Experimental study on axial compression of corroded reinforced concrete columns strengthened with FRP strips under erosion environment

-

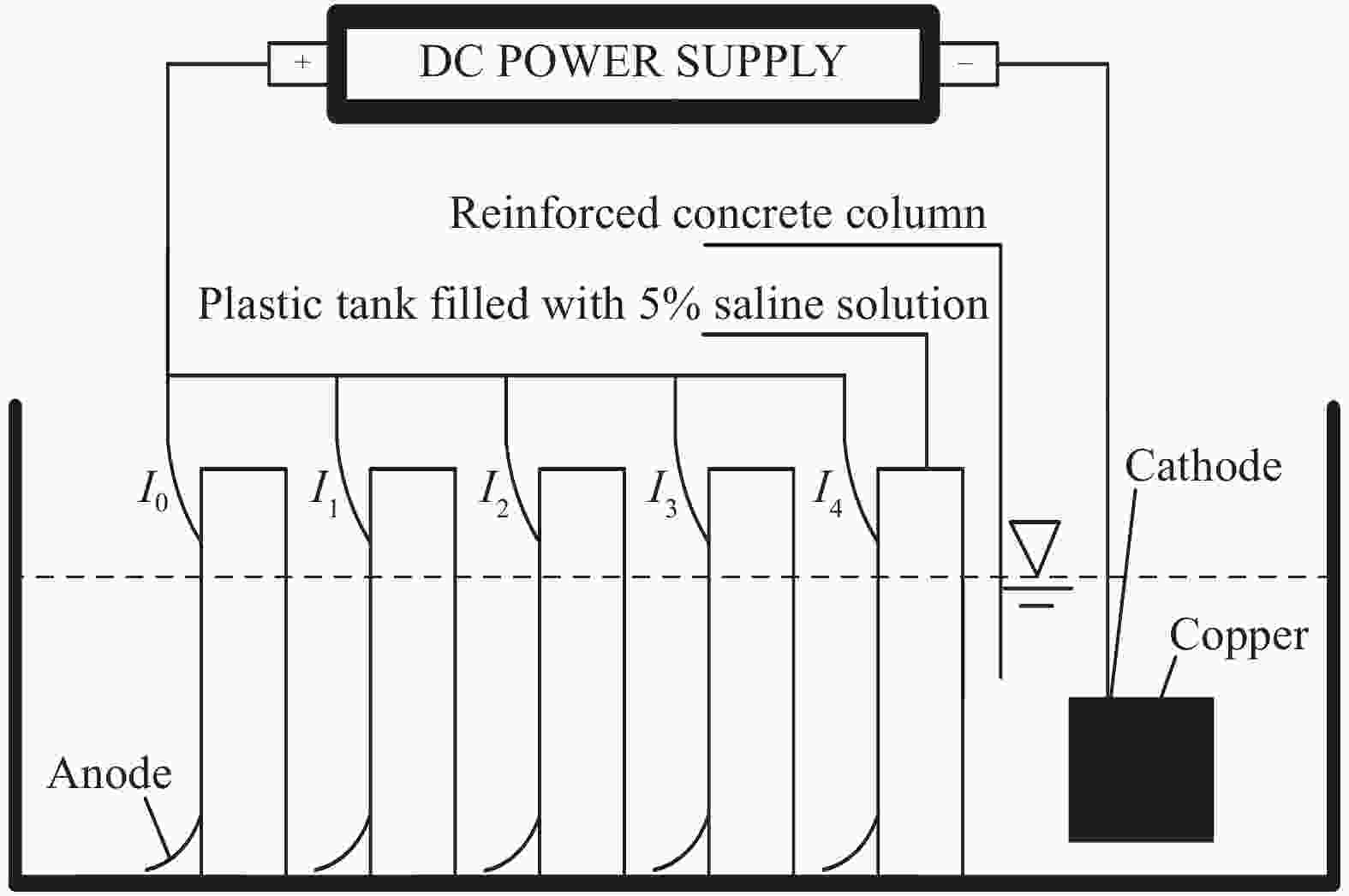

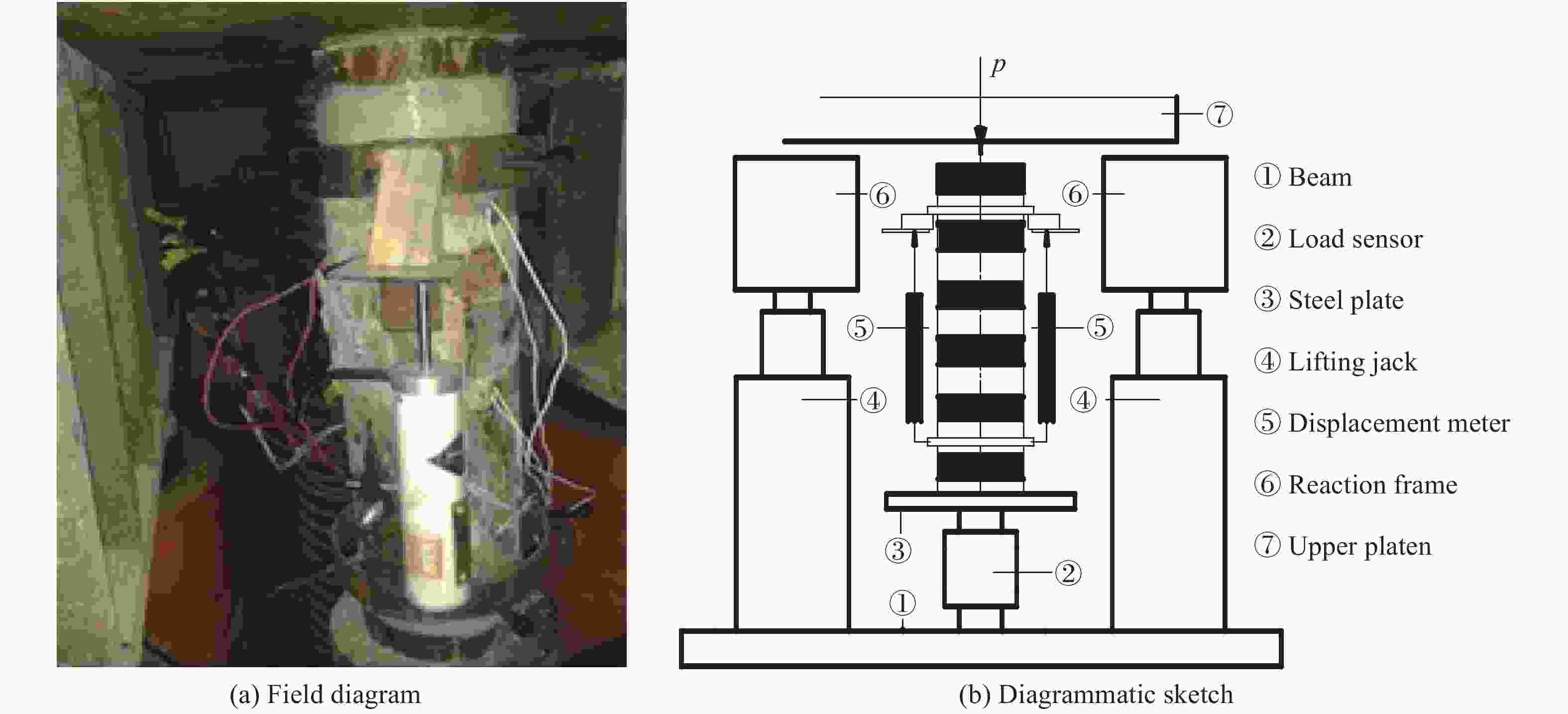

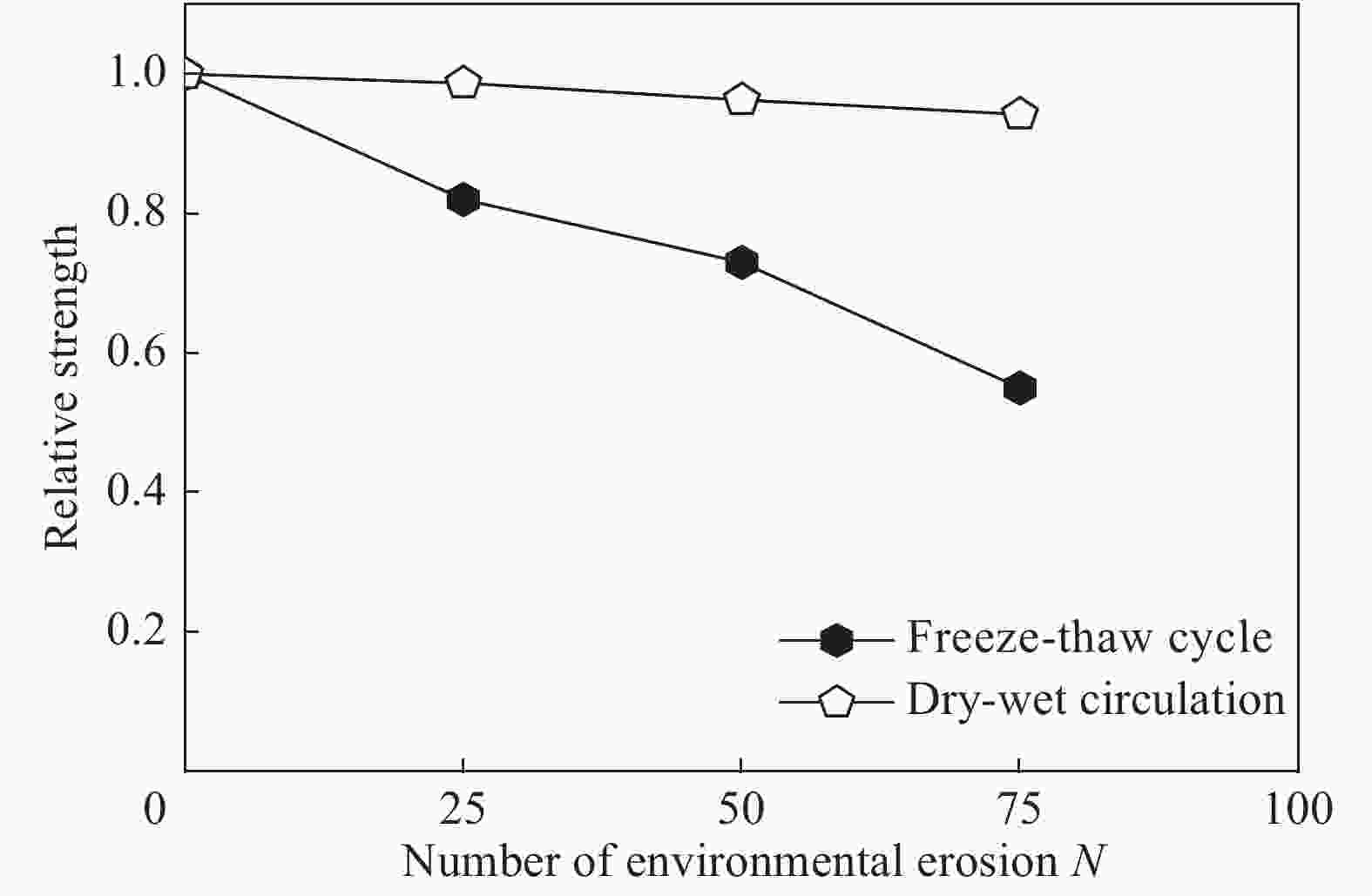

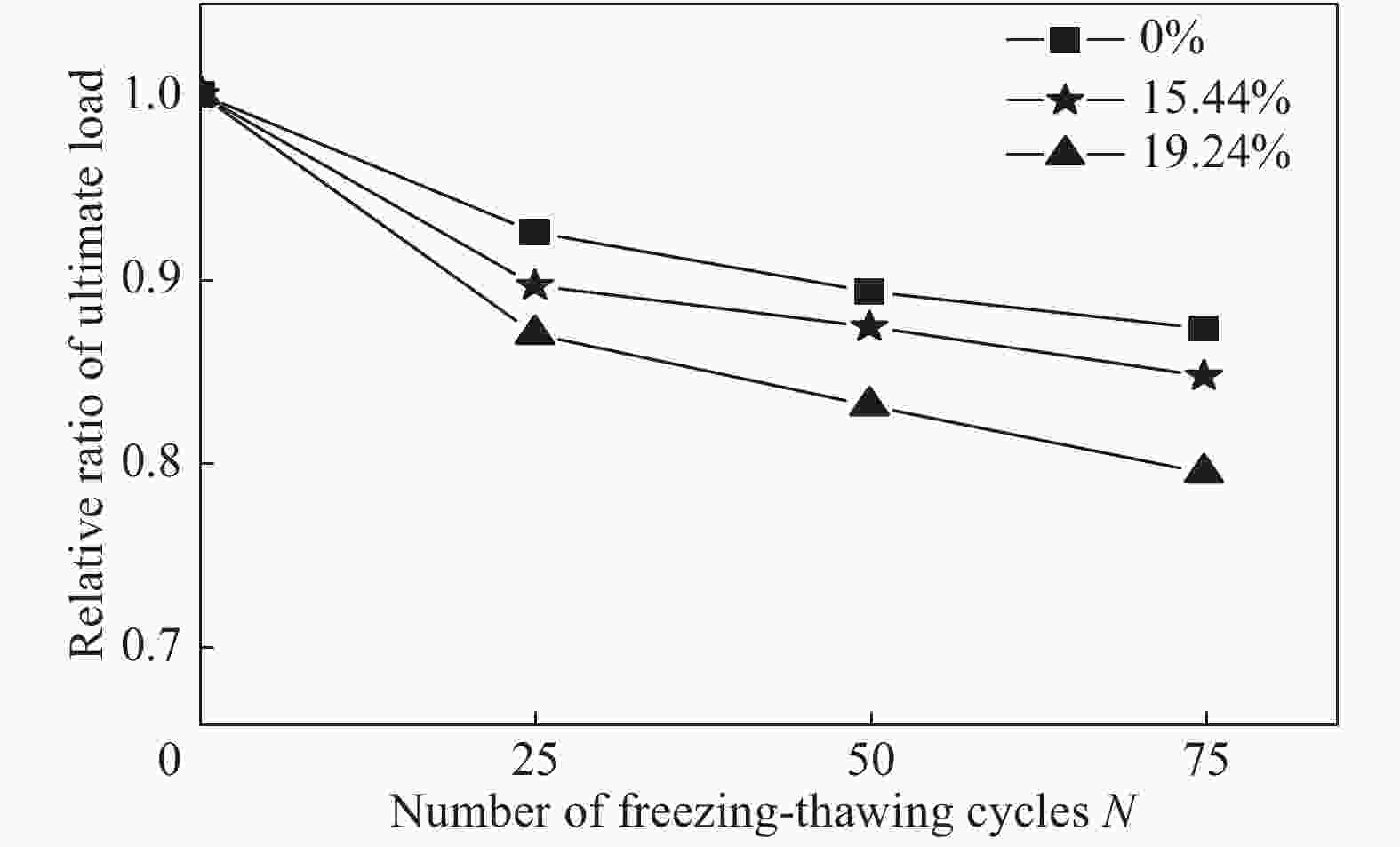

摘要: 通过侵蚀环境下碳纤维增强聚合物(CFRP)复合材料条带和玻璃纤维增强聚合物(GFRP)复合材料条带加固锈蚀钢筋混凝土圆柱试验,分析了侵蚀环境对混凝土强度、纤维增强聚合物基复合材料加固锈蚀柱的极限荷载和荷载-轴向位移曲线的影响。结果表明,混凝土强度受冻融环境影响较大,受干湿环境影响较小;纤维增强聚合物(FRP)复合材料加固锈蚀柱的轴向极限荷载与冻融循环次数、钢筋锈蚀率及FRP复合材料种类有关,随冻融循环次数分别增加到25次、50次、75次,GFRP复合材料条带和CFRP复合材料条带加固锈蚀钢筋混凝土圆柱的轴向极限荷载分别降低了10.97%、13.37%、16.04%和5.95%、4.66%、4.33%;FRP复合材料加固锈蚀柱的刚度和耗能受侵蚀环境种类、侵蚀环境作用次数、锈蚀率及FRP复合材料种类的影响。在试验研究的基础上,通过理论分析侵蚀环境下混凝土强度损伤系数和锈蚀钢筋强度退化方程,提出了侵蚀环境下FRP复合材料条带加固锈蚀钢筋混凝土圆柱轴心受压承载力计算方法。

-

关键词:

- 侵蚀环境 /

- 冻融循环 /

- 纤维增强聚合物复合材料 /

- 锈蚀钢筋混凝土圆柱 /

- 轴心受压承载力

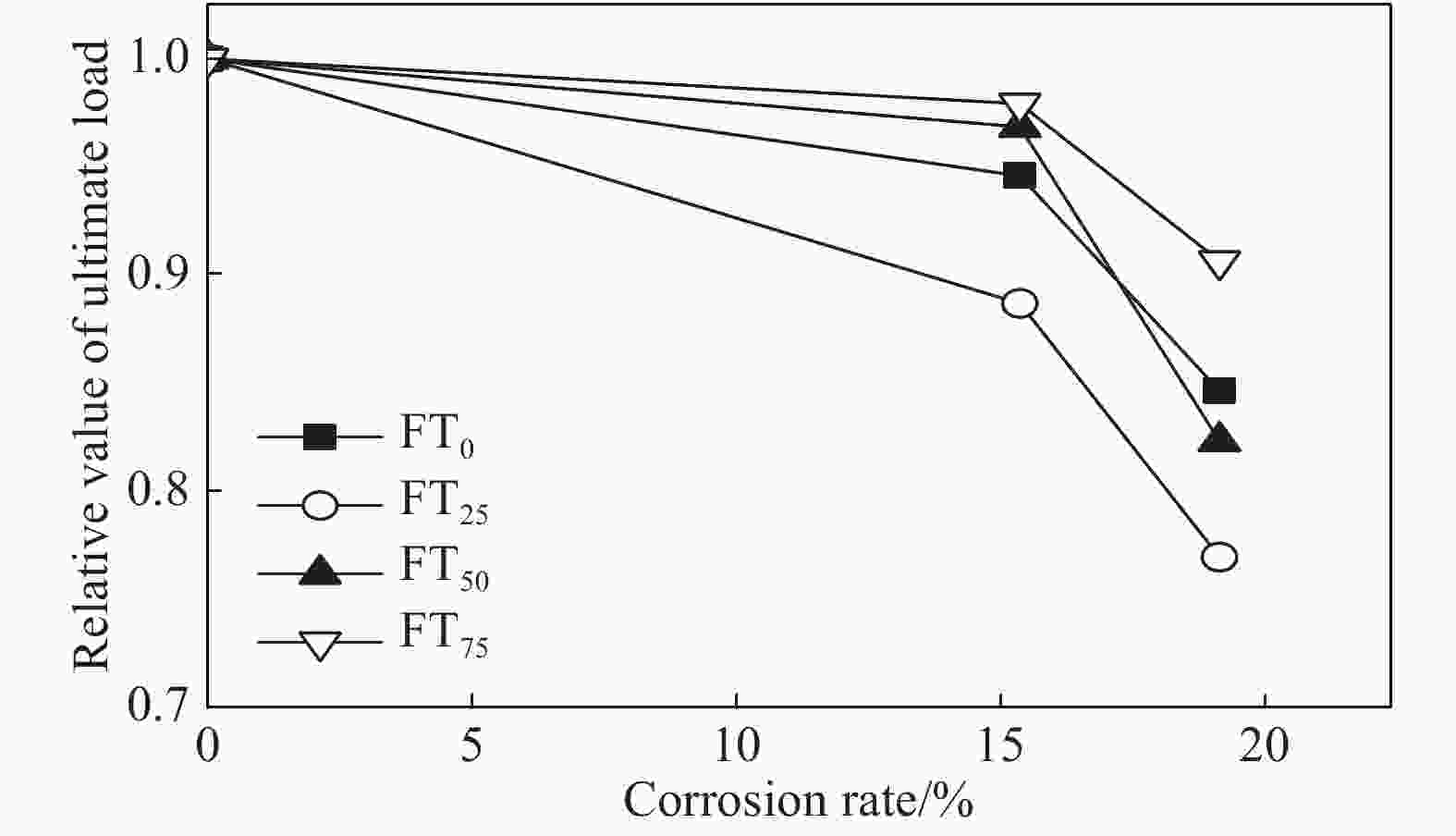

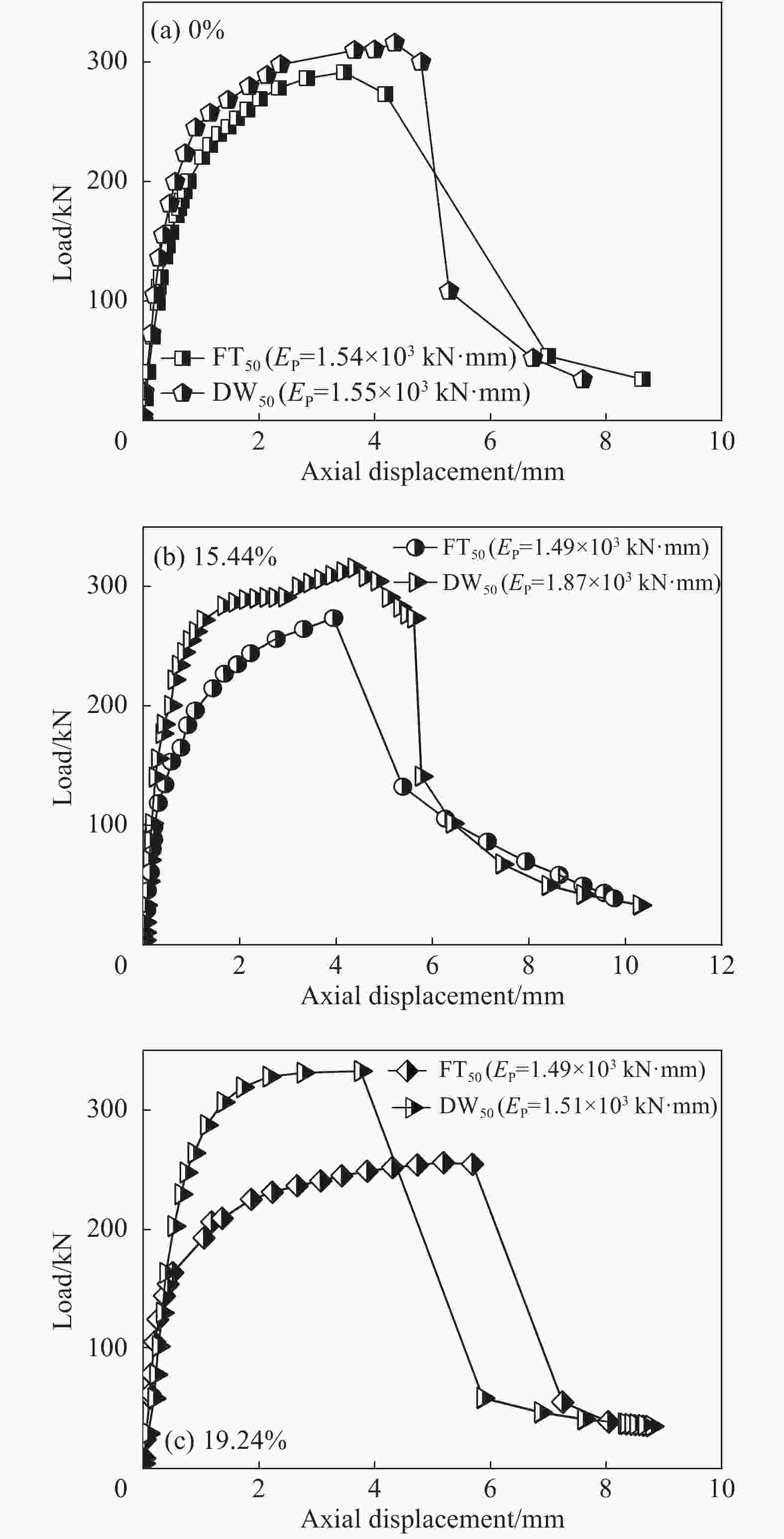

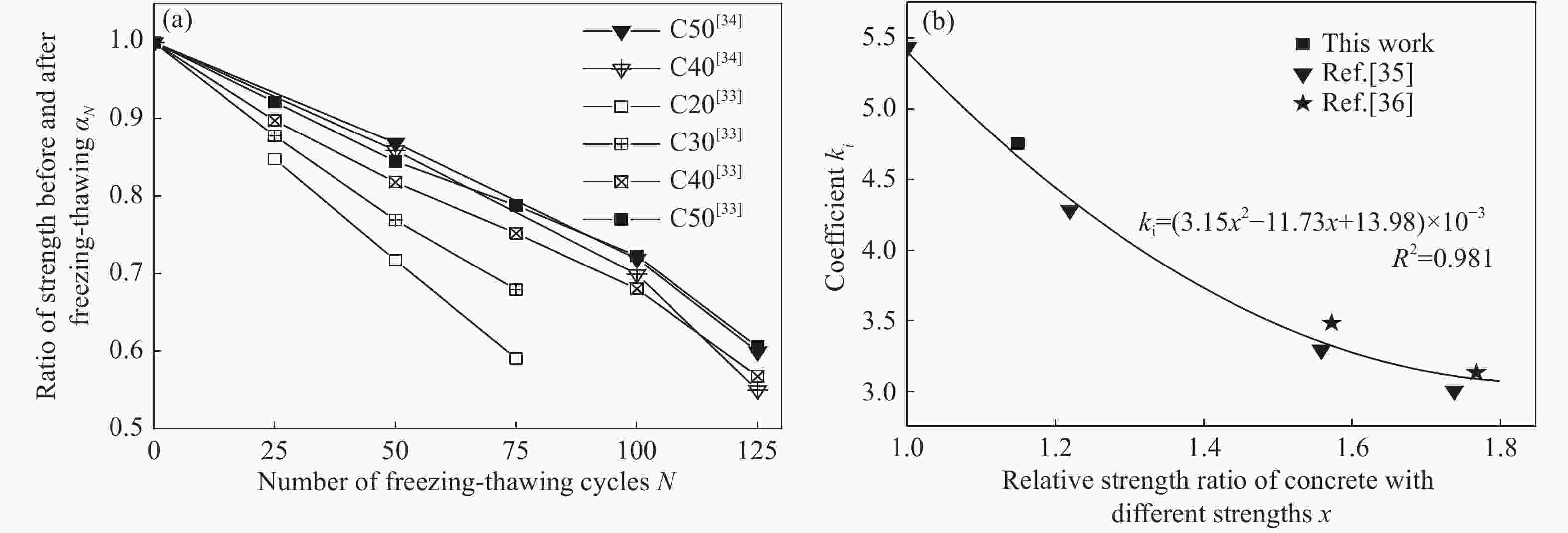

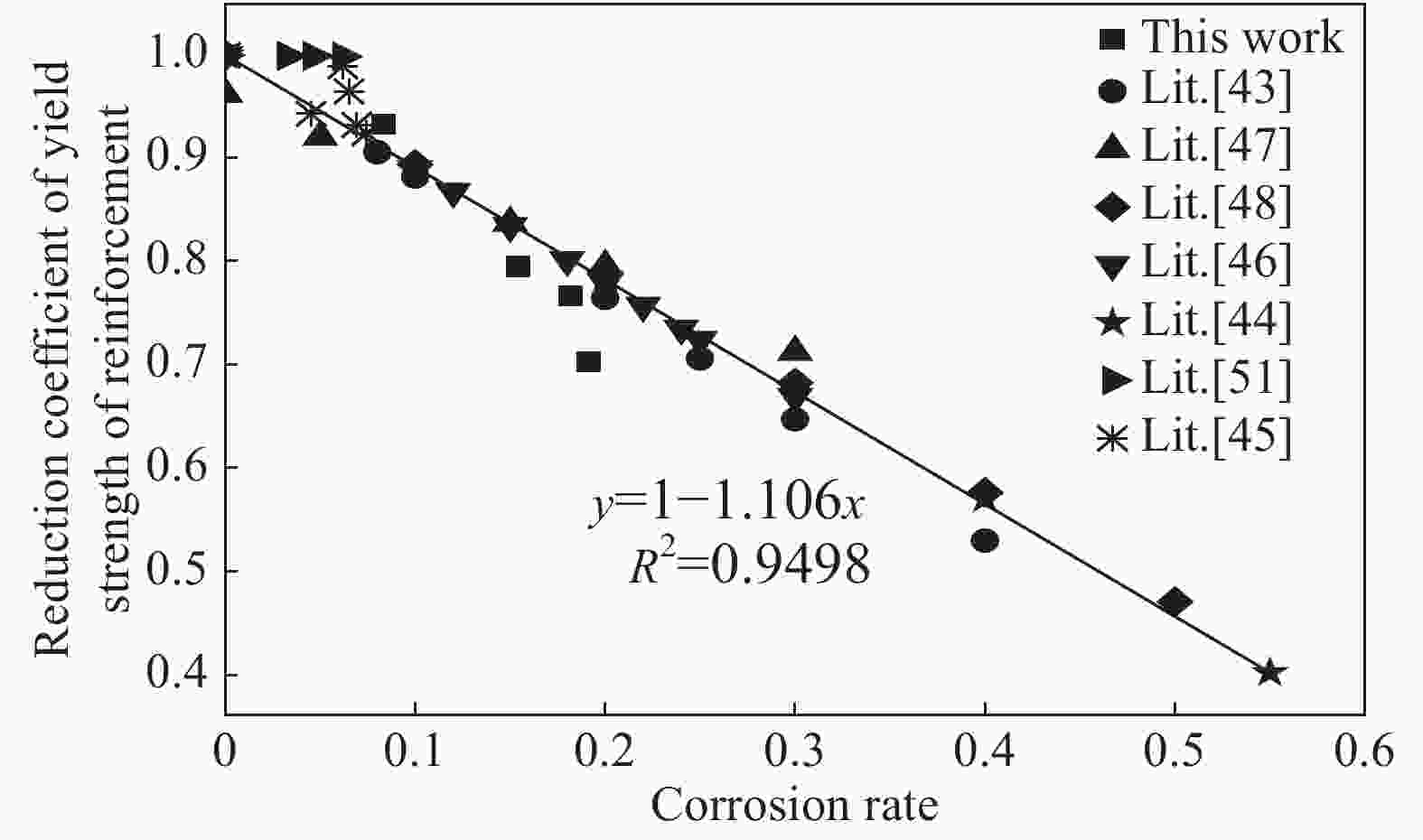

Abstract: Through the test of corroded reinforced concrete columns which were strengthened with carbon fiber reinforced polymer (CFRP) composite strips and glass fiber reinforced polymer (GFRP) composite strips in the erosion environment, the influences of erosion environment on the concrete strength, the ultimate load and the axial load-displacement relationship curve of corroded and FRP strengthened concrete columns were analyzed. The result shows that the strength of the concrete is greatly affected by the freeze-thaw environment and is less affected by the dry and wet environment. The axial ultimate load of FRP reinforced damaged columns is related to the number of freeze-thaw cycles, the corrosion rate of steel bars and the type of FRP composite. With the increase of freeze-thaw cycles from 0 to 25, 50 and 75, the axial ultimate loads of corroded reinforced concrete columns strengthened with GFRP composite and CFRP composite strips are decreased by 10.97%, 13.37%, 16.04% and 5.95%, 4.66%, 4.33% respectively. The load-axial displacement curve of the FRP composite reinforced corrosion column reflects the stiffness and the energy consumption of the column, and both of which are affected by the type of erosion environment, the number of times of the erosion environment, the corrosion rate of steel bars and the type of FRP composite. Through the experimental research, the damage coefficient of concrete strength and the regression equation of the strength of corroded bar in the erosion environment were theoretically analyzed. A method for calculating the axial compression capacity of corroded reinforced concrete columns strengthened with FRP composite strips under erosion environment was presented. -

图 10 锈蚀率固定时冻融循环次数对GFRP复合材料条带加固锈蚀钢筋混凝土圆柱荷载-轴向位移曲线的影响

Figure 10. Influence of freeze-thaw cycles on load-axial displacement curves of corroded reinforced concrete columns strengthened with GFRP strips with fixed corrosion rates

Ep—Area enclosed by the load displacement curve and the abscissa, reflecting the energy dissipation (Ep) of the structure

表 1 侵蚀环境下纤维增强聚合物(FRP)条带加固锈蚀钢筋混凝土圆柱轴心受压试验设计

Table 1. Experiment design on axial compression of corroded reinforced concrete columns strengthened with fiber reinforced ploymer(FRP) strips under erosion environment

Number Type of FRP Corrosion rate a/% Type of environment Number of times of the environment GFRP-Concrete(0%,FTn) GFRP 0 Freeze-thaw 0,25,50,75 GFRP-Concrete(15.44%,FTn) GFRP 15.44 Freeze-thaw 0,25,50,75 CFRP-Concrete(15.44%,FTn) CFRP 15.44 Freeze-thaw 0,25,50,75 GFRP-Concrete(19.24%,FTn) GFRP 19.24 Freeze-thaw 0,25,50,75 GFRP-Concrete(a, DW50) GFRP 0,15.44,19.24 Dry-wet 50 Notes: FT—Freeze-thaw cycle; DW—Dry-wet cycle; GFRP—Glass fiber reinforced polymer; CFRP—Carbon fiber reinforced polymer. 表 2 FRP条带加固锈蚀钢筋混凝土柱的计算值与试验值比较

Table 2. Comparison of calculated value and experimental value of corroded reinforced concrete columns strengthened with FRP strips

Number ${a_N}$ ${k_{\rm{f}}}$ ${\gamma _{{\rm{se}}}}$ ${A_{{\rm{ce}}}}$/mm2 ${N_{\rm{e}}}$/kN ${N_{{\rm{ue}}}}$/kN ${N_{\rm{e}}}$/${N_{{\rm{ue}}}}$ GFRP-Concrete(0%,FT0) 1 4.82 1 7 850 340 340.92 1.00 GFRP-Concrete(0%,FT25) 0.92 4.82 1 7 850 324.17 318.71 1.02 GFRP-Concrete(0%,FT50) 0.83 4.82 1 7 850 289.2 296.44 0.97 GFRP-Concrete(0%,FT75) 0.75 4.82 1 7 850 231.1 274.35 0.91 GFRP-Concrete(15.44%,FT0) 1 4.34 0.829 7 069.72 321.6 304.01 1.05 GFRP-Concrete(15.44%,FT25) 0.92 4.34 0.829 7 069.72 287.5 284.00 1.02 GFRP-Concrete(15.44%,FT50) 0.83 4.34 0.829 7 069.72 280.1 263.94 1.06 GFRP-Concrete(15.44%,FT75) 0.75 4.34 0.829 7 069.72 226.3 244.05 0.93 CFRP-Concrete(15.44%,FT0) 1 4.34 0.829 7 069.72 453.6 425.15 1.06 CFRP-Concrete(15.44%,FT25) 0.92 4.34 0.829 7 069.72 390.5 348.80 1.11 CFRP-Concrete(15.44%,FT50) 0.83 4.34 0.829 7 069.72 348.3 328.99 1.06 CFRP-Concrete(15.44%,FT75) 0.75 4.34 0.829 7 069.72 324.6 309.16 1.05 GFRP-Concrete(19.24%,FT0) 1 4.13 0.787 6 720.14 287.83 288.98 0.99 GFRP-Concrete(19.24%,FT25) 0.92 4.13 0.787 6 720.14 249.5 269.96 0.93 GFRP-Concrete(19.24%,FT50) 0.83 4.13 0.787 6 720.14 238.1 250.96 0.95 GFRP-Concrete(19.24%,FT75) 0.75 4.13 0.787 6 720.14 209.5 231.98 0.92 GFRP-Concrete(0%,DW50) 1 4.82 1 7 850 316 340.92 0.93 GFRP-Concrete(15.44%,DW50) 1 4.34 0.829 7 069.72 312.33 304.01 1.03 GFRP-Concrete(19.24%,DW50) 1 4.13 0.787 6 720.14 318.5 288.98 1.10 GFRP-Concrete(0%,FT0)[7] 1 4.82 1 7 850 350 346.9 1.01 GFRP-Concrete(0%,FT50)[7] 0.84 4.82 1 7 850 306 302.5 1.01 GFRP-Concrete(0%,FT75)[7] 0.76 4.82 1 7 850 307 280.5 1.10 GFRP-Concrete(0%,FT100)[7] 0.68 4.82 1 7 850 332 258.3 1.18 CFRP-Concrete(0%,FT0)[7] 1 4.82 1 7 850 415 398.7 1.04 CFRP-Concrete(0%,FT50)[7] 0.84 4.82 1 7 850 353 355.0 0.99 CFRP-Concrete(0%,FT75)[7] 0.76 4.82 1 7 850 361 333.3 1.09 CFRP/Concrete(0%,FT100)[7] 0.68 4.82 1 7 850 354 311.4 1.14 CFRP-Concrete(0%,FT0)[52] 1 5.38 1 50 000 1 585 1671.1 0.95 CFRP-Concrete(26.6%,FT0)[52] 1 5.38 1 50 000 1 287 1304.4 0.99 Average value − − − − − − 1.020 Coefficient of variation − − − − − − 0.002 Notes: Upper right corner [7] and [52] of the specimen number indicate that the data is from refernces [7] and [52]; ${k_{\rm{f}}}$—Contribution of the constraint effect of FRP strips to the axial compression capacity; ${\gamma _{{\rm{se}}}}$—Yield strength reduction coefficient of corroded steel bars; ${A_{{\rm{ce}}}}$—Section area of the column under the erosion environment; ${N_{\rm{e}}}$(${N_{{\rm{ue}}}}$)—Experimental value(the calculated value) of the bearing capacity of the corroded reinforced concrete column strengthened with FRP strip under axial compression under the erosion environment; ${N_{\rm{e}}}/{N_{{\rm{ue}}}}$—Ratio between the measured value of the test and the calculated value of equation (11). -

[1] MONTEIRO P, KURTIS K E. Time to failure for concrete exposed to severe sulfate attack[J]. Cement and Concrete Research,2003,33(7):987-993. [2] ODRIOZOLA M, GUTIÉRREZ P A. Comparative study of different test methods for reinforced concrete durability assessment in marine environment[J]. Materials and Structures,2008,41(3):527-541. doi: 10.1617/s11527-007-9263-8 [3] 张芹. 钢筋混凝土氯离子侵蚀与锈胀致裂过程耦合分析方法研究[D]. 南京: 东南大学, 2018.ZHANG Q. Study on coupling analysis method of chloride corrosion and rust expansion cracking process of reinforced concrete[D]. Nanjing: Southeast University, 2018(in Chinese). [4] 任慧韬. 纤维增强复合材料加固混凝土结构基本力学性能和长期受力性能研究[D]. 大连: 大连理工大学, 2003.REN H T. Study on the basic mechanical properties and long-term stress properties of concrete structures reinforced with fiber-reinforced composites[D]. Dalian: Dalian University of Technology, 2003(in Chinese). [5] WANG Y L, CHEN G P, WAN B L, et al. Behavior of circular ice-filled self-luminous FRP tubular stub columns under axial compression[J]. Construction and Building Materials,2020,232(30):117287. [6] 卢亦焱. 纤维增强复合材料与钢材复合加固混凝土结构研究进展[J]. 建筑结构学报, 2018, 39(10):138-146.LU Y Y. Research progress of fiber reinforced composite and steel composite reinforced concrete structure[J]. Journal of Building Structure,2018,39(10):138-146(in Chinese). [7] 李趁趁. FRP加固混凝土结构耐久性试验研究[D]. 大连: 大连理工大学, 2006.LI C C. Experimental study on durability of FRP reinforced concrete structures[D]. Dalian: Dalian University of Technology, 2006(in Chinese). [8] WANG Y L, CAI G C, LI Y Y, et al. Behavior of circular fiber-reinforced polymer-steel-confined concrete columns subjected to reversed cyclic loads: Experimental studies and finite-element analysis[J]. J. Struct. Eng.,2019,145(9):04019085. doi: 10.1061/(ASCE)ST.1943-541X.0002373 [9] FAHMY M F M W Z. Evaluating and proposing models of circular concrete columns confined with different FRP composites[J]. Composites Part B: Engineering,2010,41(3):199-213. doi: 10.1016/j.compositesb.2009.12.001 [10] REALFONZO R N A. Concrete confined by FRP systems: confinement efficiency and design strength models[J]. Composites Part B: Engineering,2011,42(4):736-755. doi: 10.1016/j.compositesb.2011.01.028 [11] SUN W B. Experimental study on the compressive behaviors of CFRP tube-encased concrete columns[J]. Theoretical and Applied Mechanics Letters,2011,1(2):31-34. [12] WU Y F, WEI Y Y. Effect of cross-sectional aspect ratio on the strength of CFRP-confined rectangular concrete columns[J]. Engineering Structures,2010,32(1):32-45. [13] 中国工程建设标准化协会. 碳纤维片材加固修复混凝土结构技术规程: CECS146—2007[S]. 北京: 中国标准出版社, 2007.China Engineering Construction Standardization Association. Technical specification for reinforcing concrete structures with carbon fiber sheets: CECS146−2007[S]. Beijing: China Standard Press, 2007(in Chinese). [14] 中华人民共和国住房和城乡建设部. 混凝土结构加固设计规范: GB/T 50367—2013[S]. 北京: 中国建筑工业出版社, 2013.Ministry of Housing and Urban-Rural Development, PRC. Specification for reinforcement of concrete structures: GB/T 50367—2013[S]. Beijing: China Architecture & Building Press, 2013(in Chinese). [15] 中华人民共和国住房和城乡建设部. 纤维增强复合材料建设工程应用技术规范: GB50608—2010[S]. 北京: 中国标准出版社, 2010.Ministry of Housing and Urban-Rural Development of People's Republic of China . Technical specifications for application of fiber reinforced composite construction engineering: GB50608—2010[S]. Beijing: China Standard Press, 2010(in Chinese). [16] 于爱民, 李趁趁, 高丹盈, 等. 恶劣环境下纤维增强聚合物片材拉伸性能[J]. 复合材料学报, 2017(7):1496-1504.YU A M, LI C C, GAO D Y, et al. Tensile properties of fiber-reinforced polymer sheets in harsh environments[J]. Acta Materiae Compositae Sinica,2017(7):1496-1504(in Chinese). [17] 全国纤维增强塑料标准化技术委员会与全国航空器标准化技术委员会. 定向纤维增强聚合物基复合材料拉伸性能试验方法: GB/T 3354—2014[S]. 北京: 中国标准出版社, 2014.National Fiber Reinforced Plastics Standardization Technical Committee and National Aircraft Standardization Technical Committee. Test method for tensile properties of directional fiber reinforced polymer matrix composites: GB/T 3354—2014[S]. Beijing: China Standards Press, 2014(in Chinese). [18] 中华人民共和国住房和城乡建设部. 普通混凝土长期性能和耐久性能试验方法标准: GB/T 50082—2009[S]. 北京: 建筑工业出版社, 2009.Ministry of Housing and Urban-Rural Development of People's Republic of China. Test method standard for long-term performance and durability of ordinary concrete: GB/T 50082—2009[S]. Beijing: Building Industry Press, 2009(in Chinese). [19] 高丹盈, 李趁趁, 赵广田. 纤维增强聚合物条带约束混凝土圆柱的耐久性[J]. 水利学报, 2008(6):739-746. doi: 10.3321/j.issn:0559-9350.2008.06.016GAO D Y, L C C, ZHAO G T. The durability of fiber-reinforced polymer strip confined concrete columns[J]. Journal of Hydraulic Engineering,2008(6):739-746(in Chinese). doi: 10.3321/j.issn:0559-9350.2008.06.016 [20] 张玲玲, 张陵, 马建勋. 外粘贴CFRP加固混凝土结构在海洋环境下的耐久性试验研究[J]. 土木工程学报, 2010(1):77-81.ZHANG L L, ZHANG L, MA J X. Experimental study on durability of CFRP reinforced concrete structures in marine environment[J]. China Civil Engineering Journal,2010(1):77-81(in Chinese). [21] 曹建国, 李金玉. 混凝土冻融破坏机理的研究[J]. 水利学报, 1999, 1:41-49. doi: 10.3321/j.issn:0559-9350.1999.01.008CAO J G, LI J Y. Study on the freezing and thawing failure mechanism of concrete[J]. Journal of Hydraulic Engineering,1999,1:41-49(in Chinese). doi: 10.3321/j.issn:0559-9350.1999.01.008 [22] 唐光普, 刘西拉, 施士升. 冻融条件下混凝土破坏面演化模型研究[J]. 岩石力学与工程学报, 2006(12):2572-2578. doi: 10.3321/j.issn:1000-6915.2006.12.026TANG G P, LIU X L, SHI S S. Study on evolution model of concrete failure surface under freezing and thawing condition[J]. Chinese Journal of Rock Mechanics and Engineering,2006(12):2572-2578(in Chinese). doi: 10.3321/j.issn:1000-6915.2006.12.026 [23] 唐光普, 刘西拉. 基于唯象损伤观点的混凝土冻害模型研究[J]. 四川建筑科学研究, 2007(3):138-143. doi: 10.3969/j.issn.1008-1933.2007.03.039TANG G P, LIU X L. Study on freezing damage model of concrete based on phenodortic damage theory[J]. Sichuan Building Science,2007(3):138-143(in Chinese). doi: 10.3969/j.issn.1008-1933.2007.03.039 [24] 蔡昊. 混凝土抗冻耐久性预测模型[D]. 北京: 清华大学, 1998.CAI H. Prediction model of concrete frost resistance durability[D]. Beijing: Tsinghua University, 1998(in Chinese). [25] 莫斯克文·伊万诺夫·阿列克谢列夫. 混凝土和钢筋混凝土的腐蚀及其防护方法[M]. 北京: 化学工业出版社, 1998.MOSKOWWEN I A. Corrosion of concrete and reinforced concrete and their protection methods[M]. Beijing: Chemical Industry Press, 1998(in Chinese). [26] NEVILLE A M. Properties of concrete[M]. New York: John W iley & Sons Inc, 1996: 561−565. [27] 于爱民, 李趁趁, 高丹盈. FRP加固锈蚀钢筋凝土圆柱轴心受压承载力试验研究[J]. 复合材料学报, 2018, 35(5):1315-1324.YU A M, LI C C, GAO D Y. Experimental study on axial compressive load-bearing capacity of corroded reinforced concrete columns strengthened with FRP[J]. Journal of Composite Materials,2018,35(5):1315-1324(in Chinese). [28] KOOTSOOKOS A M A P. Seawater durability of glass and carbon-polymer composites[J]. Composites Science and Technology,2004,64:1503-1511. doi: 10.1016/j.compscitech.2003.10.019 [29] 周长东. 玻璃纤维聚合物加固混凝土柱的力学性能研究[D]. 大连: 大连理工大学, 2003.ZHOU C D. Mechanical properties of glass fiber reinforced polymer reinforced concrete columns[D]. Dalian: Dalian University of Technology, 2003(in Chinese). [30] HUANG L, GAO C, YAN L, et al. Reliability assessment of confinement models of carbon fiber reinforced polymer-confined concrete[J]. Journal of Reinforced Plastics and Composites,2016,35(12):996-1026. [31] BENZAID R, MESBAH H, CHIKH N E. FRP-confined concrete cylinders: Axial compression experiments and strength model[J]. Journal of Reinforced Plastics and Composites,2010,29(16):2469-2488. [32] GIRGIN Z. Modified johnston failure criterion from rock mechanics to predict the ultimate strength of fiber reinforced polymer (FRP) confined columns[J]. Polymers,2014,6(1):59-75. [33] 富立志. 冻融环境下混凝土单轴受拉性能的试验研究[D]. 扬州: 扬州大学, 2010.FU L Z. Experimental study on the uniaxial tension behavior of concrete in freeze-thaw environment[D]. Yangzhou:Yangzhou University, 2010(in Chinese). [34] 曹大富, 葛文杰, 郭容邑, 等. 冻融循环作用后钢筋混凝土梁受弯性能试验研究[J]. 建筑结构学报, 2014(6):137-144.CAO D F, GE W J, GUO R Z, et al. Experimental study on the flexural behavior of reinforced concrete beams subjected to freezing and thawing cycles[J]. Journal of Architectural Structure,2014(6):137-144(in Chinese). [35] 马钊. 冻融循环后混凝土偏心受压构件正截面承载能力的试验研究[D]. 扬州: 扬州大学, 2012.MA Z. Experimental study on the normal section bearing capacity of concrete eccentric compression members after freeze-thaw cycles[D]. Yangzhou: Yangzhou University, 2012(in Chinese). [36] 张燕. 冻融循环和氯盐腐蚀作用下钢筋与混凝土粘结锚固性能的试验研究[D]. 扬州: 扬州大学, 2007.ZHANG Y. Experimental study on bond and anchorage performance between steel bars and concrete under freeze-thaw cycle and chloride corrosion[D]. Yangzhou: Yangzhou University, 2007(in Chinese). [37] 陈瑞明. 冻融与锈蚀耦合对无粘结预应力梁承载力的影响[D]. 重庆: 重庆交通大学, 2016.CHEN R M. Influence of freeze-thaw and corrosion coupling on bearing capacity of unbonded prestressed beams[D]. Chongqing: Chongqing Jiao Tong University, 2016(in Chinese). [38] 沙勇, 杨君, 窦立军. 冻融和锈蚀环境下混凝土受弯构件的刚度计算模式研究[J]. 长春工程学院学报(自然科学版), 2012(4):10-12.SHA Y, YANG J, DOU L J. A study on the rigidity calculation model for concrete flexural member under freeze-thaw and corrosion environments[J]. Journal of Changchun Institute of Technology (Natural Science Edition),2012(4):10-12(in Chinese). [39] 杜晓雷. 钢筋混凝土梁在冻融循环和锈蚀下的受弯性能研究[D]. 长春: 吉林大学, 2011.DU X L. Research on flexural behavior of reinforced concrete beams subjected to freeze-thaw cycles and corro-sion[D]. Changchun: Jilin University, 2011(in Chinese). [40] 周禹. 钢筋锈蚀与冻融作用下钢筋混凝土梁的抗弯性能[D]. 沈阳: 沈阳建筑大学, 2012.ZHOU Y. Bending resistance of reinforced concrete beams under corrosion and freeze-thaw cycles of steel bars[D]. Shenyang: Shenyang University of Construction, 2012(in Chinese). [41] 付明春. 基于锈蚀与冻融作用下钢筋混凝土梁的抗弯性能分析[J]. 沈阳工程学院学报(自然科学版), 2015(2):189-192.FU M C. Analysis of flexural performance of reinforced concrete beams based on corrosion and freeze-thaw[J]. Journal of Shenyang Institute of Engineering (Natural Science Edition),2015(2):189-192(in Chinese). [42] 惠云玲, 林志伸, 李荣. 锈蚀钢筋性能试验研究分析[J]. 工业建筑, 1997(6):11-14.HUI Y L, LIN Z S, LI R. Analysis and analysis of performance of corroded reinforcing bars[J]. Industrial Construction,1997(6):11-14(in Chinese). [43] 张伟平, 商登峰, 顾祥林. 锈蚀钢筋应力-应变关系研究[J]. 同济大学学报(自然科学版), 2006(5):586-592. doi: 10.3321/j.issn:0253-374X.2006.05.004ZHANG W P, SHANG D F, GU X L. Study on stress-strain relationship of corroded steel bars[J]. Journal of Tong ji University(Natural Science),2006(5):586-592(in Chinese). doi: 10.3321/j.issn:0253-374X.2006.05.004 [44] 张伟平, 顾祥林, 金贤玉, 等. 混凝土中钢筋锈蚀机理及锈蚀钢筋力学性能研究[J]. 建筑结构学报, 2010(S1):327-332.ZHANG W P, GU X L, JIN X Y, et al. Study on corrosion mechanism of steel bar in concrete and mechanical properties of rusted steel bars[J]. Journal of Building Structures,2010(S1):327-332(in Chinese). [45] 李凤兰, 侯维玲, 侯朋兵. 锈蚀钢筋的力学性能试验研究[J]. 华北水利水电学院学报, 2013(4):61-64.LI F L, HOU W L, HOU P B. Experimental study on mechanical properties of corroded steel bars[J]. Journal of North China Institute of Water Conservancy and Hydroelectric Power,2013(4):61-64(in Chinese). [46] 李士彬, 张鑫, 贾留东, 等. 箍筋锈蚀钢筋混凝土梁的抗剪承载力分析[J]. 工程力学, 2011(S1):60-63.LI S B, ZHANG X, JIA L D, et al. Analysis of shear strength of corroded reinforced concrete beams with stirrups[J]. Engineering Mechanics,2011(S1):60-63(in Chinese). [47] 袁迎曙, 贾福萍, 蔡跃. 锈蚀钢筋的力学性能退化研究[J]. 工业建筑, 2000(1):43-46. doi: 10.3321/j.issn:1000-8993.2000.01.012YUAN Y S, JIA F P, CAI Y. Research on degradation of mechanical properties of corroded reinforced bars[J]. Industrial Construction,2000(1):43-46(in Chinese). doi: 10.3321/j.issn:1000-8993.2000.01.012 [48] 牛荻涛, 卢梅, 王庆霖. 锈蚀钢筋混凝土梁正截面受弯承载力计算方法研究[J]. 建筑结构, 2002(10):14-17.NIU D T, LU M, WANG Q L. Study on calculation method of flexural bearing capacity of normal section of corroded reinforced concrete beams[J]. Building Structure,2002(10):14-17(in Chinese). [49] 侯朋兵. 不均匀锈蚀钢筋混凝土梁承载力试验研究[D]. 郑州: 华北水利水电学院, 2012.HOU P B. Experimental study on bearing capacity of unevenly corroded RC beams[D]. Zhengzhou: North China Institute of Water Conservancy and Electric Power, 2012(in Chinese). [50] 章鑫森, 戴靠山. 锈蚀钢筋的力学性能退化模型[J]. 重庆建筑, 2004(S1):84-85.ZHANG X S, DAI K S. Determination of mechanical properties of corroded reinforcement[J]. Chongqing Architecture,2004(S1):84-85(in Chinese). [51] 吴庆, 袁迎曙. 锈蚀钢筋力学性能退化规律试验研究[J]. 土木工程学报, 2008(12):42-47. doi: 10.3321/j.issn:1000-131X.2008.12.007WU Q, YUAN Y S. Experimental study on degradation of mechanical properties of corroded steel bars[J]. China Civil Engineering Journal,2008(12):42-47(in Chinese). doi: 10.3321/j.issn:1000-131X.2008.12.007 [52] 陈红秋, 蒋凤昌, 周桂香, 等. CFRP加固锈蚀钢筋混凝土柱承载力试验研究[J]. 建筑技术, 2011, 12(12):1134-1138. doi: 10.3969/j.issn.1000-4726.2011.12.023CHEN H Q, JIANG F C, ZHOU G X, et al. Experimental study on bearing capacity of CFRP reinforced corroded RC columns[J]. Architecture Technology,2011,12(12):1134-1138(in Chinese). doi: 10.3969/j.issn.1000-4726.2011.12.023 -

下载:

下载: