Effect of composite volume fraction on impact wear properties of zirconium oxide toughened alumina particles/40Cr architecture composites

-

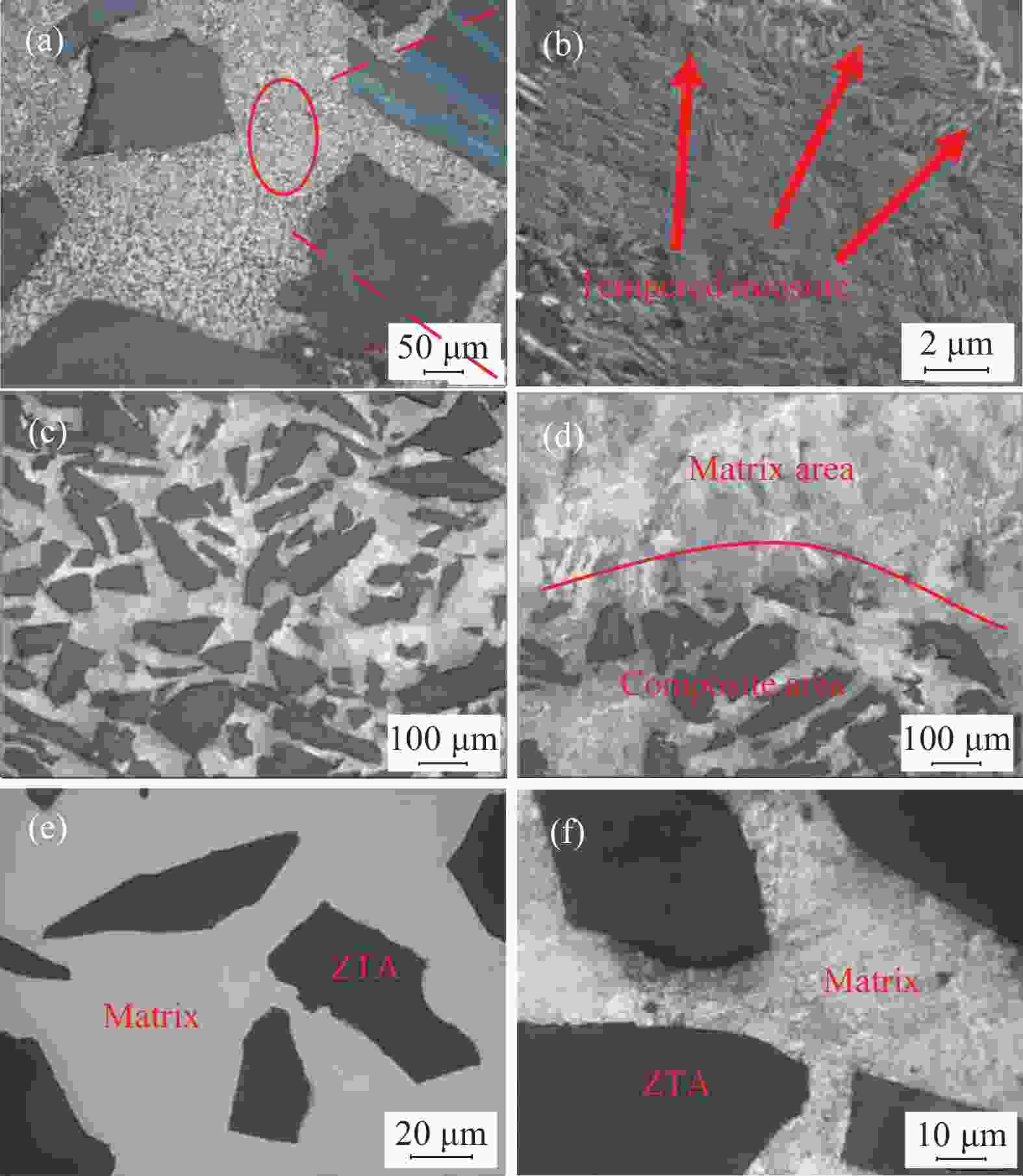

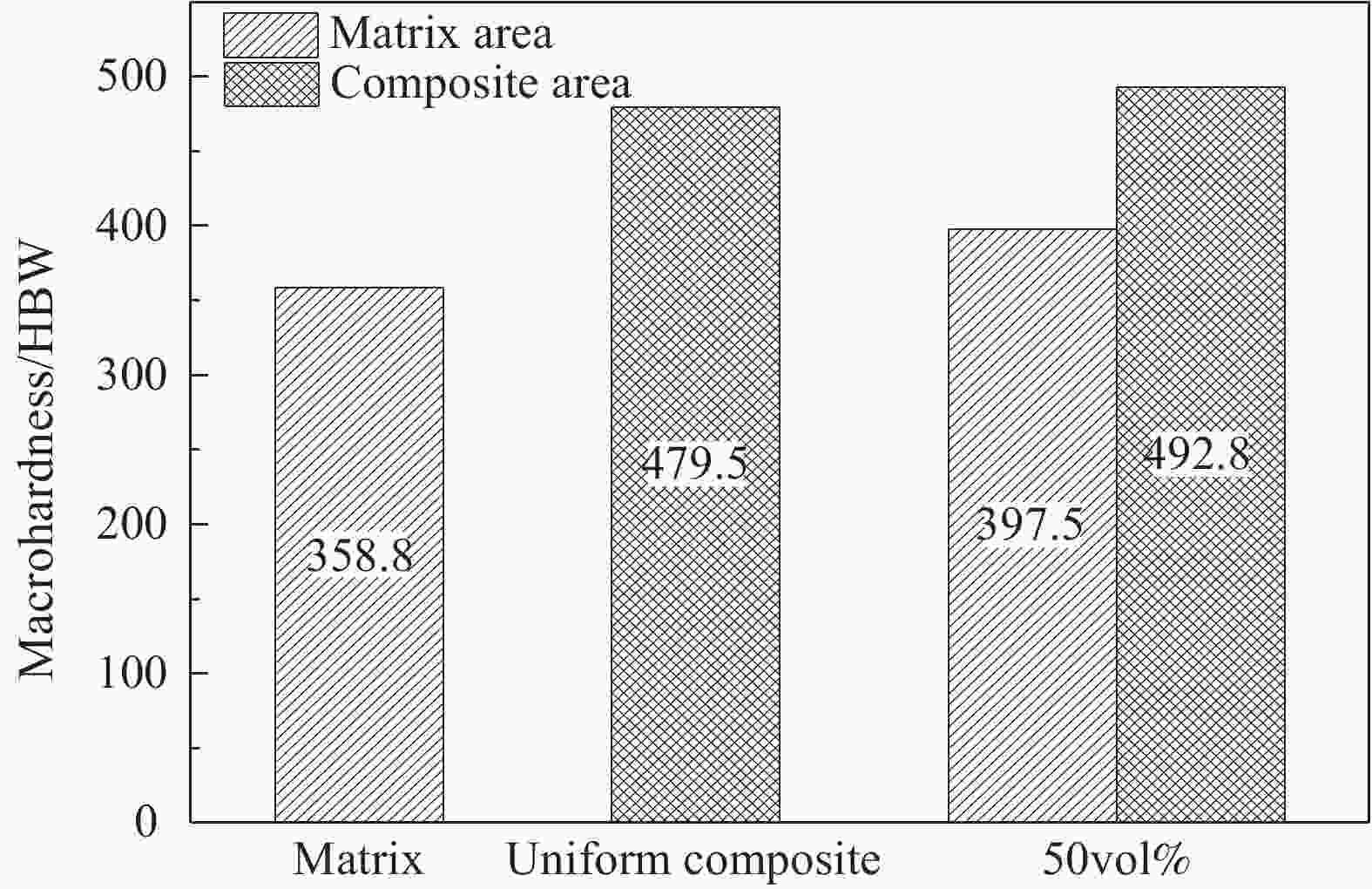

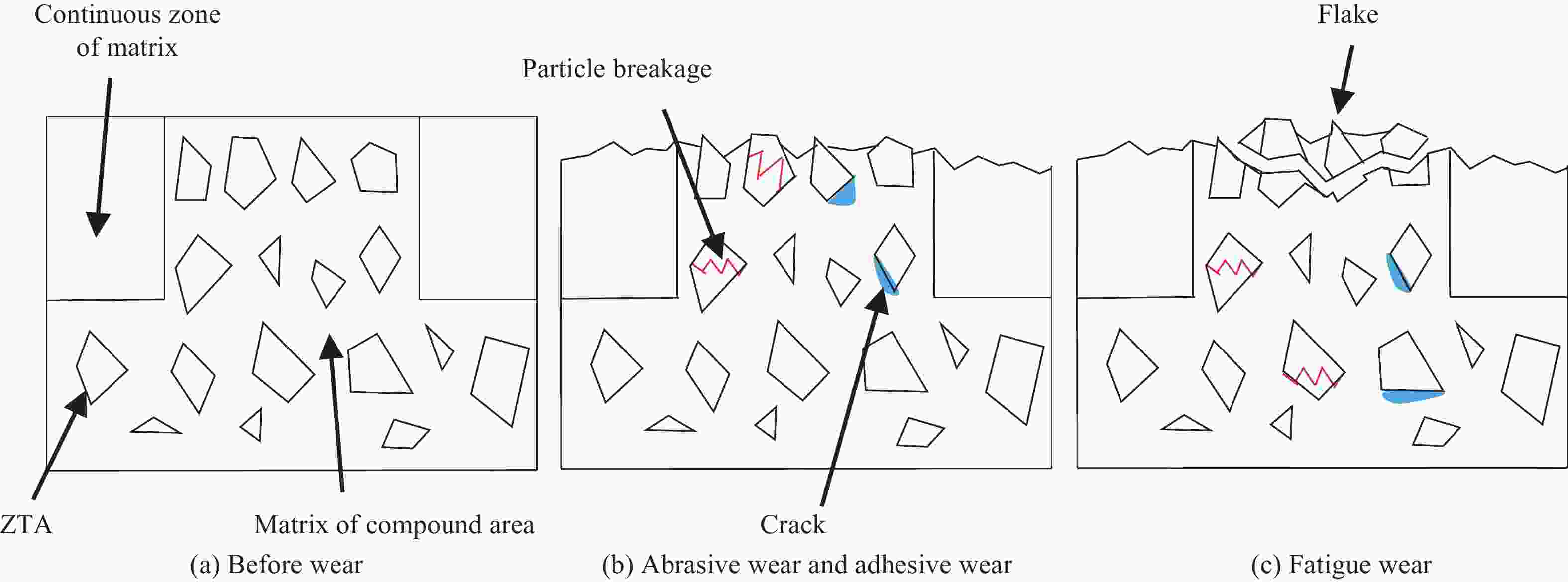

摘要: 为研究空间结构复合材料中复合区体积分数对复合材料冲击磨损性能的影响,采用挤压铸造法制备了不同复合区体积分数(35vol%、50vol%、65vol%)的氧化锆增韧氧化铝颗粒(ZTAP)三维网络增强40Cr钢基复合材料(ZTAP/40Cr空间结构复合材料),经过850℃淬火和460℃回火,在冲击功为1.5 J下进行无磨料冲击磨损实验。结果表明:复合区体积分数为35vol%、50vol%、65vol%的ZTAP/40Cr空间结构复合材料磨损率分别为4.68×10−3 cm3/h、3.40×10−3 cm3/h、1.04×10−3 cm3/h,ZTAP/40Cr复合材料和40Cr钢的磨损率分别为13.41×10−3 cm3/h和79.87×10−3 cm3/h。ZTAP/40Cr空间结构复合材料的耐磨性随复合区体积分数增加而提高。进一步分析表明,ZTAP/40Cr空间结构复合材料的冲击磨损机制包含表面发生的磨粒磨损和黏着磨损,主要是基体黏着和整个表面被犁削及亚表层萌生的疲劳磨损,是由反复冲击过程中产生的ZTAP破碎和ZTAP与40Cr界面开裂导致的材料块状脱落。Abstract: In order to study the effect of composite volume fraction on the impact wear properties of composites in architecture composites, the zirconium oxide toughened alumina particles(ZTAP) 3D network reinforced 40Cr steel matrix composites(ZTAP/40Cr architecture composite) with different composite volume fractions(35vol%, 50vol%, 65vol%) were fabricated by squeeze casting, which were subjected to no abrasives impact wear test with an impact energy of 1.5 J after quenching at 850℃ and tempering at 460℃. The results show that when the volume fraction of the composite area is 35vol%, 50vol% and 65vol%, the wear rates of the ZTAP/40Cr architecture composites are 4.7×10−3 cm3/h, 3.4×10−3 cm3/h and 1.0×10−3 cm3/h, respectively. The wear rates of the ZTAP/40Cr composite and the 40Cr steel are 13.41×10−3 cm3/h and 79.87×10−3 cm3/h, respectively. The wear resistance of the ZTAP/40Cr architecture composite increases as the volume fraction of the composite area increases. Further analysis show that the impact wear mechanism of the ZTAP/40Cr architecture composite includes abrasive wear and adhesive wear on the surface, mainly the adhesion of the matrix and the ploughing of the entire surface, as well as the fatigue wear of the subsurface, which is a blockage of materials caused by ZTAP breakage and ZTAP/40Cr interfacial cracking during repeated impact.

-

表 1 氧化锆增韧氧化铝颗粒三维网络增强40Cr钢基(ZTAP/40Cr)空间结构复合材料的模型设计

Table 1. Model designs of zirconium oxide toughened alumina particles 3D network reinforced 40Cr steel matrix(ZTAP/40Cr) architecture composite

Volume fraction/vol% Diameter/

mmWall thickness/

mmMode size/

mm35 3.4 2.7 15×15×30 50 4.3 2.1 15×15×30 65 5.2 1.6 15×15×30 -

[1] 周谟金, 蒋业华, 温放放, 等. 热处理对高铬铸铁基蜂窝陶瓷复合材料耐磨性的影响[J]. 材料导报, 2017, 31(14):117-121. doi: 10.11896/j.issn.1005-023X.2017.014.025ZHOU M J, JIANG Y H, WEN F F, et al. Effect of heat treatment on wear resistance of high chromium cast iron based honeycomb ceramic composites[J]. Materials Reports,2017,31(14):117-121(in Chinese). doi: 10.11896/j.issn.1005-023X.2017.014.025 [2] LU J, YU H, KANG P F, et al. Study of microstructure, mechanical properties and impact-abrasive wear behavior of medium-carbon steel treated by quenching and partitioning (Q <italic>&</italic> P) process[J]. Wear,2018,414–415:21-30. [3] WANG C Y, LI X D, CHANG Y, et al. Comparison of three-body impact abrasive wear behaviors for quenching-partitioning-tempering and quenching-tempering 20Si2Ni3 steels[J]. Wear,2016,362–363:121-128. [4] BAI W, ROY A, SUN R L, et al. Enhanced machinability of SiC-reinforced metal-matrix composite with hybrid turning[J]. Journal of Materials Processing Technology,2019,268:149-161. [5] 陈奉锐, 山泉, 李祖来, 等. 重熔温度对WC<sub>P</sub>/Fe复合材料界面特征及压缩断裂机制的影响[J]. 复合材料学报, 2018, 35(11):3106-3113.CHEN F R, SHAN Q, LI Z L, et al. Effect of remelting temperature on interface characteristics and compression fracture mechanism of WC<sub>P</sub>/Fe composites[J]. Acta Materiae Compositae Sinica,2018,35(11):3106-3113(in Chinese). [6] 韩远飞, 孙相龙, 邱培坤, 等. 颗粒增强钛基复合材料先进加工技术研究与进展[J]. 复合材料学报, 2017, 34(8):1625-1635.HAN Y F, SUN X L, QIU P K, et al. Research and progress on advanced processing technology of particle reinforced titanium matrix composites[J]. Acta Materiae Compositae Sinica,2017,34(8):1625-1635(in Chinese). [7] 韦贺, 李祖来, 山泉, 等. WC体积分数对WC<sub>P</sub>/Fe复合材料组织及压缩性能的影响[J]. 复合材料学报, 2016, 33(11):2560-2568.WEI H, LI Z L, SHAN Q, et al. Effect of WC volume fraction on structure and compressive properties of WC<sub>P</sub>/Fe composites[J]. Acta Materiae Compositae Sinica,2016,33(11):2560-2568(in Chinese). [8] 郑开宏, 高义民, 李烨飞, 等. 具有钉扎效应的CTC<sub>P</sub>/Cr26复合材料制备及界面结构[J]. 稀有金属材料与工程, 2014, 43(3):698-702.ZHENG K H, GAO Y M, LI Y F, et al. Preparation and interface structure of CTC<sub>P</sub>/Cr26 composites with pinning effect[J]. Rare Metal Materials and Engineering,2014,43(3):698-702(in Chinese). [9] ZIEJEWSKA C, MARCZYK J, SZEWCZYK-NYKIEL A, et al. Influence of size and volume share of WC particles on the properties of sintered metal matrix composites[J]. Advanced Powder Technology,2019,30(4):835-842. doi: 10.1016/j.apt.2019.01.013 [10] QIU B, XING S M, DONG Q. Fabrication and wear behavior of ZTA particles reinforced iron matrix composite produced by flow mixing and pressure compositing[J]. Wear,2019,428–429:167-177. [11] HASAN Y, RECEP S. Impact wear behavior of ball burnished 316L stainless steel[J]. Surface and Coatings Technology,2019,363:369-378. doi: 10.1016/j.surfcoat.2019.02.022 [12] 包昂, 卢德宏. WC<sub>P</sub>/高锰钢基复合材料及复合结构的冲击磨损性能[J]. 材料工程, 2018, 46(4):91-98.BAO A, LU D H. Impact wear properties of WC<sub>P</sub>/high manganese steel matrix composites and composite structures[J]. Journal of Materials Engineering,2018,46(4):91-98(in Chinese). [13] 何翠. ZGMn13Cr2高锰钢不同条件下加工硬化及冲击磨损行为研究[D]. 长沙: 湖南大学, 2016.HE C. Study on work hardening and impact wear behavior of ZGMn13Cr2 high manganese steel under different conditions[D]. Changsha: Hunan University, 2016(in Chinese). [14] 田山雪, 涂小慧, 杨浩, 等. Al<sub>2</sub>O<sub>3</sub>陶瓷增强高锰钢基复合材料耐磨性能的研究[J]. 铸造, 2017, 66(5):476-480. doi: 10.3969/j.issn.1001-4977.2017.05.009TIAN S X, TU X H, YANG H, et al. Study on wear resistance of Al<sub>2</sub>O<sub>3</sub> ceramic reinforced high manganese steel matrix composites[J]. Foundry,2017,66(5):476-480(in Chinese). doi: 10.3969/j.issn.1001-4977.2017.05.009 [15] 宋怀江, 张国赏. 碳化钨增强高锰钢基复合材料冲击磨损性能的研究[J]. 铸造技术, 2005, 26(6):468-469, 477. doi: 10.3969/j.issn.1000-8365.2005.06.006SONG H J, ZHANG G S. Study on impact wear properties of tungsten carbide reinforced high manganese steel matrix composites[J]. Foundry Technology,2005,26(6):468-469, 477(in Chinese). doi: 10.3969/j.issn.1000-8365.2005.06.006 [16] 张荻, 张国定, 李志强. 金属基复合材料的现状与发展趋势[J]. 中国材料进展, 2010, 29(4):1-7.ZHANG D, ZHANG G D, LI Z Q. Current status and development trend of metal matrix composites[J]. Materials China,2010,29(4):1-7(in Chinese). [17] 李响, 周幼辉, 童冠, 等. 超轻多孔类蜂窝夹心结构创新构型及其力学性能[J]. 西安交通大学学报, 2014, 48(9):88-94.LI X, ZHOU Y H, TONG G, et al. Innovative configuration and mechanical properties of ultra-light porous honeycomb sandwich structure[J]. Journal of Xi’an Jiaotong University,2014,48(9):88-94(in Chinese). [18] 廖冲. 空间结构形式对钢基复合材料力学性能的影响[D]. 昆明: 昆明理工大学, 2017.LIAO C. Effect of spatial structure on mechanical properties of steel matrix composites[D]. Kunming: Kunming University of Science and Technology, 2017(in Chinese). [19] 廖冲, 卢德宏, 余晶, 等. Ti活化Al<sub>2</sub>O<sub>3P</sub>/65钢复合材料的组织和性能[J]. 特种铸造及有色合金, 2017, 37(2):190-193.LIAO C, LU D H, YU J, et al. Microstructure and properties of Ti-activated Al<sub>2</sub>O<sub>3P</sub>/65steel composites[J]. Special Casting <italic>&</italic> Nonferrous Alloys,2017,37(2):190-193(in Chinese). [20] 赵馨月, 卢德宏, 郭红星, 等. 球状结构钢基MMCs/钢三维互穿网络复合材料的制备[J]. 特种铸造及有色合金, 2016, 36(8):852-855.ZHAO X Y, LU D H, GUO H X, et al. Preparation of composites of MMCs and steel with three dimensional interpenetrating network structure[J]. Special Casting <italic>&</italic> Nonferrous Alloys,2016,36(8):852-855(in Chinese). -

下载:

下载: