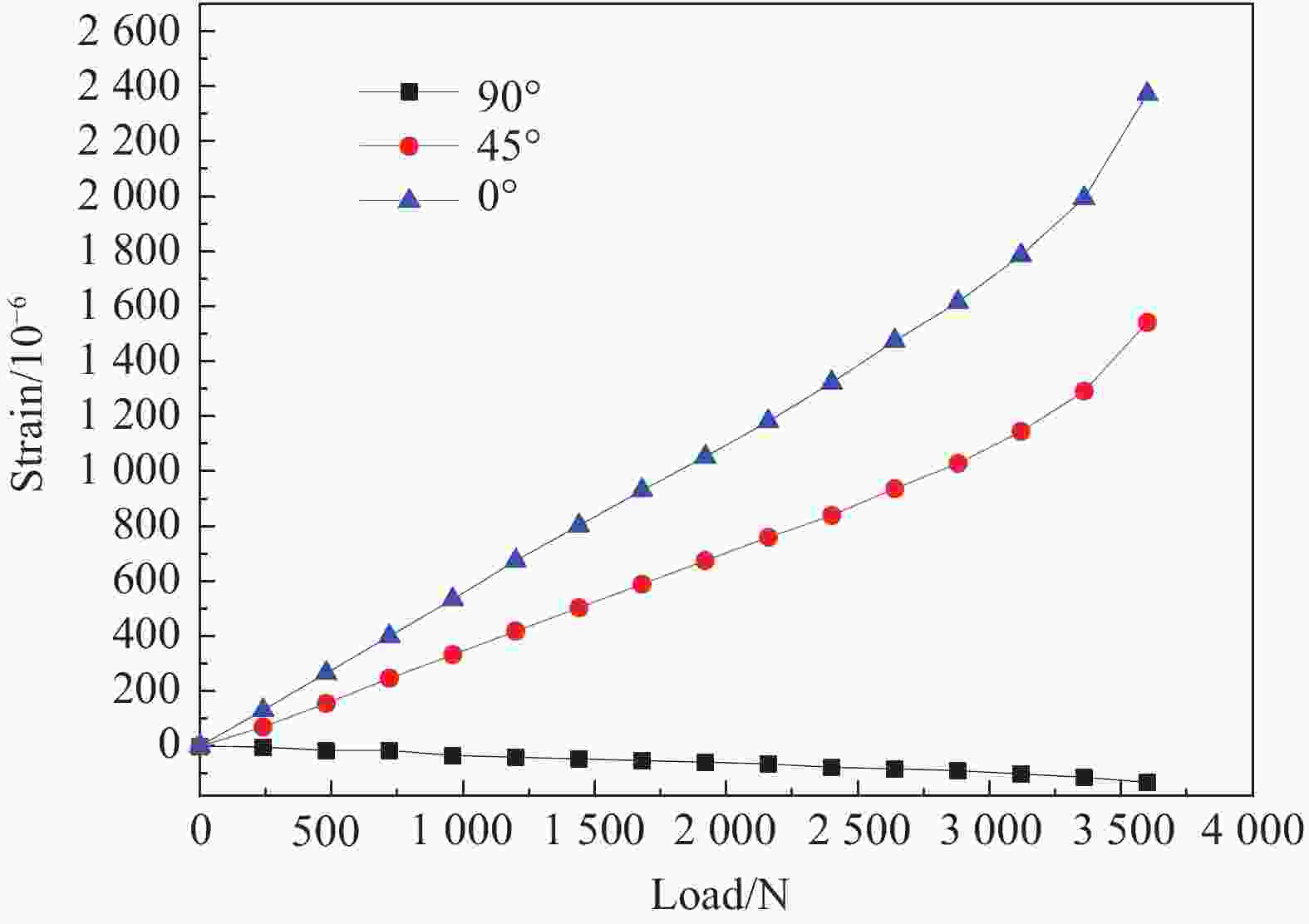

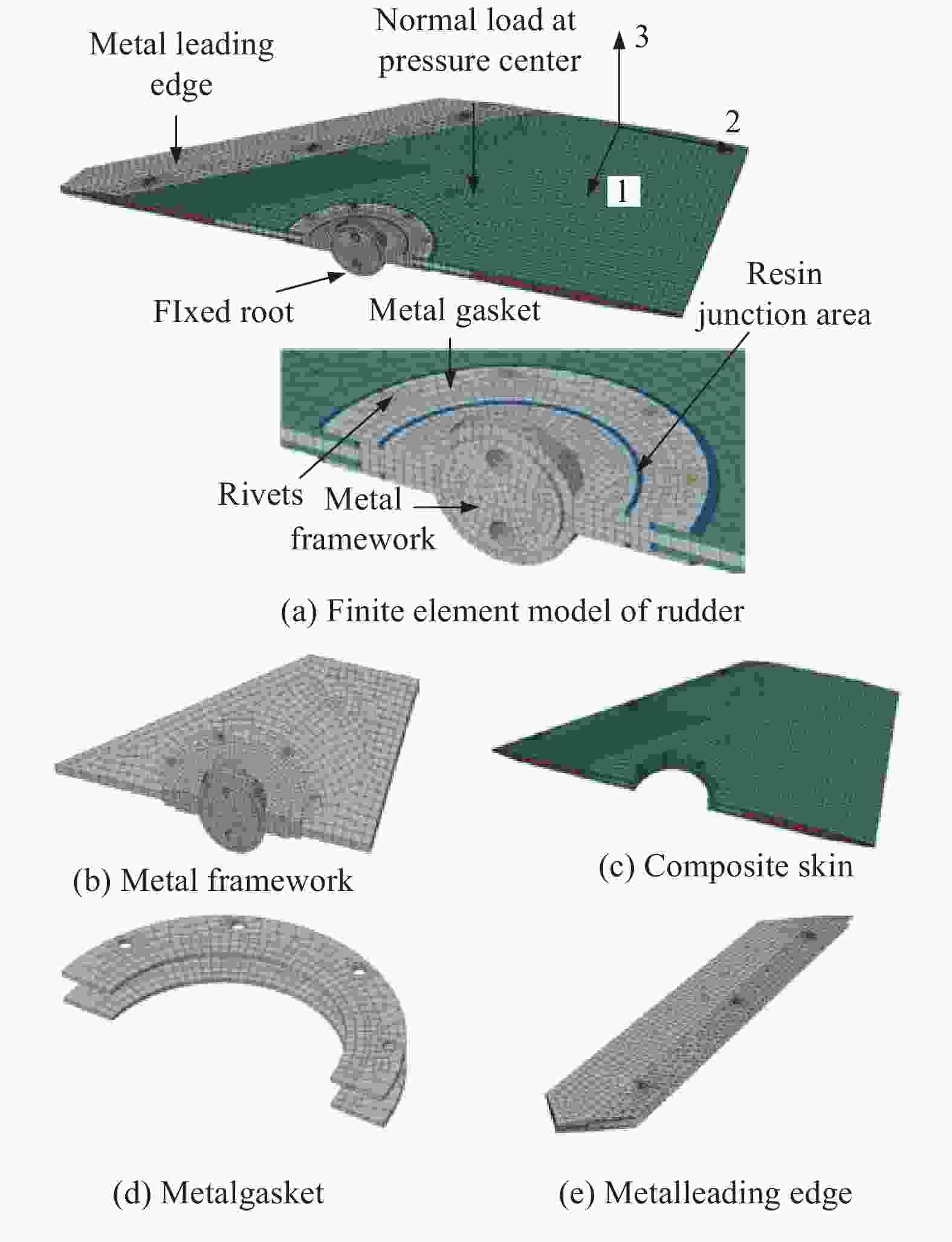

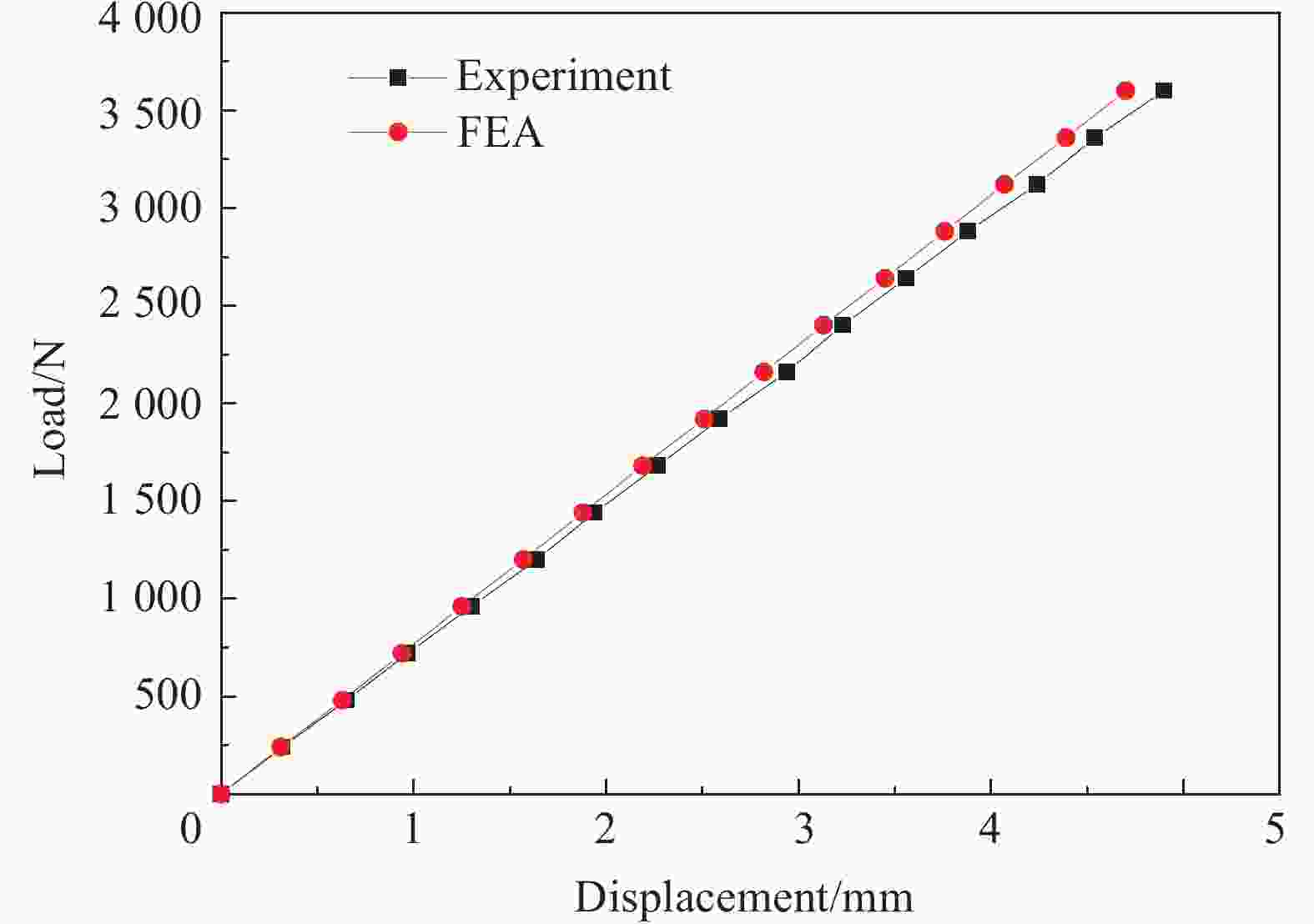

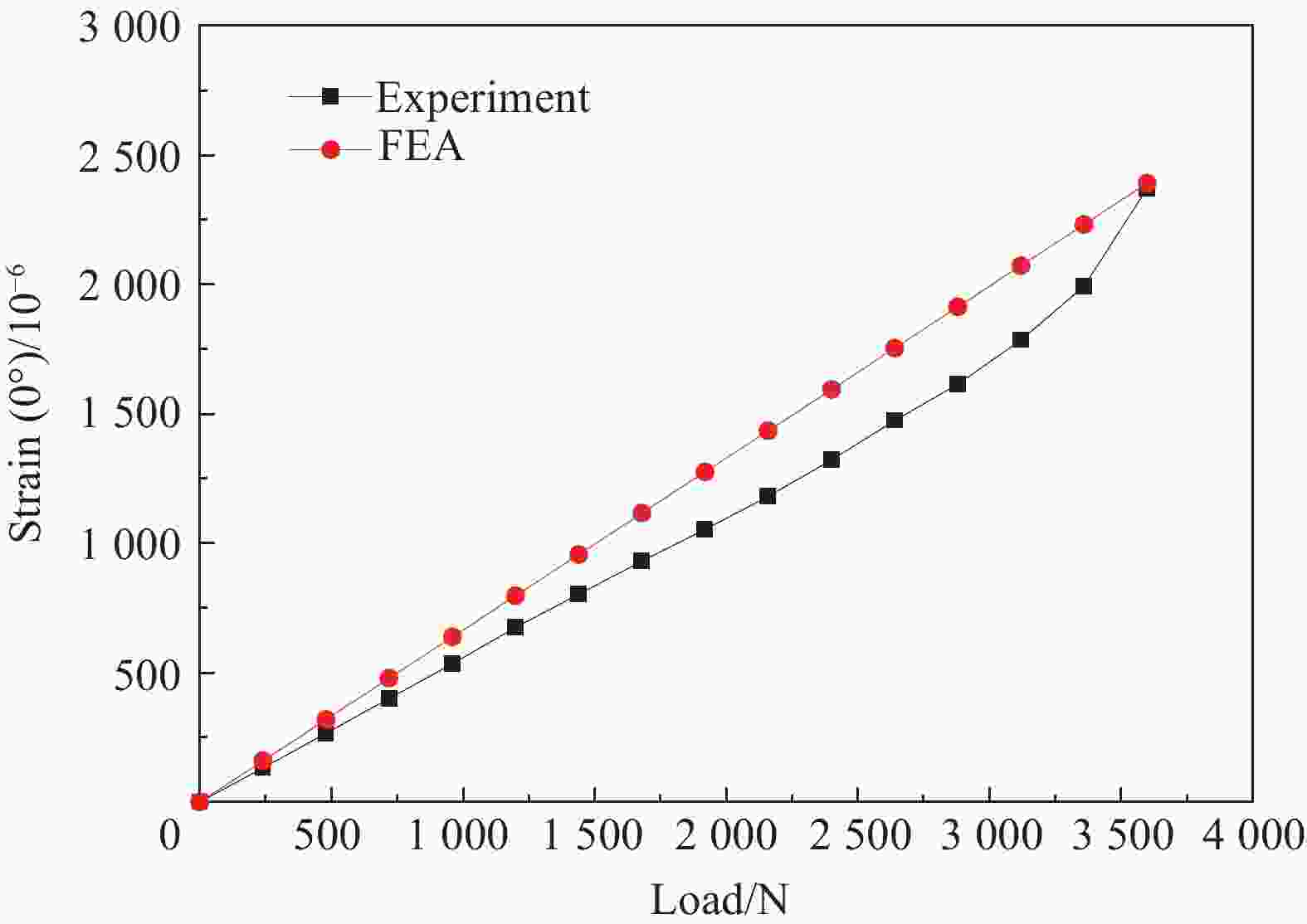

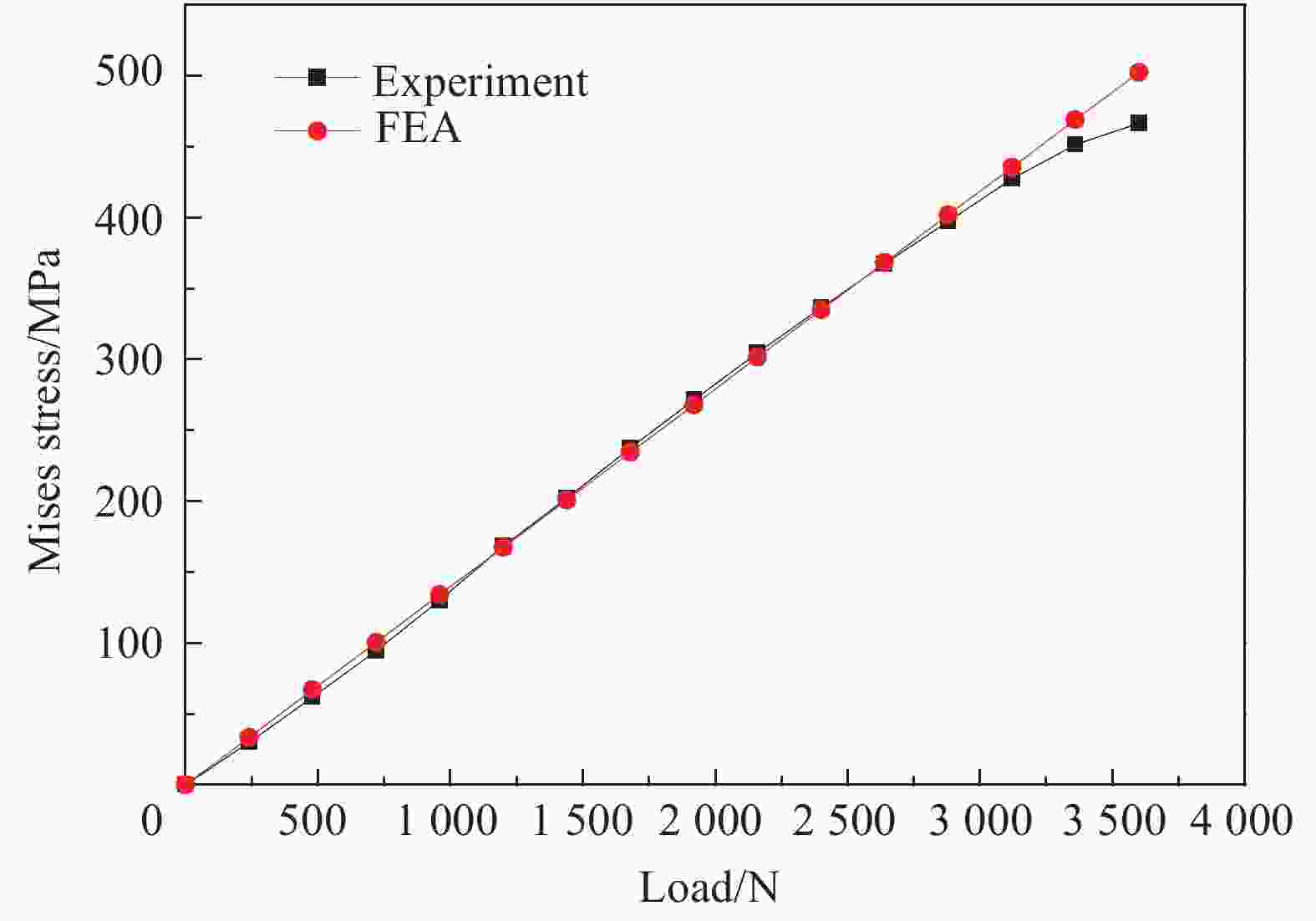

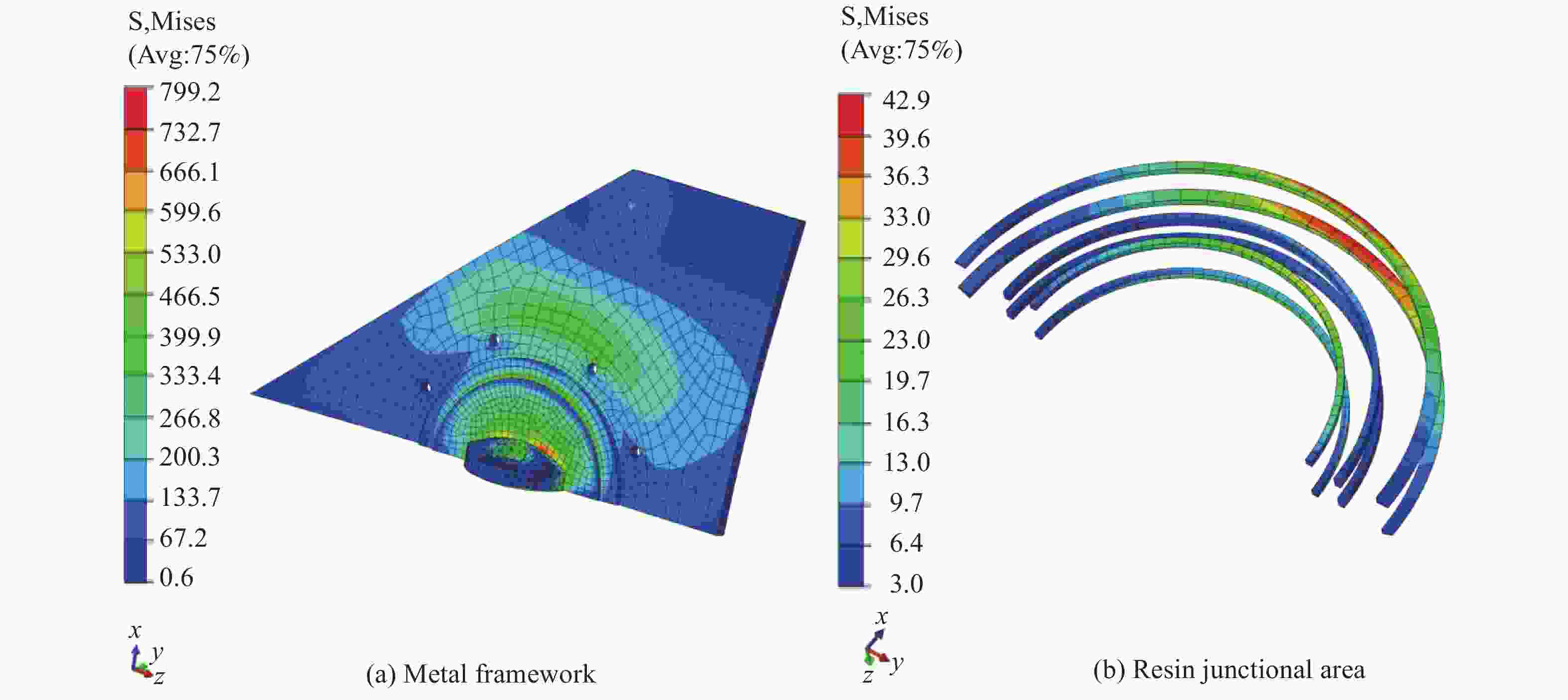

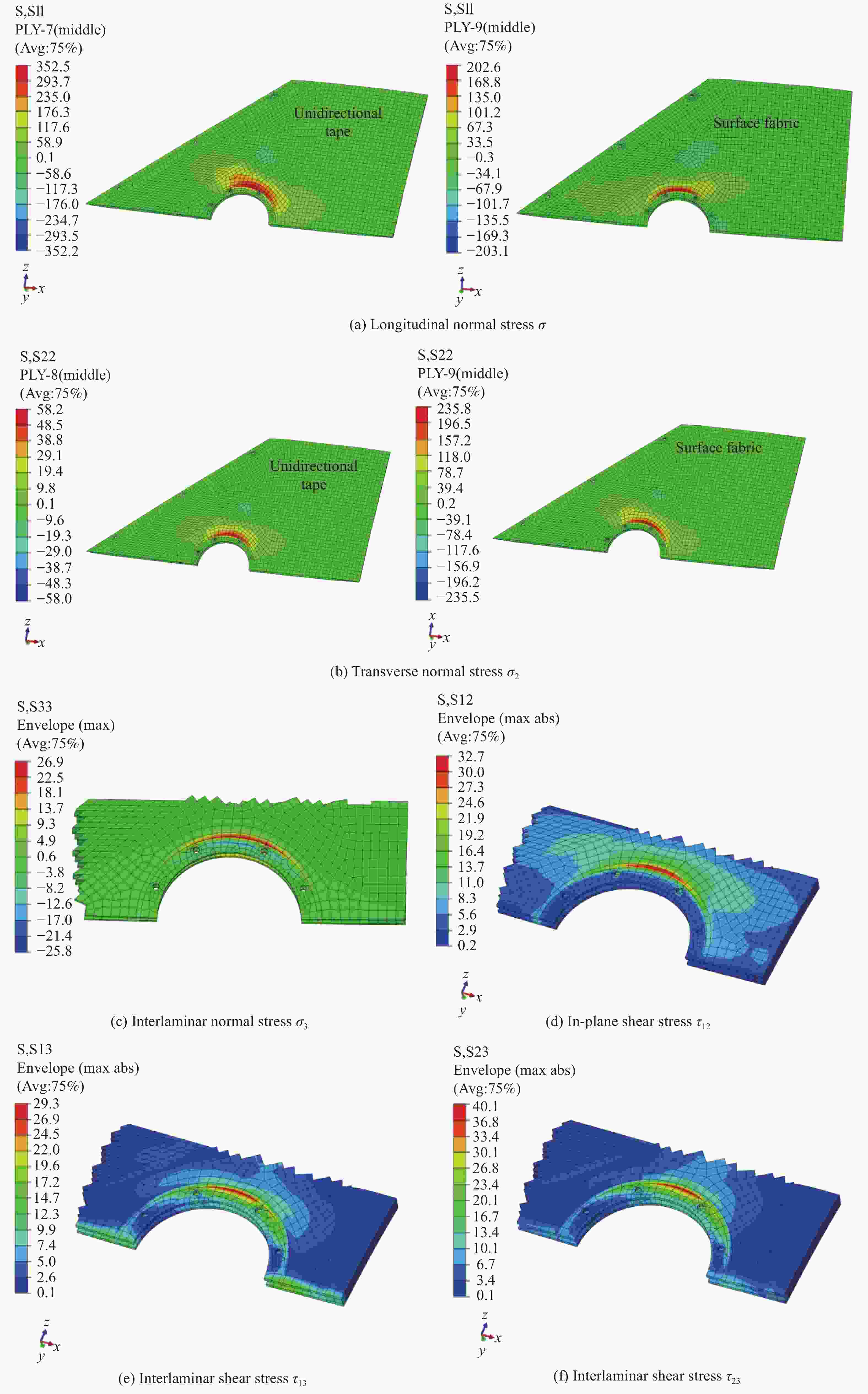

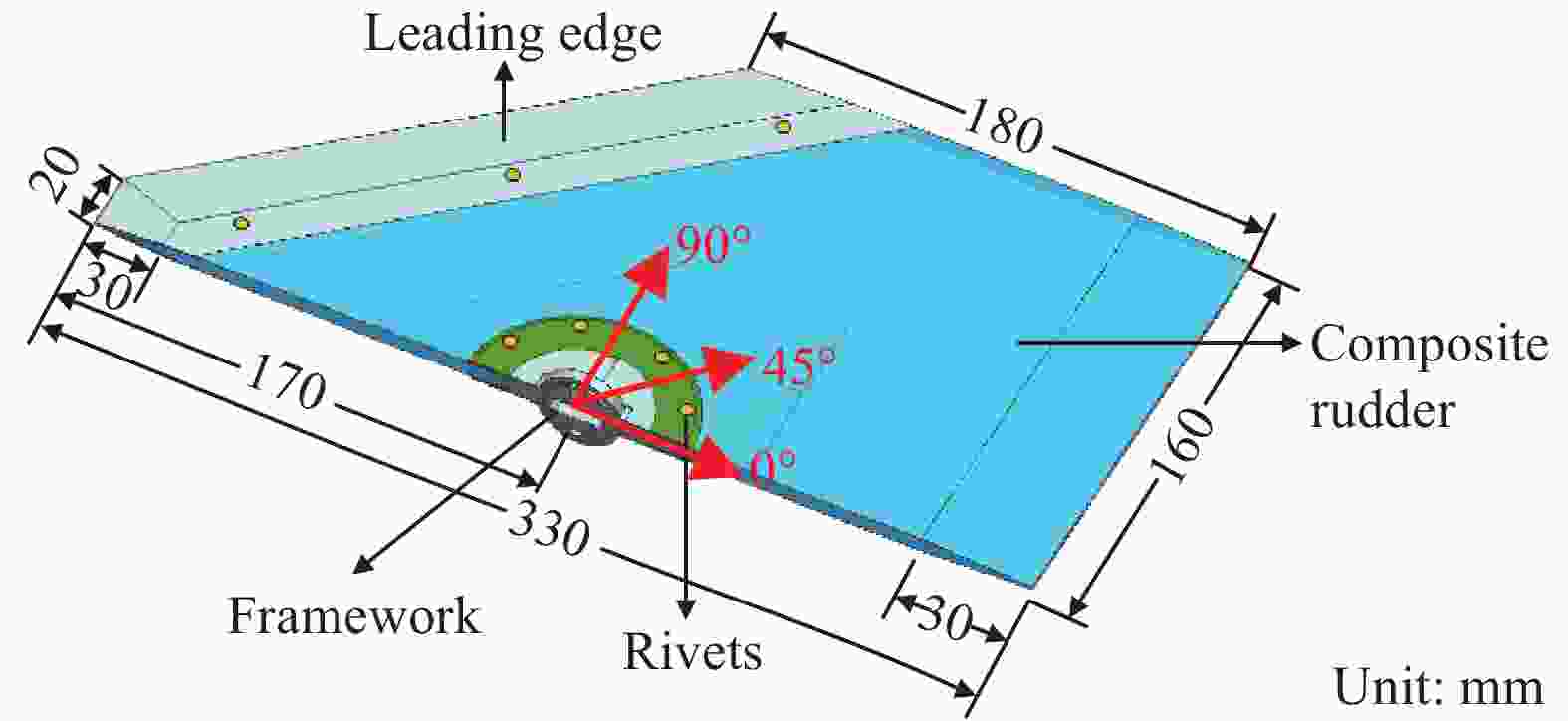

摘要: 设计了一种碳纤维/聚酰亚胺复合材料舵面结构,采用PAM-RTM软件模拟了舵面在注胶过程中的树脂流动,根据模拟结果设计了成型模具,并通过树脂传递模塑(RTM)工艺制备了耐高温碳纤维/聚酰亚胺复合材料舵面,对其进行了力学试验,并将三维有限元分析结果与试验结果对比。试验结果表明,碳纤维/聚酰亚胺复合材料舵面在150%的使用载荷下保持了结构的完整性,骨架的最大应变为2 408×10–6,复合材料蒙皮的最大应变为2 371×10–6。有限元分析结果表明,金属骨架的最大应力出现在舵轴根部圆弧过渡区,而碳纤维/聚酰亚胺复合材料蒙皮的最大应力出现在与垫片外圆弧接触处;碳纤维/聚酰亚胺复合材料舵面的初始破坏为蒙皮单向带横向拉伸失效。Abstract: The carbon fiber/polyimide composite rudder was designed. And the PAM-RTM software was used to simulate the resin flow of the rudder during the injection process. The forming die was designed according to the simulation results. The high-temperature resistant carbon fiber/polyimide composite rudder was fabricated via resin transfer molding (RTM) process accordingly and the mechanical properties under bending load were investigated to compare with the 3D finite element analysis (FEA) results. The experimental results show that the carbon fiber/polyimide composite rudder maintains the structural integrity under 150% of the service load. The maximum strain of the metal skeleton is 2 408×10–6, and the maximum strain of the carbon fiber/polyimide composite skin is 2 371×10–6. The FEA results reveal that the maximum stress of the metal skeleton appears at the arc transitional region of the rudder shaft root, while the maximum stress of the carbon fiber/polyimide composite skin emerges in the resin junctional area of the gasket outer arc. The initial damage of the carbon fiber/polyimide composite rudder is the transverse tensile failure of the skin unidirectional tape.

-

Key words:

- composite /

- rudder /

- polyimide /

- resin transfer molding /

- failure mechanism

-

表 1 U3160单向无纬帘子布碳纤维布和CF3031斜纹碳纤维机织物材料性能

Table 1. Material properties of U3160 no-weft carbon-fiber cord fabric and CF3031 twill carbon-fiber woven fabric

Project Direction CF3031 U3160 Ply thickness/mm 0.30±0.02 0.167 Areal density/(g·m−2) 220±7 160±10 Fabric density/

(tow·(100 mm)−1)warp-wise 54±2 80±4 weft-wise 54±2 40±2 Tensile breaking strength/

(N·25 mm)warp-wise ≥1 600 1 800 weft-wise ≥1 600 — 表 2 RTM350聚酰亚胺树脂基本性能

Table 2. Basic properties of RTM350 polyimide

Molecule

weight/(g·mol–1)Minimum viscosity/ (Pa·s) 270℃ viscosity/(Pa·s) Process period/h 1 066 0.39 0.61 3–4 Tg (E′) /℃ Tg (tanδ) /℃ 5% decomposition

temperature/℃361 392 537 Notes: Tg(E′)—Glass transition temperatures; Tg(tanδ)—Glass transition temperatures based on onset decline of storage modulus. 表 3 材料力学性能参数

Table 3. Mechanical properties of materials

U3160/RTM350 CF3031/RTM350 Xt/Yt/MPa 1 397/47.9 612.9/470.8 E1t/E2t/GPa 117/9.65 68/52 υ12 0.3 0.035 υ13/υ23 0.15 0.15 Xc/Yc/MPa 1 004/223 608/507.5 G12/GPa 4.69 4.4 τ12/MPa 86 86 G13/G23/GPa 3.5 3.5 τ13/τ23/MPa 93 93 Ply thickness/mm 0.167 0.2 RTM350 TC4 Stainless steel Xt/Yt /MPa 47.9 900 850 E1t/E2t /GPa 3.5 110 200 υ12 0.3 0.3 0.3 Notes: E1t, E2t—Tensile elastic moduli; υ12, υ13, υ23—Poisson’s ratios; G12, G13, G23—Shear moduli; Xt—Longitudinal tensile strength; Xc—Longitudinal compressive strength; Yt—Transverse tensile strength; Yc—Transverse compressive strength; τ12—In-plane shear stress; τ13, τ23—Interlaminar shear stresses. -

[1] 宋健朗. 先进聚合物基结构复合材料在导弹和航天中的应用[J]. 工程塑料应用, 2008, 36(7):50-54. doi: 10.3969/j.issn.1001-3539.2008.07.014SONG Jianlang. Application of advanced polymer matrix composites in missile and aerospace[J]. Engineering Plastics Application,2008,36(7):50-54(in Chinese). doi: 10.3969/j.issn.1001-3539.2008.07.014 [2] 杨鸿昌. 飞航导弹复合材料的应用概况、需求及发展前景[J]. 飞航导弹, 2000(4):60-63.YANG Hongchang. Application overview, demand and development prospect of aerospace missile composites[J]. Winged Missiles Journal,2000(4):60-63(in Chinese). [3] 罗楚养, 张朋, 李伟东, 等. 高温复合材料在空空导弹上的应用研究[J]. 航空科学技术, 2017, 28(1):19-24.LUO Chuyang, ZHANG Peng, LI Weidong, et al. Application research of high temperature composite on airborne missile[J]. Aeronautical Science and Technology,2017,28(1):19-24(in Chinese). [4] MEADOR M A. Recent advances in the development of processable high-temperature polymers[J]. Annual Review of Materials Science,1998,28(1):599-630. doi: 10.1146/annurev.matsci.28.1.599 [5] FACCIANO A. High-temperature organic composite applications for supersonic missile airframes[J]. SAMPE Journal,2000,36(1):9-23. [6] STOTLLER C L. Quiet, poworod-lift: Propulsion, NASA CP-2077[R]. NASA, 1979. [7] 杨灿. 耐高温复合材料整流罩性能及热力学分析[D]. 哈尔滨: 哈尔滨工程大学, 2014.YANG Can. Study on the high temperature-resistant composites fairing and its mechanical properties under high service temperature[D]. Harbin: Harbin Engineering University, 2014 (in Chinese). [8] 罗楚养, 吴催生, 魏仲委, 等. 高温复合材料舵面研制与试验验证[J]. 复合材料学报, 2014, 31(5):1312-1320.LUO Chuyang, WU Cuisheng, WEI Zhongwei, et al. Manufacturing and testing verification for high temperature composite rudder[J]. Acta Materiae Compositae Sinica,2014,31(5):1312-1320(in Chinese). [9] YANG S Y, GAO S Q, LI J Z. Short carbon fiber-reinforced PMR-15 polyimide composites[C]//International SAMPE Symposium and Exhibition. Anaheim: SAMPE Inc, 1998. [10] 赵伟栋, 王磊, 董波, 等. PMR型聚酰亚胺树脂基复合材料研究及应用[J]. 宇航材料工艺, 2009, 39(4):1-5. doi: 10.3969/j.issn.1007-2330.2009.04.001ZHAO Weidong, WANG Lei, DONG Bo, et al. PMR-type polyimide matrix composites and their applications[J]. Aerospace Materials <italic>&</italic> Technology,2009,39(4):1-5(in Chinese). doi: 10.3969/j.issn.1007-2330.2009.04.001 [11] 杨士勇, 高生强, 胡爱军, 等. 耐高温聚酰亚胺树脂及其复合材料的研究进展[J]. 宇航材料工艺, 2000, 30(1):1-6. doi: 10.3969/j.issn.1007-2330.2000.01.001YANG Shiyong, GAO Shengqiang, HU Aijun, et al. Progress in high temperature polyimide matrix resins and carbon fiber reinforced composites[J]. Aerospace Materials <italic>&</italic> Technology,2000,30(1):1-6(in Chinese). doi: 10.3969/j.issn.1007-2330.2000.01.001 [12] 刘强, 王晓亮, 蒋蔚, 等. BMP系列热固性聚酰亚胺树脂基复合材料的应用进展[J]. 航空制造技术, 2009(s1):22-24.LIU Qiang, WANG Xiaoliang, JIANG Wei, et al. Application progress of BMP thermosetting polyimide resin matrix composites[J]. Aeronautical Manufacturing Technology,2009(s1):22-24(in Chinese). [13] 刘志真, 郭恩玉, 邢军, 等. “离位”增韧技术在碳纤维/RTM聚酰亚胺复合材料中的应用[J]. 复合材料学报, 2010, 27(6):1-8.LIU Zhizhen, GUO Enyu, XING Jun, et al. Application of carbon fiber/RTMable polyimide composites by ex-situ toughness method[J]. Acta Materiae Compositae Sinica,2010,27(6):1-8(in Chinese). [14] 余瑞莲, 汪明, 李弘瑜, 等. RTM成型聚酰亚胺复合材料研究[J]. 宇航材料工艺, 2008, 38(2):6-8. doi: 10.3969/j.issn.1007-2330.2008.02.002YU Ruilian, WANG Ming, LI Hongyu, et al. Polyimide composite fabricated by RTM[J]. Aerospace Materials and Technology,2008,38(2):6-8(in Chinese). doi: 10.3969/j.issn.1007-2330.2008.02.002 [15] 刘志真, 李宏运, 邢军, 等. RTM聚酰亚胺树脂性能优化设计研究[J]. 材料工程, 2007(s1):80-84.LIU Zhizhen, LI Hongyun, XING Jun, et al. Research on the optimization and design of resin transform moldable polyimides[J]. Journal of Materials Engineering,2007(s1):80-84(in Chinese). [16] 益小苏. 先进复合材料技术研究与发展[M]. 北京: 国防工业出版社, 2006.YI Xiaosu. Research and development of advanced composites technology[M]. Beijing: National Defense Industry Press, 2006(in Chinese). [17] 陈建升, 左红军, 杨海霞, 等. 适用于RTM成型聚酰亚胺树脂的合成与性能研究[J]. 航空材料学报, 2006, 26(3):183-186. doi: 10.3969/j.issn.1005-5053.2006.03.038CHEN Jiansheng, ZUO Hongjun, YANG Haixia, et al. Synthesis and characterization of high temperature transfer molding polyimide resins[J]. Journal of Aeronautical Materials,2006,26(3):183-186(in Chinese). doi: 10.3969/j.issn.1005-5053.2006.03.038 [18] 刘志真, 李宏运, 邢军, 等. RTM聚酰亚胺复合材料力学性能研究[J]. 材料工程, 2007(s1):98-101.LIU Zhizhen, LI Hongyun, XING Jun, et al. Study on the mechanical property of RTMable polyimide composite[J]. Journal of Materials Engineering,2007(s1):98-101(in Chinese). [19] 李海晨, 王彪, 周振功. RTM工艺树脂流动过程数值模拟[J]. 复合材料学报, 2002, 19(2):18-23. doi: 10.3321/j.issn:1000-3851.2002.02.003LI Haichen, WANG Biao, ZHOU Zhengong. Numerical simulation of resin flow in RTM[J]. Acta Materiae Compositae Sinica,2002,19(2):18-23(in Chinese). doi: 10.3321/j.issn:1000-3851.2002.02.003 [20] 罗楚养, 熊峻江, 益小苏, 等. 基于水溶性型芯的RTM成型的整体化复合材料翼盒研制[J]. 复合材料学报, 2011, 28(3):203-209.LUO Chuyang, XIONG Junjiang, YI Xiaosu, et al. Design and manufacture of RTM-made composite wing box based on the water-soluble mandrel[J]. Acta Materiae Compositae Sinica,2011,28(3):203-209(in Chinese). [21] 刘刚, 罗楚养, 李雪芹, 等. 复合材料厚壁连杆RTM成型工艺模拟及制造验证[J]. 复合材料学报, 2012, 29(4):105-112.LIU Gang, LUO Chuyang, LI Xueqin, et al. Process simulation and manufacture testing of composite thick-wall drag brace via RTM technology[J]. Acta Materiae Compositae Sinica,2012,29(4):105-112(in Chinese). [22] LIU G, LUO C Y, ZHANG D J, et al. Mechanical performance and failure mechanism of thick-walled composite connecting rods fabricated by resin transfer molding technique[J]. Applied Composite Materials,2015,22(4):423-436. doi: 10.1007/s10443-014-9415-2 [23] 刘刚, 罗楚养, 张代军, 等. 基于NCF技术的RTM成型复合材料T型接头高效制造与验证[J]. 复合材料学报, 2012, 29(4):99-104.LIU Gang, LUO Chuyang, ZHANG Daijun, et al. Manufacture and testing of composite T-joint fabricated via RTM process based on NCF technology[J]. Acta Materiae Compositae Sinica,2012,29(4):99-104(in Chinese). [24] RENAUD L, RUIZ E, BENOIT Y, et al. PAM-RTM user’s guide & tutorials version 2004.1[M]. Rungis Cedex: ESI Group, 2004. [25] 张朋, 周立正, 包建文, 等. 耐350℃ RTM聚酰亚胺树脂及其复合材料性能[J]. 复合材料学报, 2014, 31(2):345-352.ZHANG Peng, ZHOU Lizheng, BAO Jianwen, et al. Properties of 350℃ temperature-resistant RTM polyimide matrix resin and its composites[J]. Acta Materiae Compositae Sinica,2014,31(2):345-352(in Chinese). [26] TIMOTHY G G. Advanced composites manufacturing[M]. New York: John Wiley & Sons, Inc, 1997. [27] 俞茂宏, YOSHIMINE M, 强洪夫, 等. 强度理论的发展和展望[J]. 工程力学, 2004, 21(6):1-20. doi: 10.3969/j.issn.1000-4750.2004.06.001YU Maohong, YOSHIMINE M, QIANG Hongfu, et al. Advances and prospects for strength theory[J]. Engineering Mechanics,2004,21(6):1-20(in Chinese). doi: 10.3969/j.issn.1000-4750.2004.06.001 [28] 沈观林, 胡更开, 刘彬. 复合材料力学[M]. 北京: 清华大学出版社, 2006.SHEN Guanlin, HU Gengkai, LIU Bin. Mechanics of composite materials[M]. Beijing: Tsinghua University Press, 2006(in Chinese). -

下载:

下载: