Preparation and strain sensitive performance of cellulose nanofiber-carbon nanotubes/ thermoplastic polyurethane composite films

-

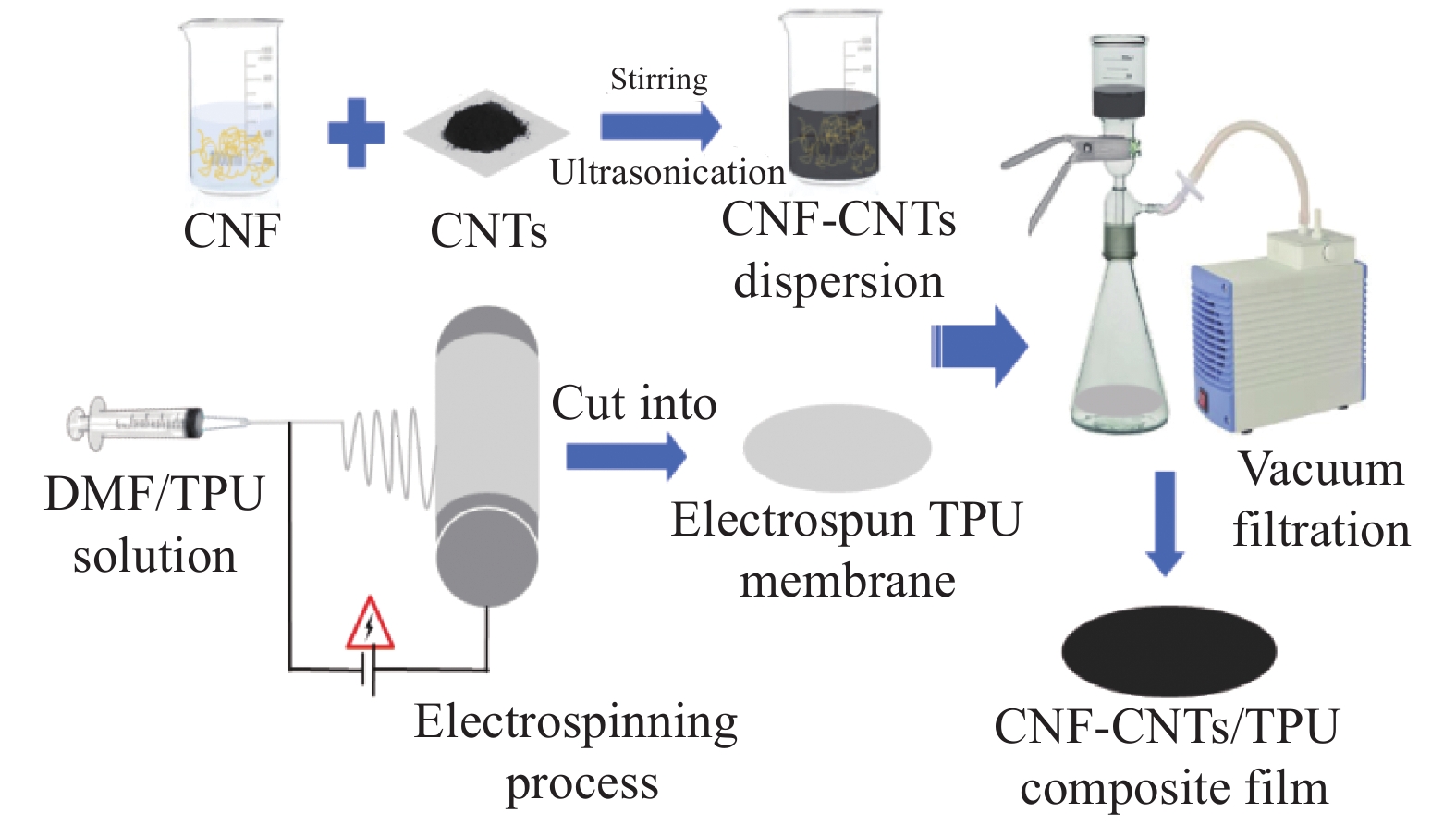

摘要: 采用2,2,6,6−四甲基哌啶−1−氧自由基(TEMPO)氧化法制备了不同羧基含量的纳米纤维素(CNF),并将其用作碳纳米管(CNTs)的分散剂,通过超声、离心处理制备出稳定均一的CNF−CNTs分散液,然后通过朗伯−比尔定律测定CNF−CNTs分散液中CNTs的浓度,研究了不同CNF羧基含量对CNTs的分散效果。此外,利用静电纺丝法制备出柔性、多孔的热塑性聚氨酯(TPU)薄膜作为基体,以CNF−CNTs分散液作为导电填料,通过真空抽滤法将CNF−CNTs负载于TPU多孔膜上,制备出CNF−CNTs/TPU复合薄膜,并探究了不同CNF羧基含量对CNF−CNTs/TPU复合薄膜应变响应性能的影响规律。结果表明,羧基含量对CNF的分散性能具有重要影响。随着CNF羧基含量的提高,CNF对CNTs分散效果越好,CNF−CNTs/TPU复合薄膜具有更大的应变响应范围。当CNF羧基含量为1.698 mmol/g时,CNF−CNTs/TPU复合薄膜的应变响应范围高达507%,灵敏度系数为335,表现出优异的应变响应性能。Abstract: The 2,2,6,6−Tetramethylpiperidine−1−oxyl radical (TEMPO) oxidation was used for preparation of cellulose nanofibers (CNF) with different carboxyl contents. Then the prepared CNF was used as the dispersing agent to disperse carbon nanotubes (CNTs) and the concentration of CNF−CNTs dispersion was measured by Lambert−Beer’s law to study the dispersion effect of CNF with different carboxyl contents. In addition, the CNF−CNTs/thermoplastic polyurethanes (TPU) composite film was prepared by pumping CNF−CNTs fillers in the prepared electrospun TPU film through vacuum filtration. The influence of carboxyl content of CNF on the strain sensitive performance of CNF−CNTs/TPU composite film was investigated. The result shows that, with the increase of the carboxyl content of CNF, the CNF has a better dispersion effect on CNTs, and the prepared CNF−CNTs/TPU composite film possesses a larger workable strain range. When the carboxyl content of CNF achieves 1.698 mmol/g, the CNF−CNTs/TPU composite film displays a large workable strain range of 507% and a high gauge factor of 335, exhibiting excellent strain sensitive performance.

-

表 1 不同CNF羧基含量的CNF-CNTs/TPU复合薄膜的编号及成分

Table 1. Serial numbers and component details of CNF-CNTs/TPU composite films with different carboxyl contents of CNF

No. Carboxyl content of CNF/(mmol·g−1) CNF/

wt%CNTs/

wt%TPU/

wt%CNF-CNTs/TPU1 0.663 2.4 1.2 96.4 CNF-CNTs/TPU2 0.947 2.4 1.2 96.4 CNF-CNTs/TPU3 1.348 2.4 1.2 96.4 CNF-CNTs/TPU4 1.698 2.4 1.2 96.4 -

[1] ZHU B W, WANG H, LIU Y Q, et al. Skin-inspired haptic memory arrays with an electrically reconfigurable architecture[J]. Advanced Materials,2016,28(8):1559-1566. doi: 10.1002/adma.201504754 [2] TRUNG T Q, LEE N E. Recent progress on stretchable electronic devices with intrinsically stretchable components[J]. Advanced Materials,2017,29(3):1603167. [3] LIM S, SON D, KIM J, et al. Transparent and stretchable interactive human machine interface based on patterned graphene heterostructures[J]. Advanced Functional Materials,2014,25(3):375-383. [4] LEE J, KWON H, SEO J, et al. Conductive fiber-based ultrasensitive textile pressure sensor for wearable electronics[J]. Advanced Materials,2015,27(15):2433-2439. doi: 10.1002/adma.201500009 [5] HEMPEL M, NEZICH D, KONG J, et al. A novel class of strain gauges based on layered percolative films of 2D materials[J]. Nano Letters,2012,12(11):5714-5718. doi: 10.1021/nl302959a [6] ZHENG Y, LI Y, LI Z, et al. The effect of filler dimensionality on the electromechanical performance of polydimethylsiloxane based conductive nanocomposites for flexible strain sensors[J]. Composites Science and Technology,2017,139:64-73. [7] ZHANG M, WANG C, WANG H, et al. Carbonized cotton fabric for high-performance wearable strain sensors[J]. Advanced Functional Materials,2016,27(2):1604795. [8] HWANG B U, LEE J H, TRUNG T Q, et al. Transparent stretchable self-powered patchable sensor platform with ultrasensitive recognition of human activities[J]. ACS Nano,2015,9(9):8801-8810. doi: 10.1021/acsnano.5b01835 [9] SHI G, ZHAO Z, PAI J H, et al. Highly sensitive, wearable, durable strain sensors, and stretchable conductors using graphene/silicon rubber composites[J]. Advanced Functional Materials,2016,26(42):7614-7625. doi: 10.1002/adfm.201602619 [10] LU N S, LU C, YANG S X, et al. Highly sensitive skin mountable strain gauges based entirely on elastomers[J]. Advanced Functional Materials,2012,22(19):4044-4050. doi: 10.1002/adfm.201200498 [11] ZHU H F, WANG X W, LIANG J, et al. Versatile electronic skins for motion detection of joints enabled by aligned few-walled carbon nanotubes in flexible polymer composites[J]. Advanced Functional Materials,2017,27(21):1606604. [12] KIM B S, SHIN K Y, PYO J B, et al. Reversibly stretchable, optically transparent radio-frequency antennas based on wavy Ag nanowire networks[J]. ACS Applied Materials & Interfaces,2016,8(4):2582-2590. [13] LI X M, YANG T T, YANG Y, et al. Large-area ultrathin graphene films by single-step Marangoni self-assembly for highly sensitive strain sensing application[J]. Advanced Functional Materials,2016,26(9):1322-1329. doi: 10.1002/adfm.201504717 [14] ZHU L, ZHOU X, LIU Y, et al. Highly sensitive, ultrastretchable strain sensors prepared by pumping hybrid fillers of carbon nanotubes/cellulose nanocrystal into electrospun polyurethane membranes[J]. ACS Applied Materials & Interfaces,2019,11(13):12968-12977. [15] HU W, NIU X, ZHAO R, et al. Elastomeric transparent capacitive sensors based on an interpenetrating composite of silver nanowires and polyurethane[J]. Applied Physics Letters,2013,102(8):083303. [16] BAE S H, LEE Y, SHARMA B K, et al. Graphene-based transparent strain sensor[J]. Carbon,2013,51:236-242. doi: 10.1016/j.carbon.2012.08.048 [17] KONG J H, JANG N S, KIM S H, et al. Simple and rapid micropatterning of conductive carbon composites and its application to elastic strain sensors[J]. Carbon,2014,77:199-207. doi: 10.1016/j.carbon.2014.05.022 [18] HAJIAN A, LINDSTROM S B, PETTERSON T, et al. Understanding the dispersive action of cellulose nanofiber for carbon nanomaterials[J]. Nano Letters,2017,17(3):1439-1447. doi: 10.1021/acs.nanolett.6b04405 [19] 方志强. 高透明纸的制备及其在电子器件中的应用[D]. 广州: 华南理工大学, 2014.FANG Z Q. Highly transparent paper for electronic devices[D]. Guangzhou: South China University of Technology, 2014(in Chinese). [20] 何文, 李吉平, 金辉, 等. 毛竹纳米纤维素的烷基化改性[J]. 南京林业大学学报(自然科学版), 2016, 40(2):144-148.HE W, LI J P, JIN H, et al. Alkylated modification of bamboo cellulose nanofiber[J]. Journal of Nanjing Forestry University (Natural Science Edition),2016,40(2):144-148(in Chinese). [21] HAMEDI M M, HAJIAN A, FALL A B, et al. Highly conducting, strong nanocomposites based on cellulose nanofiber-assisted aqueous dispersions of single-wall carbon nanotubes[J]. ACS Nano,2014,8(3):2467-2476. doi: 10.1021/nn4060368 [22] LI Y, ZHU H, SHEN F, et al. Cellulose nanofiber as green dispersant for two-dimensional energy materials[J]. Nano Energy,2015,13:346-354. doi: 10.1016/j.nanoen.2015.02.015 [23] 吴波, 邵发宁, 何文, 等. TEMPO氧化纤维素纳米纤丝对多壁碳纳米管分散性的影响[J]. 复合材料学报, 2019, 36(9):2212-2219.WU B, SHAO F N, HE W, et al. Dispersion effect of TEMPO oxidized cellulose nanofibrils on multi-walled carbon nanotubes[J]. Acta Materiae Compositae Sinica,2019,36(9):2212-2219(in Chinese). [24] 朱朋辉, 陈港, 欧华杰, 等. 纳米纤维素/碳纳米管复合薄膜的制备及湿敏性能[J]. 华南理工大学学报(自然科学版), 2019, 47(8):129-135.ZHU P H, CHEN G, OU H J, et al. Preparation and humidity sensitive performance of nanocellulose/carbon nanotube composite films[J]. Journal of South China University of Technology (Natural Science Edition),2019,47(8):129-135(in Chinese). [25] PARK B, KIM J, KANG D, et al. Dramatically enhanced mechanosensitivity and signal-to-noise ratio of nanoscale crack-based sensors: Effect of crack depth[J]. Advanced Materials,2016,28(37):8130-8137. doi: 10.1002/adma.201602425 -

下载:

下载: